Ford F250 2012 Parts Layout Overview

Understanding the intricate layout of various elements within a vehicle is essential for maintaining and upgrading its functionality. Whether you are performing regular maintenance or seeking to replace specific elements, having a clear visual reference is invaluable. The arrangement of key components can provide insights into how different systems interact and operate.

Identifying critical elements is the first step in ensuring that everything runs smoothly. From mechanical systems to electrical circuits, the efficient organization of these elements plays a crucial role in the overall performance of the vehicle. By recognizing how each part fits into the larger structure, you can address potential issues before they escalate.

In this guide, we will explore how to navigate through various sections of a vehicle’s internal structure. This will help users familiarize themselves with the primary systems and their respective locations. Understanding these connections allows for better maintenance, improved diagnostics, and more effective repairs.

Comprehensive Overview of Ford F250 Components

Understanding the various systems and elements that make up this model is essential for maintaining its functionality and performance. This section explores key components, their interactions, and how they contribute to the overall operation of the vehicle.

Engine and Transmission

The heart of the vehicle, the engine, works alongside the transmission to deliver power to the wheels. These crucial mechanisms ensure efficient power distribution and smooth gear shifting. Proper maintenance of these elements can significantly enhance the driving experience and extend the vehicle’s lifespan.

Suspension and Braking Systems

For optimal ride comfort and safety, the suspension and braking systems play a critical role. The suspension absorbs road impacts, providing stability, while the brakes ensure reliable stopping power. Regular checks and adjustments to these systems are vital for maintaining control and handling in various driving conditions.

Engine Assembly Breakdown and Key Parts

Understanding the structure of the engine is crucial for effective maintenance and repairs. By breaking down the various components, it’s possible to gain a clearer picture of how each element contributes to the overall function. Each part works in unison, ensuring the optimal operation of the system.

Below is a simplified overview of the essential sections and components found in most engine systems:

| Component | Description | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder Block | The foundation housing the cylinders and other vital components that help convert fuel into energy. | ||||||||||||||||||

| Pistons | Moving elements that transfer the energy from combustion to the crankshaft, creating mechanical movement. | ||||||||||||||||||

| Crankshaft | A rotating shaft that transforms linear motion from the pistons into rotational energy used to drive the vehicle. | ||||||||||||||||||

| Camshaft | Controls the timing of valve openings, synchronizing them with the pistons’ movements for efficient fuel combustion. | ||||||||||||||||||

| Valves | Allow air and fuel to enter the cylinders and exhaust gases to exit, regulating the

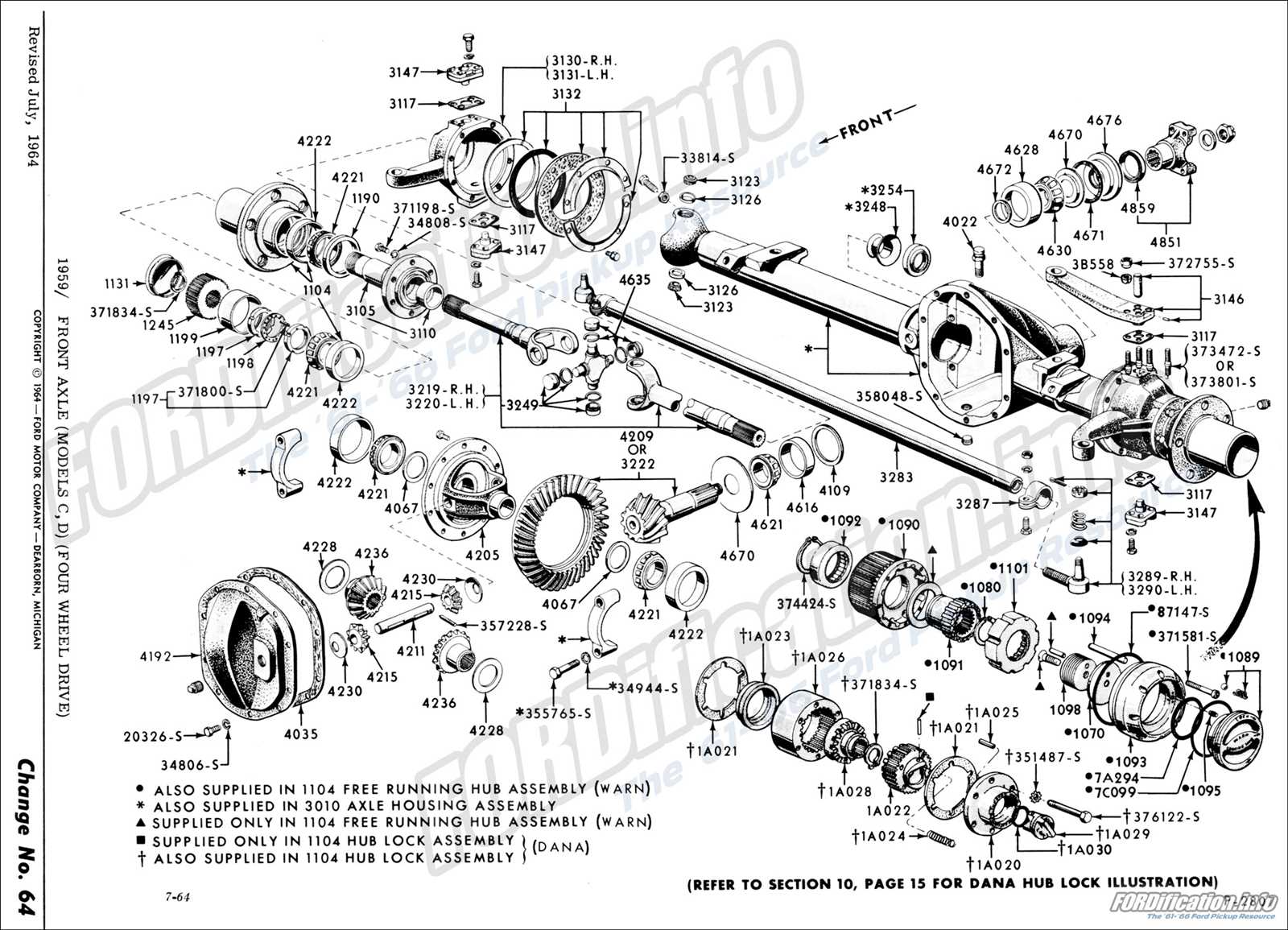

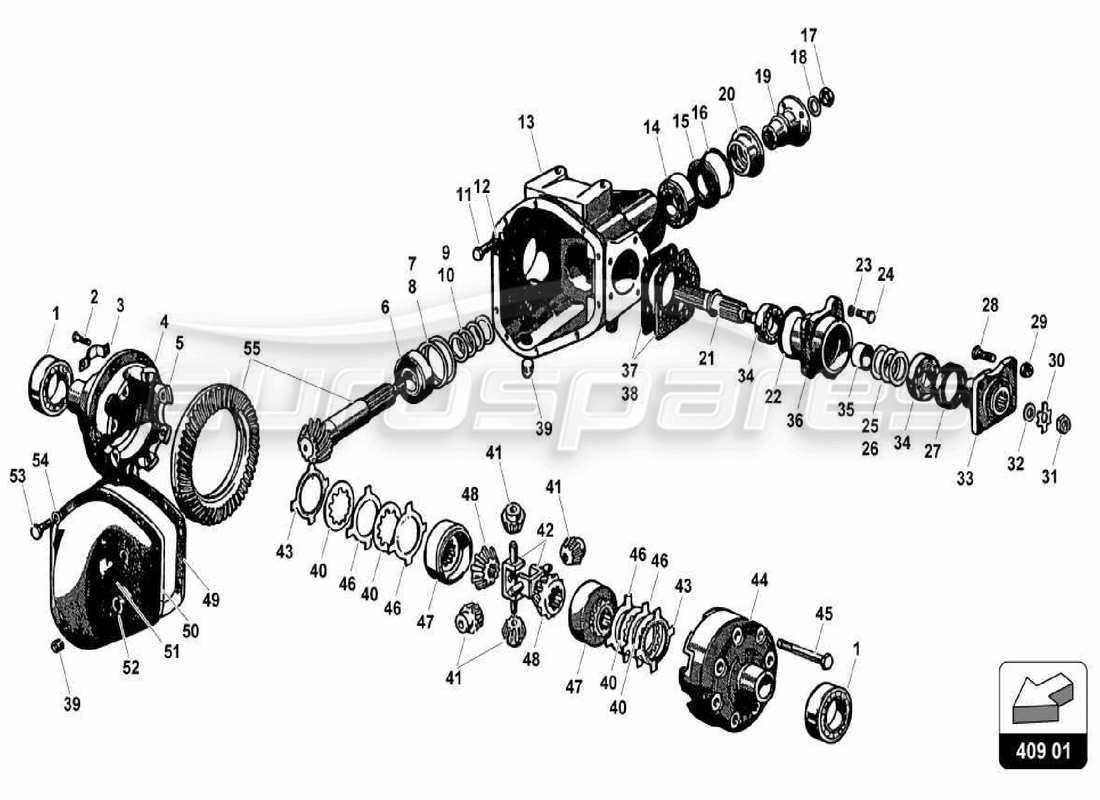

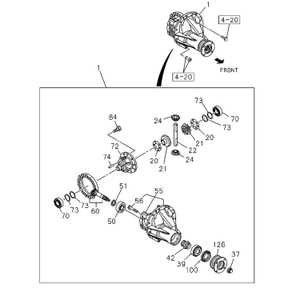

Transmission System Layout and Specifications

The structure of the transmission system is designed to ensure efficient power distribution between the engine and the wheels. It consists of several interconnected elements that work in harmony to provide seamless shifting, smooth acceleration, and overall vehicle performance. Each part plays a crucial role in maintaining a stable driving experience, ensuring both reliability and responsiveness on various road conditions. Main components of this system include the gearbox, driveshaft, and clutch. Together, they manage the transfer of torque, adjusting the speed and direction of the vehicle as needed. These elements are designed to minimize energy loss and maximize power efficiency, contributing to the overall longevity of the system. Proper maintenance and regular inspections are essential to keep the transmission running optimally. Suspension Configuration and Major Elements

The suspension system plays a crucial role in ensuring a smooth ride by absorbing shocks and maintaining stability. Its design and key components are essential for providing comfort, control, and safety. Understanding the core elements that make up this system helps in maintaining vehicle performance and handling on various terrains. Main Structural Components

Supporting Elements

Brake System Components and Maintenance TipsThe braking mechanism is an essential part of any vehicle’s overall performance and safety. Understanding the main elements that make up this system, along with proper upkeep practices, can help ensure long-lasting and reliable operation. Below is an overview of key components and some important tips for maintaining them. Key Components of the Braking System

Maintenance Tips for Longevity

Electrical Wiring and Key Connections

The intricate network of electrical connections plays a vital role in the functionality of modern vehicles. Understanding the layout and interconnections within this system is essential for efficient maintenance and troubleshooting. Each component relies on a well-structured wiring system to operate effectively. In any automotive electrical setup, key connections can be categorized into various sections:

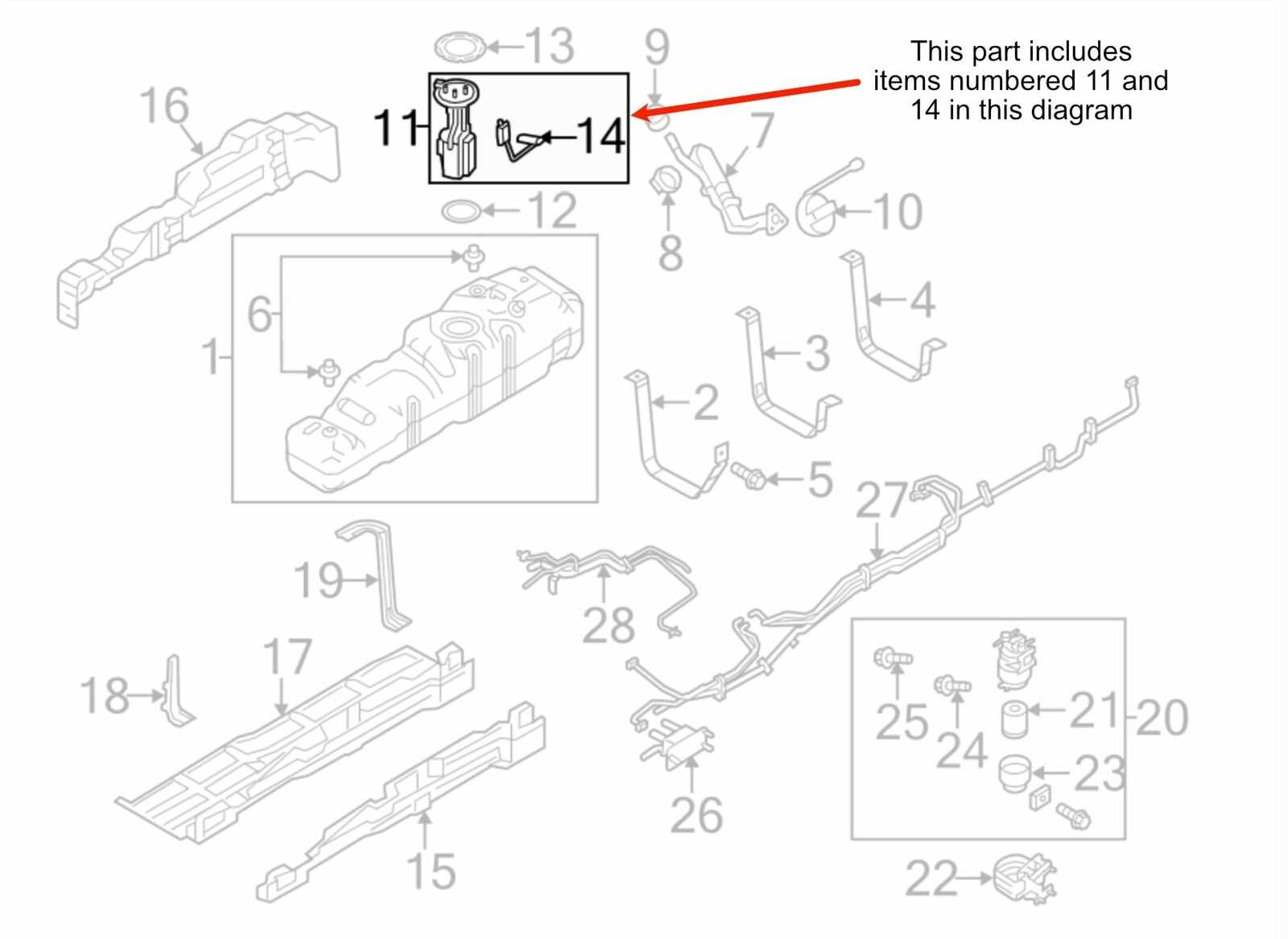

Maintaining proper connections is crucial for the longevity of electrical components. Regular inspections help identify potential issues such as corrosion or loose connections. Proper tools and techniques can significantly ease the process of repairs or modifications. Fuel System Diagram and Component Functions

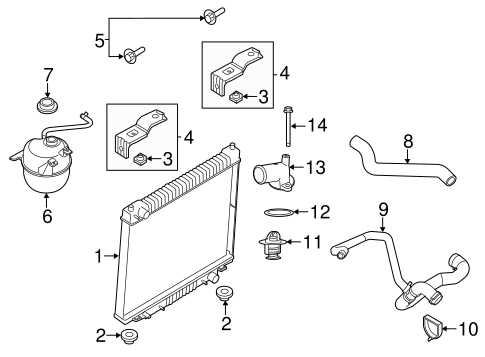

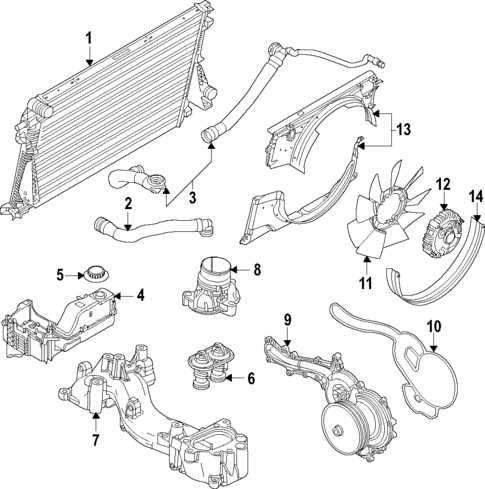

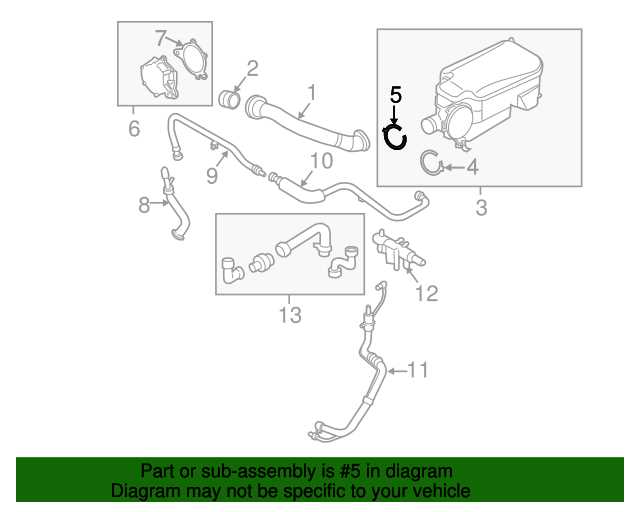

The fuel delivery mechanism in vehicles plays a crucial role in ensuring optimal engine performance and efficiency. Understanding the layout and individual roles of various elements within this system is essential for effective maintenance and troubleshooting. Each component works in harmony to provide the necessary fuel to the engine, facilitating smooth operation. Fuel Tank: The reservoir that stores fuel until it is needed by the engine. Its design ensures safe storage and accessibility for fuel transfer. Fuel Pump: This device is responsible for drawing fuel from the tank and delivering it under pressure to the engine. It can be electric or mechanical, depending on the vehicle’s design. Fuel Filter: A crucial element that removes impurities and contaminants from the fuel before it reaches the engine. This helps in maintaining engine cleanliness and performance. Fuel Injectors: These components atomize the fuel and inject it directly into the engine’s combustion chamber, allowing for efficient mixing with air and optimal combustion. Fuel Pressure Regulator: This part maintains the correct fuel pressure within the system, ensuring that injectors receive a steady supply of fuel for consistent engine operation. Return Line: A pathway that allows excess fuel to flow back to the tank, helping to regulate fuel pressure and prevent overflow. Each of these elements is integral to the functionality of the fuel system, contributing to the overall efficiency and performance of the vehicle. Cooling System Parts and Installation GuideThis section provides an overview of the components involved in the cooling mechanism of a vehicle, along with guidance on their installation. Understanding the elements that contribute to effective temperature regulation is essential for maintaining optimal engine performance and preventing overheating issues. Proper installation and functioning of these components are crucial for the longevity of the engine. Below is a comprehensive outline of the key components involved in the cooling system, including their functions and installation notes.

Exhaust System Configuration and Key Sections

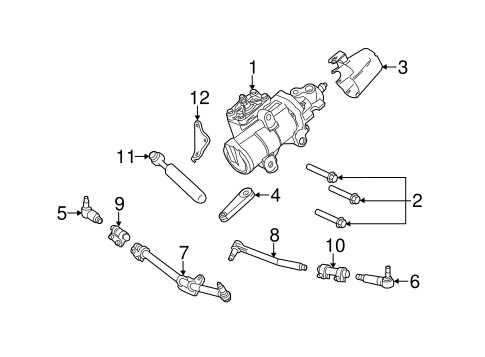

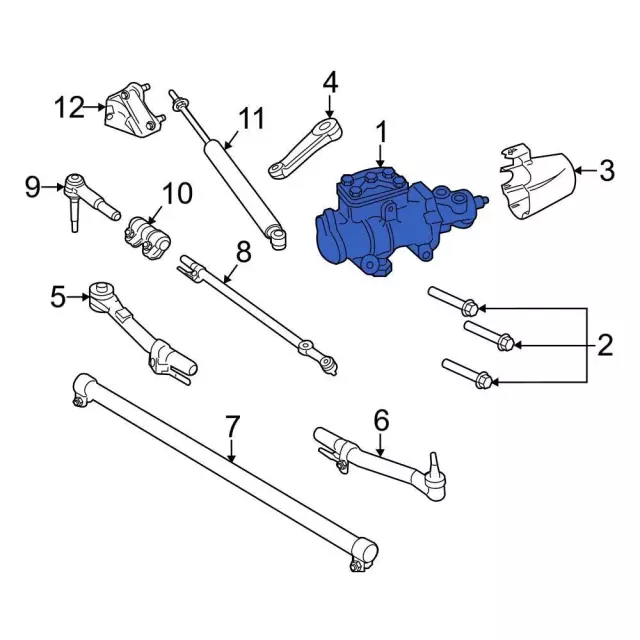

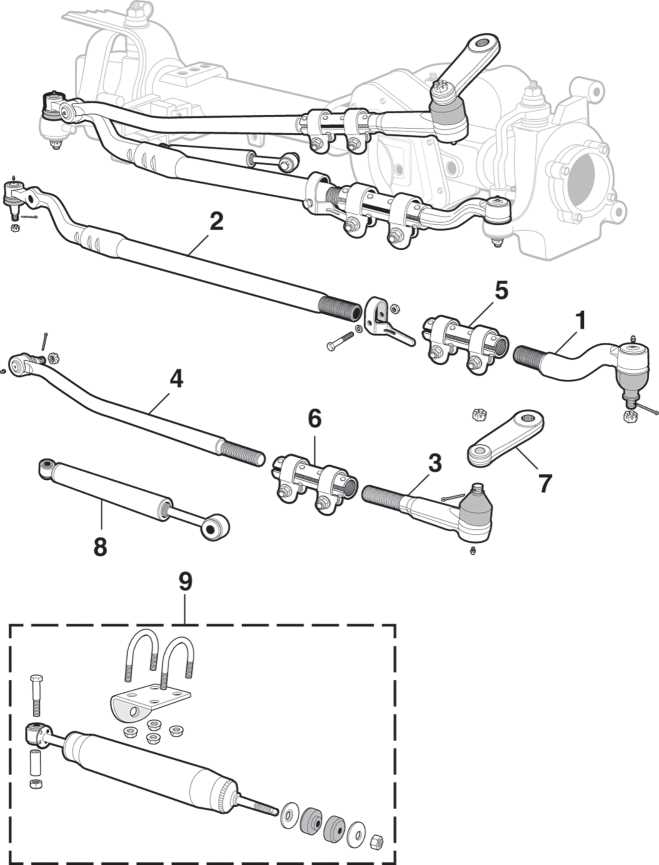

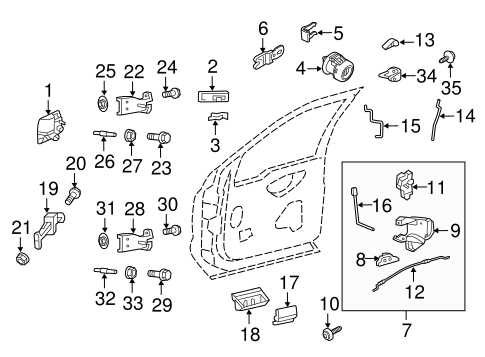

The exhaust arrangement in a vehicle plays a crucial role in optimizing engine performance and minimizing emissions. This system consists of several integral components that work together to direct exhaust gases away from the engine efficiently. Understanding the layout and function of these elements is essential for effective maintenance and enhancement of vehicle efficiency. Key Components: The primary elements of the exhaust setup include the manifold, catalytic converter, muffler, and exhaust pipes. Each part has a specific role in controlling gas flow, reducing harmful emissions, and managing sound levels. Manifold: This initial segment collects exhaust gases from the engine cylinders and channels them toward the next components. Its design is crucial for ensuring optimal gas flow and minimizing back pressure. Catalytic Converter: Positioned downstream of the manifold, this component facilitates chemical reactions that convert harmful substances in the exhaust into less harmful emissions. Its effectiveness is vital for meeting environmental regulations. Muffler: The muffler is designed to reduce noise produced by the exhaust gases. Its configuration directly influences the sound profile of the vehicle while ensuring that the gases are expelled quietly and efficiently. Exhaust Pipes: These pipes connect all the components, directing the treated exhaust gases out of the vehicle. Their diameter and length can affect overall performance, making it important to consider during modifications or replacements. Steering Mechanism and Key Assembly PartsThe steering system plays a crucial role in the overall functionality of a vehicle, ensuring precise maneuverability and stability. This assembly consists of various components that work together to facilitate smooth steering responses, allowing for effective control during navigation. Understanding the elements involved in this mechanism is essential for proper maintenance and repair. Among the critical components are the steering wheel, which serves as the primary interface for the driver, and the column that connects it to the steering gear. Additionally, the rack and pinion system, which converts the rotational motion of the wheel into lateral movement, is vital for directing the vehicle. The inclusion of linkages and joints ensures that the steering system remains responsive to driver input. Moreover, the key assembly plays a significant part in securing the steering column, preventing unauthorized movement and ensuring safety. This assembly typically includes the ignition switch and related hardware that facilitate the operation of the vehicle. Understanding the relationship between these components can greatly enhance troubleshooting and repair processes. Body Frame Structure and Key Reinforcements

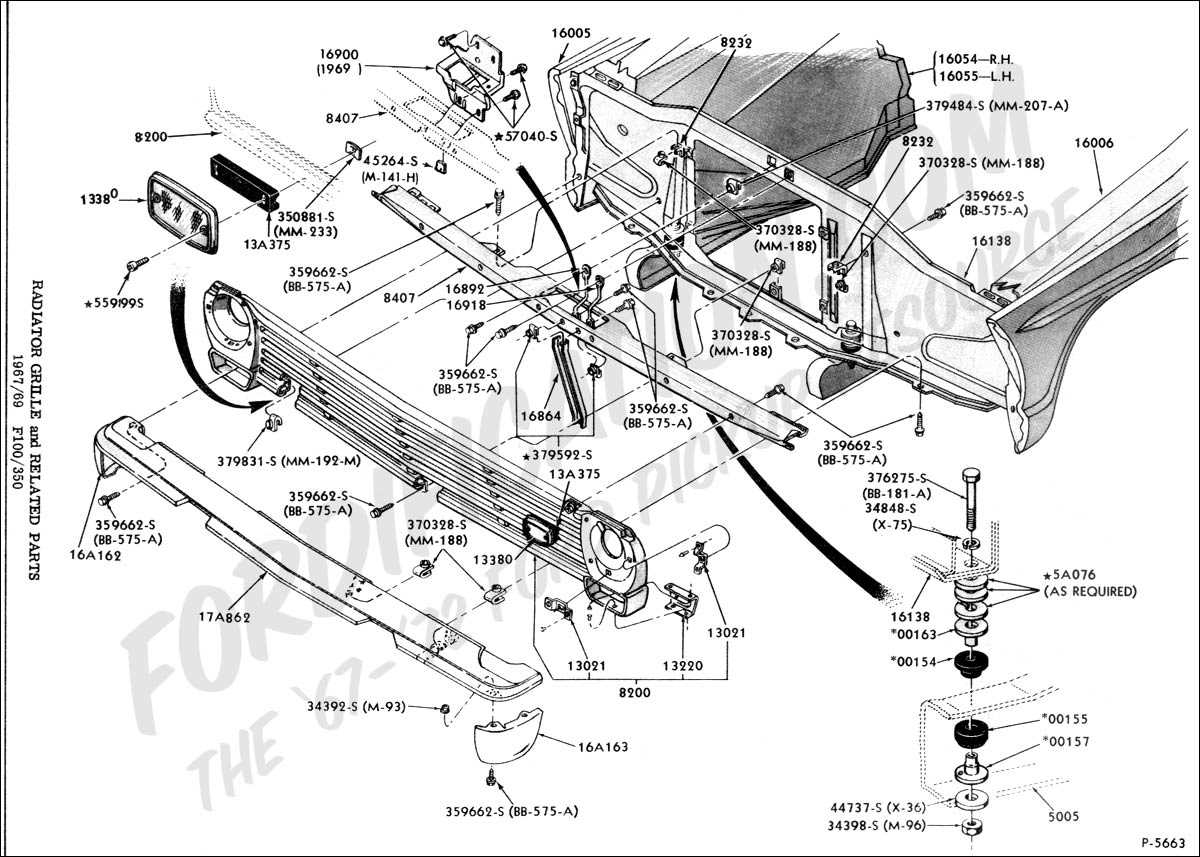

The foundation of any vehicle’s design is its frame, which plays a crucial role in maintaining structural integrity and ensuring safety. A robust framework not only supports various components but also provides the necessary strength to withstand external forces during operation. Understanding the elements that contribute to this framework is essential for assessing overall durability and performance. Frame Composition

The structure is typically composed of high-strength materials, designed to absorb impacts and distribute loads efficiently. Various sections are strategically placed to enhance stability and minimize flexing. The use of advanced engineering techniques results in a lightweight yet resilient framework that meets rigorous performance standards. Reinforcement Elements

Key reinforcements are integrated into the frame to bolster its resistance against stress and deformation. These reinforcements include cross members and brackets, which play a significant role in maintaining alignment and supporting critical components. Proper reinforcement not only enhances safety but also extends the lifespan of the vehicle by mitigating wear and tear. |