Comprehensive Guide to Case 580K Parts Diagram

In the realm of construction and agriculture, the intricacies of heavy equipment play a crucial role in ensuring efficiency and productivity. A thorough understanding of these complex machines is essential for operators and technicians alike. Familiarity with the various elements that make up this machinery not only enhances operational skills but also aids in troubleshooting and maintenance.

Every piece of equipment consists of numerous interconnected parts, each serving a specific function. By examining the arrangement and relationships among these components, one can gain valuable insights into the overall operation and performance of the machine. This exploration enables users to identify potential issues and streamline repair processes.

Visual representations of these assemblies offer a clear perspective on how each segment contributes to the overall functionality. Such illustrations are indispensable for training and reference, making it easier for professionals to navigate the complexities of mechanical systems. Understanding these illustrations is key to mastering the effective use of heavy machinery in various applications.

Understanding Case 580K Components

This section aims to explore the essential elements that comprise a specific type of heavy machinery, enhancing your comprehension of its functionality and maintenance. Grasping the intricate relationships between these components can significantly improve operational efficiency and troubleshooting skills.

Fundamental parts of this equipment include the engine, hydraulic system, and transmission. Each of these plays a critical role in the overall performance, contributing to tasks such as lifting, digging, and moving materials. By delving into their functions, one can appreciate how they work together to achieve ultimate effectiveness.

Moreover, understanding the accessory systems, such as the electrical and cooling systems, is vital. These components support the primary mechanisms, ensuring they operate smoothly and reliably under various conditions. A thorough knowledge of these elements empowers operators and technicians to address potential issues proactively.

Overview of Case 580K Diagram

This section presents a comprehensive look at the structural representation of a popular construction machine. Understanding this visual guide is essential for effective maintenance and repair, ensuring optimal performance and longevity of the equipment.

| Component | Description |

|---|---|

| Engine | The power source that drives the entire system. |

| Transmission | Facilitates the transfer of power from the engine to the wheels. |

| Hydraulic System | Enables the operation of various attachments and functions. |

| Chassis | The framework that supports all components and provides stability. |

| Controls | Interface for the operator to manage the machine’s functions. |

Key Parts and Their Functions

This section provides an overview of essential components in heavy machinery and their specific roles in ensuring optimal performance. Understanding these elements is crucial for effective maintenance and operation.

-

Engine:

The heart of the machine, responsible for converting fuel into mechanical energy, driving the entire system.

-

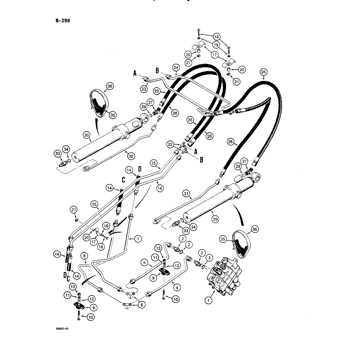

Hydraulic System:

This system powers various functions by using pressurized fluid to transmit force, enabling lifting and digging capabilities.

-

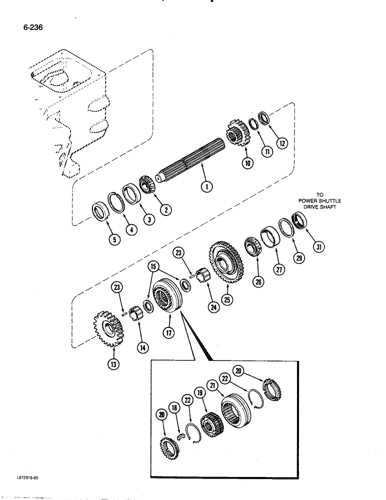

Transmission:

Facilitates the transfer of power from the engine to the wheels or tracks, allowing for speed and torque adjustments.

-

Chassis:

The structural framework that supports all components and provides stability during operation.

-

Control System:

Comprises the levers and electronic systems that allow the operator to maneuver and manage the equipment’s functions effectively.

Familiarity with these critical elements can enhance understanding of machinery functionality and assist in troubleshooting issues as they arise.

Importance of Accurate Diagrams

Accurate visual representations are crucial in various fields, serving as essential tools for understanding complex systems. These illustrations provide clarity, ensuring that users can easily interpret and navigate intricate information. Without precise visuals, misunderstandings and errors are more likely to occur, potentially leading to inefficiencies and costly mistakes.

Key reasons for the significance of precise illustrations include:

- Enhanced Communication: Clear visuals facilitate better communication among team members, reducing the risk of misinterpretation.

- Improved Maintenance: Detailed illustrations allow technicians to identify components quickly, streamlining repair and maintenance processes.

- Training Efficiency: Accurate visuals are invaluable in training scenarios, helping new users grasp concepts more rapidly.

- Documentation Standards: Well-crafted representations serve as reliable documentation, aiding in compliance and quality assurance.

- Time Savings: Efficiently designed visuals help users locate information faster, saving valuable time in operational settings.

Ultimately, investing in high-quality illustrations not only enhances understanding but also fosters a more effective and efficient working environment.

Common Issues with Component Identification

Understanding the different elements of machinery is crucial for maintaining optimal performance. However, pinpointing the exact location or function of specific elements can sometimes present challenges. This section explores frequent obstacles encountered when attempting to recognize or distinguish various segments and their roles.

Confusing Labels and Markings

One common hurdle is dealing with unclear or inconsistent labels. Over time, markings on certain elements can fade or become obscured due to wear, making it difficult to discern their precise function. Additionally, some older models may have different labeling conventions, adding to the confusion for those unfamiliar with them. Proper documentation is essential, but often hard to come by.

Similarity Between Parts

Another issue arises when multiple segments appear visually similar but serve different purposes. Identifying these components correctly is important to prevent mismatches during repairs or replacements. Without a detailed guide, this can lead to errors in maintenance, which may cause further operational problems. Comparing specifications and using reference materials can help mitigate such risks.

Tools for Viewing Diagrams

Understanding intricate mechanical layouts requires specific software that can handle technical visuals with clarity. These resources make it possible to explore detailed illustrations, providing a clear view of every element and connection. Below is a selection of tools that are essential for accessing and analyzing such visuals.

- PDF Readers: Many technical layouts are available in PDF format, making software like Adobe Acrobat or Foxit Reader a popular choice. These programs offer zooming and annotation features, allowing for detailed examination of every component.

- CAD Software: For those requiring more interactivity, computer-aided design programs such as AutoCAD or FreeCAD provide the ability to manipulate and view three-dimensional illustrations. This is particularly useful for understanding spatial arrangements.

- Online Viewers: Various online platforms enable access to visuals directly through a web browser. Websites that support SVG and DXF file formats are convenient for users who need quick access without software installation.

- Mobile Applications: For on-the-go access, apps available on smartphones and tablets can be useful. They allow users to view and reference complex illustrations directly from a mobile device, making it easier to consult visual information in various settings.

Choosing the right tool depends on the format of the visual and the level of detail required for analysis. Each option has its strengths, ensuring a tailored approach to accessing technical information.

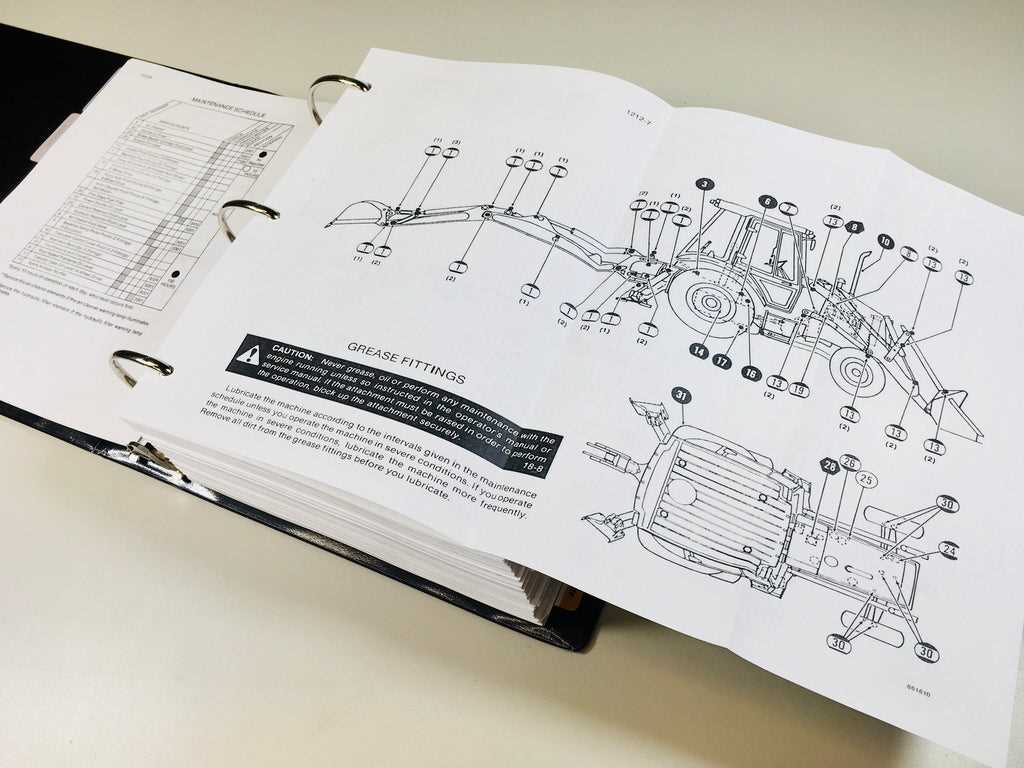

Maintenance Tips for Case 580K

Proper upkeep is crucial for ensuring the longevity and efficiency of this versatile machine. Regular attention to key components and adherence to a structured maintenance schedule can prevent unexpected breakdowns and extend its operational life. Below are some essential suggestions and steps to keep the machinery in optimal condition.

Engine and Hydraulic System Care

Routine checks of the engine, along with timely oil changes, play a pivotal role in maintaining performance. It’s important to inspect the fluid levels, including hydraulic oil, and to monitor for any leaks or unusual noises during operation. Keeping the cooling system clean prevents overheating, which can lead to serious mechanical issues.

| Task | Frequency | Details |

|---|---|---|

| Oil Replacement | Every 250 hours | Use high-quality lubricants suitable for heavy-duty engines to ensure smooth operation. |

| Hydraulic Filter Change | Every 500 hours | Replace filters to maintain optimal fluid flow and prevent contaminants from damaging the system. |

| Coolant Inspection | Monthly | Check levels and ensure the coolant is clean to avoid overheating and corrosion inside the system. |

Tire and Brake Maintenance

Ensuring that the tires are properly inflated and free of wear can improve traction and safety during use. The braking mechanism should also be checked regularly for responsiveness and any signs of wear. Properly functioning brakes are essential for safe operation, especially when working on uneven or rough terrain.

Replacing Worn-Out Parts Effectively

Maintaining the longevity of heavy-duty equipment involves timely upgrades and renewals of components that show signs of aging. Identifying the right moment for replacement can prevent further damage and ensure the machinery functions optimally. Understanding how to tackle this process can save both time and expenses while enhancing overall reliability.

Recognizing Signs of Wear

To ensure effective restoration, it’s essential to observe indicators like unusual noises, decreased efficiency, or visible damage. These warning signs often signal the need for renewal, helping to avoid unexpected failures during operation. A consistent inspection routine can highlight issues before they escalate into more significant problems.

Choosing Compatible Replacements

When selecting new components, ensuring compatibility is crucial for maintaining original functionality. Using properly matched parts not only simplifies the installation process but also ensures a seamless integration with existing systems. Prioritizing high-quality materials during replacements contributes to the durability and performance of the machine.

Where to Find Original Diagrams

For those looking to locate authentic visual guides for their machinery, understanding the best sources can make a significant difference. These resources often include detailed illustrations that help identify various components and their connections, allowing for easier maintenance and repair.

Online Resources and Digital Libraries

Many online platforms host collections of technical illustrations, often shared by enthusiasts or authorized distributors. These platforms can be a great starting point for anyone seeking a clear visual reference, especially for older models. Some websites offer downloadable files or online viewing options, providing easy access to essential details.

Manufacturer Websites and Authorized Dealers

Reaching out to the producer’s official website or approved resellers can provide access to high-quality technical visuals. These sources typically offer the most accurate and up-to-date information, ensuring that all references match the exact specifications needed for repairs or upgrades. Many also have customer support services to help guide users in finding the right materials.

Using Diagrams for Repairs

Visual guides play a crucial role in the maintenance process, offering a clear representation of different components and their connections. By relying on these illustrations, individuals can pinpoint issues more accurately, reducing the time and effort required for troubleshooting. Such references allow for a better understanding of how each element interacts within the overall structure.

Efficiency in Troubleshooting can be significantly enhanced by consulting these visuals. They serve as a roadmap, making it easier to identify faulty sections or disconnected elements. This approach minimizes guesswork, allowing for targeted actions during repairs.

Understanding Component Interactions through these resources helps ensure that each element is reassembled correctly after maintenance. It aids in avoiding errors that could lead to further complications, making them invaluable for both novices and experienced technicians.

Expert Recommendations for Parts Upgrades

Enhancing the performance and reliability of heavy-duty equipment often involves choosing the right enhancements. Understanding which components to upgrade can lead to increased efficiency and longer service life. Below are some key suggestions to ensure optimal improvements.

- Engine Efficiency Enhancements: Consider high-quality filters and injectors that offer improved fuel delivery. These updates can contribute to smoother operations and reduced fuel consumption, especially in demanding conditions.

- Hydraulic System Optimization: Upgrading to more durable seals and hoses can prevent leaks and ensure consistent pressure. Select models that match the original specifications to maintain compatibility and ease of installation.

- Transmission and Drive Improvements: For better power distribution and reduced wear, opt for modern clutch assemblies and gear systems. Newer designs can extend operational lifespan and minimize maintenance needs.

- Cab Comfort and Control Features: Installing updated control panels and ergonomic seating can significantly enhance operator comfort. These changes reduce fatigue during long work hours, improving productivity.

- Electrical System Upgrades: Consider replacing outdated wiring and switches with more efficient options. Advanced alternators and batteries ensure stable performance and reduce downtime due to electrical issues.

These recommendations focus on achieving a balance between performance improvements and cost-effectiveness, ensuring the equipment remains reliable in varied operational environments.