Complete Guide to John Deere LA165 Parts Diagram

When it comes to maintaining outdoor machinery, having a clear understanding of its various elements is crucial. A well-structured overview of these components can significantly enhance your ability to troubleshoot and repair. Whether you’re a seasoned technician or a weekend warrior, familiarizing yourself with the layout and function of each piece can streamline your maintenance efforts.

Visual aids serve as an excellent resource for anyone looking to improve their knowledge of equipment intricacies. They allow users to quickly identify essential parts and understand their relationships within the overall system. This foundational knowledge not only aids in repairs but also helps in making informed decisions regarding replacements and upgrades.

Moreover, diving deep into the specifics of each component can reveal insights that transform your approach to machinery care. Emphasizing the ultimate goal of maximizing performance and longevity, a comprehensive guide can empower users to tackle challenges with confidence.

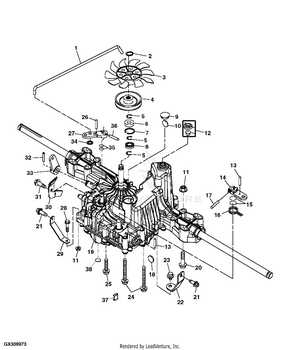

Understanding John Deere LA165 Components

Exploring the essential elements of lawn care machinery reveals a complex interplay of components that work harmoniously to ensure optimal performance. Each part plays a critical role in the overall functionality and efficiency of the equipment, making comprehension of these elements vital for effective maintenance and operation.

| Component | Function |

|---|---|

| Engine | Drives the machine, providing power for cutting and movement. |

| Deck | Houses the cutting blades and determines the mowing width. |

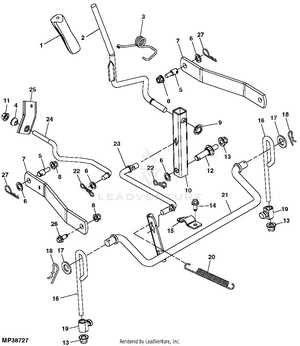

| Transmission | Transfers power from the engine to the wheels, enabling movement. |

| Blades | Cut the grass to the desired height, ensuring a neat finish. |

| Wheels | Support the machinery and facilitate movement across various terrains. |

Key Features of the LA165 Model

The model stands out in its category due to a combination of innovative technology and user-friendly design, making it an ideal choice for various lawn maintenance tasks. Below are the essential attributes that enhance its functionality and performance.

- Powerful Engine: Equipped with a robust engine, this model delivers reliable performance, ensuring effective grass cutting and overall efficiency.

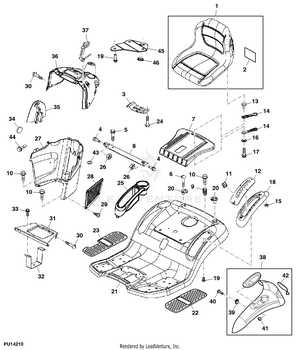

- Cutting Deck: The wide cutting deck allows for a more extensive mowing area, reducing the time needed to maintain your lawn.

- Adjustable Cutting Heights: Users can easily modify the cutting height to achieve the desired grass length, offering versatility for different lawn types.

- Comfortable Operator Experience: The ergonomic seat and intuitive controls enhance user comfort, making longer mowing sessions more manageable.

- Durable Build: Constructed with high-quality materials, this model ensures longevity and resilience against wear and tear.

These features collectively contribute to a seamless and efficient lawn care experience, making this model a popular choice among homeowners and landscape professionals alike.

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for effective maintenance and repair. Visual representations of these elements provide users with a clear overview, facilitating easier identification and understanding of each section. This clarity enhances efficiency and reduces the likelihood of errors during service tasks.

Enhanced Maintenance Efficiency

Utilizing visual aids streamlines the process of upkeep. Technicians can quickly locate necessary elements, allowing for faster repairs and less downtime. This ultimately leads to improved operational productivity.

Reducing Repair Errors

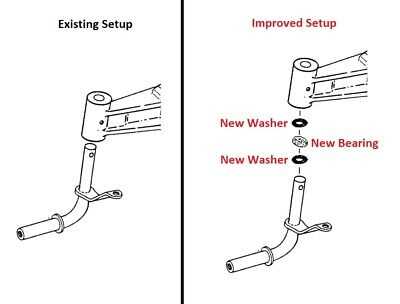

Clear illustrations minimize the chances of mistakes during reassembly or part replacement. By providing precise references, users can ensure that each component is correctly installed, thereby enhancing the longevity of the equipment.

| Benefit | Description |

|---|---|

| Time-saving | Accelerates identification of components. |

| Accuracy | Ensures correct assembly of machinery. |

| Informed Decisions | Aids in understanding the function of each part. |

Common Replacement Parts for LA165

Maintaining a lawn care machine is essential for ensuring its longevity and optimal performance. Various components may need to be replaced over time due to wear and tear or damage. Familiarizing yourself with the most commonly replaced items can help you keep your equipment in peak condition.

Blades: One of the most critical components, sharp and well-maintained cutting edges ensure a clean cut. Regularly replacing dull blades enhances efficiency and promotes healthier grass growth.

Batteries: A reliable power source is vital for starting the machine and operating various electrical features. Over time, batteries can lose their ability to hold a charge and may need to be replaced.

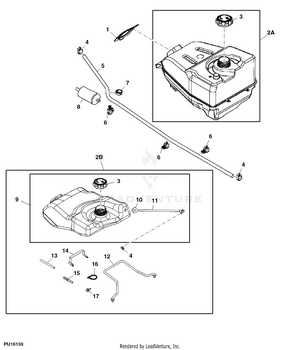

Filters: Air and fuel filters play a crucial role in maintaining engine performance. Clogged filters can restrict airflow and fuel flow, leading to reduced efficiency. Regular replacement is recommended to keep the engine running smoothly.

Belts: These components transfer power between the engine and the cutting deck. They can wear out or become damaged, affecting the machine’s ability to operate effectively. Inspecting and replacing belts as needed can prevent further complications.

Wheels: Ensuring that wheels are in good condition is essential for maneuverability and stability. If they become worn or damaged, replacing them can significantly improve the handling of the machine.

By staying informed about these vital components, you can proactively manage maintenance and extend the life of your lawn care equipment.

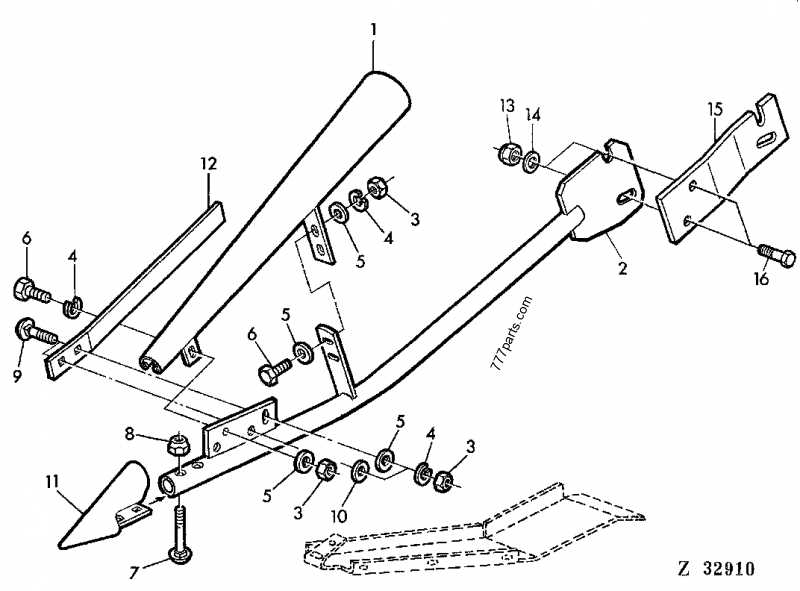

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repair tasks. These illustrations offer a detailed view of the elements involved, making it easier to identify and locate each piece within a system.

To effectively interpret these visual aids, consider the following steps:

- Familiarize Yourself with Symbols: Each representation uses specific icons to denote different types of components.

- Identify Sections: Break down the illustration into manageable segments to avoid feeling overwhelmed.

- Refer to the Legend: Most visuals include a legend explaining the symbols and their meanings.

- Use Reference Numbers: Cross-reference any numerical codes with a list of available components for precise identification.

- Check Orientation: Ensure you’re viewing the illustration from the correct perspective, as it may affect the arrangement of the parts.

By following these guidelines, you can delve into the details of any visual aid and ensure you have the ultimate understanding needed for your tasks.

Where to Find Authentic Parts

When it comes to maintaining machinery, sourcing genuine components is crucial for optimal performance and longevity. Reliable sources ensure that the replacements you acquire meet the required standards and specifications, providing peace of mind during operation.

Authorized Dealers are often the best starting point for acquiring authentic components. These vendors are typically recognized by manufacturers and offer a wide selection of original items that guarantee compatibility and quality.

Online Marketplaces can also be valuable resources. Reputable websites specializing in equipment offer extensive catalogs and user reviews, which can help you make informed decisions. Always verify the seller’s credibility to avoid counterfeit products.

Local Repair Shops are another excellent option. Many independent mechanics have access to genuine components and can provide valuable advice based on their expertise. Establishing a relationship with a local professional can also lead to better deals and personalized service.

Lastly, consider joining Online Forums or communities. Enthusiasts and professionals often share insights on where to find authentic items, including recommendations for trustworthy suppliers and specific online platforms.

Maintenance Tips for LA165 Owners

Proper upkeep is essential for ensuring longevity and optimal performance of your equipment. Regular maintenance not only prevents costly repairs but also enhances efficiency during operation. Here are some vital recommendations for owners to keep their machinery in top shape.

| Task | Frequency | Details |

|---|---|---|

| Check Oil Level | Every 10 hours | Ensure oil is at the correct level and change if needed. |

| Clean Air Filter | Every 25 hours | Inspect and clean to maintain airflow; replace if damaged. |

| Sharpen Blades | Every 25 hours | Keep blades sharp for efficient cutting; sharpen or replace as necessary. |

| Inspect Belts | Every 50 hours | Check for wear and tear; replace if frayed or cracked. |

| Battery Maintenance | Monthly | Check terminals for corrosion and ensure proper charge levels. |

By following these guidelines, you can effectively extend the lifespan of your equipment and ensure it operates at its ultimate capacity.

Benefits of Using Genuine Parts

Utilizing authentic components in machinery maintenance ensures optimal performance and longevity. These original elements are specifically designed to fit and function seamlessly, enhancing the overall efficiency of your equipment.

Quality Assurance

One of the primary advantages of employing original components is the assurance of quality. These items undergo rigorous testing and meet strict industry standards, which translates to:

- Enhanced durability

- Improved reliability

- Lower risk of malfunction

Optimal Performance

Genuine components are engineered to work perfectly with your machinery. This compatibility results in:

- Smoother operation

- Better fuel efficiency

- Increased productivity

In summary, choosing original components not only protects your investment but also maximizes the efficiency and lifespan of your machinery.

Identifying Compatible Accessories

Understanding how to choose the right components for your equipment can enhance performance and longevity. By recognizing key attributes and specifications, users can ensure optimal functionality and compatibility with existing systems.

Key Considerations

When selecting additional items, it’s vital to assess factors such as size, material, and design. Matching these characteristics with the equipment’s requirements will lead to more effective integration and utilization.

Finding Reliable Sources

Always refer to reputable suppliers or manufacturers to obtain authentic and compatible items. Online platforms often provide detailed information, including user reviews and compatibility guides.

| Accessory Type | Key Features | Compatibility Notes |

|---|---|---|

| Blades | Durability, sharpness | Check size and fitting |

| Batteries | Voltage, capacity | Ensure proper voltage rating |

| Tires | Tread design, size | Verify specifications for optimal grip |

DIY Repairs: A Practical Guide

Engaging in do-it-yourself repairs can be a rewarding experience that enhances your skills and saves money. This guide aims to empower individuals to tackle various maintenance tasks effectively, ensuring that equipment remains in optimal condition. By understanding the fundamentals and using the right resources, anyone can confidently address common issues.

Essential Tools and Supplies

Before starting any repair, it’s crucial to gather the necessary tools and materials. A well-equipped toolkit often includes wrenches, screwdrivers, pliers, and safety gear. Additionally, having a stock of replacement components on hand can significantly streamline the process, allowing for quicker fixes and less downtime.

Step-by-Step Approach

Taking a methodical approach is key to successful repairs. Begin by diagnosing the problem accurately, followed by consulting reliable resources for guidance. Break down the repair into manageable steps, documenting your progress. This systematic method not only enhances efficiency but also builds confidence for future projects.

Resources for Troubleshooting Issues

When facing difficulties with machinery, having access to reliable information can significantly enhance the repair process. Utilizing various tools and resources helps users identify problems, understand component functions, and find effective solutions. Here are some recommended materials that can aid in diagnosing and resolving issues efficiently.

| Resource Type | Description | Link/Source |

|---|---|---|

| User Manuals | Comprehensive guides that provide detailed instructions and specifications. | Visit Manuals |

| Online Forums | Community-driven platforms where users share experiences and solutions. | Join Forums |

| Video Tutorials | Visual guides that demonstrate troubleshooting and repair techniques. | Watch Videos |

| Technical Support | Professional assistance from experts in the field for complex issues. | Contact Support |

Utilizing these resources can empower users to tackle challenges more effectively, ensuring the machinery operates smoothly and reliably.