Comprehensive Yamaha G1 Parts Diagram for Easy Reference

The intricate design of a musical instrument requires a deep understanding of its various elements and how they work together. This exploration reveals not only the craftsmanship involved but also the significance of each section in contributing to the overall performance and sound quality.

To truly appreciate this classic model, one must delve into the individual components that define its structure. Each piece plays a vital role, influencing everything from resonance to playability. By examining these elements, musicians and enthusiasts alike can enhance their knowledge and maintenance skills.

Ultimately, having a clear overview of the arrangement and function of these crucial elements ensures a richer experience, whether you’re a performer or a curious learner. This guide aims to provide valuable insights into the assembly and functionality of this renowned instrument.

Understanding Yamaha G1 Parts

Exploring the various components of musical instruments can greatly enhance one’s appreciation and knowledge of their functionality. Each element plays a crucial role in the overall performance and sound quality, contributing to the unique character of the instrument. By examining these elements closely, enthusiasts can gain insight into maintenance, repairs, and upgrades.

Every section of the instrument serves a specific purpose, from the structure that supports the framework to the intricate mechanisms that facilitate sound production. Familiarity with these elements not only aids in effective troubleshooting but also fosters a deeper connection to the instrument itself. This exploration invites players and technicians alike to delve into the nuances that define quality and craftsmanship.

Moreover, understanding these components can lead to informed decisions regarding enhancements or replacements, ensuring optimal performance over time. Knowledge of each segment empowers users to make precise adjustments, ultimately leading to a more satisfying musical experience. Engaging with these details unlocks the ultimate potential of the instrument.

Overview of the Yamaha G1 Model

This section provides an insight into a classic instrument known for its craftsmanship and sound quality. The model is revered in various musical circles for its unique features and performance capabilities.

- Introduced in the late 20th century.

- Recognized for its distinctive tonal quality.

- Often favored by both professionals and enthusiasts.

Musicians appreciate its responsiveness and durability, making it a reliable choice for diverse playing styles.

- Notable construction materials enhance its longevity.

- Available in various finishes, appealing to a wide audience.

- Maintenance and care are essential for optimal performance.

Overall, this model stands out in the world of musical instruments, offering an ultimate blend of elegance and functionality.

Importance of Parts Diagrams

Understanding the various components of a machine is crucial for effective maintenance and repair. Visual representations of these elements provide invaluable insights, facilitating a deeper comprehension of how each piece interacts within the whole system.

Here are some key reasons why these visual aids are essential:

- Clarity: They offer a clear view of individual elements, making it easier to identify and locate specific items.

- Organization: Visual guides help organize information, breaking down complex assemblies into manageable sections.

- Efficiency: Technicians can quickly reference the illustrations, saving time during diagnostics and repairs.

- Accuracy: Accurate identification of components reduces the risk of errors when ordering replacements or making adjustments.

- Educational Tool: They serve as an effective educational resource for those learning about machinery and its functions.

In summary, these visual tools are vital for anyone involved in the upkeep of mechanical systems, enhancing understanding and ensuring smoother operations.

Main Components of Yamaha G1

This section explores the essential elements that contribute to the functionality and performance of the G1 model. Understanding these components is crucial for maintenance and optimal use, ensuring that the instrument delivers its full potential over time.

Structural Elements

The framework of the G1 is designed for stability and resonance, which significantly influences sound quality. Key structural components include the body, soundboard, and ribs, each playing a vital role in producing the rich tones associated with this model.

Mechanisms and Hardware

The internal mechanisms encompass action parts, hammers, and pedals that work in harmony to enable precise control and responsiveness. Each component is meticulously crafted to enhance the overall playing experience, ensuring that musicians can achieve their desired sound with ease.

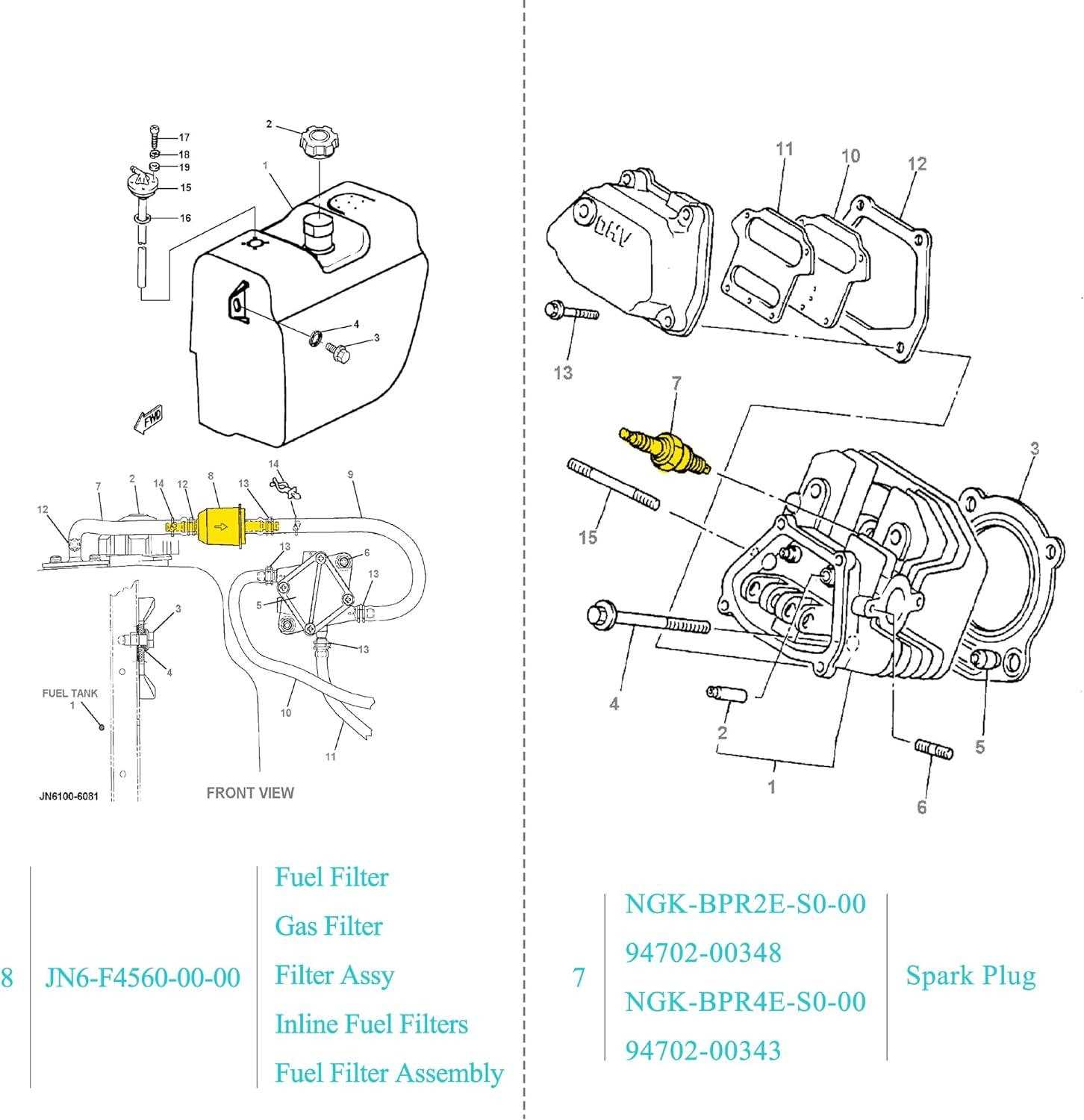

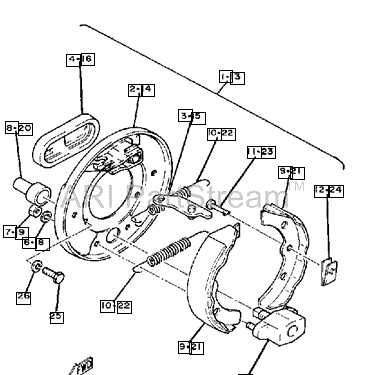

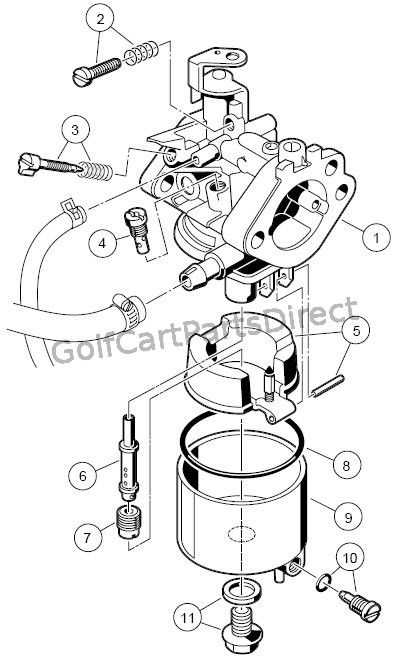

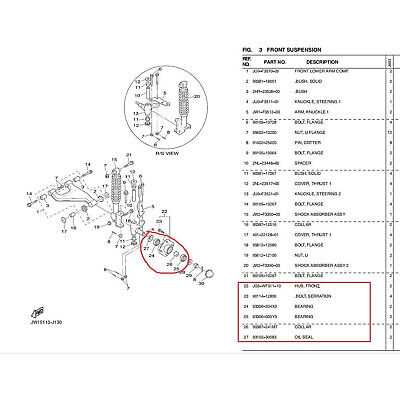

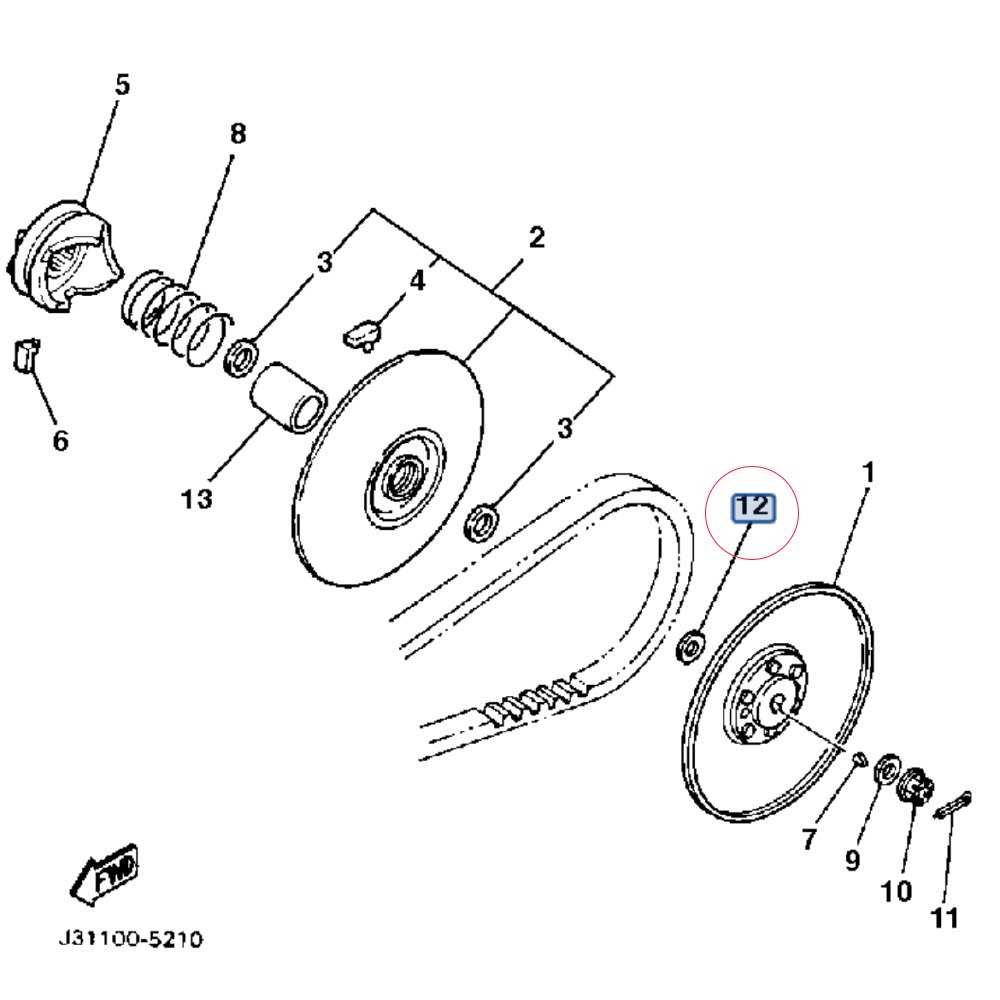

Identifying Key Parts Visually

Understanding the layout of components is essential when maintaining or restoring complex equipment. A visual approach allows users to grasp how individual elements connect and operate within the whole system, streamlining troubleshooting and repairs.

Main Structures and Their Functionality

Recognizing the primary sections, such as the frame and operational mechanisms, helps differentiate between essential and supplementary elements. These structures serve as the foundation, ensuring stability and smooth operation.

Details That Matter

Smaller elements, like fasteners or electrical connections, may seem insignificant but play a crucial role in the system’s performance. Identifying these components early can prevent potential failures and ensure seamless functionality over time. A clear visual reference makes spotting missing or worn-out elements easier during inspections

Common Issues with Yamaha G1

Vehicles of this type, especially older models, often encounter various mechanical and electrical challenges over time. Regular use, environmental conditions, and natural wear can lead to the need for occasional troubleshooting and maintenance to keep everything running smoothly.

Engine Performance Problems

Reduced power output, starting difficulties, and unusual noises may indicate issues with the motor or fuel system. Cleaning or replacing filters and inspecting ignition components can often resolve these challenges. Overheating could also result from inadequate airflow or blocked cooling passages, which require prompt attention.

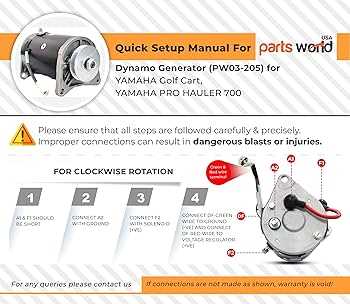

Electrical and Wiring Issues

Electrical failures, such as non-responsive lights or malfunctioning controls, are often traced back to worn-out connections, fuses, or wiring faults. Inspecting the battery and ensuring all contacts are clean can prevent sudden breakdowns. Regular maintenance of switches and connectors helps avoid interruptions

Maintenance Tips for Longevity

Consistent upkeep ensures that your equipment remains reliable and functions smoothly over time. A proactive approach to maintenance can prevent minor issues from developing into major problems, extending the overall service life.

Regular Cleaning Routine

- Wipe surfaces frequently to avoid dust buildup that can interfere with performance.

- Use appropriate cleaning solutions for different materials to prevent corrosion or damage.

- Check for moisture in sensitive areas and dry them thoroughly to avoid deterioration.

Inspect and Tighten Components

- Conduct visual inspections to identify loose connections or worn-out elements.

- Tighten bolts, screws, or fittings periodically to maintain structural stability.

- Replace any damaged components promptly to avoid further complications.

Following these simple steps will help you enjoy long-term performance and

Where to Find Parts Diagrams

Locating visual references for mechanical components can be essential for repairs and maintenance. These resources provide clear breakdowns of how individual elements fit together, making it easier to identify what may need replacement or adjustment.

Manufacturer Websites

Official websites of manufacturers often host detailed technical references for various models. By browsing through product categories or entering specific serial numbers, users can access comprehensive illustrations to assist with disassembly and troubleshooting.

Online Catalogs and Forums

Digital catalogs and community platforms are another valuable source for technical illustrations. Many enthusiasts share their knowledge through forum discussions, linking to specific diagrams and providing advice on installation and compatibility with different models.

How to Read a Parts Diagram

Understanding technical illustrations is essential for anyone looking to maintain or repair mechanical systems. These visual guides present the relationship between components, helping users identify what goes where and how different elements fit together.

Identify section groupings: Many visual guides organize components into logical sections. Look for clusters or labeled areas that correspond to different assemblies or functions, such as the engine or electrical system.

Use reference numbers: Numbers or codes next to individual components often correspond to a list or chart. This key helps you match the visual element with its description, ensuring you choose the correct part or tool.

Follow connections and flow: Pay attention to lines or arrows, as they often indicate the flow of fluids, energy, or mechanical movement. This makes it easier to understand how different sections interact with each other.

Check for notes and symbols: Some diagrams include special symbols or additional notes. These can provide crucial details, such as assembly instructions or torque specifications, that are not immediately obvious from the image alone.

OEM vs. Aftermarket Parts Explained

Choosing between original and alternative components can be challenging. Each option offers specific advantages depending on quality expectations, pricing considerations, and availability. Understanding these differences helps in making informed decisions for maintenance and upgrades.

What Are OEM Components?

OEM, or Original Equipment Manufacturer components, are designed by the same producers who created the original product. These components offer a precise fit and maintain the original quality standard, making them a reliable choice for those seeking compatibility and performance consistency.

Aftermarket Alternatives: Pros and Cons

- Cost-effectiveness: Aftermarket options tend to be more affordable, offering budget-friendly solutions without compromising too much on functionality.

- Variety: A wider selection is often available, with multiple brands offering different variations and improvements over the original design.

- Quality differences: While some aftermarket components exceed original standards, others may not match the durability or precision of OEM options.

Benefits of Using Genuine Parts

Choosing authentic components ensures that your equipment maintains peak performance over time. These elements are specifically crafted to align with the original design, providing enhanced reliability and longevity.

- Improved Performance: Authentic elements are designed to fit perfectly, ensuring the smooth operation of your machine.

- Longer Lifespan: Original components minimize the risk of wear and tear, extending the operational life of your equipment.

- Safety Assurance: Using certified components reduces the chances of malfunctions, keeping both the user and the equipment secure.

- Cost Efficiency: Although genuine replacements may be pricier initially, they help prevent frequent repairs, lowering long-term maintenance costs.

- Environmental Impact: Reliable components reduce waste by decreasing the need for premature replacements, supporting sustainable use of resources.

Resources for DIY Repairs

Maintaining and fixing equipment independently requires the right knowledge and tools. Having access to clear guidance and instructional resources makes it easier to troubleshoot issues and handle replacements. These resources can help enthusiasts extend the lifespan of their machines while avoiding unnecessary expenses.

Online Communities and Forums

Communities built around specific models offer valuable insights and step-by-step solutions. Many hobbyists and experts share repair experiences, tips, and solutions for common issues. Forums also allow individuals to ask questions and get advice from those with firsthand experience.

Instructional Videos and Manuals

Video platforms and online manuals provide visual guidance for complex tasks. These resources help users follow along with detailed processes, reducing the risk of mistakes. Digital manuals often include detailed instructions and reference charts to assist with every stage of maintenance or repairs.

Connecting with Yamaha Enthusiasts

Engaging with a community of like-minded individuals can offer valuable insights and support for maintaining and enhancing your vehicle. These communities provide a space to share experiences, learn new techniques, and discover solutions to common challenges.

Online Communities and Forums

Numerous online platforms host active discussions where users exchange advice, troubleshooting tips, and recommendations. Participating in these groups fosters a sense of belonging and keeps you updated on the latest trends and solutions shared by fellow enthusiasts.

Events and Gatherings

Local meetups, rallies, and conventions bring together fans who share the same passion. These events offer opportunities to showcase personal projects, attend workshops, and connect with experts and peers, creating a vibrant network of connections.