Understanding the Components of a Water Meter Diagram

The effective operation of a measurement instrument relies on its intricate assembly of various elements, each serving a distinct role. This interconnectedness is vital for achieving accurate readings and maintaining efficiency. By exploring these components, one gains insights into the functionality and reliability of the device.

Every element within this system plays a crucial part in delivering precise data. From the sensing mechanisms to the transmission units, understanding their arrangement helps in troubleshooting and enhancing performance. Each component works harmoniously, contributing to the overall effectiveness of the tool.

To fully appreciate the complexity involved, it’s important to delve into the specific roles and interactions of each section. This exploration not only highlights the significance of every individual part but also underscores the ultimate goal of achieving seamless operation and accurate measurement.

Understanding Water Meter Components

This section explores the essential elements that contribute to the accurate measurement and management of liquid flow in various systems. Each component plays a vital role in ensuring precision and reliability.

The main constituents of these measuring devices can be categorized as follows:

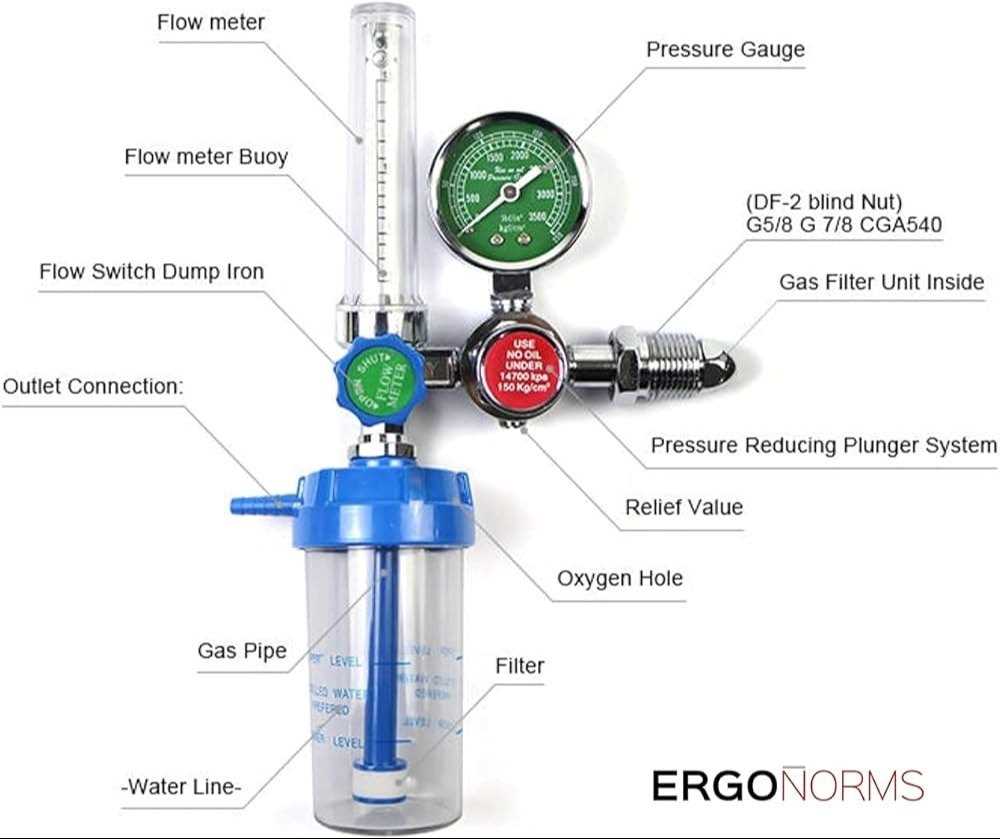

- Measurement Mechanism: This includes the primary technology used to gauge flow, such as turbine or electromagnetic methods.

- Housing: The outer casing that protects the internal components from environmental factors.

- Connection Fittings: The elements that facilitate integration with pipes or plumbing systems.

- Display Unit: A feature that shows readings and data, allowing users to monitor usage effectively.

- Calibration System: A mechanism that ensures accurate readings by adjusting the device according to standards.

Understanding these components is crucial for maintaining efficiency and ensuring accurate usage assessments in any fluid management scenario.

Types of Water Meters Explained

Understanding the various types of measurement devices used in fluid management is essential for efficient monitoring and billing. These instruments come in different forms, each designed to serve specific purposes and meet unique requirements.

Positive Displacement Devices operate by capturing a fixed volume of liquid and counting the number of times this volume is filled. They are known for their accuracy, particularly in low flow situations, making them ideal for residential applications.

Velocity Instruments utilize the speed of fluid to determine the flow rate. By measuring the movement, they provide quick readings and are commonly found in larger systems where high flow rates are typical. They often use technologies like magnetic or ultrasonic methods.

Electromagnetic Units measure the flow of conductive liquids by applying a magnetic field. These devices are highly accurate and suitable for a wide range of applications, particularly in industrial settings where various fluid types are handled.

Ultrasonic Devices leverage sound waves to calculate flow. They are non-intrusive, allowing for installation without disrupting the system. This feature makes them popular for both residential and commercial uses.

Each type offers distinct advantages, and selecting the appropriate device depends on factors such as fluid characteristics, installation environment, and required accuracy. Understanding these variations can lead to better efficiency and cost savings in fluid management systems.

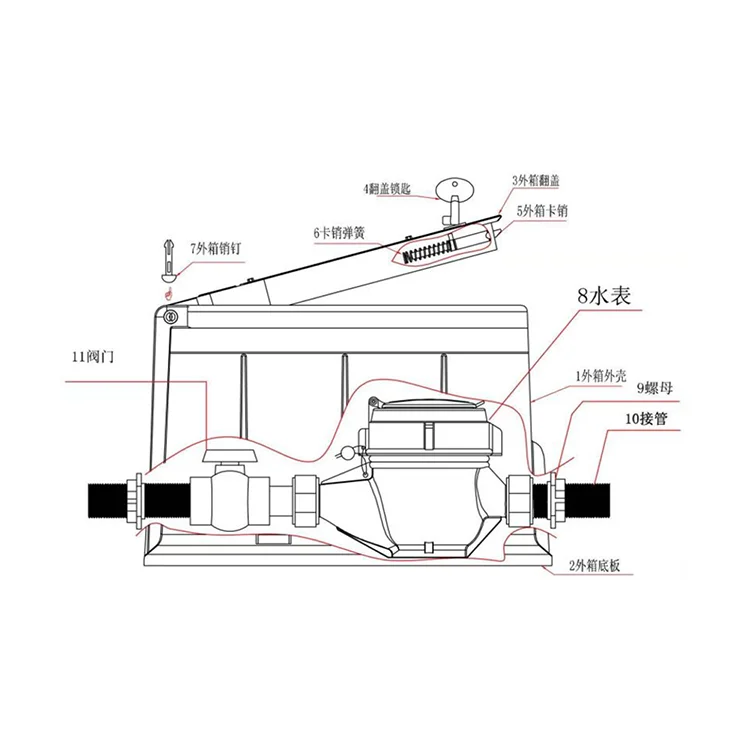

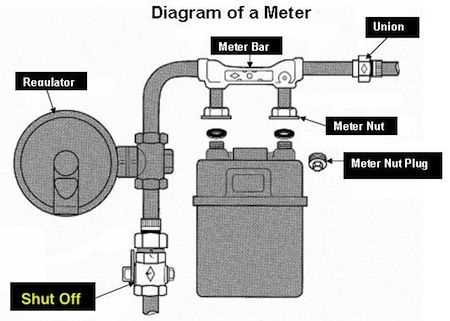

Key Parts of a Water Meter

Understanding the essential components of a fluid measurement device is crucial for both installation and maintenance. Each element plays a vital role in ensuring accurate readings and optimal functionality. This section delves into the main constituents that contribute to the device’s efficiency.

Main Components

The structure of a fluid measurement apparatus consists of several integral components, each serving a unique function. Here are some of the primary elements:

| Component | Function |

|---|---|

| Measuring Chamber | Holds the liquid and allows for measurement based on flow rate. |

| Indicator | Displays the volume consumed over a specified period. |

| Registration Mechanism | Records the total amount of fluid passing through. |

| Connecting Pipes | Facilitates the movement of liquid to and from the measuring chamber. |

| Sealing System | Prevents leaks and maintains accuracy by ensuring proper closure. |

Importance of Each Element

Each component plays a significant role in the overall performance and reliability of the measurement device. Regular checks and maintenance of these elements can enhance durability and accuracy, ensuring that the readings remain consistent over time.

Functionality of Each Component

This section delves into the various elements involved in measuring fluid flow, outlining their distinct roles and contributions to overall performance. Each component plays a crucial part in ensuring accurate readings and efficient operation, working harmoniously to achieve reliable results.

Key Elements and Their Roles

The following table summarizes the primary components and their respective functionalities:

| Component | Function |

|---|---|

| Sensor | Detects the movement of the liquid and converts it into a readable signal. |

| Display Unit | Shows the measurements in a clear format for easy interpretation. |

| Flow Regulator | Maintains a consistent flow rate to enhance measurement accuracy. |

| Body | Houses the internal components and withstands pressure from the fluid. |

| Seals | Prevents leaks and ensures the integrity of the system. |

Importance of Each Component

Understanding the significance of each element is essential for effective maintenance and troubleshooting. A malfunction in any part can lead to inaccurate readings, highlighting the need for regular checks and timely replacements to maintain optimal performance.

Importance of Accurate Measurement

Precision in measuring resources is crucial for various reasons, influencing efficiency, cost, and sustainability. Accurate readings help manage consumption effectively and ensure that systems function optimally.

- Cost Efficiency: Inaccurate readings can lead to overcharges or waste, impacting budgets significantly.

- Resource Management: Knowing exact usage patterns aids in better allocation and conservation efforts.

- Regulatory Compliance: Accurate assessments are often required by law, ensuring that businesses adhere to standards.

- System Longevity: Proper measurements help in maintaining equipment, reducing wear and tear over time.

Ultimately, the focus on precision contributes to overall sustainability and operational success, benefiting both consumers and providers alike.

Common Issues with Water Meters

Several challenges can arise with measuring devices that track fluid usage. Understanding these issues is essential for effective management and maintenance.

- Inaccurate Readings: Devices may provide incorrect usage data due to mechanical faults or external influences.

- Blockages: Sediment or debris can obstruct the flow, leading to miscalculations.

- Leakage: Physical damage can result in fluid loss, affecting overall accuracy.

- Calibration Errors: Over time, devices may drift from their original settings, necessitating adjustments.

- Temperature Sensitivity: Extreme conditions can impact performance and reliability.

Regular inspections and prompt repairs are vital to ensure accurate and reliable monitoring of consumption.

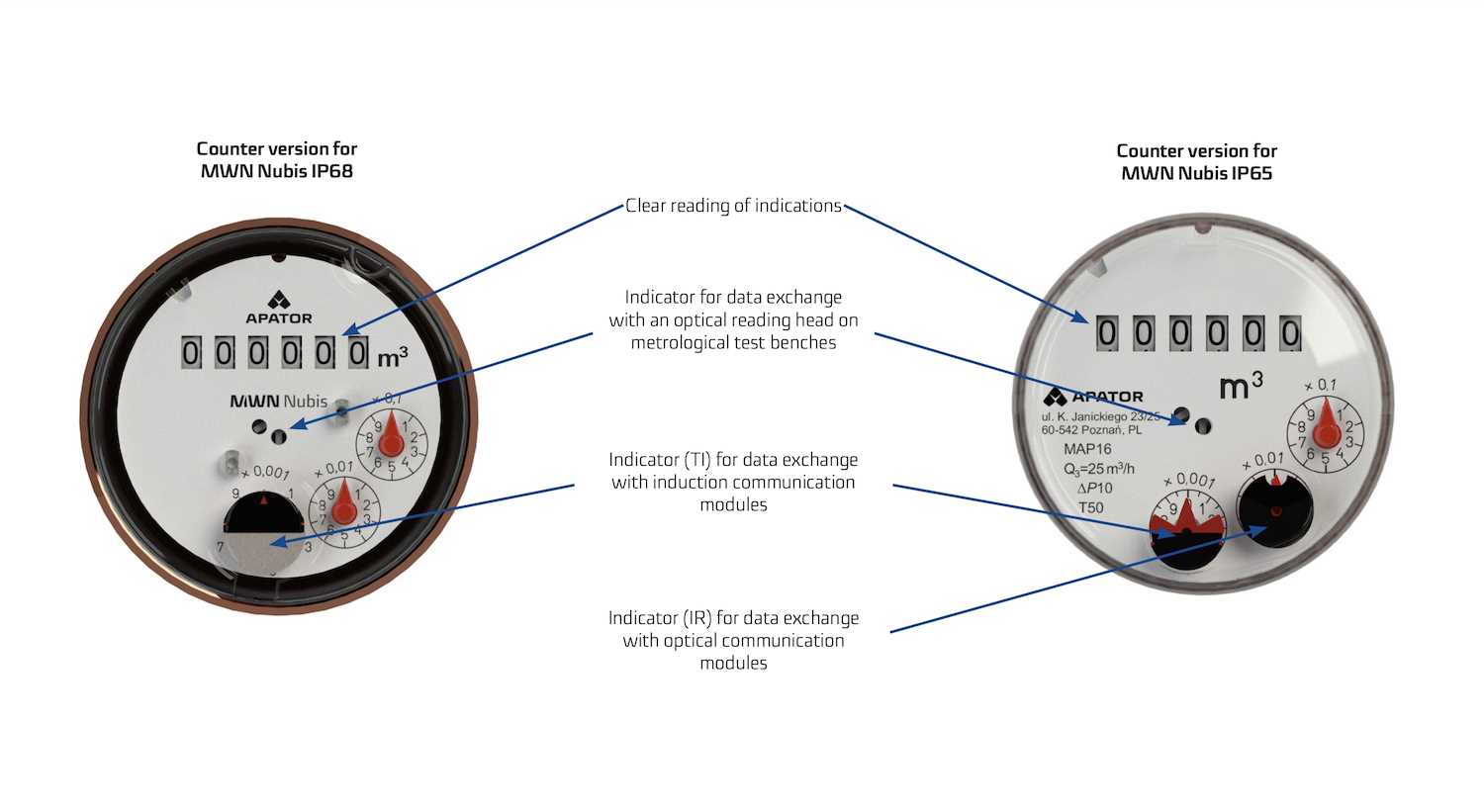

How to Read a Water Meter

Understanding how to interpret your consumption gauge is essential for monitoring usage and managing expenses. This guide will walk you through the basic steps to accurately read and comprehend the information displayed.

To begin, familiarize yourself with the components and the layout of the display. Generally, these devices present a series of numbers that indicate the volume of liquid utilized over a specified period.

| Component | Description |

|---|---|

| Digital Display | Shows current usage in clear numerical form. |

| Dial | Analog readout with rotating dials that track cumulative consumption. |

| Units Indicator | Denotes the measurement unit, such as gallons or liters. |

Regularly recording your figures can help track trends and identify potential leaks, ensuring efficient resource management. By regularly noting these readings, you can ultimately gain greater control over your consumption habits.

Maintenance Tips for Longevity

To ensure the enduring performance of your measurement devices, regular upkeep is essential. Proper care not only enhances efficiency but also extends the lifespan, preventing costly replacements.

Regular Inspections: Conduct frequent evaluations to identify any signs of wear or damage. Early detection can save you from more significant issues down the line.

Clean Components: Periodically clean all elements to remove debris and buildup. This practice helps maintain optimal functionality and accuracy.

Monitor Usage: Keep track of how often your device is used. Understanding usage patterns can inform you when maintenance is necessary.

Professional Servicing: Schedule routine professional check-ups. Experts can delve into areas that may not be visible to the untrained eye, ensuring thorough maintenance.

Environment Control: Protect your devices from extreme temperatures and humidity. A stable environment is crucial for maintaining accuracy and integrity.

Use Quality Products: When replacing any components, always choose high-quality options. Investing in reliable materials contributes to the ultimate longevity of your equipment.

Upgrading Your Water Meter System

Enhancing your measurement system can lead to significant benefits in efficiency, accuracy, and management. Modernizing this infrastructure not only optimizes performance but also reduces costs and increases reliability. The transition to advanced technologies allows for real-time data collection and better resource allocation.

Benefits of Modernization

Adopting new technologies brings several advantages. Improved accuracy ensures that usage is measured correctly, minimizing disputes and errors in billing. Additionally, smart systems facilitate remote monitoring, allowing for immediate detection of leaks or irregularities, which can save both time and money.

Implementation Steps

To effectively upgrade your system, consider a phased approach. Start with assessing current infrastructure to identify limitations. Next, research and select suitable upgrades that align with your needs. Finally, ensure proper training for personnel to handle the new technology efficiently, maximizing the investment in your improved system.

Impact of Temperature on Readings

Temperature variations can significantly influence measurement accuracy and overall performance of flow measurement devices. Understanding these effects is crucial for ensuring reliable data collection in various environments.

Factors affected by temperature include:

- Fluid viscosity changes

- Expansion of materials

- Calibration drift

As temperatures rise or fall, the following impacts may occur:

- Increased resistance to flow at lower temperatures.

- Potential inaccuracies in reading at extremes.

- Need for regular calibration adjustments to maintain accuracy.

Monitoring and mitigating temperature effects is essential for maintaining optimal functionality and ensuring precise measurements.

Water Meter Calibration Process

The calibration of measurement devices is essential for ensuring accurate readings and maintaining efficiency. This process involves comparing the device’s output against a known standard to identify any discrepancies. Regular calibration helps in preserving the reliability of measurements and can significantly impact operational costs.

Importance of Accurate Calibration

Accuracy in measurements is crucial for various applications, from billing to resource management. Regular calibration minimizes errors, enhances confidence in data, and supports compliance with regulatory standards. Neglecting this process can lead to financial losses and inefficiencies.

Calibration Steps

The calibration procedure generally includes several key steps: first, a thorough inspection of the device is performed to check for any visible damage or wear. Next, it is tested against a calibrated reference, adjusting settings as necessary to align results. Finally, documentation of the calibration process ensures traceability and accountability.

Legal Regulations for Water Meters

In the realm of resource measurement, adherence to established guidelines is crucial for ensuring accuracy, fairness, and accountability. These regulations govern the installation, maintenance, and usage of devices designed to quantify consumption, aiming to protect both consumers and service providers.

The legal framework typically encompasses several key aspects:

- Standards and Specifications: Devices must meet specific technical standards to ensure reliable performance and uniformity across installations.

- Certification and Testing: Before deployment, these instruments undergo rigorous testing to confirm compliance with relevant laws and standards.

- Installation Guidelines: Proper setup is mandated to prevent inaccuracies, with regulations specifying positioning and environmental conditions.

- Maintenance Requirements: Regular checks and calibrations are often required to maintain accuracy over time.

- Consumer Rights: Users have rights concerning billing accuracy and dispute resolution, with laws designed to protect them from overcharging.

Compliance with these regulations not only fosters trust between parties involved but also promotes sustainable resource management practices. Adhering to legal standards helps ensure that the tools used for measurement function as intended, safeguarding both the provider’s and the consumer’s interests.

Innovations in Meter Technology

Recent advancements in measurement devices have transformed how consumption is monitored and managed. These innovations aim to enhance accuracy, efficiency, and user experience, catering to the growing demand for smart solutions in resource management. With the integration of cutting-edge technologies, the landscape of monitoring has significantly evolved, providing stakeholders with enhanced capabilities.

Smart Technology Integration

The incorporation of smart technology into measurement devices has revolutionized data collection and analysis. Real-time monitoring enables users to track usage patterns and detect anomalies instantly. This shift towards intelligent systems facilitates better decision-making and encourages proactive management of resources, ultimately leading to sustainable practices.

Remote Communication Features

Modern devices now often feature remote communication capabilities, allowing for seamless data transmission. This innovation reduces the need for manual readings and enhances operational efficiency. Users can access their consumption data remotely, leading to improved transparency and convenience. As technology continues to advance, these features are expected to become more sophisticated, further simplifying the management process.