Understanding the John Deere 752 Tedder Parts Diagram

In the realm of modern agriculture, efficiency and precision are paramount. This section delves into the intricate assembly of a vital machinery type designed for enhancing forage quality and optimizing crop management. Understanding the various elements that constitute this implement can significantly impact operational performance and maintenance practices.

Each individual component plays a crucial role in the overall functionality, ensuring that the machinery operates smoothly under various conditions. By familiarizing oneself with the specific arrangement and purpose of these elements, operators can not only improve their usage but also extend the lifespan of the equipment. Furthermore, recognizing how these parts interact with one another aids in troubleshooting and repairs.

In the following segments, we will explore the layout and characteristics of each essential element, providing insights that are valuable for both seasoned professionals and newcomers to the agricultural field. This knowledge will empower users to make informed decisions regarding maintenance and potential upgrades, fostering a more productive farming environment.

Overview of John Deere 752 Tedder

This machine is designed to efficiently manage and condition grass and forage crops, enhancing the drying process. Its innovative design allows for effective operation in various field conditions, ensuring optimal performance and minimal crop loss.

Featuring a robust construction, this equipment is built to withstand the rigors of agricultural use. The layout of its components promotes ease of maintenance, allowing operators to quickly service the unit as needed. Moreover, its operational efficiency is complemented by advanced technology that ensures even distribution and thorough conditioning of the material.

Incorporating user-friendly controls, this model is accessible to both experienced and novice operators. The intuitive design not only streamlines workflow but also enhances overall productivity in the field. Its versatility makes it suitable for different types of crops, providing farmers with a reliable solution for their forage management needs.

Ultimately, this piece of equipment stands out in the market due to its performance, durability, and ease of use, making it a valuable asset for modern agricultural practices.

Key Features of the 752 Model

This model is designed to enhance efficiency and reliability in agricultural operations. Its innovative design and robust construction make it an essential tool for farmers seeking optimal performance.

- Durable Build: Constructed from high-quality materials to withstand demanding conditions.

- Efficient Operation: Features advanced mechanisms that ensure effective working speeds.

- Adjustable Settings: Customizable settings allow for tailored use in various field conditions.

- Easy Maintenance: User-friendly design facilitates quick servicing and part replacement.

These attributes contribute to its reputation as a reliable choice for those looking to maximize productivity and minimize downtime in their farming practices.

Understanding Tedder Functionality

The primary role of a forage aerator is to efficiently manage and enhance the drying process of cut grass and other crops. By spreading the material over a larger surface area, these machines allow sunlight and air to circulate, significantly speeding up moisture evaporation. This not only improves the quality of the forage but also optimizes the timing for subsequent harvesting activities.

Key Components and Their Roles

A forage aerator consists of several essential elements that work together to ensure effective operation. Each part plays a unique role in facilitating the overall functionality of the machine.

| Component | Function |

|---|---|

| Rotating Arms | Lift and fluff the material for better air exposure. |

| Gearbox | Transmits power from the tractor to the rotating arms. |

| Wheels | Provide mobility and adjust height for varying terrain. |

| Frame | Supports all components and withstands operational stress. |

Operational Efficiency

Proper maintenance and adjustment of the forage aerator can significantly enhance its performance. Regular checks on the rotating arms and gearbox can prevent wear and ensure optimal function. Additionally, understanding the terrain and environmental conditions can help operators achieve the best results, maximizing both efficiency and forage quality.

Importance of Proper Maintenance

Effective upkeep of agricultural machinery is crucial for ensuring longevity and optimal performance. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns.

Benefits of Regular Upkeep

- Improved Equipment Lifespan

- Enhanced Operational Efficiency

- Reduced Risk of Breakdowns

- Cost Savings Over Time

Key Maintenance Practices

- Regularly inspect components for wear and tear.

- Lubricate moving parts to ensure smooth operation.

- Replace worn-out items promptly to avoid further damage.

- Keep the equipment clean to prevent rust and corrosion.

Common Replacement Parts Explained

Understanding essential components that may require substitution is crucial for maintaining optimal performance in agricultural machinery. Regular wear and tear can lead to reduced efficiency, making it important to identify and address these areas proactively.

- Gear Sets: Vital for the transmission of power, these components ensure smooth operation. Replacement may be necessary if grinding noises or sluggish performance occurs.

- Drive Belts: These flexible bands transfer energy between moving parts. Cracks or fraying are clear indicators that a replacement is needed.

- Tines: Critical for effective raking, damaged or bent tines can severely impact functionality. Inspecting for wear can help maintain productivity.

- Hydraulic Hoses: Essential for fluid movement, leaks or signs of wear signal the need for replacement to prevent operational failures.

By keeping these components in mind, operators can ensure their machinery remains in peak condition, ultimately enhancing efficiency and longevity.

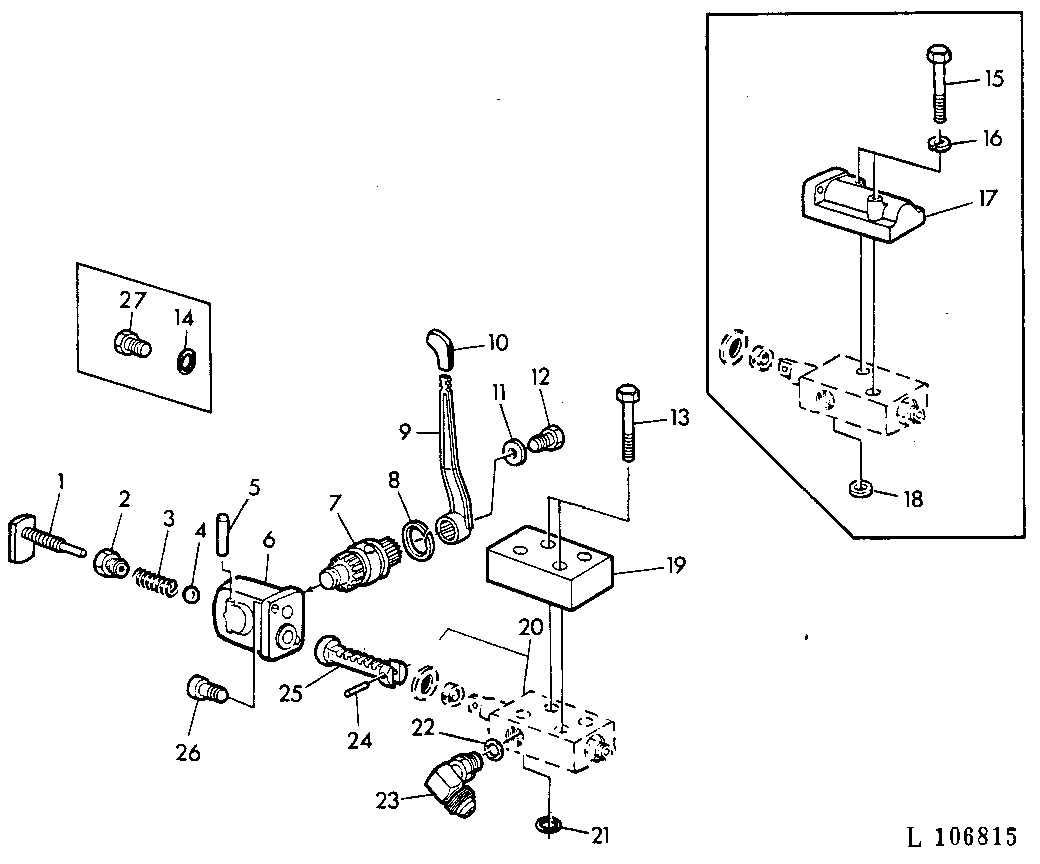

Parts Diagram Interpretation Guide

Understanding the visual representation of components is essential for effective maintenance and repair. These illustrations provide a detailed overview of various elements and their relationships, facilitating easier identification and troubleshooting. By familiarizing yourself with the layout and symbols used, you can streamline your repair process and ensure all necessary pieces are accounted for.

Begin by noting the key sections of the illustration, typically categorized by function or location. This segmentation helps in locating specific components quickly. Pay attention to annotations, which often highlight critical information such as part numbers or maintenance tips. Being aware of these details can enhance your overall comprehension of the system.

Additionally, cross-referencing with the manufacturer’s documentation can deepen your understanding. Such resources often include specific notes or updates that may not be visible in the visual guide alone. This comprehensive approach enables you to tackle any issues with confidence and precision.

How to Order Replacement Parts

Acquiring new components for your equipment can seem daunting, but it can be streamlined with the right approach. Understanding where to look and how to navigate the ordering process will ensure you get the necessary items quickly and efficiently.

Identify Required Components

Before placing an order, it’s essential to determine the exact items you need. Follow these steps:

- Consult the user manual for a comprehensive list of components.

- Inspect the equipment to identify worn or damaged parts.

- Make a note of any model or serial numbers that might aid in your search.

Finding Reliable Suppliers

Once you’ve identified what you need, the next step is sourcing reliable vendors. Consider the following options:

- Official dealerships that specialize in your equipment brand.

- Reputable online retailers with a focus on agricultural machinery.

- Local machinery repair shops that may carry a variety of components.

By following these guidelines, you can simplify the process of acquiring necessary components for your machinery, ensuring optimal performance and longevity.

Frequently Asked Questions

This section aims to address common inquiries related to equipment components and their functionalities. We understand that many users seek clarity on various aspects, and we are here to provide concise answers to enhance your understanding and experience.

What should I do if a component is damaged?

In the event of damage, it’s crucial to assess the extent of the issue. If the damage is significant, consider replacing the component. Regular maintenance can help prevent such situations.

How often should I check my equipment?

Routine inspections are recommended at least once a month, depending on usage. Regular checks can help identify wear and tear before it leads to more serious problems.

Where can I find replacement components?

Replacement components can typically be found at authorized dealers or online retailers specializing in agricultural machinery. Ensure you have the correct model information when searching.

What are the signs of wear in the components?

Common indicators include unusual noises, decreased performance, and visible wear such as cracks or bends. Addressing these signs early can prevent further damage.

Can I perform repairs myself?

Depending on your skill level and the complexity of the repair, you may be able to handle minor issues. For more intricate repairs, consulting a professional is advisable to ensure safety and effectiveness.

Benefits of Using Genuine Parts

Utilizing authentic components for agricultural machinery can significantly enhance performance and longevity. Genuine products are designed specifically for the equipment, ensuring optimal functionality and reliability over time. Choosing these original items minimizes the risk of malfunctions and maximizes efficiency during operations.

Quality Assurance

One of the primary advantages of using original components is the assurance of quality. These parts are manufactured to stringent standards and undergo rigorous testing. This guarantees:

- Consistency in performance

- Higher durability compared to aftermarket alternatives

- Improved safety features

Cost-Effectiveness

Investing in authentic components can lead to long-term savings. Although the initial cost may be higher, the benefits often outweigh this expense:

- Reduced maintenance and repair costs

- Extended lifespan of the machinery

- Enhanced resale value of the equipment

Ultimately, opting for original components fosters better efficiency and ensures that agricultural operations run smoothly without unexpected interruptions.

Tips for Enhancing Tedder Performance

Maximizing the efficiency of your hay equipment is crucial for achieving optimal results in your agricultural operations. By focusing on maintenance, adjustments, and operational techniques, you can significantly improve the performance of your machinery. Below are several strategies to consider that will help you achieve superior outcomes.

Regular Maintenance

Consistent upkeep is vital for the longevity and functionality of your equipment. Ensure all components are clean, lubricated, and free from debris. Check for any signs of wear or damage, as timely repairs can prevent larger issues. Regular inspections of the working parts will keep your machinery running smoothly and efficiently.

Optimal Adjustment and Settings

Fine-tuning the settings of your equipment can lead to improved performance. Ensure that the working height and angle are set appropriately for the specific conditions of your fields. Adjusting the tension of the components can also enhance performance, allowing for better material handling and reducing losses during operation. Experimenting with different configurations can yield better results based on varying crop types and environmental factors.

Resources for Further Learning

Expanding your knowledge in agricultural machinery maintenance and repair can significantly enhance your operational efficiency. A variety of resources are available for those looking to deepen their understanding and improve their skills in this field.

Consider exploring online forums and communities where enthusiasts share insights and experiences. Additionally, instructional videos on platforms like YouTube can provide practical demonstrations. Comprehensive manuals and guides from manufacturers also serve as valuable references for understanding specific components and their functions.

Participating in workshops or training sessions hosted by agricultural organizations can offer hands-on experience and expert advice. Finally, academic courses focused on agricultural technology can provide a strong theoretical foundation, complementing practical skills.