Comprehensive Guide to John Deere 670 Parts Diagram

When it comes to maintaining heavy machinery, having a clear overview of its individual elements is essential. Understanding how each component functions and interacts can significantly enhance the efficiency of any equipment. This knowledge not only aids in troubleshooting but also assists in making informed decisions regarding repairs and replacements.

In this section, we will explore a comprehensive representation of the various pieces that comprise a specific model of agricultural machinery. By examining these elements in detail, operators can gain valuable insights into their maintenance needs and operational capabilities.

Equipped with this information, users can delve into the intricacies of their machinery, ensuring they achieve optimal performance. Whether you’re a seasoned operator or a newcomer, familiarizing yourself with the assembly of your equipment is the ultimate step towards effective management and longevity.

Understanding John Deere 670 Components

In the realm of agricultural machinery, a comprehensive grasp of the various elements that constitute a particular model is essential for effective maintenance and operation. This section aims to provide insights into the key components of a specific tractor, facilitating a deeper appreciation of its functionality and design.

Main Features

- Engine Assembly

- Transmission System

- Hydraulic Mechanisms

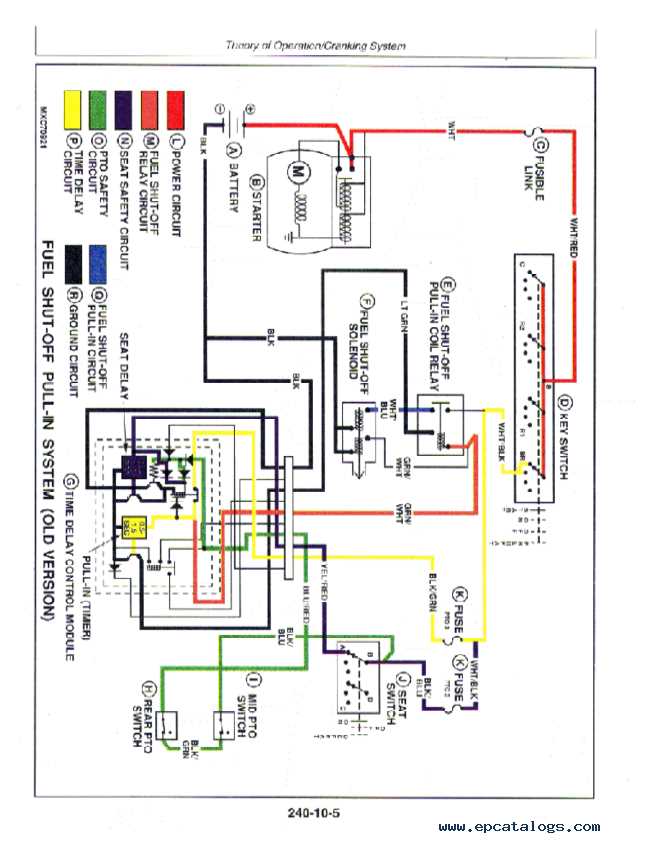

- Electrical Systems

Maintenance Considerations

- Regular oil changes for optimal performance.

- Inspecting belts and hoses for wear.

- Cleaning air filters to ensure efficiency.

- Checking fluid levels regularly.

Overview of John Deere 670 Model

This section provides a comprehensive look at a popular agricultural machine, highlighting its features, specifications, and overall functionality. Understanding the essence of this equipment is essential for operators and enthusiasts alike, ensuring optimal performance in various farming tasks.

Key Features

The machine is renowned for its robust design and reliability. Equipped with advanced technology, it offers enhanced maneuverability and efficiency, making it a preferred choice for diverse agricultural operations. The engine’s power, combined with an intuitive control system, enables seamless operation in various terrains.

Maintenance and Support

Regular upkeep is crucial for maximizing the lifespan of this equipment. Access to quality support services and replacement components ensures that users can keep their machine in top condition. Knowing how to address common issues effectively can lead to significant improvements in overall productivity.

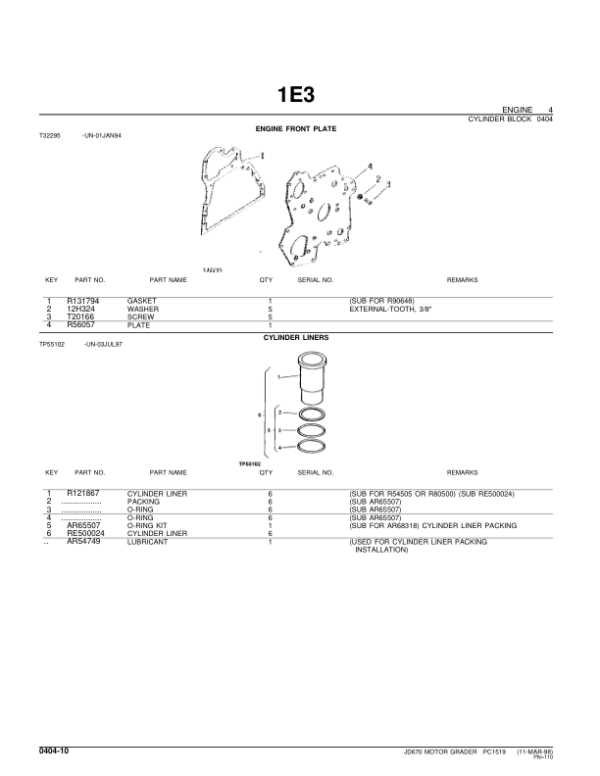

Importance of Parts Diagrams

Understanding the components of machinery is crucial for maintenance and repair tasks. Visual representations facilitate the identification of each element, ensuring that users can efficiently address issues that arise. This clarity helps in both troubleshooting and ordering replacements when necessary.

Enhancing Efficiency

Having a visual guide enables technicians to work more swiftly. By clearly illustrating the arrangement and function of various elements, individuals can minimize downtime and increase productivity during service sessions.

Aiding Communication

Clear representations also serve as a valuable tool for communication among team members. When everyone can reference the same visual, it reduces the chances of misunderstanding, leading to smoother collaborative efforts in repair or maintenance tasks.

Key Features of the 670 Tractor

This remarkable agricultural machine combines innovative design with powerful functionality, making it a preferred choice for various farming tasks. Its robust construction and user-friendly features enhance productivity while ensuring reliability in the field.

Power and Performance

Equipped with a high-performance engine, this tractor delivers exceptional torque and horsepower. This ensures efficient operation across different terrains, whether tackling heavy tillage or transporting materials. The transmission system is engineered for smooth shifting, allowing for seamless transitions between speeds.

Comfort and Usability

The operator station is designed with ergonomics in mind, providing ease of use during long hours of work. Features such as adjustable seating, intuitive controls, and excellent visibility contribute to a comfortable driving experience. Additionally, maintenance access is simplified, enabling quick servicing to keep the machine in top condition.

Common Replacement Parts Explained

Over time, machinery components experience wear and tear, requiring routine updates to maintain optimal performance. This section explores some of the most frequently exchanged elements, ensuring longevity and smooth operation of equipment.

Engine and Power System Components

- Filters: Crucial for maintaining a clean engine, these are regularly switched out to prevent debris buildup.

- Belts: Often subject to stretching or cracking, they are essential for transferring power to various systems.

- Hoses: With constant fluid circulation, these may degrade, leading to necessary replacements.

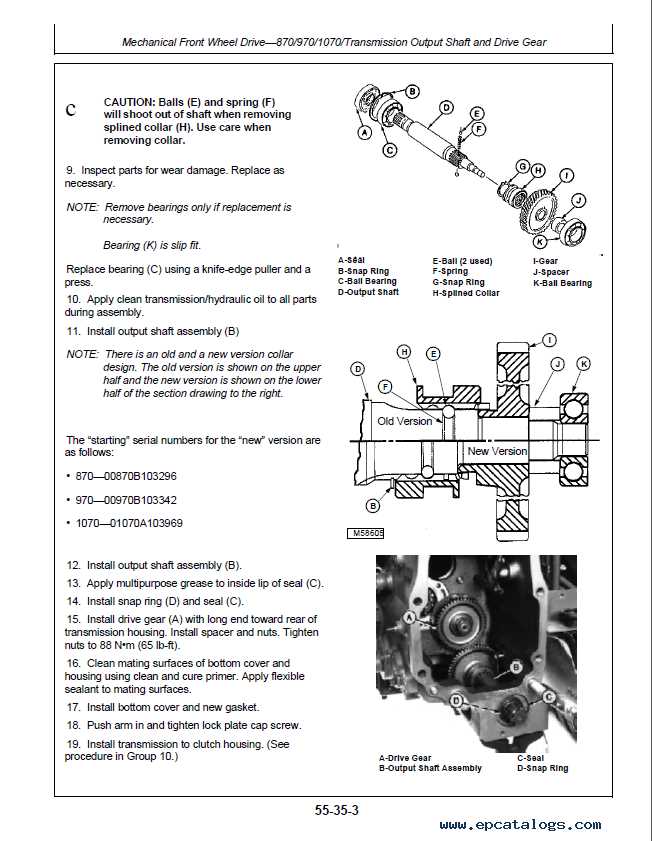

Transmission and Drive Elements

- Clutches: Regular use can lead to slippage, requiring fresh units for smooth shifting.

- Gears: As core elements of motion transfer, worn gears need timely changes to prevent system inefficiencies.

- Bearings: These ensure smooth rotation and, once worn, need prompt replacement to avoid further damage.

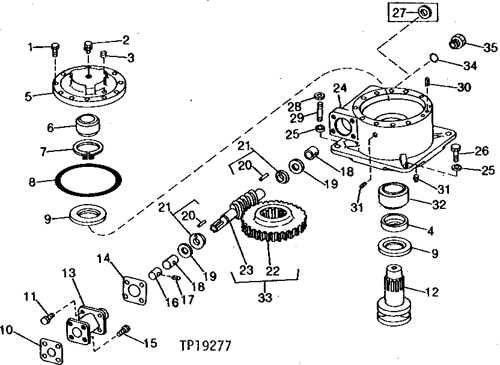

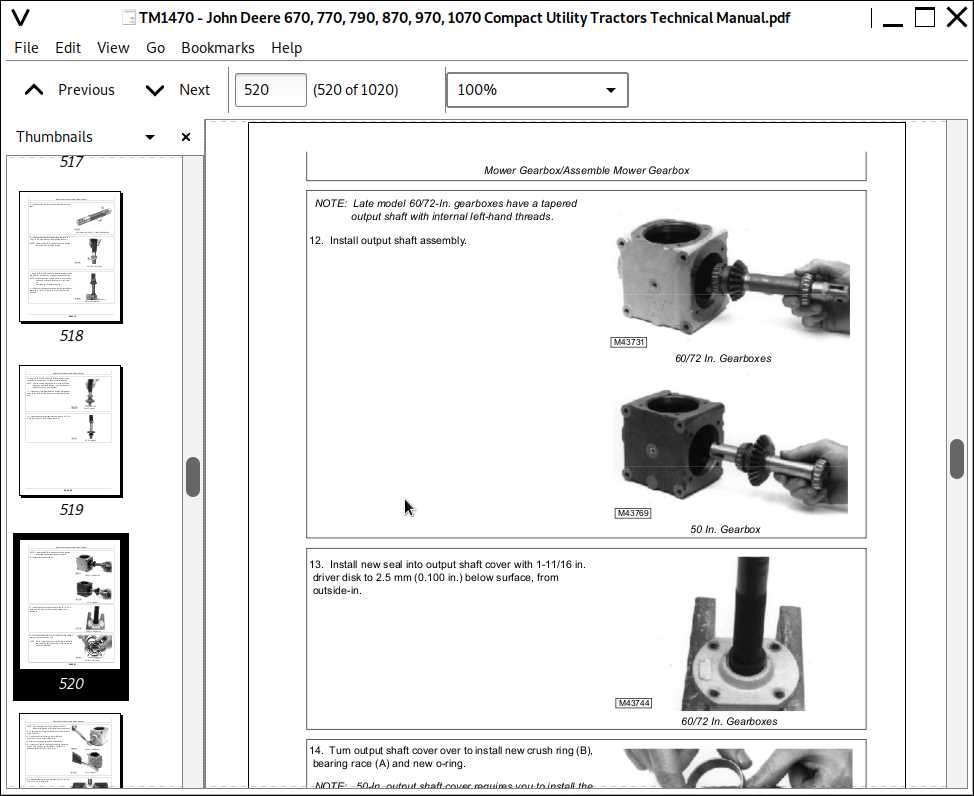

How to Use Parts Diagrams

Understanding the visual representation of components in machinery can greatly simplify repairs and maintenance. These diagrams break down complex systems into their individual elements, allowing for clear identification of each unit. By referencing these layouts, you can easily locate the necessary parts and determine how they interact within the larger structure.

Locating Components

When using technical illustrations, the first step is to familiarize yourself with the various symbols and numbers. These are typically labeled on the drawing to correspond with the list of components. Matching these identifiers ensures that you’re selecting the correct piece for any replacement or maintenance task.

Understanding Component Relationships

The layout of a technical drawing is designed to show how each part connects to others. Pay attention to the orientation of each element to understand how it fits within the overall system. This understanding is crucial when reassembling or troubleshooting mechanical issues.

| Component | Function | Location in Diagram |

|---|---|---|

| Gear | Transmits rotational force | Center, identified by #4 |

| Bolt | Secures two pieces together | Upper right corner, labeled #12 |

Sources for Genuine Parts

When it comes to maintaining your equipment, ensuring you have access to original and reliable components is crucial. Proper sourcing not only prolongs the lifespan of your machine but also ensures its safe and efficient operation. Finding dependable suppliers and distributors is essential for obtaining high-quality replacements.

| Supplier | Location | Contact |

|---|---|---|

| Trusted Equipment Distributor | North America | [email protected] |

| Quality Machinery Supply | Europe | [email protected] |

| Global Parts Network | Asia | [email protected] |

Identifying Parts by Diagram Sections

Understanding how various components fit together is essential for efficient system maintenance and repair. Visual representations offer a clear breakdown of each section, helping to quickly identify the required elements for specific tasks. By organizing each area logically, the schematic simplifies the process of recognizing key elements within a structure.

Detailed section views allow technicians to focus on specific areas without the confusion of unnecessary details. Each region highlights the relevant elements, ensuring a streamlined approach to identifying the necessary components.

Organized schematics are a crucial tool in any technical process, offering clarity and ease of use for even the most complex assemblies. This structured approach facilitates a deeper understanding of the system’s layout, making it easier to locate and work with specific elements.

Maintenance Tips for John Deere 670

Regular upkeep is crucial for ensuring that your machinery operates smoothly over time. A consistent maintenance routine can prevent unexpected malfunctions and extend the life of your equipment. By paying attention to key components and regularly addressing potential wear and tear, you can maintain peak performance in various working conditions.

Check lubrication levels: Proper lubrication is essential to reduce friction and prevent damage to moving elements. Ensure that all necessary points are greased according to the manufacturer’s recommendations to keep everything running efficiently.

Inspect the hydraulic system: Over time, hydraulic systems can develop leaks or face pressure issues. Regularly inspect hoses and connections to identify any signs of leakage or wear, and replace faulty components to prevent larger system failures.

Monitor tire pressure: Keeping tires at the correct pressure not only improves fuel efficiency but also ensures better traction and stability during operation. Regularly check the air pressure and inflate or deflate as needed for optimal performance.

Finding Aftermarket Parts Options

When it comes to maintaining or upgrading agricultural machinery, exploring alternatives beyond original components can offer a cost-effective solution. Many manufacturers and suppliers provide a wide range of substitutes that are designed to fit various models, ensuring functionality and compatibility without breaking the budget.

- Check compatibility by cross-referencing specifications to ensure the right fit.

- Look for reviews from other users who have successfully implemented alternative solutions.

- Compare warranties and return policies to protect your purchase.

- Consider sourcing from certified distributors for better reliability.

By exploring these options, you can find reliable alternatives that meet your equipment needs and keep your machinery running efficiently.

Repairing vs. Replacing Components

When machinery begins to show signs of wear, the question often arises whether it is more beneficial to fix the existing parts or completely replace them. This decision can have a significant impact on both the longevity of the equipment and the overall costs involved.

Key Considerations for Repairs

Opting for repairs can be a more cost-effective solution, especially for minor issues that do not affect the overall functionality of the machine. Regular maintenance and swift response to small damages can prevent larger, more expensive problems from developing.

Benefits of Replacements

On the other hand, replacing components ensures that the machine continues to operate at peak efficiency. In cases where repairs may only provide a temporary fix, investing in new parts guarantees better performance and reduces the risk of further breakdowns.

Utilizing Online Resources for Parts

Finding the right components for your machinery can be a challenging task, especially when dealing with older or less common models. However, the internet offers a wealth of tools that make this process significantly easier. With a few clicks, you can explore various databases, manuals, and interactive diagrams that help identify and source the necessary items for repairs or upgrades.

Below are some ways you can make the most of digital platforms for your needs:

- Use specialized websites to locate specific components by entering your equipment model.

- Download manuals or service guides that provide detailed schematics and lists of individual parts.

- Access forums or community groups where experienced users offer insights and advice.

- Leverage search engines to find suppliers and pricing options quickly.

By utilizing these methods, you can streamline the search process and ensure that you have access to the best resources for maintaining or repairing your equipment.