Cub Cadet Zero-Turn Mower Parts Diagram Explained

In the realm of lawn care, efficient machinery plays a pivotal role in achieving a pristine landscape. This section delves into the intricacies of the various elements that constitute a specialized cutting machine, shedding light on their functions and interconnections. By grasping these components, users can enhance their maintenance skills and prolong the lifespan of their equipment.

Every mechanical system is a complex interplay of numerous parts, each contributing to the overall performance. Recognizing how these elements interact can lead to better troubleshooting and informed decision-making during repairs. A well-structured visualization of these components serves as an invaluable resource for both novice and seasoned operators alike.

Furthermore, understanding the specific arrangement and purpose of each element empowers individuals to conduct more efficient maintenance routines. With proper knowledge, users can not only address issues promptly but also optimize the performance of their machines, ensuring that they remain reliable companions in the pursuit of a well-manicured yard.

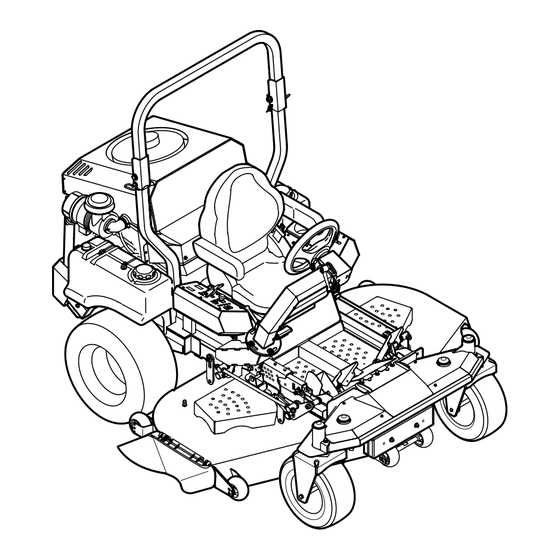

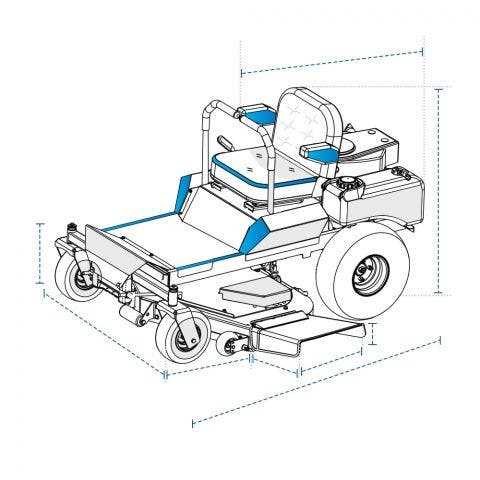

Cub Cadet Zero-Turn Mower Overview

This section provides a comprehensive look at a specific type of landscape maintenance equipment known for its maneuverability and efficiency. Designed for both residential and commercial use, these machines offer the ultimate experience in cutting grass with precision.

Equipped with advanced technology, they allow users to navigate around obstacles with ease. Their robust engines and cutting decks ensure optimal performance, making them ideal for tackling large areas quickly.

Maintenance and repair are crucial for longevity, and understanding the structure can significantly enhance user experience. Familiarity with each component empowers owners to optimize functionality and ensure reliability over time.

In summary, this equipment stands out due to its innovative design and user-friendly features, making it a popular choice among lawn care enthusiasts.

Importance of Understanding Parts Diagram

Comprehending the layout and components of machinery is crucial for effective maintenance and troubleshooting. Having a clear visual representation allows users to identify each segment, facilitating smoother repairs and replacements.

Accurate knowledge of the assembly not only enhances the efficiency of operations but also minimizes the risk of errors during upkeep. By familiarizing oneself with the configuration, one can quickly pinpoint issues and take appropriate action.

Moreover, this understanding empowers users to make informed decisions when sourcing replacements or upgrades, ultimately leading to a more reliable and longer-lasting machine. Investing time in studying the configuration pays off in the long run.

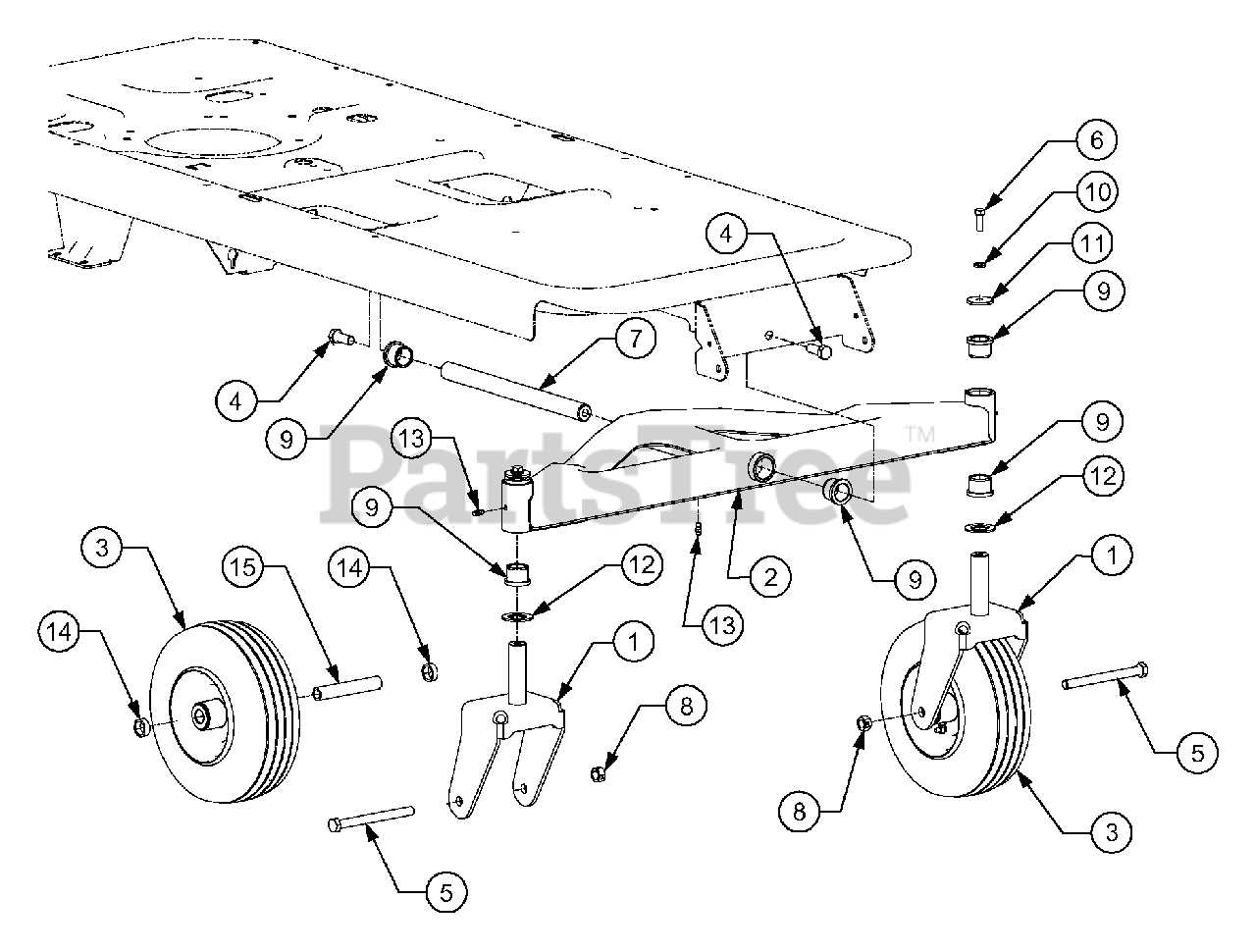

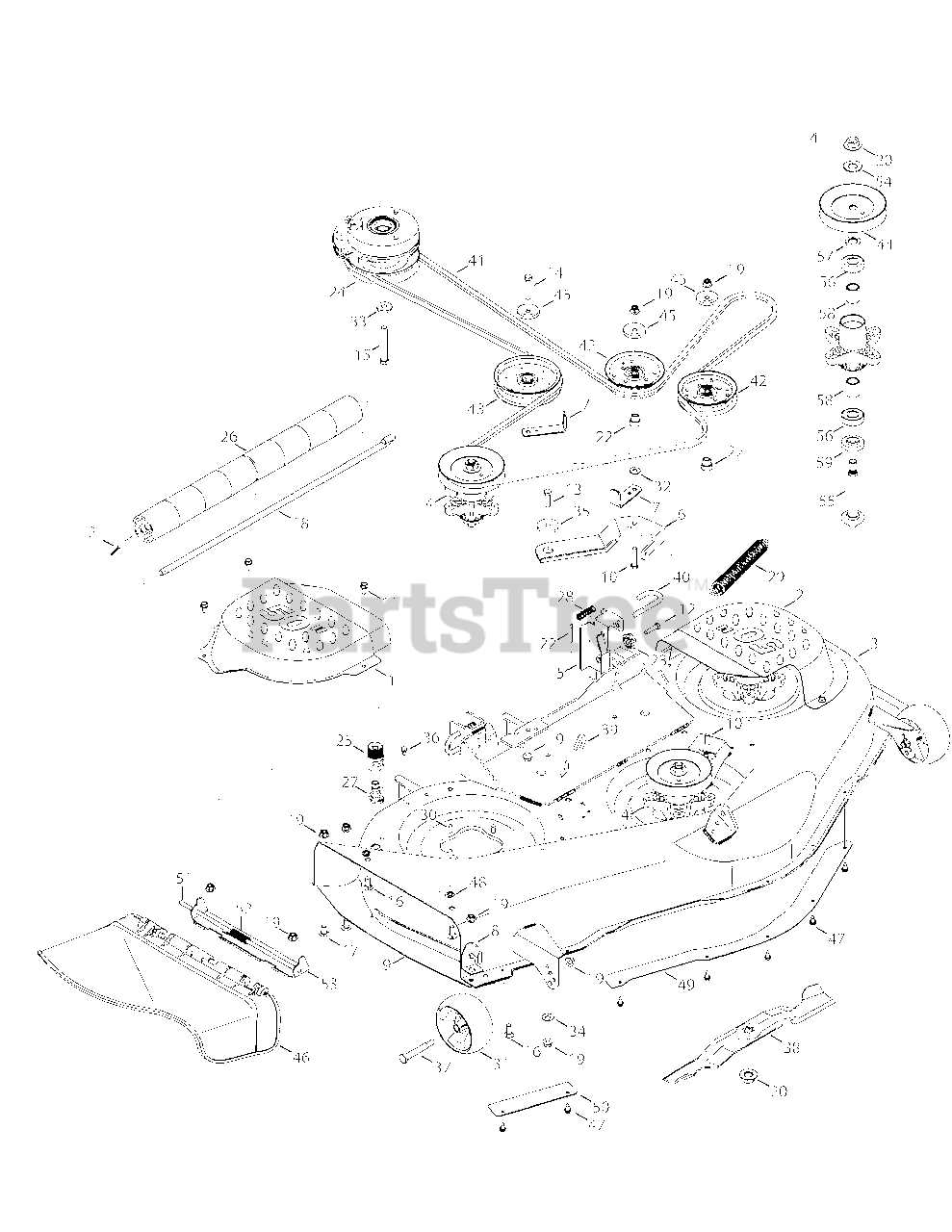

Key Components of Zero-Turn Mowers

Understanding the essential elements of lawn care machines is crucial for effective maintenance and operation. These machines are designed with specific functionalities that enhance maneuverability and efficiency in various terrains. Familiarity with their key components allows users to optimize performance and ensure longevity.

1. Cutting Deck: This is the primary component responsible for the quality of the cut. The design influences the machine’s ability to handle different grass types and lengths.

2. Drive System: The drive mechanism controls speed and direction, offering superior agility compared to traditional models. This system is often hydraulic, providing precise handling.

3. Engine: The power source is vital for overall performance. Higher horsepower engines typically result in better cutting efficiency and faster operation.

4. Wheels and Tires: The choice of wheels affects traction and stability. Larger, more robust tires enable better handling on uneven surfaces.

5. Control System: The steering levers or joysticks allow the operator to navigate with ease. An ergonomic design enhances comfort during prolonged use.

6. Safety Features: Integrated mechanisms, such as seat switches and blade brakes, are critical for ensuring operator safety during operation.

By delving into these components, users can enhance their understanding of how each part contributes to the overall functionality of the equipment, leading to better care and maintenance practices.

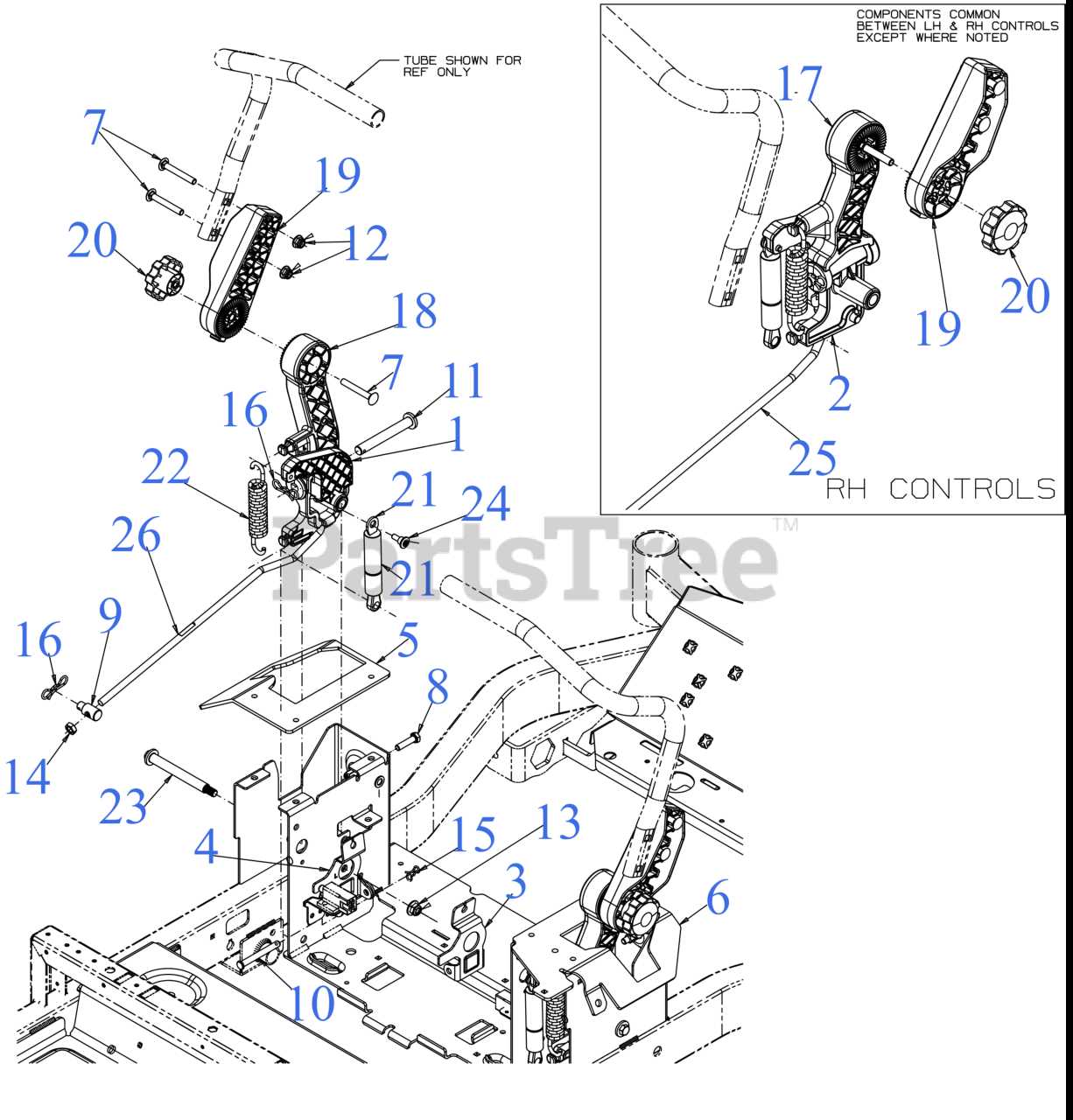

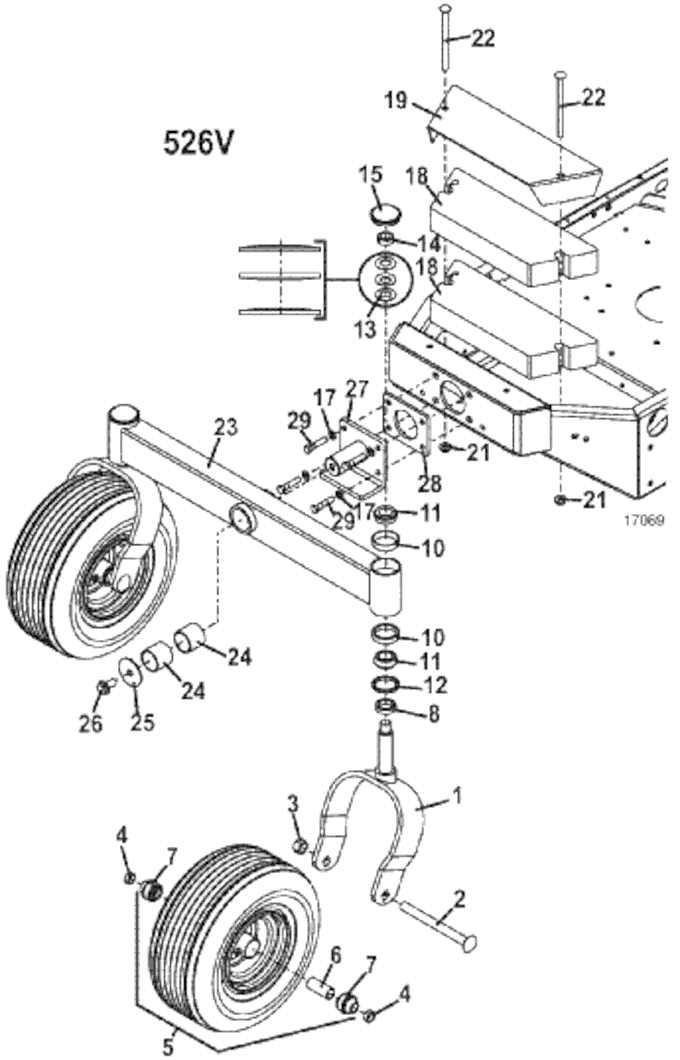

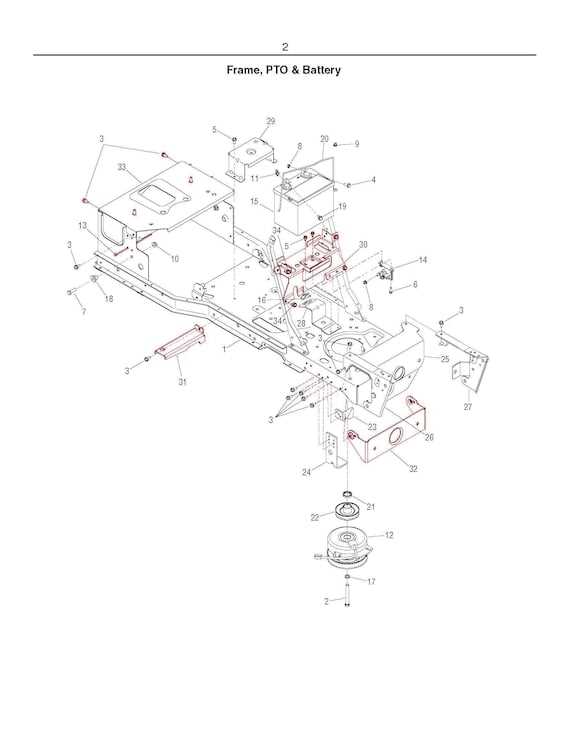

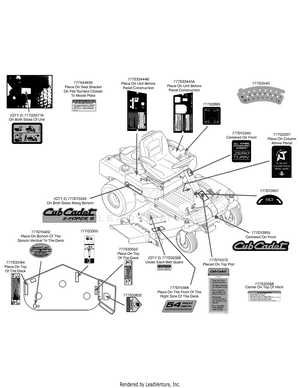

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visuals provide a detailed breakdown of components, allowing users to identify, order, and replace specific items. Grasping the layout and labeling conventions is key to navigating these resources efficiently.

Here are some tips to help you interpret these visuals:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the legend or key, which explains the symbols and color codes used in the illustration. |

| 2 | Identify major sections by following the flow of the image, often arranged in a logical sequence from top to bottom or left to right. |

| 3 | Look for callouts or annotations that provide additional information about specific components, including part numbers and descriptions. |

| 4 | Cross-reference any identified items with the manufacturer’s catalog to ensure compatibility and obtain correct replacements. |

| 5 | Take notes as you explore the illustration, marking down any components that require attention or replacement. |

By following these guidelines, you can enhance your understanding of these resources, leading to more efficient repairs and maintenance of your equipment.

Common Issues and Solutions

When operating a landscaping machine, users may encounter various challenges that can hinder performance. Understanding these common problems and their respective solutions can enhance efficiency and prolong the lifespan of the equipment. Below are some typical issues and practical remedies to keep the machine running smoothly.

Engine Troubles

Engine-related difficulties are frequent and can stem from multiple factors. Here are some common symptoms and their solutions:

- Starting Issues: If the engine won’t start, check the battery charge, ensure the fuel is fresh, and inspect the ignition system.

- Overheating: Monitor the cooling system for blockages, verify the coolant level, and clean any debris from the engine.

- Strange Noises: Unusual sounds may indicate loose components or insufficient lubrication. Inspect and tighten parts as necessary.

Cutting Performance

Problems with cutting efficiency can lead to unsatisfactory results in lawn maintenance. Consider the following:

- Uneven Cutting: This may result from dull blades or uneven tire pressure. Sharpen blades and check the tire inflation.

- Clumping of Grass: If grass is clumping during mowing, ensure that the discharge chute is clear and the cutting deck is clean.

- Stalling: Frequent stalling can occur due to heavy grass load or improper speed. Adjust the speed and clear any obstructions in the deck.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment. Regular attention not only enhances performance but also ensures safety and efficiency. Here are some key practices to keep in mind.

- Regular Cleaning: Remove grass clippings and debris after each use to prevent buildup that can affect functionality.

- Inspect Components: Frequently check for wear and tear on belts, blades, and wheels. Early detection can save time and money.

- Fluid Checks: Ensure oil and coolant levels are adequate. Change them as recommended in the user manual to maintain optimal performance.

- Sharpen Blades: Keeping blades sharp promotes clean cuts and reduces strain on the engine. Sharpen or replace as needed.

Incorporating these practices into your routine can greatly enhance the reliability and durability of your machinery. Regular maintenance is not just a chore; it’s an investment in long-term performance.

- Store Properly: Keep your equipment in a dry, sheltered area to protect it from the elements.

- Follow Manufacturer Guidelines: Adhere to maintenance schedules and recommendations provided in the instruction manual.

- Use Quality Fuel: Ensure you are using the correct type of fuel to prevent engine issues.

By following these maintenance tips, you can ensure your equipment remains in excellent condition for years to come.

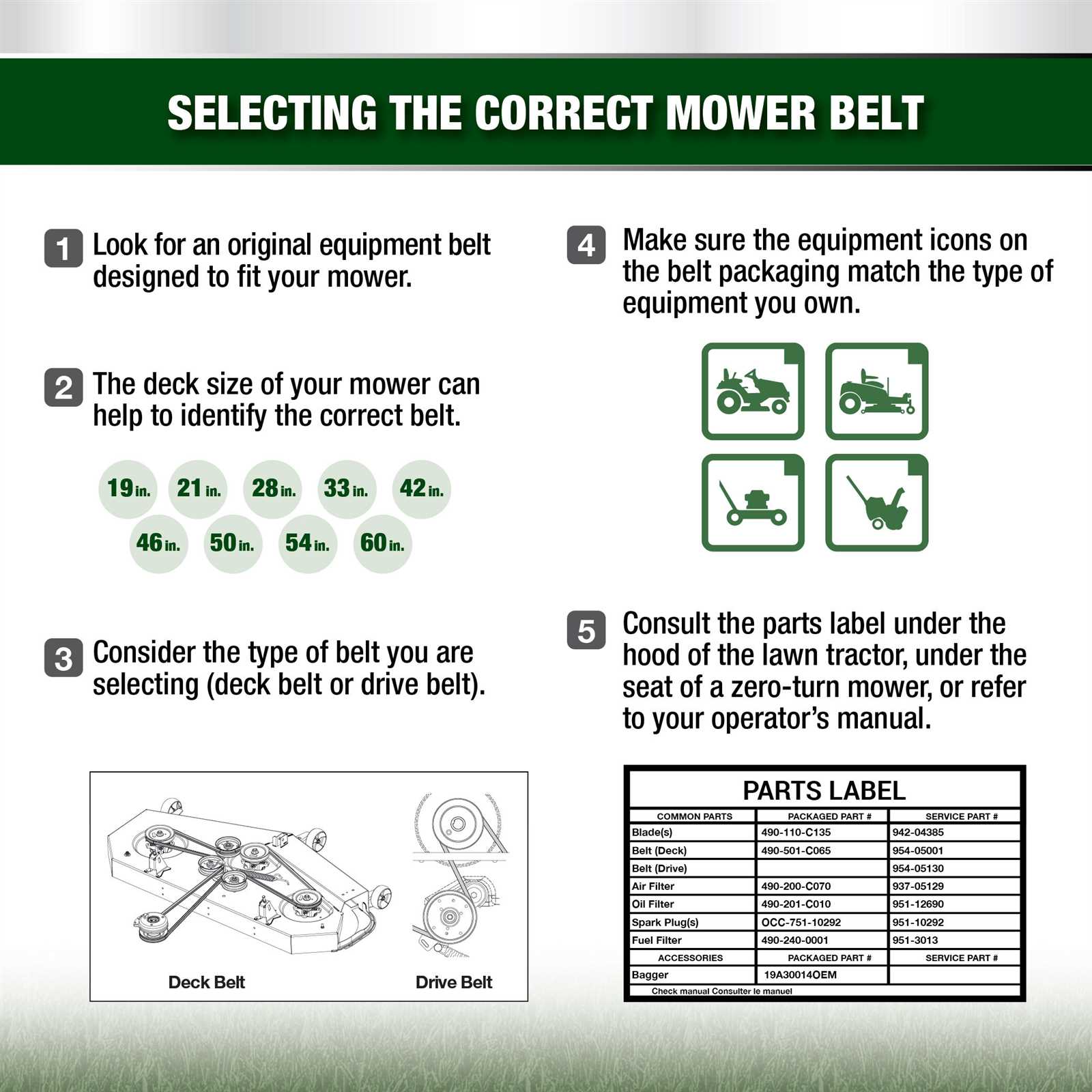

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward process if you know where to look and how to approach it. Understanding the essential elements and having a plan can save both time and frustration. Here are some effective strategies to ensure you find what you need with minimal effort.

Online Resources

The internet offers a plethora of options for sourcing replacements. Here are some key platforms to consider:

- Manufacturer Websites: Visit official sites for accurate specifications and direct links to available components.

- Online Retailers: Explore major e-commerce sites that specialize in lawn equipment; they often have extensive inventories.

- Forums and Communities: Join groups dedicated to lawn care where enthusiasts share advice and links to reliable sources.

Physical Stores and Local Services

Sometimes, a hands-on approach is preferable. Check these local options:

- Authorized Dealers: Find local dealers who can provide genuine components and expert advice.

- Repair Shops: Many repair services stock commonly needed items or can order them for you.

- Home Improvement Stores: Large chains often have a dedicated section for outdoor equipment where you can browse options.

By utilizing both online and local resources, you can efficiently find the necessary components to keep your equipment in top shape.

Benefits of Genuine Parts Usage

Utilizing authentic components in your machinery ensures optimal performance and longevity. These original items are specifically designed to fit and function seamlessly, reducing the risk of malfunctions and enhancing overall efficiency.

One significant advantage is reliability. Genuine components undergo rigorous testing to meet industry standards, providing peace of mind during operation. This reliability often translates to reduced maintenance costs over time, as authentic parts are less likely to fail.

Moreover, using original replacements can maintain the value of your equipment. When you decide to sell or trade, having a history of genuine components can be a strong selling point, appealing to potential buyers who prioritize quality.

Finally, incorporating authentic items can contribute to better warranty coverage. Many manufacturers stipulate that only original components be used to preserve warranty conditions, safeguarding your investment for years to come.

Comparing Aftermarket vs. Original Parts

When it comes to maintaining your equipment, choosing between generic replacements and manufacturer-specific components can significantly impact performance and longevity. Understanding the differences between these options is crucial for making an informed decision.

Quality and Performance

- Original components are designed specifically for your equipment, ensuring a perfect fit and optimal performance.

- Aftermarket options may vary in quality, with some offering comparable performance while others might fall short.

Cost Considerations

- Original components typically come at a higher price due to brand assurance and reliability.

- Aftermarket options often provide a more budget-friendly alternative, but it’s important to weigh the potential trade-offs in quality.

Assembly Instructions for Major Components

Proper assembly of key elements is crucial for optimal performance and longevity. This section provides essential guidelines to ensure that each component is accurately fitted and functions seamlessly within the overall system.

Step 1: Begin by reviewing the list of major components. Ensure all necessary items are on hand before starting the assembly process.

Step 2: Lay out the components in an organized manner. This will facilitate easier access and help prevent misplacement during assembly.

Step 3: Follow the manufacturer’s instructions for each part, paying close attention to alignment and securing methods. Use appropriate tools to avoid damaging any elements.

Step 4: Once assembled, conduct a thorough inspection. Ensure all connections are tight and check for any potential issues that may affect functionality.

Step 5: Finally, perform a test run to confirm that everything operates smoothly. Address any discrepancies immediately to achieve the ultimate performance.

Tools Needed for Parts Replacement

When undertaking maintenance or repairs on outdoor equipment, having the right tools is essential for a smooth and efficient process. The appropriate instruments not only facilitate easier handling but also ensure that replacements are performed correctly and safely.

Here is a list of essential tools you may need:

- Socket Set: Useful for loosening and tightening various fasteners.

- Wrench Set: Ideal for gripping and turning nuts and bolts.

- Screwdrivers: A variety of sizes, including flathead and Phillips, for different types of screws.

- Pliers: Handy for gripping, twisting, and cutting wires or small components.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Utility Knife: Useful for cutting through packaging or materials.

Additionally, having a clean workspace and proper safety gear, such as gloves and goggles, is crucial when replacing components. A well-organized toolbox can enhance efficiency and reduce the risk of misplacing vital tools.

Before beginning any replacement task, always consult the equipment’s manual for specific requirements and guidelines, ensuring that you have all necessary tools on hand.

Where to Access Parts Diagrams Online

Finding detailed schematics for various machinery can be crucial for effective maintenance and repairs. Fortunately, numerous online resources provide access to these valuable illustrations, allowing users to identify components and understand assembly processes. These platforms cater to both casual users and professionals, ensuring that everyone can find the information they need.

Manufacturer Websites

Most manufacturers offer official websites where users can find a wealth of resources, including interactive diagrams and detailed breakdowns of their equipment. By visiting these sites, you can access technical documents and guides specific to your model, ensuring accuracy and reliability in the information you obtain.

Online Retailers and Forums

Several online retailers specialize in equipment and accessories, often providing access to schematics as part of their service. Additionally, forums and community groups dedicated to machinery maintenance can be excellent sources for sharing diagrams and discussing issues. Engaging with fellow enthusiasts can lead to discovering hard-to-find illustrations and tips for troubleshooting.