Comprehensive Guide to Stihl MS 150 TC Parts Diagram

For anyone keen on maintaining their cutting tool, grasping the layout and functionality of its elements is crucial. A thorough comprehension not only enhances efficiency but also extends the lifespan of the equipment. With a focus on exploration, this guide aims to shed light on the essential mechanisms involved.

Every saw has unique features that contribute to its performance. Familiarizing oneself with these components empowers users to troubleshoot issues effectively and perform necessary repairs. By delving into the intricacies of each section, users can ensure their device operates at its ultimate potential.

Understanding the connections between various parts fosters a more profound respect for the engineering behind these machines. It opens up opportunities for customization and optimization, ultimately leading to a more satisfying user experience in the field.

Understanding Stihl MS 150 TC

This section explores the essential features and components of a popular cutting tool designed for efficiency and precision. Understanding its functionality and design can enhance user experience and maintenance practices.

Key Features

- Lightweight design for ease of handling

- Powerful engine for optimal performance

- User-friendly controls for enhanced safety

Maintenance Tips

- Regularly check and clean the air filter.

- Inspect the cutting chain for wear and tear.

- Ensure proper lubrication to prevent overheating.

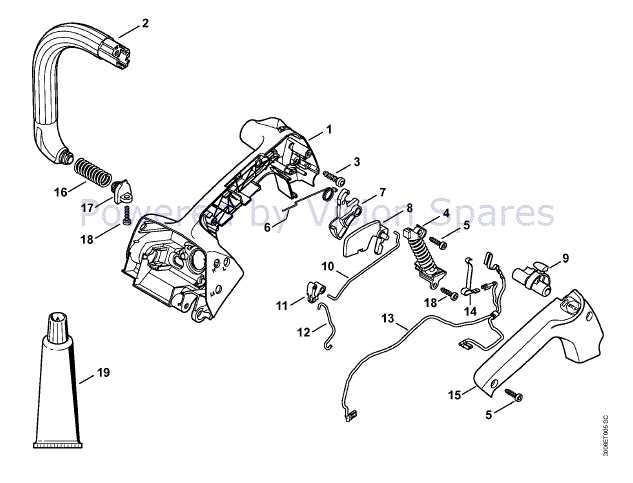

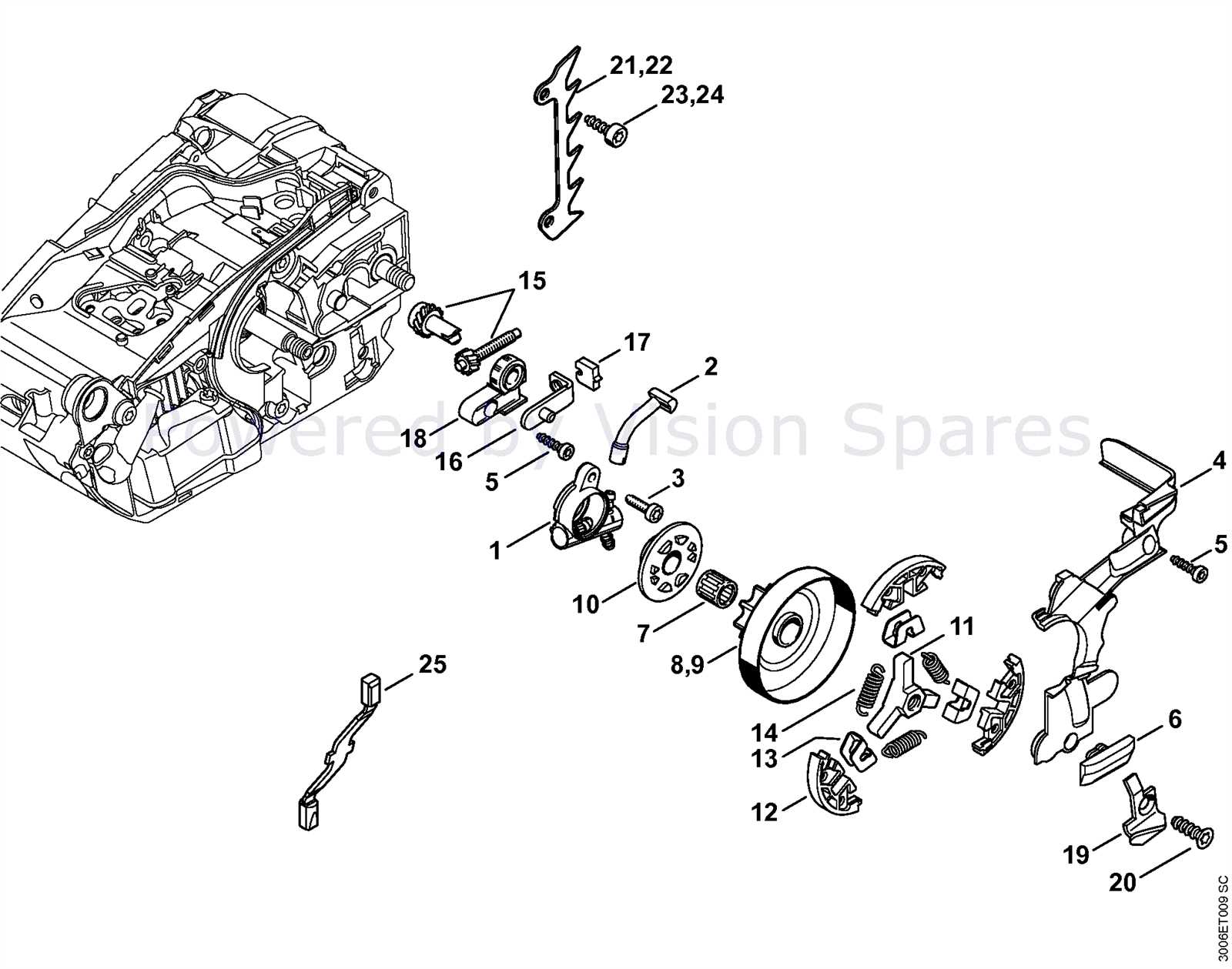

Importance of Parts Diagrams

Understanding the assembly and individual components of a machine is crucial for efficient maintenance and repair. These visual representations serve as essential guides, enabling users to identify and locate specific elements easily.

Key benefits include:

- Facilitating quick identification of components.

- Enhancing troubleshooting efficiency.

- Assisting in reassembly after servicing.

- Providing clarity in understanding the overall structure.

Moreover, these illustrations play a vital role in ensuring that replacements are accurate and compatible, ultimately extending the lifespan of equipment.

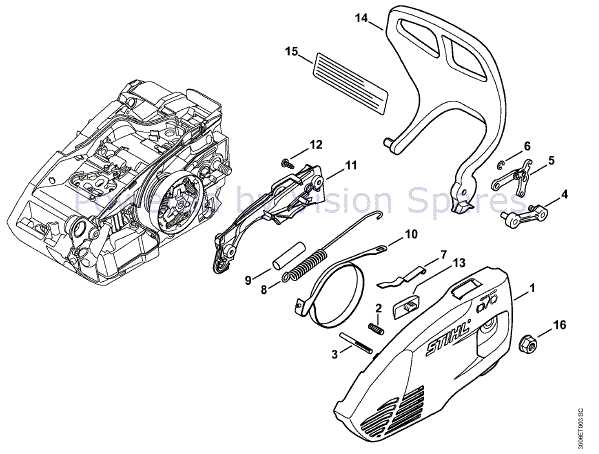

Main Components of the Chainsaw

Understanding the essential elements of a cutting tool is crucial for both maintenance and operation. Each component plays a vital role in ensuring efficiency and safety during use.

- Engine: The heart of the tool, providing the necessary power.

- Guide Bar: The long, flat piece that supports the chain during cutting.

- Chain: A series of sharp links that perform the actual cutting.

- Clutch: Engages and disengages the chain from the engine, allowing for controlled operation.

- Fuel System: Includes the tank and lines, delivering the mixture for combustion.

- Air Filter: Prevents debris from entering the engine, promoting longevity.

- Handle: Provides a grip for maneuverability and control.

- Safety Features: Includes chain brakes and throttle lock to enhance user protection.

Each of these components works together to achieve optimal performance and ensure a smooth cutting experience.

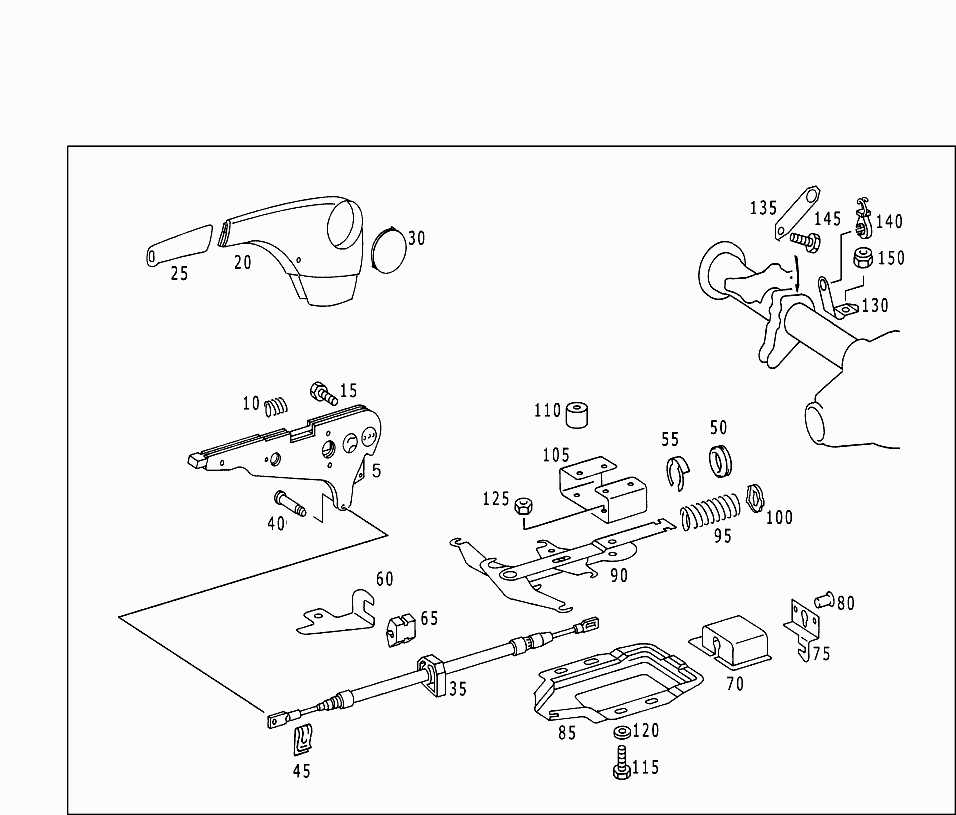

How to Read a Parts Diagram

Understanding a component illustration is essential for anyone looking to maintain or repair equipment. These visual aids serve as valuable references, showcasing the various elements and their relationships. By mastering how to interpret these visuals, you can identify parts quickly and effectively, ensuring smooth operation of your machinery.

Start by Familiarizing Yourself with the Layout: Most illustrations will feature a specific arrangement, often categorizing parts by their function or location. Take a moment to observe how components are grouped together, which can provide insight into their roles within the system.

Identify the Numbering System: Each item on the illustration is typically labeled with a unique identifier. This numbering allows for easy cross-referencing with a parts list, where detailed descriptions and specifications can be found. Be sure to note these identifiers as you study the visual representation.

Pay Attention to Annotations: Look for any accompanying notes or legends that clarify the illustration. These may include information about assembly sequences, part specifications, or even maintenance tips. Understanding these annotations can greatly enhance your ability to perform repairs or replacements.

Utilize a Reference Guide: It can be beneficial to consult a manual or online resources that provide context for the illustration. This additional information can help you grasp the functionality of each component, as well as common issues and solutions associated with them.

By becoming proficient in reading component illustrations, you’ll empower yourself to tackle maintenance tasks with confidence and efficiency, ultimately prolonging the life of your equipment.

Common Issues and Solutions

In the operation of any high-performance cutting tool, occasional technical challenges may arise. Understanding the most frequent issues and how to address them can help maintain efficiency and prolong the equipment’s lifespan. Below is a list of common problems users may encounter, along with practical solutions to resolve them effectively.

- Engine won’t start: Ensure the fuel tank is filled with the correct mixture and check the spark plug for any signs of wear or fouling. Clean or replace the spark plug if necessary.

- Power loss during operation: Inspect the air filter for dirt or blockages. A clogged filter can restrict airflow, causing the engine to underperform. Clean or replace the filter as needed.

- Chain not cutting properly: Examine the chain for dull or damaged teeth. Regular sharpening is essential for optimal cutting performance. Replace the chain if it shows significant wear.

- Excessive vibration: Check the anti-vibration mounts for any damage or loosening. Tighten or replace them if required to reduce discomfort and prevent further mechanical issues.

- Overheating: Ensure proper lubrication of the chain and cooling of the engine by frequently checking oil levels and cleaning the cooling fins.

By addressing these typical concerns promptly, users can keep their cutting tool in peak condition and avoid unnecessary downtime.

Maintenance Tips for Longevity

To ensure your equipment operates efficiently over the years, regular care and attention are essential. Consistent upkeep not only prolongs the life of your tool but also maintains its optimal performance. By focusing on specific areas and performing routine checks, you can avoid common issues and ensure reliability during each use.

Regular Cleaning is crucial to prevent the accumulation of dirt and debris, which can hinder functionality. After each use, clean all accessible areas, removing dust and residue that may cause blockages or wear over time.

Lubrication is another key factor in extending the lifespan of your tool. Keep all moving parts well-oiled to reduce friction and prevent premature damage. Ensure that you use the correct type of oil recommended for your tool’s components.

Inspection should be done periodically to identify potential wear or damage. Look for any signs of rust, corrosion, or wear on crucial components, and replace them if necessary to prevent bigger issues in the future.

Sharpness of blades or cutting parts is also vital. Dull edges not only affect performance but can also cause unnecessary strain on the motor, leading to more significant issues down the road. Regularly sharpen blades or replace them when needed.

By following these maintenance practices, you can ensure your tool remains dependable and performs at its best, year after year.

Where to Find Replacement Parts

When it comes to maintaining your equipment, finding suitable components for repairs is essential for ensuring long-term performance. Whether you’re dealing with minor issues or more complex problems, having access to quality replacements is a key factor in keeping your tool in top condition.

Authorized Dealers

One of the best places to start is with official distributors. These suppliers often provide genuine products that are specifically designed for your machine. Shopping through these channels ensures compatibility and high standards of quality, reducing the risk of future breakdowns.

Online Retailers

Another convenient option is browsing online stores that specialize in tools and accessories. Many of these platforms offer a wide selection of replacement pieces, often with detailed descriptions and customer reviews to help guide your purchase. Be sure to verify the credibility of the seller to avoid counterfeit items.

DIY Repairs and Modifications

For those who enjoy taking care of their own equipment, handling maintenance and adjustments can be a rewarding experience. By understanding how your device operates, you can extend its lifespan and ensure it works efficiently. Before attempting any repairs, it’s essential to know the components and how they function together. This knowledge will help identify issues and implement the necessary improvements.

Essential Tools and Techniques

Having the right tools on hand is critical for successful repairs. Make sure you are equipped with proper screwdrivers, wrenches, and other essential items. Moreover, it’s vital to be familiar with common techniques such as tightening screws, replacing worn-out parts, and ensuring proper alignment. Taking a systematic approach will help prevent mistakes and ensure the

Comparing with Other Stihl Models

When exploring various chainsaws, it’s important to consider how different models meet the needs of professionals and casual users. Some are designed with more power, while others prioritize ease of use or specialized functions. Understanding the variations in size, weight, and capabilities can help you make an informed decision.

Power and Precision

Certain models focus on delivering higher output for cutting through dense materials, offering an advantage for those tackling heavy-duty tasks. Others may provide precision for more detailed work, ideal for users who need more control and less fatigue over long periods.

Design and Handling

Not all designs are created equal, and different saw

Safety Precautions When Repairing

When working on any tool, ensuring safety is the top priority. It’s essential to approach every repair with caution to prevent injuries and equipment damage. Proper handling, attention to detail, and adherence to guidelines are crucial in maintaining a safe environment during repairs.

Personal protective equipment should always be worn. This includes gloves, protective eyewear, and appropriate clothing. These items help shield against potential hazards like sharp components and flying debris.

Before beginning any repair, disconnect the power source to prevent accidental operation. This is a critical step in avoiding unexpected movements or mechanical failures that could cause harm.

Additionally, keep the workspace organized and free of clutter. Ensure that all tools and parts are easily accessible and in good condition to minimize risks. Finally, always follow manufacturer guidelines and consult manuals for specific repair instructions to avoid unnecessary accidents.

Tools Required for Maintenance

When maintaining any mechanical equipment, it’s essential to have the right set of instruments. Proper tools ensure smooth and efficient upkeep, helping prevent damage and ensuring all components work correctly. Understanding the required tools in advance allows for organized and effective maintenance work.

Basic Tools

For routine care, a set of screwdrivers, wrenches, and pliers are indispensable. These tools are used to access various parts, adjust screws, and handle small fixings. Keeping them in good condition is crucial for precise work.

Specialized Equipment

In addition to basic tools, specialized instruments like a torque wrench and sharpening kit are often needed. These tools help ensure that bolts are tightened to the

Community Resources and Forums

Online communities and discussion boards are invaluable platforms where users can share knowledge, experiences, and solutions related to specific models of equipment. These forums often host a wealth of information, including maintenance tips, troubleshooting advice, and suggestions for optimizing the performance of various tools. Enthusiasts and professionals alike contribute to these discussions, making them a key resource for anyone seeking guidance or insights.

Popular Forums and Platforms

There are several well-established online forums where users gather to discuss technical issues and exchange ideas. These platforms often have dedicated sections for different types of tools, allowing users to focus on the topics that matter most. Whether you’re a seasoned expert or just getting started, these communities provide support and answers to your