Comprehensive Guide to Ryobi Electric Lawn Mower Parts Diagram

When maintaining your outdoor space, having a clear understanding of the assembly and components of your gardening tools can significantly enhance efficiency and performance. This section delves into the intricate layout of a popular type of gardening machine, providing insight into its various elements and how they work in harmony to ensure effective operation.

Comprehending the configuration of these essential implements not only aids in troubleshooting common issues but also facilitates informed decisions regarding maintenance and upgrades. By exploring the intricate relationships between each component, users can gain valuable knowledge that empowers them to optimize their gardening tasks.

Moreover, familiarity with the structural design can help users identify compatible accessories and replacements, ultimately prolonging the lifespan of the equipment. As we navigate through the details, you’ll discover practical tips and detailed visuals that illustrate the core components, ensuring you’re well-equipped for your gardening endeavors.

Understanding Ryobi Electric Lawn Mowers

When it comes to maintaining a vibrant outdoor space, having the right tools is essential. This section explores the key components and mechanisms behind these innovative cutting devices, providing insight into their functionality and efficiency. By understanding how these machines operate, users can make informed decisions for optimal maintenance and performance.

Key Features

- Environmentally friendly operation

- Low noise levels for a peaceful experience

- Lightweight design for easy maneuverability

- Adjustable cutting heights for versatility

Maintenance Tips

- Regularly check and clean the blades for optimal performance.

- Inspect battery health to ensure efficient energy use.

- Store in a dry location to prolong lifespan.

- Follow the manufacturer’s guidelines for upkeep.

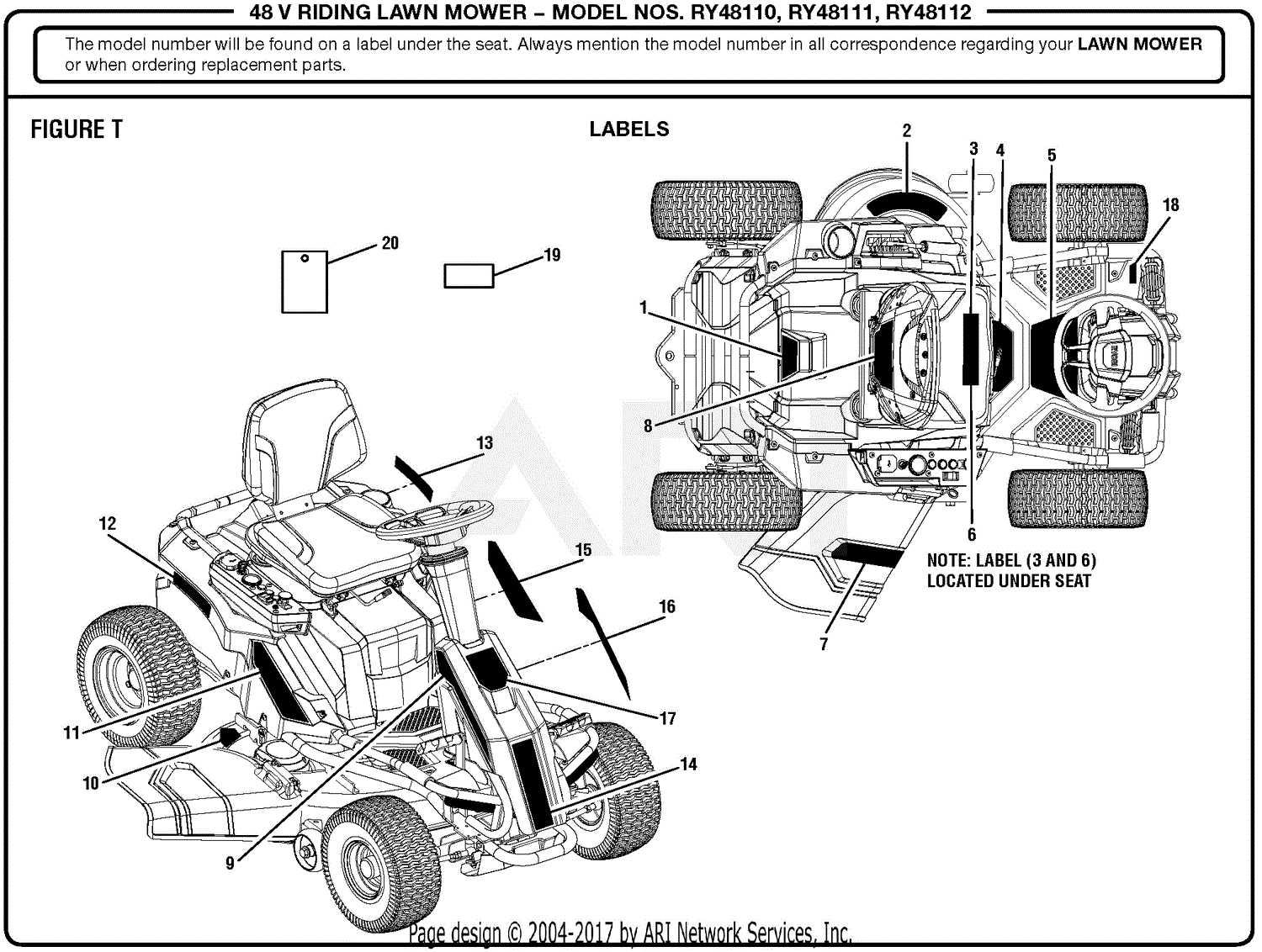

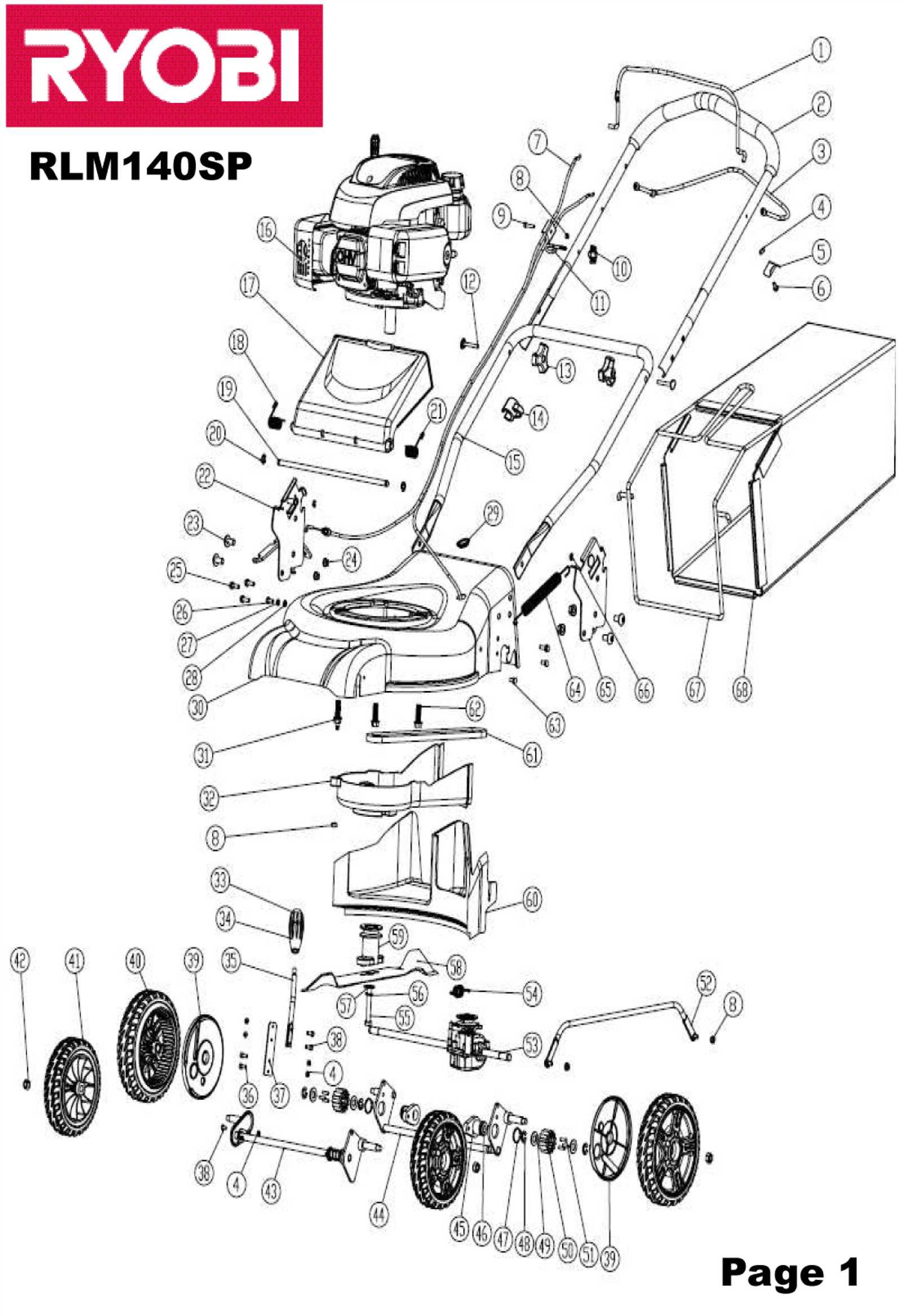

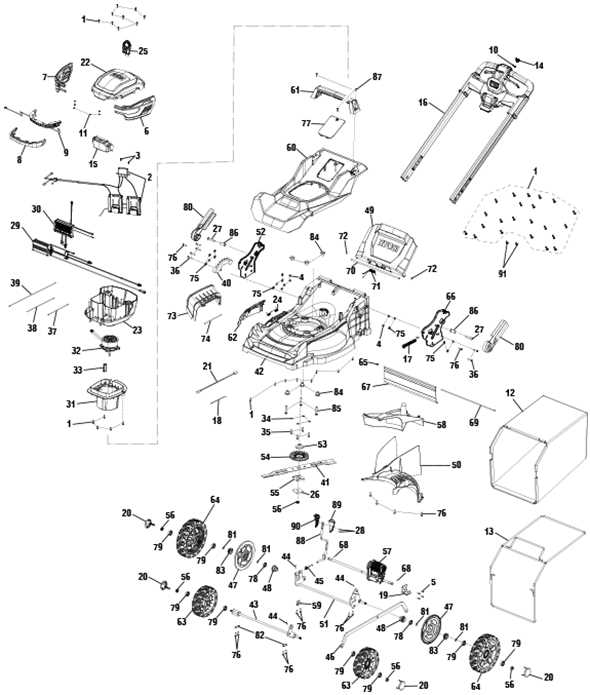

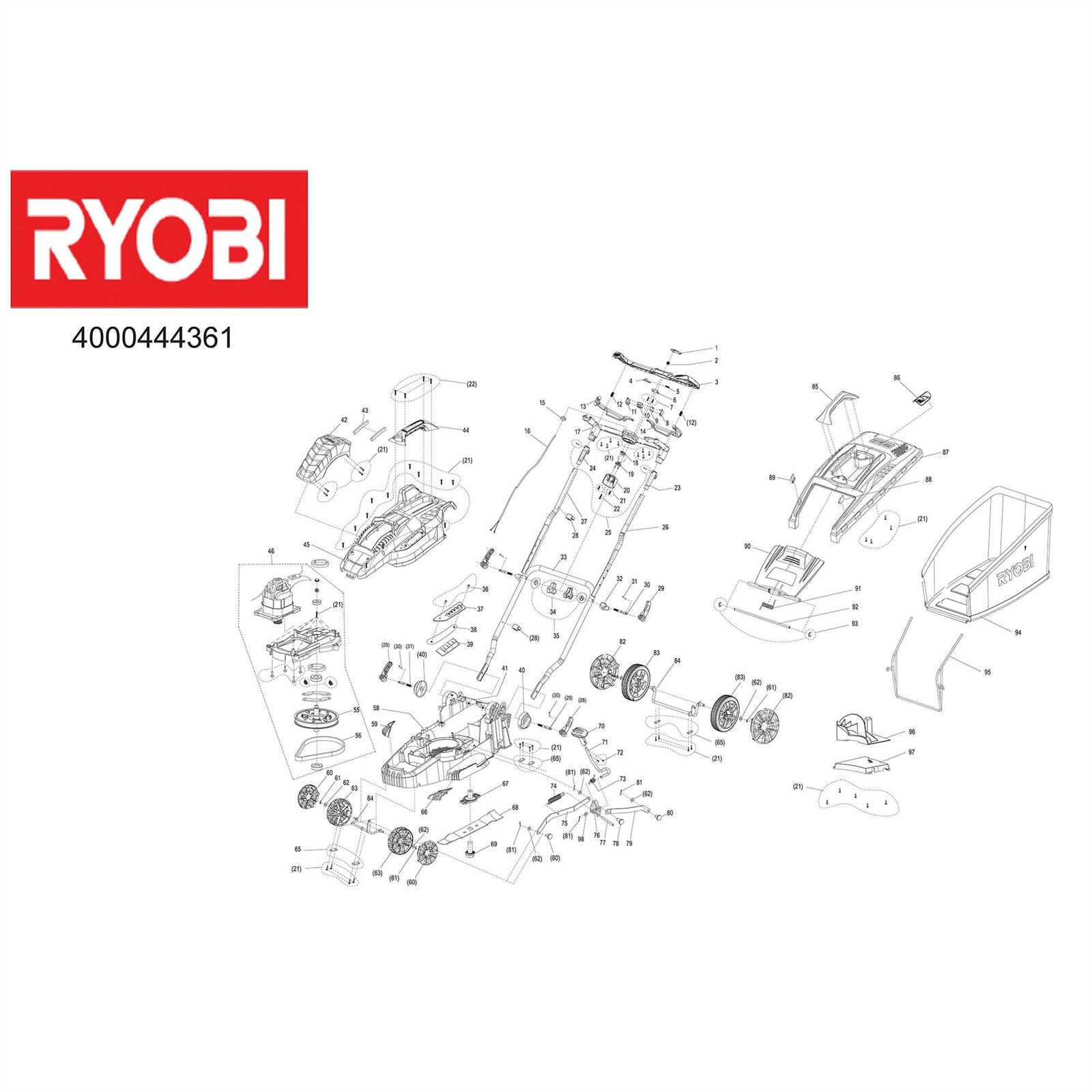

Common Parts of Ryobi Mowers

Understanding the essential components of gardening tools is crucial for maintenance and optimal performance. Each element plays a significant role in ensuring efficient operation and longevity of the equipment.

Blades are perhaps the most vital feature, as they directly impact the cutting efficiency. Sharp and well-maintained edges guarantee a clean and precise trim.

Battery units provide the necessary power, making it essential to select high-quality options for prolonged usage. A reliable energy source ensures that the device operates smoothly without interruptions.

Chassis forms the foundational structure, offering stability and support. A durable framework can withstand various environmental conditions while ensuring user safety.

Handles are designed for comfort and control, allowing for easy maneuverability. Ergonomically designed grips enhance user experience during extended periods of operation.

Wheels facilitate movement across different terrains. The size and material of these components affect the agility and overall ease of use.

Being familiar with these fundamental elements helps users make informed decisions regarding maintenance, replacement, and upgrades, ultimately enhancing the gardening experience.

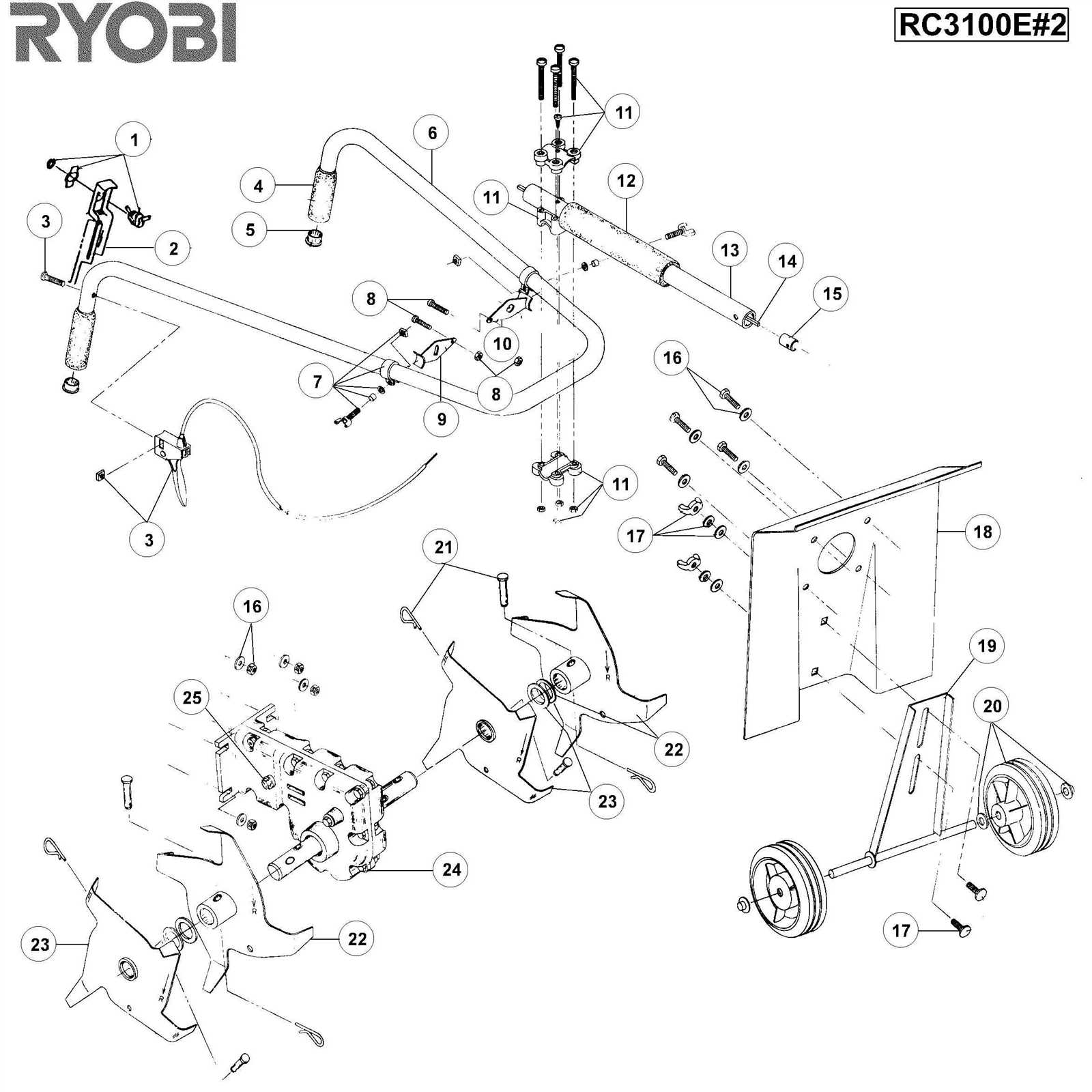

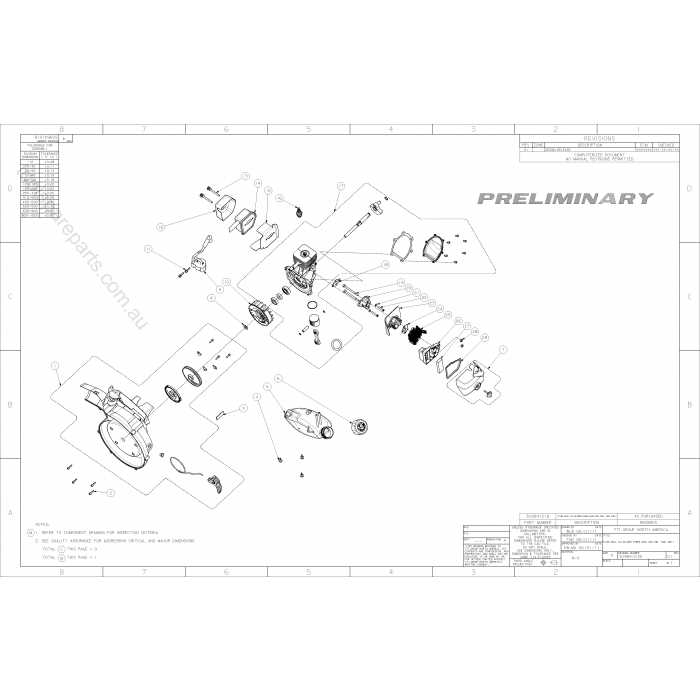

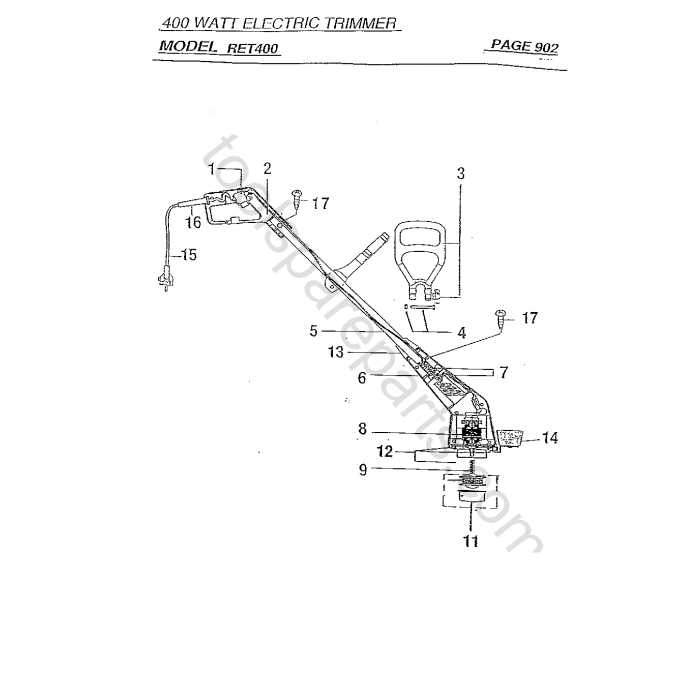

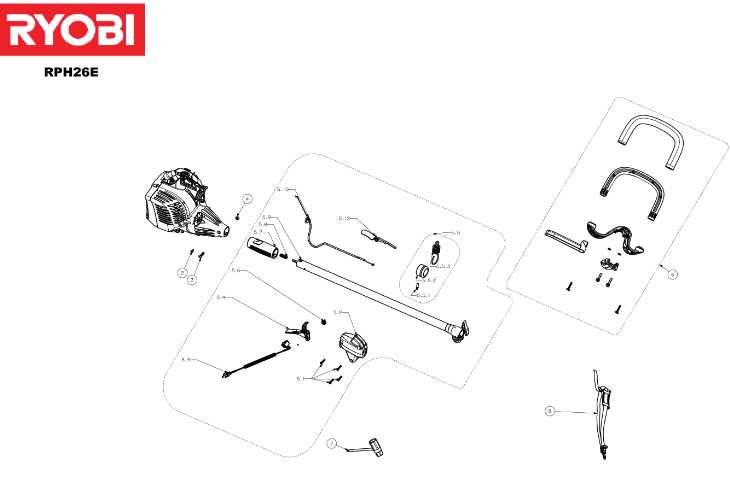

Importance of a Parts Diagram

A detailed schematic serves as an invaluable resource for anyone engaged in maintenance or repair tasks. It provides a visual representation of the components involved, facilitating a clearer understanding of how each element interacts within the overall system. This clarity can significantly reduce confusion during the assembly or disassembly process.

Moreover, such illustrations enhance the efficiency of troubleshooting. By identifying specific sections and components, users can quickly pinpoint issues and determine the necessary steps to rectify them. This not only saves time but also minimizes the risk of damage that may occur from improper handling.

In addition, having access to a clear layout encourages proper reassembly and can ensure that all parts are correctly placed, leading to optimal performance. Overall, this resource is essential for achieving both effective repairs and maintenance, ensuring longevity and reliability of the equipment.

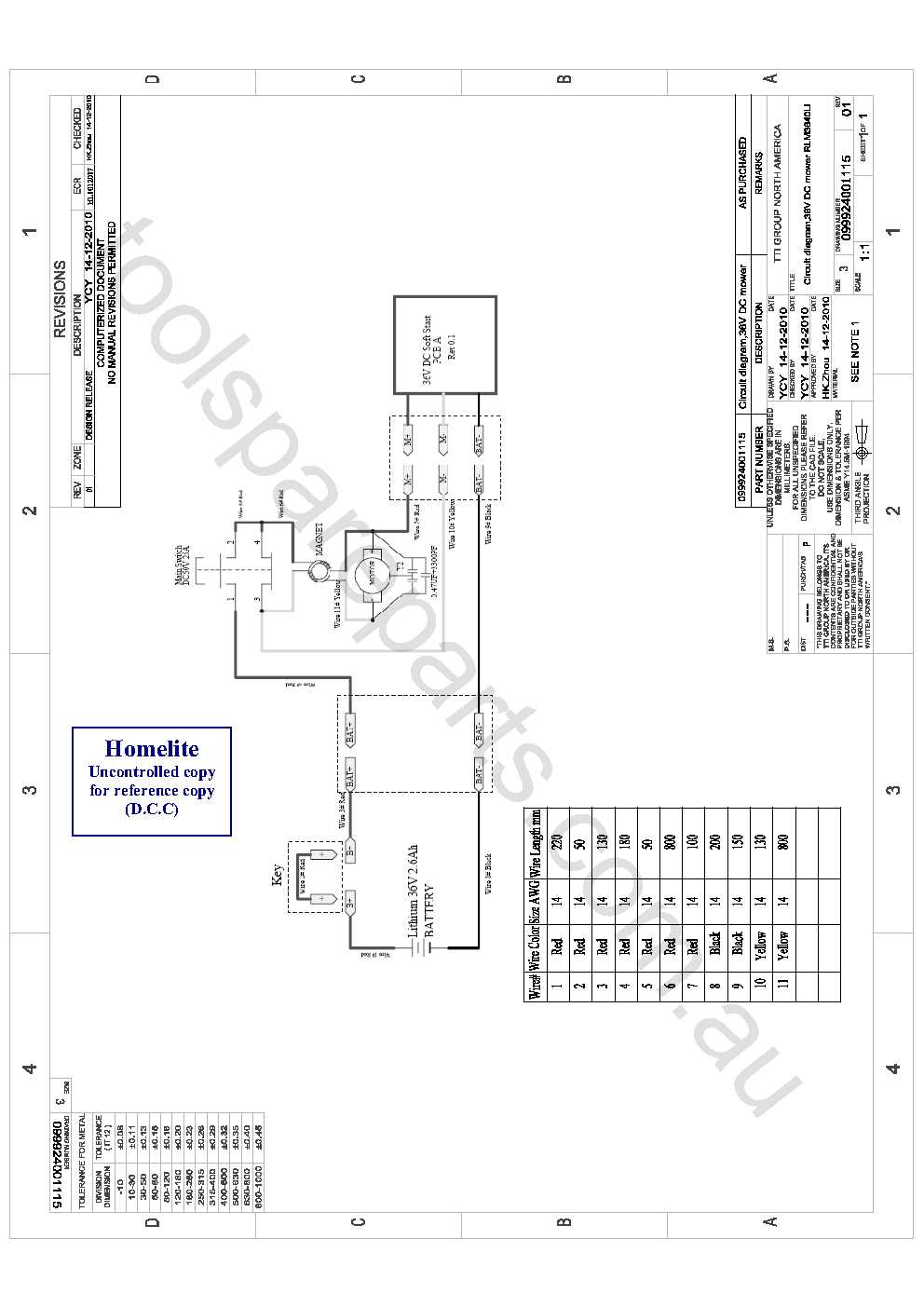

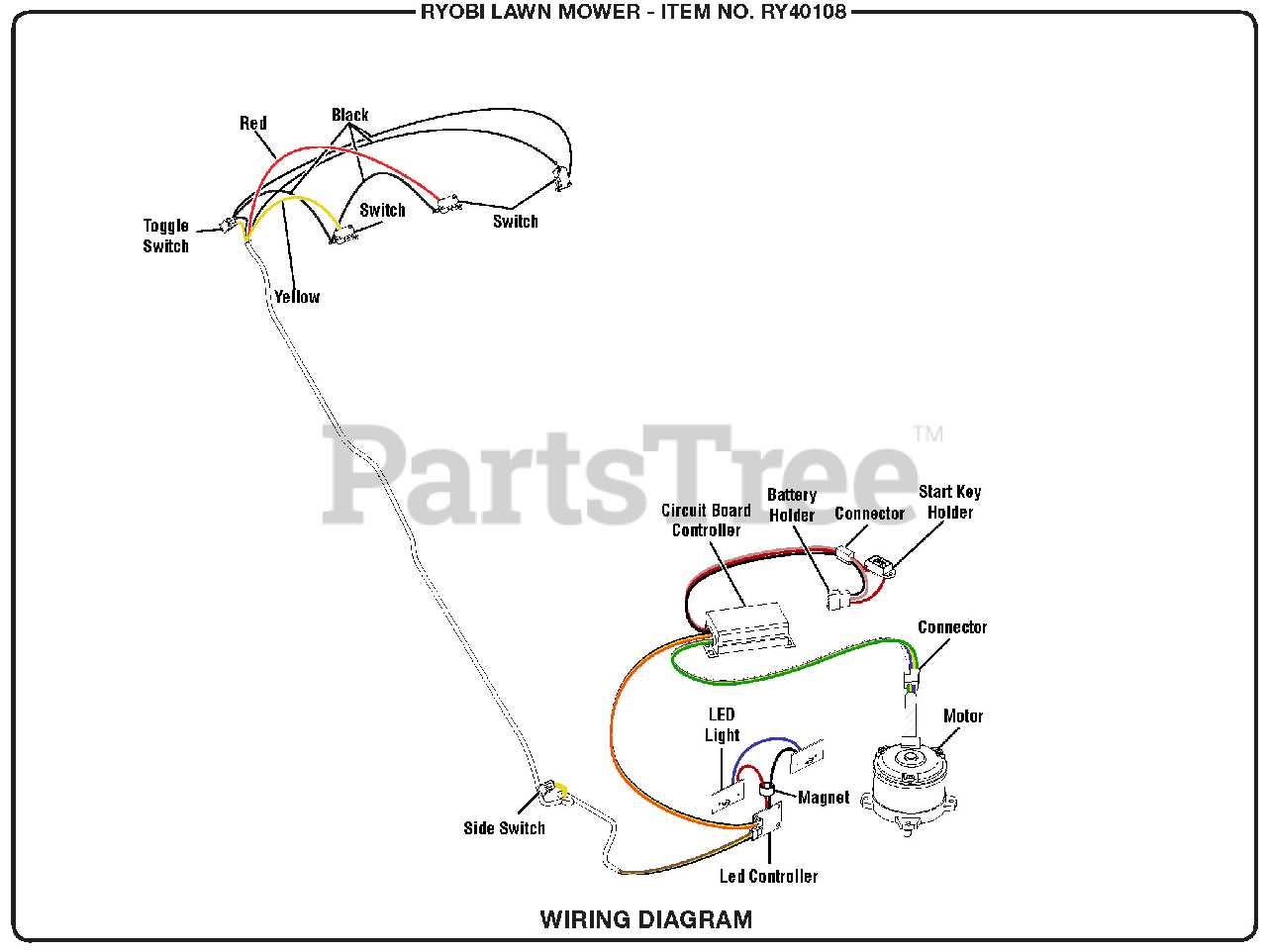

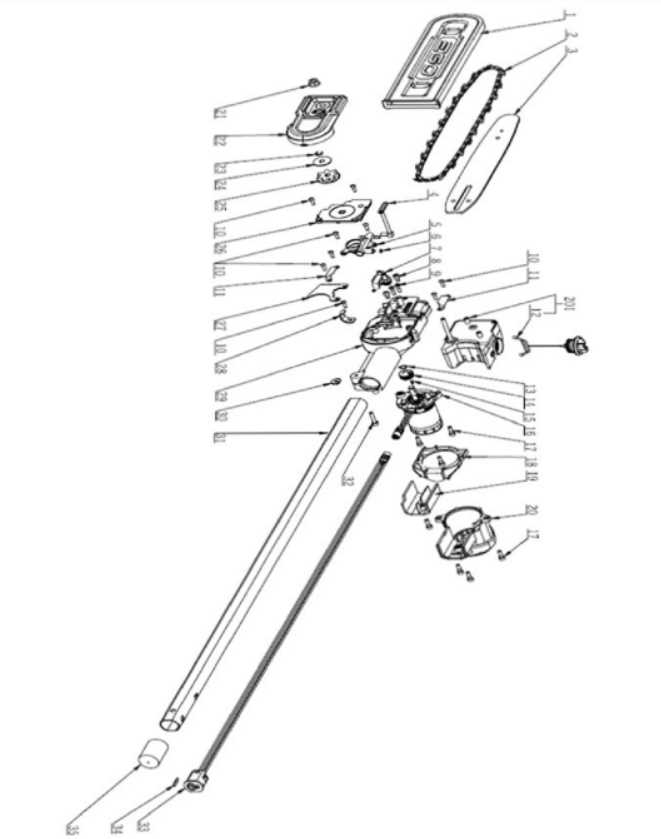

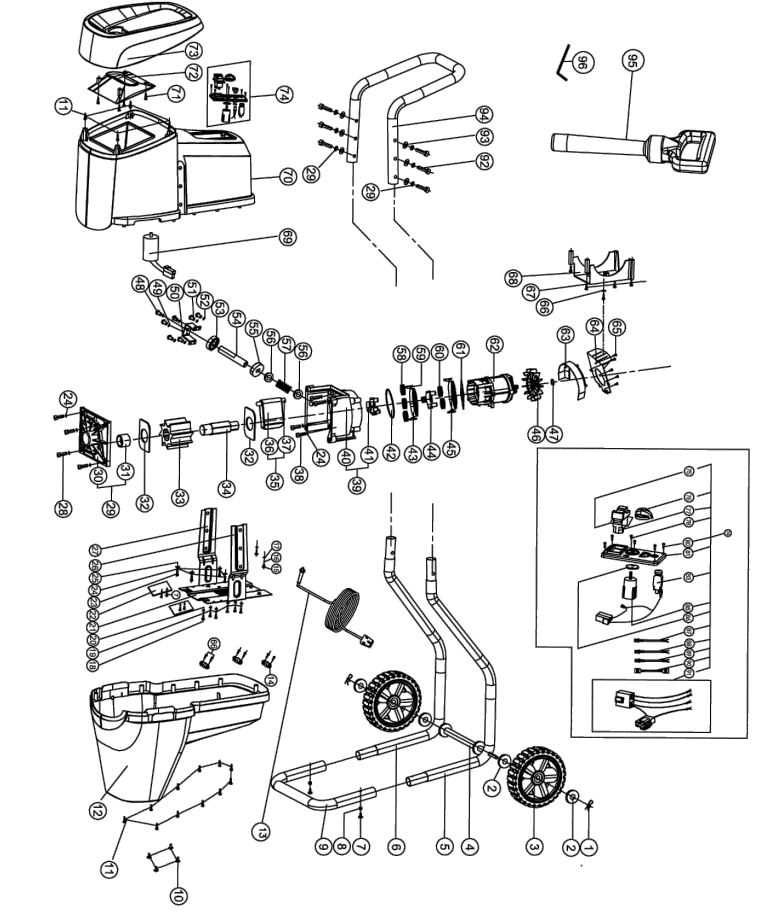

How to Read the Diagram

Understanding a schematic can greatly enhance your ability to identify and replace components within your equipment. These visual representations serve as a roadmap, guiding you through the various elements and their interconnections. By mastering the key symbols and layouts, you can efficiently navigate the complexities of your device.

1. Familiarize Yourself with Symbols: Each element on the schematic is represented by a specific symbol. Take time to learn what these symbols signify. Common shapes often denote different types of components, such as motors, batteries, or switches.

2. Follow the Connections: Lines connecting the symbols indicate how components interact. Understanding the flow of energy or information through these lines is crucial. Pay attention to the paths, as they reveal how each part operates within the system.

3. Identify Key Sections: Schematics are typically divided into sections, each representing a functional area. Recognizing these sections will help you locate the parts relevant to your repair or maintenance tasks.

4. Refer to the Legend: Most diagrams include a legend that explains the symbols and designations used. Always refer to this legend for clarification, especially when you encounter unfamiliar symbols.

5. Take Notes: As you analyze the schematic, jot down any observations or questions. This practice will reinforce your understanding and prepare you for any troubleshooting or component replacement.

By following these steps, you can confidently interpret a schematic, ensuring that your repair or maintenance efforts are both effective and efficient.

Replacing Blades and Other Components

Maintaining optimal performance of your outdoor cutting tool involves periodic replacement of essential elements. Regularly updating these components ensures efficiency and enhances the lifespan of the equipment.

Before starting any replacements, ensure the device is turned off and disconnected from the power source. Gather the necessary tools, and follow safety precautions to prevent accidents.

| Component | Replacement Frequency | Tools Required |

|---|---|---|

| Blades | Every 20-30 hours of use | Socket wrench, screwdriver |

| Battery | Every 2-3 years | Screwdriver |

| Deck | Inspect annually | Wrench set |

| Wheels | As needed | Wrench set |

Consult your user manual for specific guidance on replacing components, as each model may have unique requirements. Regular maintenance not only improves functionality but also promotes a healthy cutting experience.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires consistent care and attention. Implementing a routine maintenance schedule not only enhances performance but also minimizes the likelihood of unexpected failures.

Regular Cleaning

Keeping the exterior and internal components free from debris is essential. Regularly remove grass clippings and dirt to prevent buildup, which can hinder functionality.

Periodic Checks

Conducting inspections of essential components helps identify wear and tear early. Look for signs of damage and replace any worn parts promptly to maintain optimal performance.

| Task | Frequency |

|---|---|

| Clean exterior | After each use |

| Inspect blades | Monthly |

| Check battery | Every season |

| Sharpen blades | Every 10 uses |

Identifying Faulty Parts Easily

Recognizing malfunctioning components in your gardening equipment can save time and enhance performance. Understanding the common signs of wear or failure is essential for effective maintenance and prolonging the lifespan of your tools.

Common Indicators of Defects

- Unusual Noises: Listen for grinding, squeaking, or rattling sounds that indicate internal issues.

- Decreased Efficiency: Noticeable drops in performance, such as slower operation or uneven cutting, can suggest a problem.

- Visual Inspection: Look for cracks, wear, or damage on external components that could impair functionality.

Steps to Diagnose Issues

- Start with a thorough visual check of all accessible areas.

- Test the functionality of each mechanism separately to isolate the fault.

- Refer to the user manual for troubleshooting guidance specific to your model.

By systematically evaluating these factors, you can efficiently pinpoint issues and ensure your equipment operates at its best.

Where to Purchase Replacement Parts

Finding the right components for your equipment is essential for maintaining its performance and longevity. Whether you need to replace a worn-out item or upgrade to a newer version, knowing where to source these essentials can save you time and effort. There are several reliable options available that cater to different needs and preferences.

Authorized Retailers

Visiting authorized sellers ensures that you receive genuine components specifically designed for your device. These outlets often have knowledgeable staff who can assist you in selecting the right items. Additionally, they may offer warranties and guarantees on their products, providing extra peace of mind with your purchase.

Online Marketplaces

Many online platforms offer a wide selection of components at competitive prices. Shopping online allows for easy comparison of options and the convenience of home delivery. Ensure that you check the reviews and ratings of sellers to guarantee a positive shopping experience. Popular websites often feature user-friendly interfaces to help you quickly locate the required items.

Benefits of Genuine Ryobi Parts

Using authentic components for your outdoor equipment is essential for maintaining performance and longevity. These original elements are designed to fit perfectly and operate seamlessly, ensuring that your machinery functions as intended. By opting for genuine replacements, you can enhance reliability and efficiency while minimizing the risk of complications that may arise from inferior alternatives.

Quality and Durability

Authentic components are manufactured to the highest standards, guaranteeing durability and consistent performance. This quality assurance means that you can trust these parts to withstand the rigors of regular use, resulting in fewer repairs and extended lifespan for your equipment.

Optimal Performance

Original elements are engineered to work harmoniously with the existing systems of your machinery. This compatibility leads to improved efficiency, allowing your equipment to operate at its best. Choosing genuine replacements ensures that you maintain optimal functionality and achieve the desired results every time.

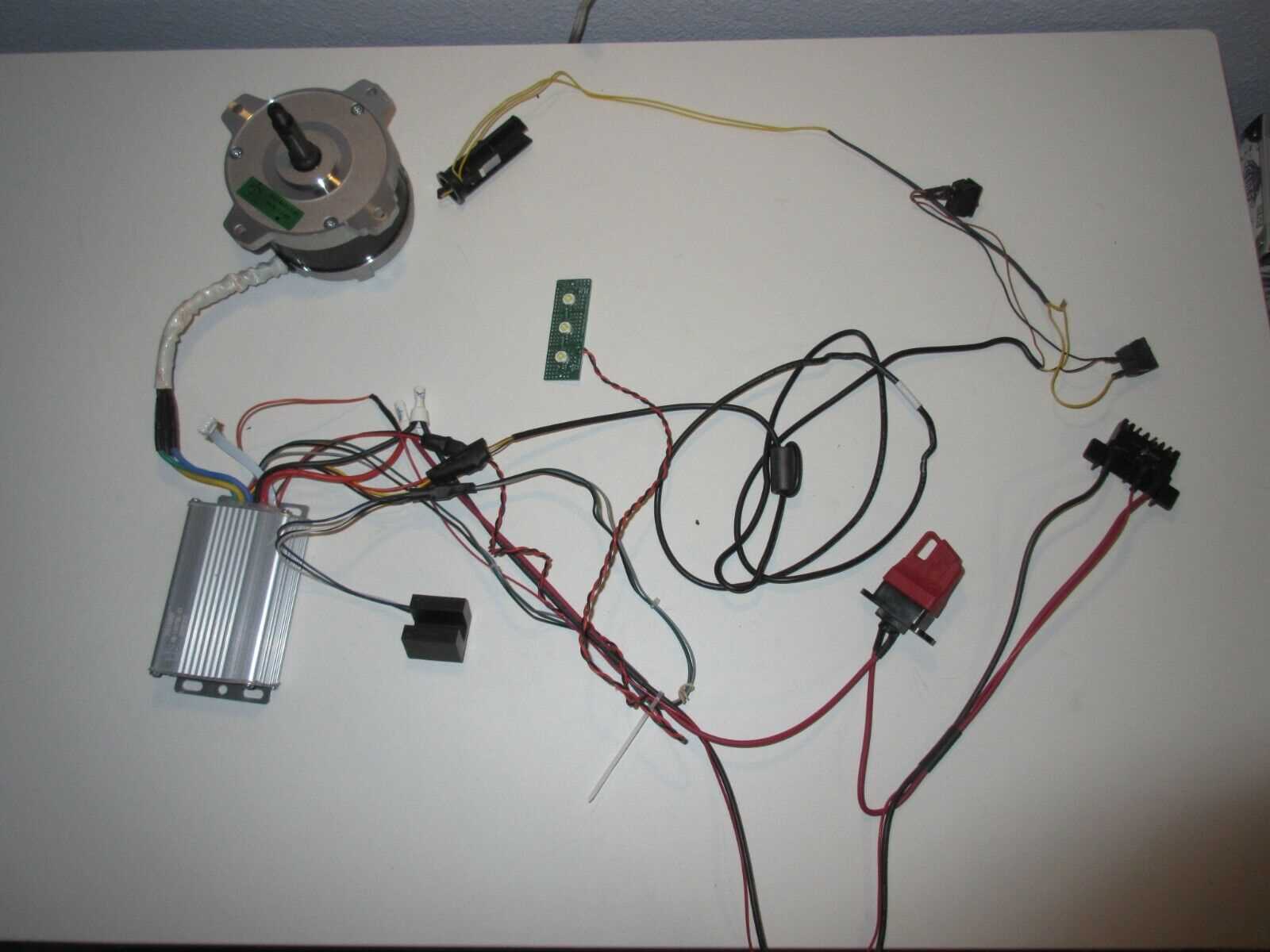

Tools Needed for DIY Repairs

When undertaking maintenance tasks on outdoor equipment, having the right tools is essential for effective and safe repairs. A well-equipped toolkit not only simplifies the process but also ensures that you can address various issues that may arise. Below is a list of necessary tools that will help you successfully complete your DIY projects.

| Tool | Description |

|---|---|

| Screwdriver Set | Essential for loosening and tightening screws of various sizes. |

| Wrench Set | Useful for gripping and turning nuts and bolts securely. |

| Socket Set | Facilitates quick removal and installation of fasteners. |

| Pliers | Great for holding, twisting, or cutting wires and small components. |

| Multimeter | Helps in diagnosing electrical issues and measuring voltage and resistance. |

| Torque Wrench | Ensures that nuts and bolts are tightened to the correct specifications. |

| Safety Gear | Includes gloves and goggles to protect yourself during repairs. |

Equipping yourself with these tools will greatly enhance your ability to perform repairs efficiently and safely, ultimately prolonging the lifespan of your equipment.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components and their maintenance. Understanding these elements is crucial for ensuring optimal functionality and longevity of your equipment. Below are some frequently posed questions that can help clarify any uncertainties.

What should I do if a component is damaged?

If you notice that a specific element is not functioning as it should, it’s important to assess the extent of the damage. In many cases, replacing the faulty part can restore performance. Consult the user manual for guidance on identifying compatible replacements and installation procedures.

How often should I inspect the components?

Regular maintenance is essential for peak performance. It is advisable to check the elements at least once a season, or more frequently if you use your equipment often. Look for signs of wear or any abnormalities, and ensure everything is securely attached. Early detection of issues can prevent larger problems down the line.