Understanding the Fleck 5600SXT Parts Diagram for Efficient Water Softening

In the realm of water treatment systems, an intricate interplay of various elements ensures optimal functionality and efficiency. Each component serves a vital role, contributing to the overall performance of the system, while enhancing water quality and user satisfaction.

To truly grasp the workings of these systems, it is essential to explore the detailed configurations and arrangements of each part. This knowledge not only aids in maintenance but also empowers users to make informed decisions regarding repairs and upgrades.

By delving into the specifics of these mechanisms, individuals can achieve a deeper understanding of how water treatment solutions operate, ultimately leading to improved performance and longevity of the equipment.

Understanding the Fleck 5600SXT System

This section aims to provide insight into a sophisticated water treatment mechanism designed to enhance the quality of water for various applications. By examining its components and functionalities, users can better appreciate its efficiency and maintenance needs.

The system operates through a series of interconnected elements that work together to ensure optimal performance. Key features include:

- Automatic regeneration process

- Programmable control settings

- Efficient water flow management

Understanding these components allows for effective troubleshooting and maintenance, ensuring long-term reliability.

- Start with regular inspections of the control unit.

- Monitor the resin tank for optimal performance.

- Keep an eye on the brine tank and salt levels.

By delving into these aspects, users can maximize the system’s capabilities and maintain high water quality consistently.

Components of the Fleck 5600SXT

This section provides an overview of the essential elements that contribute to the functionality and efficiency of the water treatment system. Understanding these components is crucial for effective maintenance and operation.

Key Elements

- Control Head

- Mineral Tank

- Brine Tank

- Bypass Valve

Functionality

- The control head regulates the system’s processes and timing.

- The mineral tank houses the media responsible for filtration.

- The brine tank holds the salt used for regeneration.

- The bypass valve allows for water flow adjustment during maintenance.

Importance of Each Part

Understanding the significance of individual components within a water softening system is crucial for optimal performance and longevity. Each element plays a unique role, contributing to the overall efficiency and effectiveness of the unit.

Functional Roles

Each component serves a specific purpose, from regulating flow to facilitating regeneration. Recognizing how these roles interact helps users maintain their systems effectively.

Maintenance and Longevity

Regular attention to every segment ensures the unit operates smoothly, minimizing breakdowns and enhancing durability. By prioritizing care for each piece, users can ultimately achieve a more reliable and efficient experience.

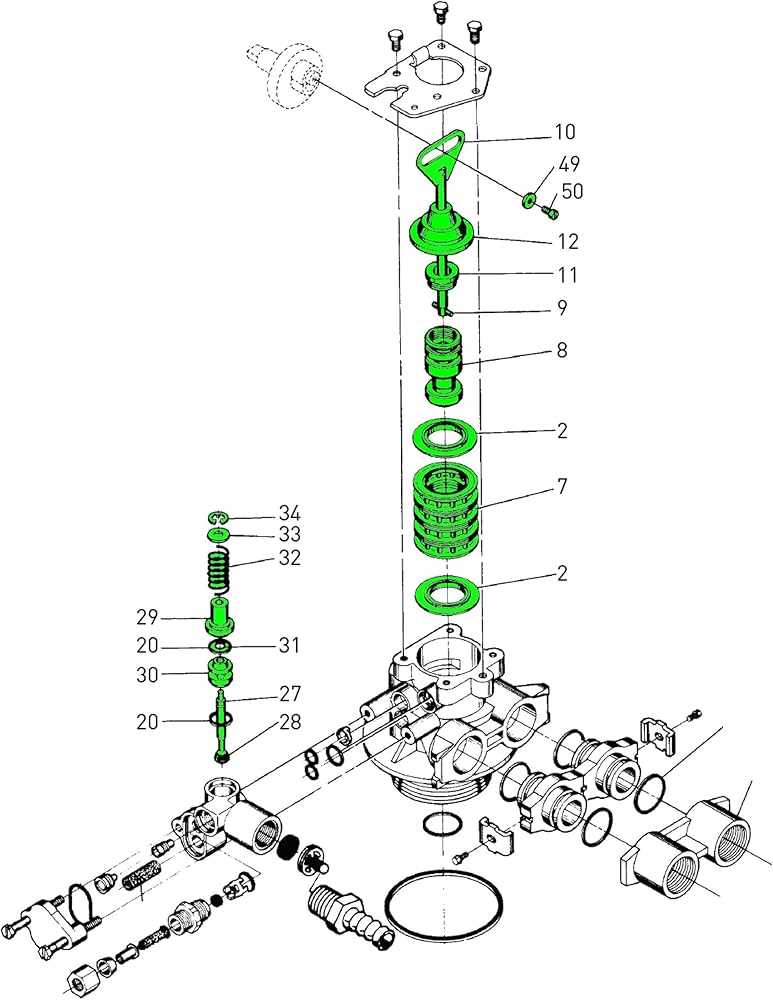

How to Read the Diagram

Understanding a schematic representation of a system can greatly enhance your ability to troubleshoot and maintain equipment. These illustrations provide a visual guide to the various components and their interconnections, enabling you to identify parts and their functions with ease.

To effectively interpret the visual guide, start by familiarizing yourself with the symbols used. Each shape and line has a specific meaning, representing different elements such as valves, sensors, and pipes. Key legends are often included to help clarify these representations, so take a moment to consult them.

Next, pay attention to the flow of the system. Arrows typically indicate the direction of movement, whether it be fluid or energy. Following this flow will assist you in understanding how each component interacts within the overall framework. Additionally, observe the connections between parts, as these can reveal critical relationships that impact performance.

Finally, take note of any notes or annotations that may accompany the illustration. These can provide valuable insights or instructions pertinent to installation, maintenance, or troubleshooting. By combining all these elements, you can gain a comprehensive understanding of the system’s layout and functionality.

Common Issues and Solutions

Understanding typical problems that arise in water treatment systems can help users maintain optimal performance. This section explores frequent challenges faced by users and offers practical solutions to enhance efficiency and longevity.

| Issue | Description | Solution |

|---|---|---|

| System Not Regenerating | Device fails to enter regeneration cycle. | Check timer settings and ensure power supply is stable. |

| Water Pressure Issues | Low or fluctuating water pressure observed. | Inspect for blockages or leaks in the plumbing system. |

| Unpleasant Odors | Water emits strange smells. | Perform a thorough cleaning and check for contamination. |

| Salt Bridges | Solid salt forms in the brine tank. | Break up the bridge manually and refill with fresh salt. |

Maintenance Tips for Longevity

Ensuring the durability and efficient operation of your water treatment system requires regular upkeep and attention. By following some simple yet effective practices, you can extend the lifespan of your equipment and maintain optimal performance over time.

Regular Inspection: Schedule routine checks to identify any signs of wear or malfunction. Early detection of issues can prevent costly repairs and ensure smooth operation.

Water Quality Monitoring: Keep an eye on the quality of your water supply. Testing for hardness and other contaminants can help you determine if adjustments or treatments are necessary, ensuring your system operates effectively.

Component Cleaning: Periodically clean essential components to remove buildup and debris. This simple action can significantly enhance performance and reduce the risk of clogs or inefficiencies.

Replace Worn Parts: Stay proactive by replacing any components that show signs of deterioration. Using quality replacements helps maintain efficiency and reduces the likelihood of breakdowns.

Follow Manufacturer Guidelines: Adhere to the recommendations provided by the manufacturer regarding maintenance schedules and procedures. This ensures that you are performing necessary tasks correctly and at the right intervals.

Use Proper Settings: Ensure that the system settings are optimized for your specific water conditions. Adjusting settings as needed can improve performance and prolong the life of the equipment.

By implementing these maintenance strategies, you can achieve reliable operation and enhance the longevity of your water treatment system, ultimately saving time and resources in the long run.

Upgrading Fleck 5600SXT Parts

Enhancing the components of your water treatment system can lead to improved efficiency and longevity. By investing in high-quality replacements and upgrades, you can ensure optimal performance while addressing any specific needs of your setup. This guide will help you navigate the process of selecting and implementing these enhancements effectively.

Key Upgrades to Consider

When looking to elevate your system, consider focusing on the most critical elements that influence functionality. These may include advanced control heads, premium resin, and upgraded bypass valves. Each of these components plays a vital role in overall system performance.

Comparison of Component Options

| Component | Standard Option | Upgraded Option |

|---|---|---|

| Control Head | Basic Mechanical | Digital Programmable |

| Resin | Standard Grade | High Efficiency |

| Bypass Valve | Plastic | Heavy-Duty Brass |

Installation Process Overview

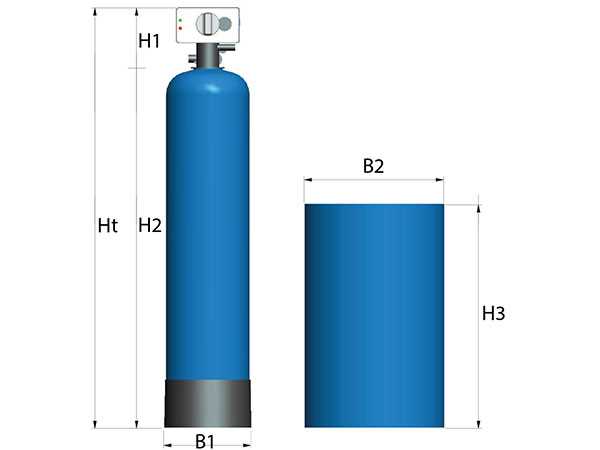

Setting up a water treatment system involves a series of essential steps that ensure optimal functionality and longevity. This process requires careful planning and attention to detail to create an efficient and effective configuration that meets the specific needs of the household or facility.

Preparation Steps

Before beginning the installation, it is crucial to gather all necessary components and tools. A comprehensive assessment of the site will help determine the best location for the unit, taking into account factors such as water supply and accessibility for maintenance.

Installation Procedure

Once preparations are complete, the installation can commence. This includes securing the unit in place, connecting it to the water supply, and ensuring proper alignment of all components. Following manufacturer guidelines during this phase will help prevent potential issues and ensure a seamless operation from the start.

Frequently Asked Questions

This section addresses common inquiries regarding the components and mechanisms of a particular water treatment system. Below, you will find answers to frequently posed questions that can assist users in better understanding the functionality and maintenance of their devices.

Common Queries

- What are the key features of this water treatment system?

- How do I properly maintain the unit?

- What should I do if I notice a malfunction?

Installation and Troubleshooting

- Is professional installation recommended?

- What are the common issues that may arise during setup?

- How can I troubleshoot problems effectively?

For more detailed information, users are encouraged to refer to the manual or consult with a qualified technician. Understanding these aspects will ensure optimal performance and longevity of the equipment.

Cost Analysis of Replacement Parts

Understanding the financial implications of component substitution is crucial for maintaining efficient operation. This evaluation encompasses the pricing of individual elements, potential long-term savings, and the overall impact on system performance.

Factors Influencing Costs

Several variables play a role in determining the expenses associated with replacement components. These include brand reputation, material quality, and availability in the market. Additionally, the complexity of installation can influence labor costs.

Cost Comparison Table

| Component | Estimated Cost | Notes |

|---|---|---|

| Element A | $50 | High durability, longer lifespan |

| Element B | $30 | Moderate quality, average lifespan |

| Element C | $20 | Budget-friendly, frequent replacement needed |

Choosing Quality Parts for Replacement

When it comes to maintaining water filtration systems, selecting high-quality components is crucial for ensuring optimal performance and longevity. Substituting inferior items can lead to inefficiency, increased wear, and potential system failures. Therefore, understanding the importance of quality replacements can significantly impact the overall functionality of the system.

Benefits of High-Quality Components

- Durability: Superior materials withstand the rigors of continuous use, reducing the frequency of replacements.

- Performance: Premium items contribute to better efficiency, ensuring the system operates at peak performance.

- Warranty Protection: Many reputable brands offer warranties that protect your investment when using their components.

Tips for Selecting Reliable Replacements

- Research Brands: Investigate manufacturers known for producing trustworthy items in the filtration industry.

- Read Reviews: Check customer feedback to gauge the performance and reliability of specific components.

- Verify Compatibility: Ensure that the chosen replacements are designed to fit your specific system model.

By prioritizing quality over cost, you can enhance the efficiency and reliability of your water filtration system, leading to long-term satisfaction and peace of mind.

Comparison with Other Systems

When evaluating water treatment systems, it’s essential to understand how different models perform under various conditions. This analysis aims to highlight key differences in functionality, efficiency, and maintenance requirements across several popular alternatives.

Functionality and Efficiency

Various systems utilize distinct technologies, impacting their effectiveness in softening water. Some employ salt-based methods, while others use alternative processes such as reverse osmosis. Efficiency can vary significantly, with some units designed for higher flow rates, making them suitable for larger households, while others focus on conserving water and minimizing waste.

Maintenance and Longevity

Maintenance is another critical aspect that distinguishes these systems. Certain models require frequent replenishment of materials, while others boast longer operational life with minimal intervention. Understanding these maintenance demands can guide users in selecting a system that aligns with their lifestyle and preferences.

Expert Recommendations and Advice

In the realm of water treatment systems, understanding key components and their functionalities can significantly enhance system performance. Expert insights can guide users in optimizing their equipment for longevity and efficiency, ensuring a smoother operation and reducing maintenance costs.

Maintenance Tips

Regular inspection of critical elements is vital. Ensure that all seals and connections are tight, and periodically check for wear and tear. Replacing worn parts proactively can prevent costly breakdowns and extend the system’s lifespan.

Choosing the Right Components

When selecting replacement items, prioritize high-quality options that align with your system’s specifications. Investing in reputable brands can lead to improved performance and reliability over time, making your system the ultimate choice for clean water needs.