Comprehensive Guide to John Deere 709 Rotary Cutter Parts Diagram

Understanding the intricate elements of agricultural machinery is crucial for effective maintenance and operation. This section provides an overview of the essential components that contribute to optimal functionality in various types of equipment.

By exploring the arrangement and relationships of these elements, users can enhance their grasp of how each piece plays a role in overall performance. A clear visual representation aids in identifying specific areas that may require attention or replacement.

In the quest for efficiency, knowing the layout and interconnections of machinery can lead to significant improvements in operational productivity. Proper insight into these structures ultimately empowers users to make informed decisions regarding upkeep and repairs.

Understanding John Deere 709 Rotary Cutter

This section explores the essential aspects of a popular agricultural implement designed for effective land management. With its robust construction and efficient functionality, it serves a vital role in maintaining fields and ensuring optimal growth conditions.

Key Features: The implement is known for its durability and performance in various environments. Its design allows for easy maneuverability and precise cutting, making it suitable for different types of terrain.

Maintenance and Care: Regular upkeep is crucial to ensure longevity and efficiency. Understanding the various components can help operators identify potential issues before they escalate, ensuring smooth operation throughout its lifespan.

Key Features of the Rotary Cutter

Understanding the essential attributes of a mowing implement can significantly enhance its effectiveness and usability. These characteristics contribute to optimal performance in various agricultural and landscaping tasks, ensuring that users achieve the best possible results.

Durability and Construction

- Robust materials designed to withstand tough conditions.

- Heavy-duty build that resists wear and tear.

- Reinforced components for enhanced longevity.

Performance and Efficiency

- Powerful cutting mechanisms for quick grass and brush management.

- Adjustable height settings for versatile applications.

- Easy maneuverability to navigate through various terrains.

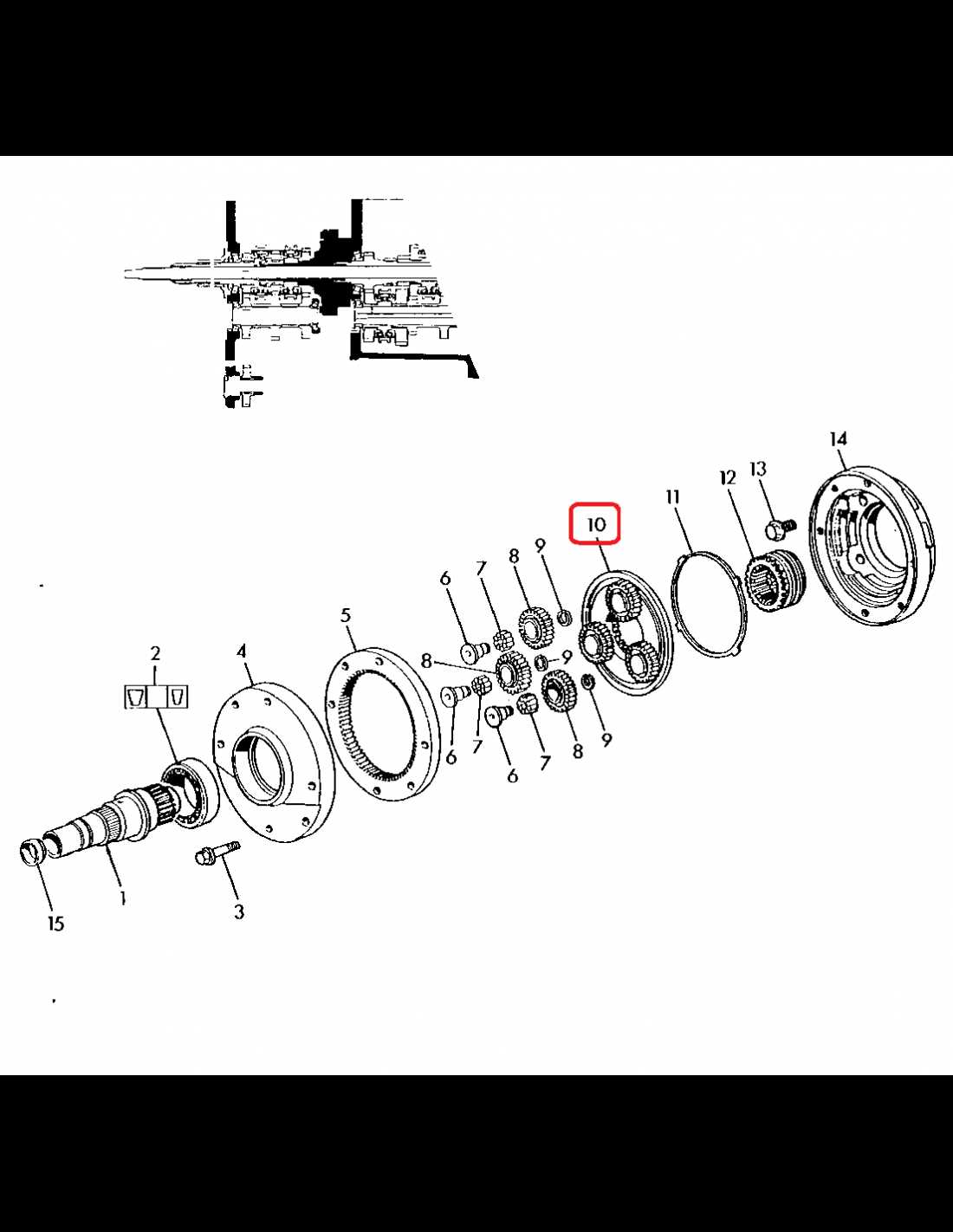

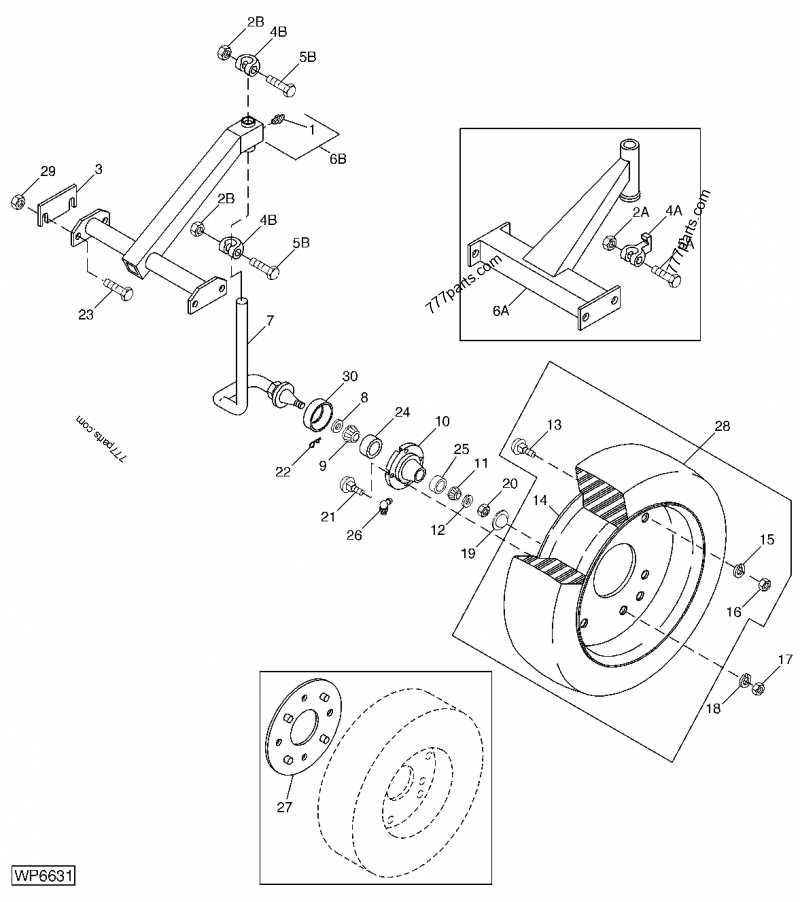

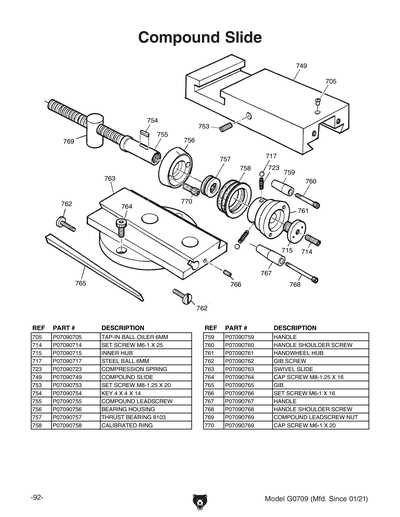

Importance of Parts Diagrams

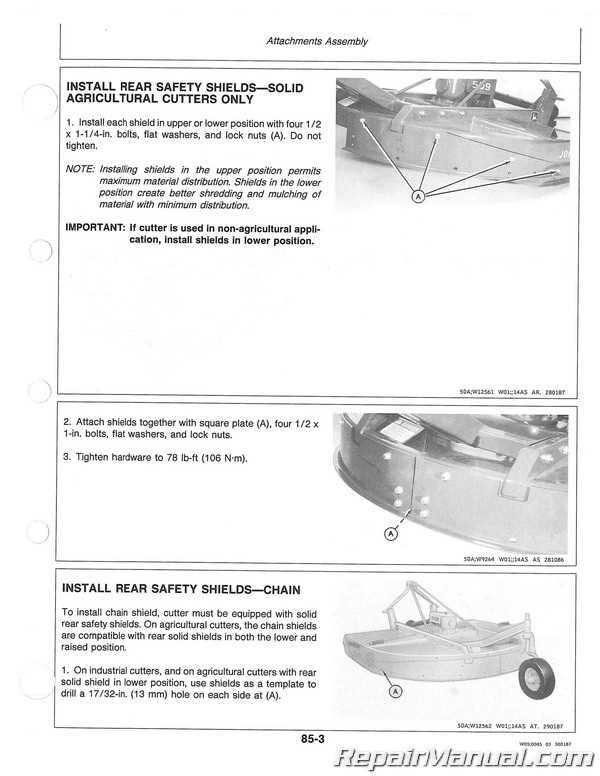

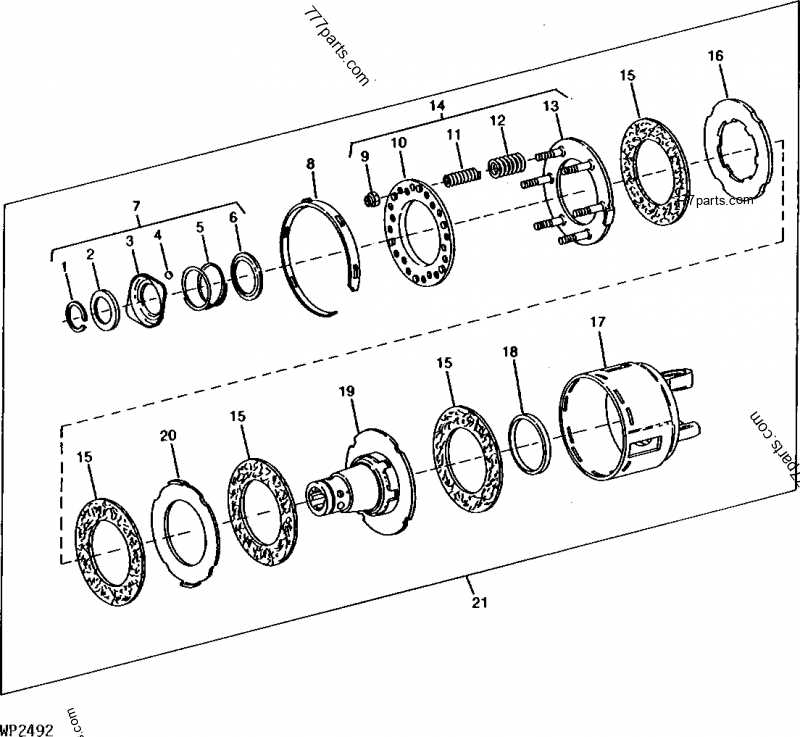

Visual representations of components are essential for understanding the assembly and maintenance of machinery. They provide clear guidance, enabling users to identify individual elements and their interconnections. This clarity is crucial for both repairs and routine upkeep, as it minimizes the risk of errors and enhances efficiency.

Moreover, such illustrations serve as valuable references, allowing technicians and operators to quickly locate and replace worn or damaged items. By streamlining the repair process, these resources ultimately contribute to the longevity and performance of equipment.

Additionally, detailed visual guides foster a deeper comprehension of machine functionality. Users can delve into the mechanics, gaining insights that enhance their operational skills and confidence. This knowledge not only improves individual performance but also promotes a culture of safety and diligence in the workplace.

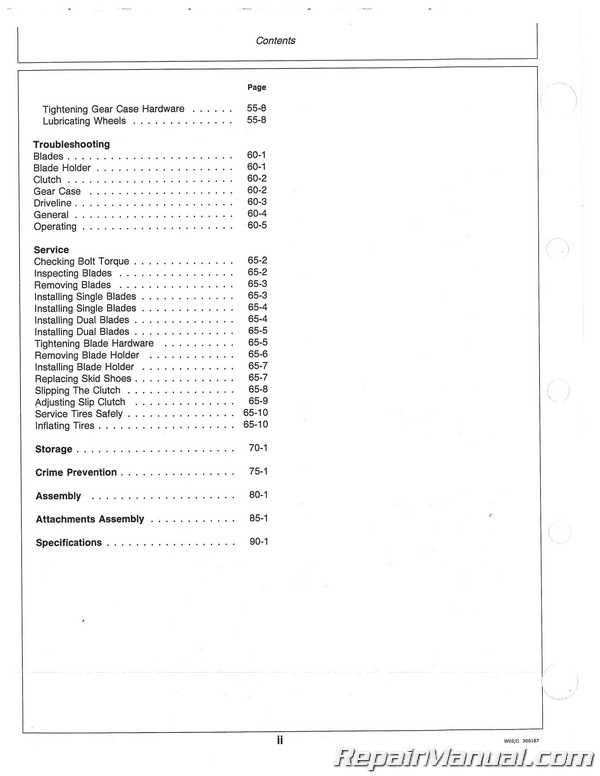

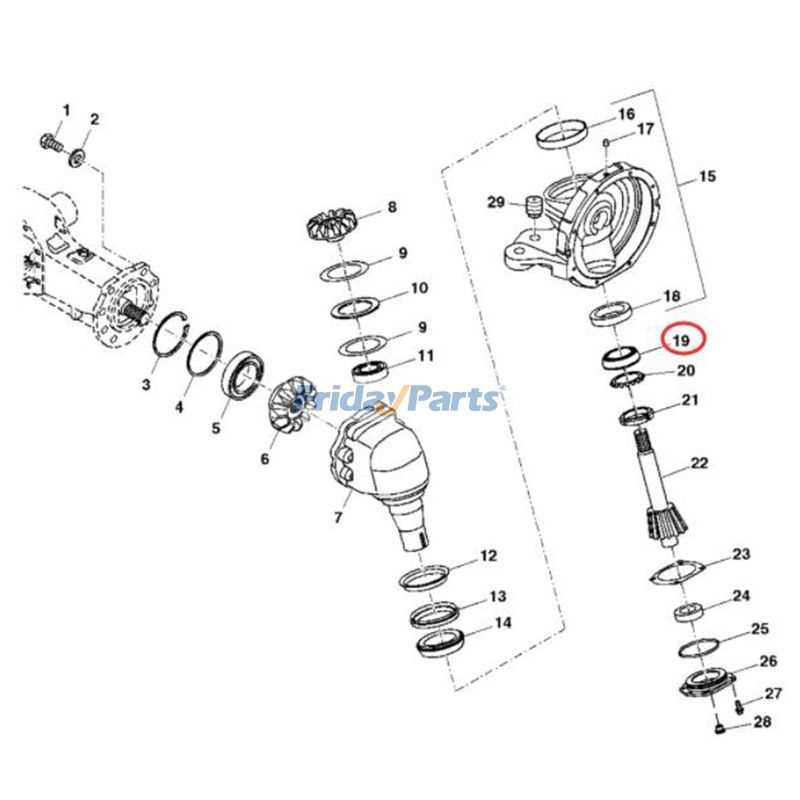

Common Issues with Rotary Cutters

Maintaining efficiency and performance in mowing equipment is crucial for optimal results. Various challenges can arise during operation, impacting productivity and effectiveness. Understanding these common problems can help users address them promptly.

- Blade Wear: Over time, blades can dull or become damaged, leading to uneven cuts.

- Electrical Failures: Issues with wiring or connections may cause malfunctioning of powered components.

- Hydraulic Leaks: Leaks can diminish power and efficiency, requiring immediate attention.

- Bearing Failures: Worn or damaged bearings can result in excessive vibration and noise.

- Debris Buildup: Accumulation of grass and debris can hinder performance and lead to overheating.

By being aware of these frequent challenges, operators can ensure better maintenance and prolonged lifespan of their equipment.

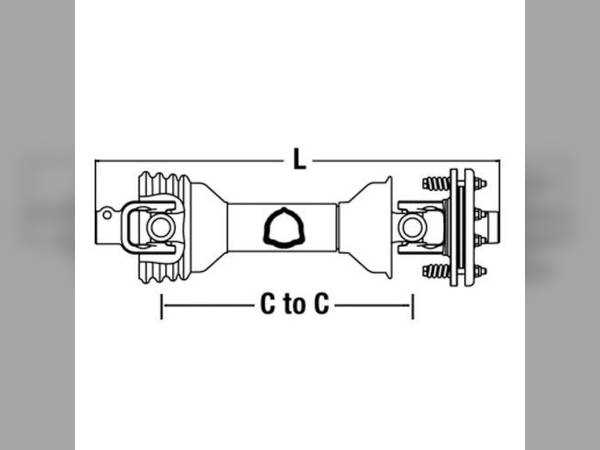

Essential Replacement Parts Overview

Maintaining optimal performance in machinery requires a thorough understanding of vital components that may need replacement over time. Recognizing these key elements is crucial for ensuring efficiency and longevity of equipment.

Blades play a significant role in achieving precise cutting, and regular inspection can prevent uneven wear. Belts are essential for transferring power, making their condition critical for smooth operation. Additionally, housings protect internal mechanisms from debris, so monitoring their integrity is important.

Moreover, gearboxes facilitate movement and should be checked periodically for any signs of wear or damage. Lastly, ensuring that bearings are in good condition reduces friction and enhances overall performance.

How to Read Parts Diagrams

Understanding visual schematics is crucial for effective maintenance and repair of machinery. These illustrations provide a clear representation of components and their arrangement, aiding in identifying necessary replacements or adjustments.

Key Elements to Identify

- Labels: Often indicate the name or number of each component.

- Connections: Show how parts interact and are assembled.

- Legend: Provides explanations for symbols or color codes used in the illustration.

Steps to Follow

- Start by locating the legend to understand symbols.

- Identify the main components and their respective labels.

- Trace connections to comprehend how parts fit together.

- Make notes of any specific components that require attention.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. By following a few essential practices, you can significantly extend the life of your machinery and enhance its performance. Consistent maintenance not only prevents unexpected breakdowns but also optimizes efficiency during operation.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove debris and dirt after each use to prevent buildup that can hinder performance. |

| Inspect Components | Check belts, blades, and other parts for wear and tear to address issues before they escalate. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and prevent rust. |

| Storage Conditions | Store equipment in a dry, sheltered area to protect it from the elements and minimize damage. |

| Schedule Professional Servicing | Have a qualified technician perform thorough inspections and repairs at regular intervals. |

Finding Quality Replacement Parts

Ensuring optimal performance of your machinery often hinges on sourcing high-quality components. Whether for routine maintenance or urgent repairs, selecting the right items can significantly enhance longevity and efficiency. The quest for reliable alternatives is crucial for preserving operational integrity and minimizing downtime.

When searching for suitable replacements, it is vital to consider reputable suppliers that offer genuine or premium aftermarket options. Researching customer reviews and product specifications can aid in identifying trusted brands known for their durability and compatibility. Additionally, understanding the specifics of your equipment can streamline the selection process, ensuring that the components you choose will fit seamlessly and perform as expected.

Another essential aspect is to seek out resources such as user manuals and online communities where enthusiasts share insights. Engaging with these networks can provide valuable recommendations and tips for acquiring the best items. Ultimately, investing time in finding quality replacements will lead to better performance and peace of mind in your operations.

Safety Precautions During Repairs

When performing maintenance on machinery, adhering to safety guidelines is crucial to prevent accidents and ensure a smooth process. Proper precautions not only protect the individual conducting the repairs but also safeguard the equipment itself from damage.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots. These items help minimize the risk of injury from sharp edges, flying debris, and heavy components.

Work Environment Safety

Ensure the workspace is clean and well-lit. Remove any unnecessary tools and materials that could create tripping hazards. Additionally, confirm that the machinery is powered down and secure before starting any repair work, preventing unintentional activation.

Where to Source OEM Parts

Finding high-quality original equipment manufacturer components is essential for maintaining the efficiency and longevity of your machinery. These authentic pieces ensure optimal performance, reliability, and compatibility, making them a preferred choice for many operators.

One of the best places to start your search is through the manufacturer’s official website. They often provide a comprehensive catalog of available components, along with specific part numbers and descriptions. Additionally, authorized dealers or local distributors can be invaluable resources, offering both genuine products and expert guidance on selection.

Online marketplaces and specialized retailers also carry a wide range of OEM items. It is crucial, however, to verify the authenticity of the seller to avoid counterfeit alternatives. Reviews and ratings can help you gauge the reliability of various vendors.

Lastly, industry forums and communities can be great for recommendations on where to find these essential components. Fellow enthusiasts and professionals often share their experiences and preferred sources, providing insights that can save you time and money.

Upgrades for Improved Performance

Enhancing the efficiency of agricultural equipment can significantly boost productivity and longevity. Implementing specific upgrades allows for better handling, reduced wear, and optimized functionality. Consider the following enhancements to elevate performance.

Key Upgrades to Consider

- Improved Blade Quality

- Enhanced Gearbox Options

- Advanced Safety Features

- Durable Deck Coatings

Benefits of Upgrading

- Increased Cutting Efficiency

- Lower Maintenance Costs

- Extended Equipment Lifespan

- Improved Operator Comfort