John Deere L130 Engine Parts Diagram for Easy Maintenance and Repair

Maintaining and repairing any mechanical equipment requires a thorough understanding of its internal structure. Whether you are dealing with routine upkeep or addressing specific mechanical issues, having a clear picture of the machine’s core systems is essential. This is especially true for those machines designed to handle heavy-duty tasks in outdoor settings, where efficient performance is key. Knowing how different mechanisms interact allows for quicker troubleshooting and smoother operation in the long term.

In this section, we will explore the detailed layout of key elements that power a well-known lawn care vehicle. We will break down each major component, explaining its role and how it connects to the broader system. This knowledge will not only help in identifying potential issues but also in sourcing the correct replacements when necessary, ensuring the machine remains in peak condition for years to come.

Additionally, we will provide a visual representation to aid in understanding the placement and function of each element. By the end of this overview, you will be well-equipped to handle common maintenance tasks, from diagnosing performance issues to performing part replacements with confidence.

John Deere L130 Engine Overview

The power unit of this model is known for its reliable performance and durability, making it a popular choice for those seeking consistent operation over time. It is designed to handle various tasks, offering a balance between efficiency and strength, suitable for both light and moderate workloads. This section provides an outline of key features and components, highlighting its structure and operational capabilities.

Main Features

- High fuel efficiency ensuring extended working hours without frequent refueling.

- Enhanced cooling system to prevent overheating during prolonged use.

- Robust construction allowing for steady performance in diverse conditions.

Key Components

- Fuel system designed for optimal combustion and reduced emissions.

- Air filtration unit that minimizes debris intake, ensuring smoother function.

- Lubrication mechanism maintaining critical moving parts for prolonged life.

Main Components of L130 Engine

The power unit under consideration consists of several interconnected elements that work together to ensure smooth operation and efficient performance. Each segment plays a critical role in driving the system, with all parts designed to complement each other, optimizing functionality. By understanding these key sections, one can better appreciate the intricate mechanisms behind the overall operation of this machinery.

| Component | Description | |

|---|---|---|

| Cylinder Head | The top section that houses intake and exhaust valves, crucial for air-fuel mixture regulation and combustion efficiency. | |

| Pistons | These moving parts are responsible for converting energy from combustion into mechanical motion, driving the crankshaft. | |

| Crankshaft | A rotating shaft that translates the linear motion of the pistons into rotational power, driving other components. | |

| Carburetor | This device mixes air and fuel in the correct proportions before combustion, ensuring the engine runs smoothly. | |

| Ignition System | A combination of spark plugs, wires, and electrical components that ignites the fuel mixture, initiating the power cycle. | |

| Cooling System | A network of fans and fluids designed to dissipate heat, preventing overheating and maintaining optimal temperature. |

| Component | Description |

|---|---|

| Power Unit | The main source that generates force for operation. |

| Transmission System | Transfers energy from the power unit to the wheels or blades. |

| Cooling Mechanism | Regulates temperature to prevent overheating. |

| Fuel Delivery System | Supplies the necessary fuel for combustion. |

| Exhaust System | Channels away byproducts of combustion safely. |

By utilizing this table and understanding the function of each segment, you will be better equipped to identify and troubleshoot issues that may arise. Always consult your user manual or reliable sources for specific configurations related to your model.

Common Issues with L130 Engine

The machinery in question is prone to several typical complications that can hinder its performance and efficiency. Understanding these prevalent challenges is crucial for maintaining optimal functionality and ensuring longevity. This section delves into some frequent concerns that users may encounter and offers insights into potential remedies.

Overheating Problems

One of the most frequently reported challenges is overheating. This issue can stem from various factors, such as insufficient coolant levels, a malfunctioning thermostat, or clogged cooling fins. Regular checks and maintenance of the cooling system can help prevent this condition. Additionally, ensuring proper airflow around the unit is essential to mitigate overheating.

Starting Difficulties

Another common issue involves trouble with ignition. Users may experience problems when attempting to start the unit, which could result from a weak battery, worn spark plugs, or faulty wiring. It is advisable to regularly inspect the electrical components and replace worn parts to facilitate smoother start-ups.

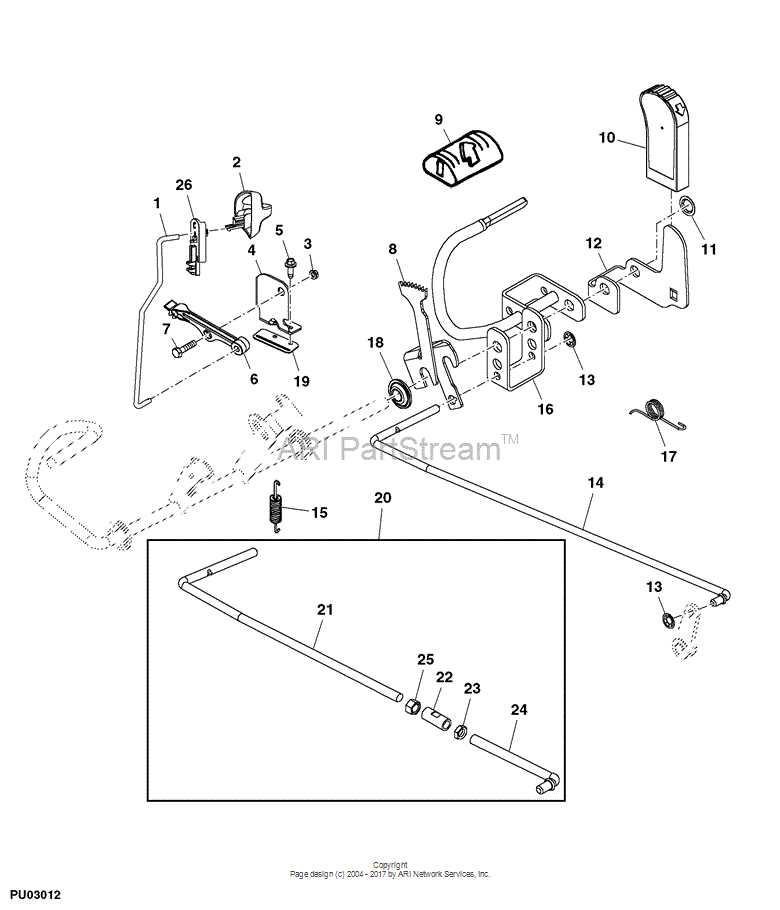

Replacing the L130 Carburetor

Swapping out the fuel delivery component of your mower can significantly enhance its performance and longevity. This essential part is crucial for regulating the mixture of air and fuel that powers the machinery. A replacement can restore efficiency, improve throttle response, and reduce emissions, making it a vital task for maintenance.

Signs of a Failing Carburetor

- Difficulty starting the mower

- Engine stalling or misfiring

- Poor acceleration

- Excessive fuel consumption

- Visible leaks or corrosion

Steps to Replace the Fuel Delivery Component

- Gather the necessary tools and a new replacement part.

- Ensure the machine is turned off and disconnected from any power source.

- Carefully remove the air filter cover and the filter itself.

- Disconnect the fuel line and any linkage connected to the carburetor.

- Unscrew the bolts holding the old component in place and lift it out.

- Position the new component in the same location and secure it with bolts.

- Reconnect the fuel line and linkage, then replace the air filter.

- Test the mower to ensure it runs smoothly.

Understanding the L130 Fuel System

The fuel delivery mechanism in small machinery plays a crucial role in ensuring optimal performance and efficiency. This system is designed to transport fuel from the tank to the combustion chamber, where it mixes with air to facilitate combustion. A comprehensive understanding of this system’s components and functionality can greatly enhance maintenance and troubleshooting efforts.

At the heart of this mechanism is the fuel tank, which stores the necessary fuel for operation. From the tank, the liquid flows through a filter that removes impurities, ensuring that only clean fuel reaches the combustion area. This filtration process is vital to prevent engine damage and maintain smooth operation.

Following the filter, the fuel pump is responsible for creating the necessary pressure to push the fuel into the delivery lines. This component can be mechanical or electric, depending on the specific design of the machine. Proper functioning of the fuel pump is essential, as any failure can lead to inadequate fuel supply, resulting in performance issues.

Once the fuel reaches the delivery lines, it is transported to the carburetor or fuel injection system, where it is mixed with air. This mixture is crucial for efficient combustion. Adjustments to the fuel-air ratio can significantly impact engine performance, fuel efficiency, and emissions.

Regular maintenance of the fuel system, including cleaning or replacing filters and ensuring the pump operates correctly, is essential for prolonging the lifespan of the machinery. Understanding how each component interacts within the system allows operators to diagnose problems more effectively and perform necessary repairs or replacements.

Ignition System Breakdown for L130

The ignition system plays a crucial role in the functionality of any small machinery, ensuring reliable startup and optimal performance. Understanding its components and their interactions is essential for effective maintenance and troubleshooting. This section delves into the intricacies of the ignition system, highlighting key elements that contribute to the smooth operation of your equipment.

Components Overview: The ignition system consists of several vital parts, including the spark plug, ignition coil, and various wiring connections. Each component works in unison to produce a spark that ignites the fuel-air mixture, enabling the machinery to operate efficiently.

Spark Plug: This component is essential for initiating combustion within the combustion chamber. It generates a high-voltage spark that ignites the compressed fuel mixture, allowing for smooth operation. Regular inspection and timely replacement of the spark plug are necessary to maintain optimal performance.

Ignition Coil: Acting as a transformer, the ignition coil amplifies the battery voltage to create a powerful spark. It is crucial for providing the necessary energy for ignition. Faulty coils can lead to misfires and reduced efficiency, emphasizing the need for routine checks and replacements.

Wiring Connections: Proper electrical connections are vital for the ignition system’s performance. Damaged or corroded wires can disrupt the flow of electricity, leading to ignition failure. Regular inspection of all connections ensures reliability and helps prevent potential issues.

Maintenance Tips: To ensure longevity and reliability, regular maintenance of the ignition system is recommended. This includes cleaning connections, checking for wear, and replacing components as necessary. A well-maintained ignition system not only improves performance but also extends the lifespan of the equipment.

In summary, understanding the ignition system’s components and their functions is key to effective management and maintenance of your machinery. By ensuring each part operates correctly, you can enhance overall performance and reliability.

Engine Cooling System of John Deere L130

The cooling mechanism of this lawn tractor plays a crucial role in maintaining optimal operating temperatures. Effective temperature regulation prevents overheating, ensuring longevity and reliable performance during use. Understanding the components and their functions within this system is essential for proper maintenance and troubleshooting.

The primary component of this cooling system is the radiator, which dissipates heat generated during operation. Coolant circulates through the engine and absorbs heat, transferring it to the radiator where it is cooled by airflow. Fans may assist in this process, enhancing airflow and improving cooling efficiency, especially in warmer conditions.

Another key element is the thermostat, which regulates the flow of coolant based on temperature. It opens and closes to maintain the engine at an ideal temperature range. Additionally, hoses connect various components, allowing coolant to flow smoothly throughout the system.

Regular inspection of the cooling components is vital for ensuring that the system operates effectively. Checking for leaks, blockages, or wear on hoses, as well as monitoring coolant levels, helps prevent overheating and potential damage to the machinery.

Understanding the cooling system’s design and function allows users to perform informed maintenance, contributing to the machine’s overall performance and durability. Proper care ensures that the equipment remains efficient, reducing the risk of costly repairs in the long run.

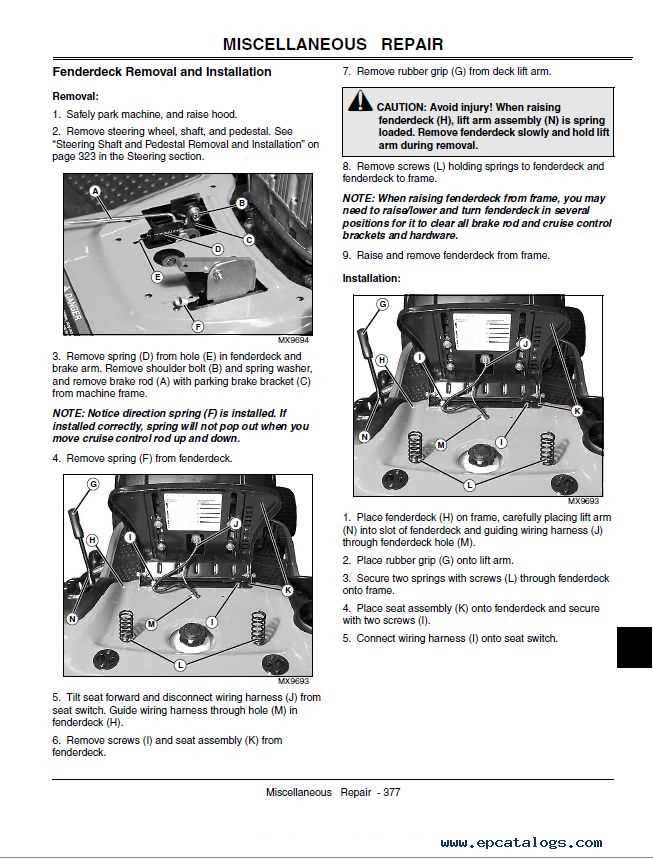

Proper Maintenance of L130 Engine

Routine inspections play a vital role in the maintenance schedule. Checking fluid levels, filters, and belts regularly can prevent minor issues from escalating into significant problems. Keeping components clean and free from debris also supports the overall health of the system.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check oil level | Weekly | Top off if necessary to maintain proper lubrication. |

| Inspect air filter | Monthly | Replace if dirty or clogged to ensure optimal airflow. |

| Examine belts and hoses | Every 2 months | Look for wear and tear, replacing any damaged components. |

| Clean exterior | As needed | Remove dirt and debris to prevent overheating and corrosion. |

| Check fuel lines | Every 6 months | Ensure there are no leaks or signs of deterioration. |

Additionally, always consult the owner’s manual for specific recommendations tailored to your equipment model. Following the outlined procedures will significantly enhance the reliability and efficiency of your machinery.

Step-by-Step Guide to Belt Replacement

Replacing the drive belt is an essential maintenance task that ensures optimal performance of your equipment. A worn or damaged belt can lead to decreased efficiency and potential mechanical failures. This guide provides a clear, step-by-step approach to assist you in completing this task safely and effectively, ensuring that your machinery continues to operate smoothly.

Tools and Materials Needed

Before starting the replacement process, gather the necessary tools and materials. You will need a set of wrenches, a socket set, and a replacement belt compatible with your model. Having a flat surface to work on and protective gloves will enhance safety and ease the process.

Replacement Process

Begin by disconnecting the power source to prevent accidental starts. Next, locate the tensioning mechanism that holds the belt in place. Carefully release the tension to remove the old belt. Install the new belt by threading it through the pulleys according to the manufacturer’s specifications. Ensure it sits correctly on each pulley and reapply the tension. Finally, reconnect the power source and test the machinery to verify that the belt operates smoothly.

Oil Change Process for L130 Engine

Regular maintenance of your mower’s propulsion unit is crucial for its optimal performance and longevity. One essential task in this maintenance routine is the replacement of the lubricant, which plays a vital role in ensuring smooth operation and preventing wear and tear. This guide will outline the steps necessary to effectively complete this process.

Tools and Materials Needed

- New lubricant

- Oil filter (if applicable)

- Oil catch pan

- Wrench or socket set

- Funnel

- Clean rags or paper towels

Steps to Change the Lubricant

- Ensure the mower is on a flat surface and turn off the ignition. Allow the propulsion unit to cool if it has been in operation.

- Place the oil catch pan underneath the drain plug to collect the old lubricant.

- Remove the drain plug using a wrench or socket, and let the used lubricant flow into the pan completely.

- If replacing the filter, locate it, unscrew it, and allow any remaining oil to drain.

- Install the new filter by hand, ensuring it is snug but not overtightened.

- Replace the drain plug securely after all oil has drained.

- Using a funnel, pour the new lubricant into the fill port, taking care not to overfill.

- Check the lubricant level with the dipstick and add more if necessary.

- Start the unit briefly to circulate the new lubricant, then check for any leaks around the drain plug and filter.

- Dispose of the old lubricant and filter responsibly at a recycling center or according to local regulations.

Following these steps will ensure that your mower’s propulsion unit remains in peak condition, extending its lifespan and maintaining performance. Regular checks and changes of the lubricant are essential for optimal functioning.

Troubleshooting the L130 Engine

Addressing issues with a lawn mower’s power unit requires a systematic approach. Understanding common challenges and their solutions can significantly enhance performance and extend the lifespan of the machinery. This section outlines typical problems and practical strategies to rectify them, ensuring efficient operation.

Common Issues and Solutions

One frequent concern involves difficulty in starting the machine. If the unit fails to ignite, check the battery for adequate charge and ensure all connections are secure. Additionally, inspect the fuel system for any clogs or stale fuel, as these can prevent proper combustion.

Performance Problems

Another common issue is reduced power output during operation. This may stem from air filter blockages or fuel delivery problems. Regularly cleaning or replacing the air filter can improve airflow, while ensuring the fuel lines are clear will facilitate optimal fuel flow. If these steps do not resolve the issue, examining the spark plug for wear or damage is advisable, as a faulty spark plug can hinder performance.

Regular maintenance and timely troubleshooting can keep your mower running smoothly. Identifying and resolving issues early can prevent costly repairs and ensure the equipment operates effectively for years to come.

Where to Find John Deere L130 Parts

Locating components for your outdoor power equipment can be a straightforward task if you know where to look. Whether you are in need of replacement items or upgrades, numerous resources are available to assist you in your search. Understanding the variety of outlets at your disposal will help you find the ideal solutions efficiently.

One of the best places to start is through authorized retailers. These suppliers often have a comprehensive selection of original equipment manufactured items, ensuring compatibility and quality. Additionally, many of these stores provide expert advice and support to help you choose the right components for your specific needs.

Online marketplaces are another excellent option. Websites dedicated to outdoor machinery often feature extensive catalogs with detailed specifications. Utilizing filters and search functions can help you quickly navigate through options and find what you need from the comfort of your home.

Moreover, consider exploring local salvage yards and second-hand stores. These places can offer significant savings and the opportunity to find rare or discontinued items. Networking with local enthusiasts through community forums or social media groups can also yield valuable recommendations and leads on where to find necessary components.

Finally, manufacturer websites often provide resources for locating authorized service centers and retailers, which can guide you toward reliable sources. Utilizing these various channels will enable you to efficiently source high-quality components for your outdoor equipment.