Comprehensive Guide to Polaris Hawkeye Parts Diagram

In the realm of off-road machinery, having a comprehensive understanding of the internal and external components is essential for optimal maintenance and repair. The intricate interplay between various elements ensures that these robust vehicles perform at their best, even in the harshest conditions. Whether you are a seasoned mechanic or an enthusiastic owner, familiarizing yourself with the specific arrangement of parts can significantly enhance your knowledge and efficiency.

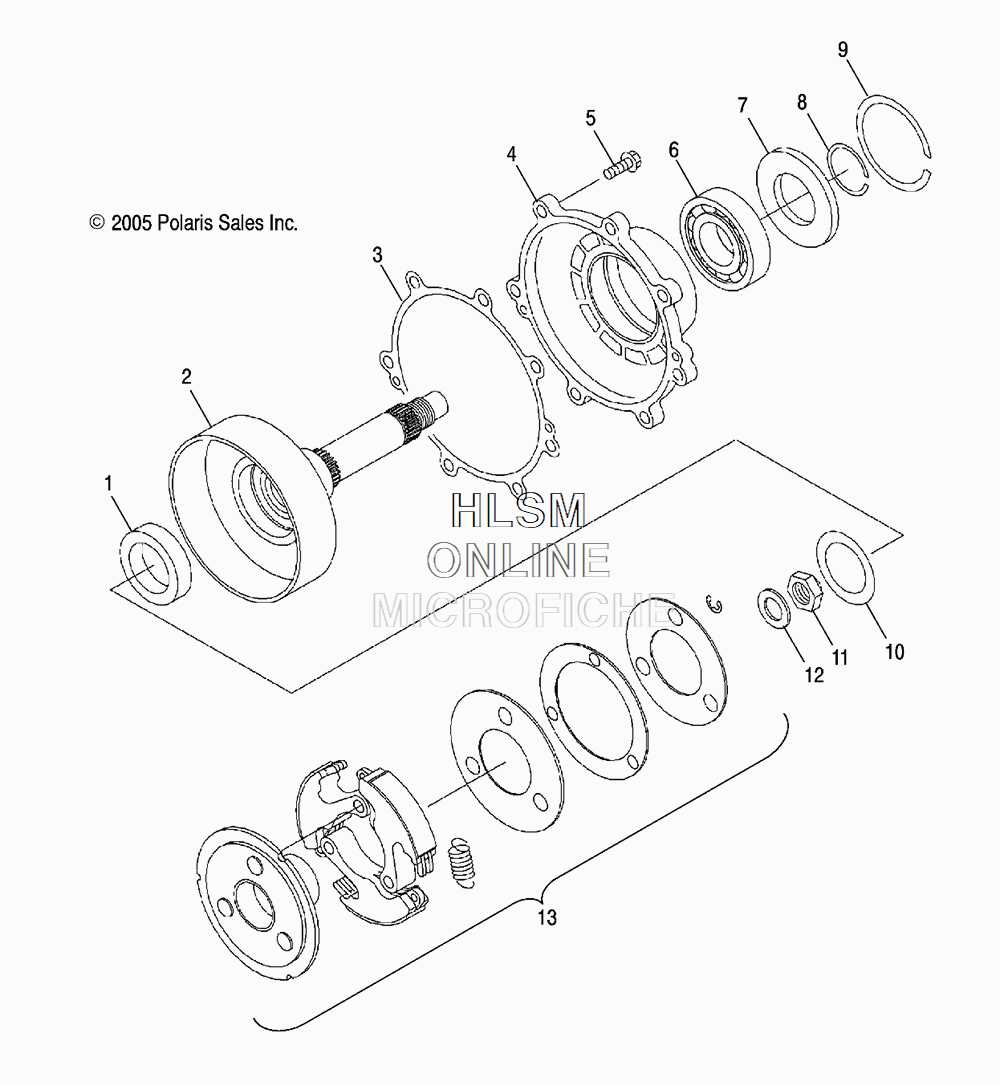

Visual representations of these assemblies provide invaluable insights, highlighting how each component interacts with the others. By studying these layouts, one can easily identify potential issues and make informed decisions during repairs. This approach not only simplifies complex tasks but also empowers individuals to take charge of their vehicles’ upkeep.

Moreover, understanding the various components allows for better customization and upgrades, enabling users to tailor their machines to meet personal preferences and performance goals. As we delve deeper into the topic, the importance of recognizing these layouts becomes increasingly clear, serving as a foundation for effective vehicle management.

Understanding Polaris Hawkeye Components

When it comes to off-road vehicles, comprehending the various elements that contribute to their functionality is crucial for enthusiasts and operators alike. Each component plays a vital role in ensuring performance, reliability, and safety. This section aims to explore the essential mechanisms that make up these rugged machines, highlighting their importance and interconnectivity.

At the heart of these vehicles is the engine, which serves as the powerhouse, providing the necessary energy for movement. Coupled with the transmission system, this allows for the smooth transfer of power to the wheels, facilitating an enjoyable driving experience. Additionally, the suspension system plays a key role in maintaining stability and comfort, absorbing shocks from uneven terrain.

Furthermore, understanding the braking system is essential for safe operation. This system is designed to bring the vehicle to a halt efficiently, ensuring the driver’s control at all times. Complementing these mechanisms are the electrical components, which manage everything from lighting to ignition, enhancing both functionality and safety.

Lastly, the frame and chassis form the structural backbone, providing durability and strength to withstand the rigors of off-road adventures. Each element is interconnected, creating a cohesive unit that operates harmoniously to deliver optimal performance in various environments.

Essential Parts Overview

This section provides a comprehensive look at the fundamental components that contribute to the functionality and performance of off-road vehicles. Understanding these elements is crucial for maintenance and upgrades, ensuring optimal operation in various conditions.

Key Components

- Engine: The powerhouse that drives the vehicle.

- Transmission: Facilitates power transfer from the engine to the wheels.

- Suspension: Ensures stability and comfort over rough terrain.

- Braking System: Critical for safety and control during operation.

- Electrical System: Powers lights, gauges, and other electronic features.

Maintenance Tips

- Regularly inspect the engine and transmission for leaks and wear.

- Check suspension components for damage or fatigue.

- Ensure brakes are responsive and replace pads as needed.

- Maintain electrical connections to prevent failures.

- Consult the manufacturer’s guidelines for servicing intervals.

Benefits of a Parts Diagram

A visual representation of components plays a crucial role in maintenance and repair tasks. By offering a clear view of individual elements, it enhances understanding and facilitates efficient troubleshooting.

One significant advantage is the ease of identification. Users can quickly locate specific items within the assembly, reducing the time spent searching for parts. This efficiency can lead to quicker repairs and less downtime.

Additionally, such visuals aid in comprehending complex structures. When dealing with intricate systems, a well-organized illustration can simplify the learning process, making it accessible even to those with minimal experience.

Another benefit is improved communication. Whether among technicians or between a technician and a customer, having a shared reference point ensures that everyone is on the same page regarding repairs or replacements.

Moreover, these representations often highlight the relationships between components. Understanding how parts interact can prevent improper installations and enhance overall performance.

Lastly, having a detailed layout can assist in inventory management. Knowing exactly what is required for maintenance allows for better planning and ordering, which can ultimately lead to cost savings.

Common Issues and Solutions

When operating off-road vehicles, enthusiasts often encounter various challenges that can affect performance and reliability. Understanding these common problems and their remedies can enhance the overall experience and ensure smoother rides. Below are some frequently observed issues along with effective solutions to address them.

One prevalent issue is the electrical system failure, which can manifest as flickering lights or an inability to start. Checking the battery connections and ensuring they are clean and secure is crucial. If the battery is weak, replacing it may be necessary.

Another frequent concern is tire wear and handling difficulties. Regularly inspecting tires for uneven wear patterns can help identify alignment issues or insufficient inflation. Maintaining proper tire pressure and ensuring proper alignment can significantly improve handling and prolong tire life.

Engine performance problems can arise from a variety of factors, such as fuel quality or air filter blockage. Utilizing high-quality fuel and regularly replacing the air filter can enhance engine efficiency and prevent stalling or sluggish performance.

Lastly, suspension issues can lead to a rough ride and decreased control. Periodic inspection of shock absorbers and bushings for signs of wear can help maintain ride quality. Replacing worn components promptly will contribute to a safer and more comfortable driving experience.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires regular care and attention. Implementing a routine maintenance schedule can significantly enhance performance and extend the lifespan of your vehicle. Below are some essential practices to keep in mind.

Routine Checks

Performing periodic inspections is crucial for identifying potential issues early. This includes checking fluid levels, brakes, and tire conditions to prevent unexpected breakdowns.

Cleaning and Storage

Regular cleaning helps remove dirt and debris that can cause wear. Proper storage in a dry, sheltered location also protects your equipment from harsh weather and prolongs its life.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Fluid Checks | Monthly | Prevents engine wear |

| Tire Inspection | Every 1,000 miles | Improves safety |

| Cleaning | After every use | Reduces corrosion |

| Storage Preparation | Seasonally | Prevents damage |

How to Read the Diagram

Understanding technical illustrations is essential for identifying the correct components and their connections. These visual guides help simplify complex systems, showing how different elements interact with each other. With careful attention to detail, anyone can interpret these illustrations to perform repairs or replacements with greater ease.

Breaking Down the Illustration

Each illustration typically includes labels or symbols that represent various elements. Pay attention to these markings, as they will guide you in recognizing specific components. Also, observe the lines or arrows, which indicate relationships or pathways between different parts. Recognizing these symbols will allow you to understand the flow and connections.

Common Symbols and Markings

Illustrations often use standardized symbols to represent specific functions or connections. Familiarize yourself with these symbols as they provide crucial information. Additionally, colors or patterns may be used to highlight distinct sections, helping to distinguish between different areas of the system.

Ordering Replacement Parts Online

When it comes to maintaining your equipment, finding the correct components can be crucial for ensuring smooth operation. The internet offers a wide range of suppliers that provide the necessary tools and accessories to keep your machinery in top shape. With just a few clicks, you can locate the exact item you need, compare prices, and make an informed decision on where to purchase.

Choosing the Right Supplier is important to avoid delays and ensure the quality of the item. Look for well-established vendors who offer reliable delivery options and a clear return policy. Customer reviews can also help you evaluate the trustworthiness of the provider.

Verify Compatibility before making your final decision. Double-check model numbers or specifications to ensure that the item will fit perfectly with your equipment. Most online platforms provide detailed product descriptions, which can assist in confirming the compatibility of your purchase.

Aftermarket vs. OEM Parts

When it comes to replacing components in your vehicle, there are generally two options available: aftermarket and original equipment manufacturer (OEM) alternatives. Understanding the key differences between these options is essential for making an informed decision, as each offers its own set of benefits and drawbacks. While OEM versions are designed specifically by the manufacturer, aftermarket alternatives provide more flexibility in terms of cost and variety.

Quality and Compatibility

OEM components are engineered to match the exact specifications of your vehicle, ensuring a high level of compatibility and performance. On the other hand, aftermarket parts can vary in quality depending on the manufacturer, though many offer comparable or even superior options. However, it’s important to verify compatibility to avoid potential issues.

Cost and Availability

Aftermarket alternatives are often more affordable and easier to find, especially for older models. Meanwhile, OEM options tend to be more expensive but offer peace of mind with a guarantee of exact fit and function. Ultimately, the choice between these two depends on your priorities, whether it’s maintaining original quality or exploring cost-effective alternatives.

Installation Guide for New Parts

When upgrading or replacing components, it is essential to follow proper installation steps to ensure smooth operation and longevity. This guide will walk you through the process of fitting new elements onto your vehicle, ensuring all pieces align and function as expected.

- Start by preparing the area where the new component will be installed. Clean the surface thoroughly to remove any debris that could interfere with the installation.

- Position the new element carefully, ensuring it aligns with the existing structure. Avoid forcing the piece into place as this could cause damage.

- Secure the element using the appropriate fasteners, bolts, or screws. Tighten them gradually to ensure even pressure distribution.

- Double-check the alignment and fit before moving on. Make any necessary adjustments to ensure a perfect connection.

- Once installed, test the component to confirm it operates correctly. If any issues arise, review the installation steps or consult a professional for assistance.

Following these steps will help ensure your installation is successful and your vehicle operates as intended.

Tools Needed for Repairs

When preparing to fix your vehicle, having the right set of equipment is crucial for efficiency and safety. The tools required can vary depending on the specific task, but there are essential items that are commonly used in most repair situations. Ensuring you have these at hand will help you address the mechanical issues effectively.

For general mechanical adjustments, wrenches and screwdrivers are indispensable. A good selection of both standard and metric sizes will cover most of your needs. Additionally, pliers, adjustable spanners, and socket sets allow for a broader range of tasks.

Other useful tools include torque wrenches for ensuring precise tightness and ratchet sets for more complex repairs. Hex keys and a pry bar may also be needed for specific adjustments. Finally, having a sturdy jack and axle stands is necessary for working under the vehicle safely.

Frequently Asked Questions

In this section, we aim to address common inquiries that users often have about various components and their assembly. Whether you’re troubleshooting or seeking more information about specific elements, this guide will provide useful insights to help you resolve issues and improve your understanding.

How do I identify the correct components?

Understanding how to recognize and match different elements is essential. It’s important to consult your model’s documentation, which typically includes visual references and explanations, allowing you to confirm the correct pieces for your setup.

Can I replace individual components on my own?

Replacing individual elements can be done with basic tools and the right guidance. However, ensure that you follow step-by-step instructions to avoid damaging any surrounding parts or voiding warranties. If you’re unsure, seeking professional assistance may be the best course of action.