Cub Cadet Series 3000 Parts Diagram Overview

When it comes to maintaining outdoor machinery, having a clear visualization of its inner workings is essential. Knowing the specific elements that make up your equipment allows for more efficient repairs and enhances overall performance.

In this section, we will explore a comprehensive overview of the essential components found within this particular model. By breaking down each element, users can better appreciate how they function together to ensure optimal operation.

Whether you’re a seasoned technician or a novice enthusiast, understanding these crucial components will empower you to address any issues with confidence. Let’s delve into the intricate layout and discover the ultimate insights for effective maintenance.

Overview of the Equipment Line

This line of outdoor machinery is designed for durability and efficiency, catering to a wide range of landscaping needs. Users appreciate the robust build quality and advanced features that enhance performance, making it suitable for both residential and commercial applications.

Innovative design and engineering excellence set this equipment apart, ensuring that it meets the demands of various terrains and tasks. With an emphasis on user-friendly operation, the machines are equipped with intuitive controls and ergonomic features that promote comfort during extended use.

Maintenance and accessibility are key aspects, allowing operators to easily manage upkeep and repairs. This focus on practicality, combined with high-quality materials, ultimately leads to a reliable and long-lasting investment for those in the field.

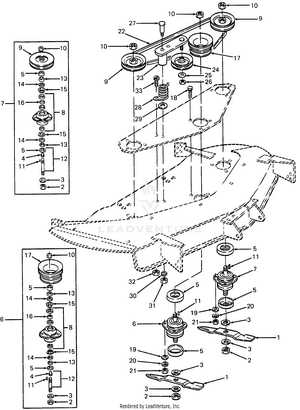

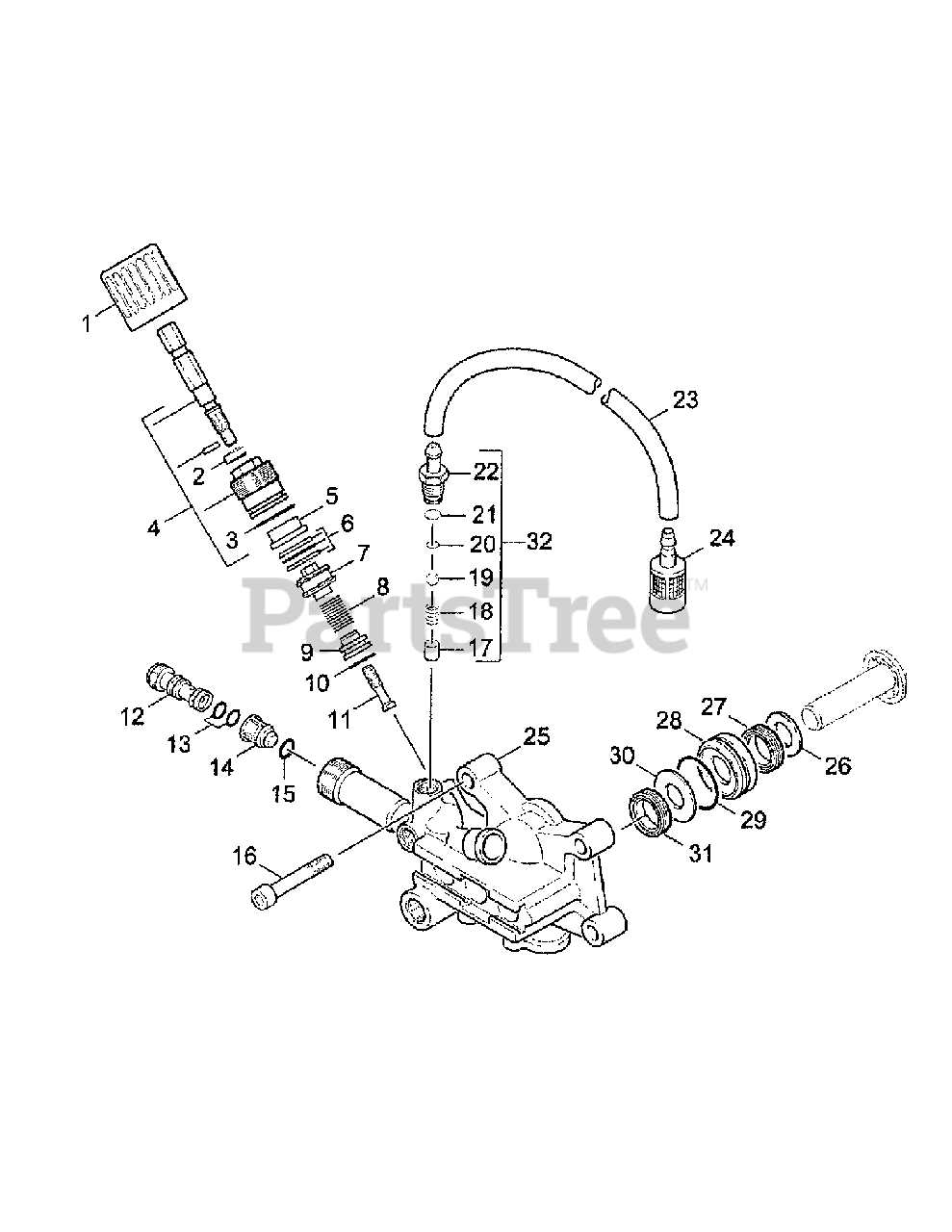

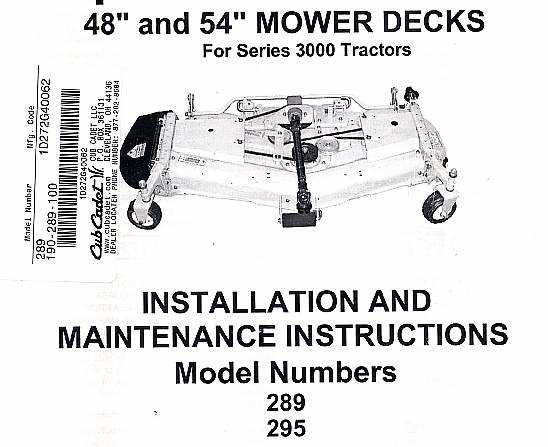

Importance of Parts Diagrams

Understanding the intricacies of machinery often requires visual representations that break down components into manageable segments. Such illustrations are vital for both maintenance and repair tasks, enabling users to identify and locate individual elements with ease.

These visuals serve as essential guides, ensuring that each piece can be replaced or serviced correctly, which ultimately enhances the lifespan and performance of the equipment. Moreover, they help streamline the repair process, reducing the likelihood of errors and saving time.

For technicians and enthusiasts alike, these references are indispensable tools that facilitate deeper engagement with the machinery, allowing for more informed decisions and actions.

Common Issues with Series 3000

This section addresses prevalent challenges faced by users of a specific line of outdoor equipment. Understanding these common problems can enhance the maintenance experience and improve overall performance.

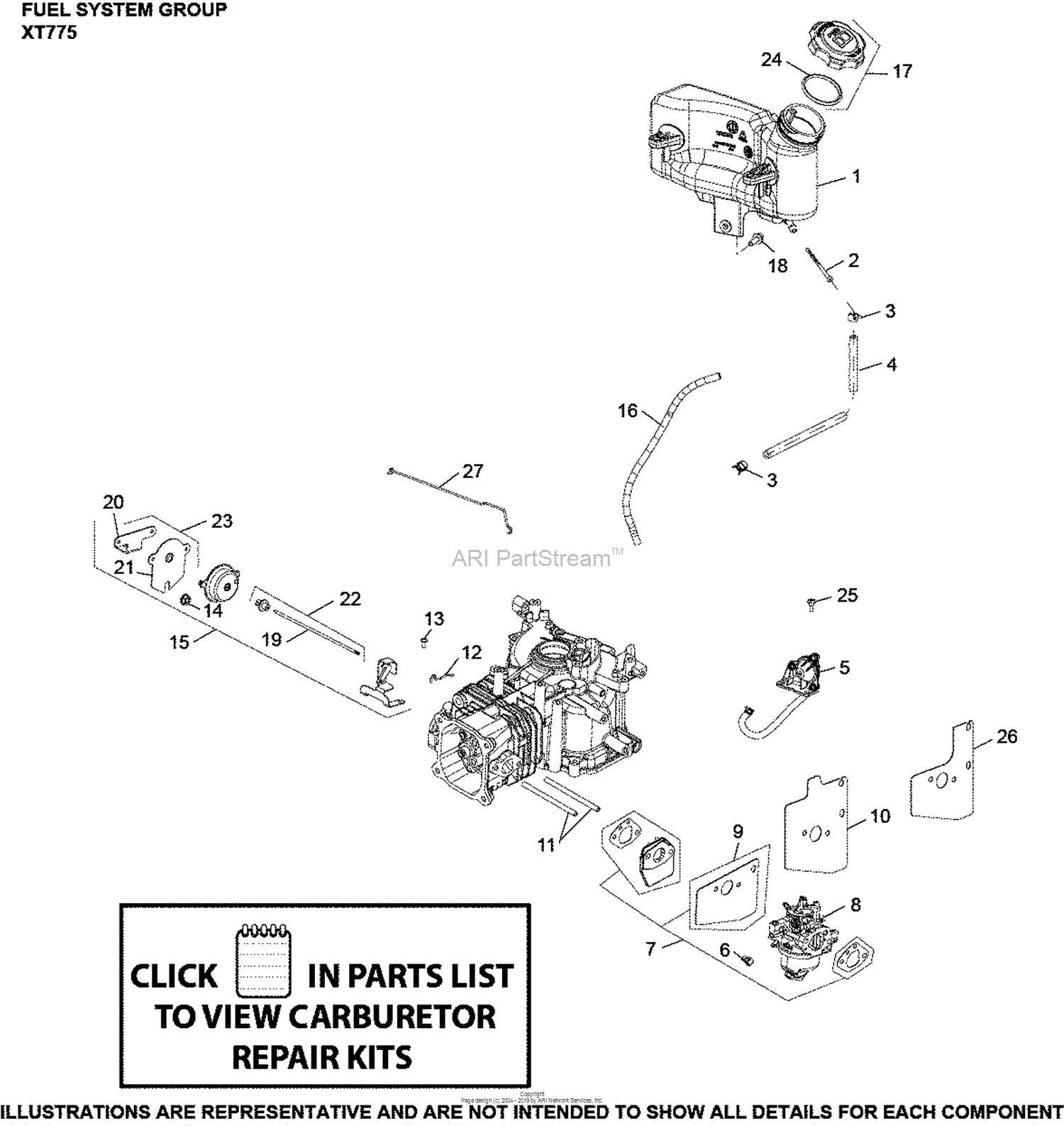

Engine Performance

One frequent issue involves engine efficiency. Users may notice irregular starts or sputtering, often stemming from fuel delivery problems or clogged filters. Regular checks can prevent more significant malfunctions.

Electrical Failures

Another common concern relates to the electrical system. Battery drainage or malfunctioning lights can disrupt operation. Ensuring connections are secure and checking battery health are essential steps to avoid these inconveniences.

Identifying Replacement Parts

When maintaining outdoor machinery, recognizing the correct components for replacement is essential for optimal performance. Familiarity with various elements ensures that your equipment runs smoothly and efficiently. Knowing how to locate and identify these crucial items will save time and enhance longevity.

Understanding Component Codes

Most equipment comes with specific identification codes that are linked to each element. These codes serve as a guide for sourcing replacements. Utilizing the manufacturer’s catalog can simplify the process, allowing you to pinpoint the exact item you need with ease.

Utilizing Visual Aids

Visual aids, such as charts or images, can significantly enhance your understanding. Referencing detailed illustrations of the machine helps to clarify which components require attention, making the identification process more intuitive. Accurate visual resources are invaluable in ensuring correct replacements.

Where to Find Diagrams Online

Accessing visual representations of machinery components has never been easier thanks to the vast resources available on the internet. Numerous platforms provide detailed illustrations that can assist both enthusiasts and professionals in understanding the intricacies of their equipment. These online resources cater to various needs, from basic maintenance to complex repairs.

Manufacturer Websites: One of the most reliable sources for accurate illustrations is the official website of the equipment manufacturer. These sites often host a wealth of resources, including user manuals, service guides, and schematic drawings. Navigating to the support or resources section can yield valuable information tailored specifically to the model in question.

Online Retailers: E-commerce platforms that specialize in machinery often feature comprehensive listings with visual aids. These platforms provide not only images but also specifications, making it easier to identify the correct components needed for repairs or replacements.

Forums and Community Groups: Engaging with online communities dedicated to machinery enthusiasts can be incredibly beneficial. Many users share their own resources, including illustrations and guides. Websites like Reddit or specialized forums often have threads where users post links to useful materials, including detailed visuals.

Technical Resources Libraries: Several websites serve as libraries for technical documentation, including diagrams and schematics. These resources can sometimes be accessed for free, or they may require a subscription. However, they are invaluable for anyone looking to delve deeper into maintenance or repair tasks.

Video Tutorials: Platforms like YouTube offer a variety of tutorials that often include visual references. Many content creators provide step-by-step guides along with on-screen diagrams, making it easier to follow along with complex procedures.

Understanding Model Variations

Different models within a particular product line can exhibit unique features and specifications, making it essential to grasp these distinctions. Recognizing the variations helps users select the right components and optimize performance.

Key Factors Influencing Variations

- Engine types and power outputs

- Transmission systems

- Design features and ergonomics

- Accessory compatibility

Identifying Your Model

To effectively navigate these differences, users should:

- Check the model number and specifications.

- Consult the manufacturer’s resources.

- Join user forums for community insights.

Tools for Maintenance and Repair

Proper upkeep and restoration of outdoor equipment require a specific set of instruments designed to enhance efficiency and accuracy. Having the right tools at your disposal not only simplifies the tasks but also ensures longevity and optimal performance of your machinery.

Essential items include wrenches, screwdrivers, and pliers, which facilitate adjustments and component replacements. Additionally, specialized tools like torque wrenches and diagnostic devices can aid in achieving the ultimate precision needed for intricate repairs.

Regular maintenance also benefits from safety equipment such as gloves and goggles to protect the user during hands-on tasks. Organizing these tools in a dedicated workspace ensures they are readily accessible, promoting a smooth workflow during maintenance activities.

Ultimately, investing in quality instruments tailored for specific functions leads to a more efficient and effective maintenance process, safeguarding the equipment against premature wear and ensuring it runs at its best.

Ordering Genuine Cub Cadet Parts

Acquiring authentic components for your outdoor equipment is essential for maintaining performance and longevity. Ensuring that you select high-quality items can significantly enhance the reliability of your machinery and prevent potential issues down the line.

Why Choose Authentic Components?

Opting for genuine items provides numerous advantages:

- Guaranteed compatibility with your equipment.

- Enhanced durability and performance.

- Access to manufacturer support and warranty options.

How to Order

Follow these steps to ensure a smooth ordering process:

- Identify the specific components needed by consulting your manual.

- Visit an authorized dealer or the manufacturer’s official website.

- Check for any available promotions or discounts.

- Add the selected items to your cart and proceed to checkout.

Comparing Aftermarket Options

When it comes to maintaining your outdoor equipment, exploring alternative components can be a wise decision. These alternatives often provide a balance between quality and cost, making them appealing to a wide range of users. However, it’s essential to assess various factors to ensure you make the best choice for your specific needs.

Here are some key aspects to consider when evaluating aftermarket alternatives:

- Quality: Assess the manufacturing standards and materials used. Higher quality options can lead to better performance and longevity.

- Compatibility: Ensure that the components fit seamlessly with your existing machinery. Misalignment can cause issues down the line.

- Price: While affordability is crucial, be cautious of significantly cheaper products that may compromise quality.

- Reviews: Look for customer feedback and ratings. Real-world experiences can provide valuable insights into reliability.

- Warranty: Consider products that come with a warranty, as this often indicates confidence in the product’s durability.

By carefully comparing these factors, you can find aftermarket options that meet your expectations without sacrificing performance. Ultimately, the right choice will enhance your equipment’s efficiency and extend its lifespan.

Tips for Efficient Repairs

Effective maintenance and restoration of machinery can significantly enhance performance and longevity. Understanding how to approach repairs methodically will save time and resources, ensuring optimal functionality.

Preparation is Key

- Gather all necessary tools and components before starting.

- Review manuals and guides to familiarize yourself with the machinery.

- Create a clean and organized workspace to minimize distractions.

Follow a Systematic Approach

- Diagnose the issue accurately before making any changes.

- Document each step taken during the repair process for future reference.

- Test the machinery thoroughly after completing repairs to ensure everything functions as intended.

Safety Precautions During Maintenance

Ensuring safety while performing upkeep on outdoor machinery is crucial to prevent accidents and injuries. Proper precautions not only protect the individual working on the equipment but also help maintain the longevity and functionality of the machine itself. Adhering to established safety protocols can significantly reduce the risk of mishaps during maintenance tasks.

First and foremost, it is essential to disconnect the power source before beginning any maintenance work. This step eliminates the risk of accidental starts, which can lead to severe injuries. Additionally, wearing appropriate personal protective equipment, such as gloves, goggles, and sturdy footwear, provides an extra layer of security against potential hazards.

Furthermore, keeping the workspace clean and organized is vital. Clutter can create tripping hazards and make it challenging to access tools and components efficiently. Always use the right tools for the job to avoid damaging parts or causing injury. If unsure about any procedure, consulting the equipment manual or seeking assistance from a qualified professional is advisable.

Finally, never underestimate the importance of maintaining proper ventilation, especially when working with fuel or chemicals. Ensuring adequate airflow helps prevent the buildup of harmful fumes, contributing to a safer working environment. By following these guidelines, individuals can perform maintenance tasks effectively while prioritizing their safety and well-being.

Customer Support Resources

Access to reliable assistance is essential for users seeking guidance with their equipment. This section highlights the various avenues available for effective support, ensuring you can swiftly find the help you need.

Online Forums: Engaging with communities through online platforms can provide valuable insights and answers from fellow enthusiasts.

Official Websites: Manufacturer sites often feature comprehensive FAQs and troubleshooting guides tailored to specific models.

Customer Service Lines: Direct communication with support representatives can resolve issues more efficiently, offering personalized assistance.

Instruction Manuals: Referring to detailed user guides can clarify functionalities and maintenance tips, enhancing your experience.

Utilizing these resources will ultimately empower you to maximize your equipment’s performance and longevity.

FAQs About Series 3000 Parts

This section addresses common inquiries regarding components and accessories related to the equipment line in question. Understanding the details can assist users in making informed decisions and maintaining their machines effectively.

| Question | Answer |

|---|---|

| What should I do if I can’t find a specific component? | Check the manufacturer’s website or authorized dealers for availability and alternatives. |

| Are replacement items covered under warranty? | Most warranties cover defects in material or workmanship, but not regular wear and tear. |

| How can I ensure compatibility with my equipment? | Refer to the model number and consult the manual or a professional for guidance. |

| Is there a recommended maintenance schedule for these components? | Regular checks and maintenance every season are advised to prolong lifespan and efficiency. |