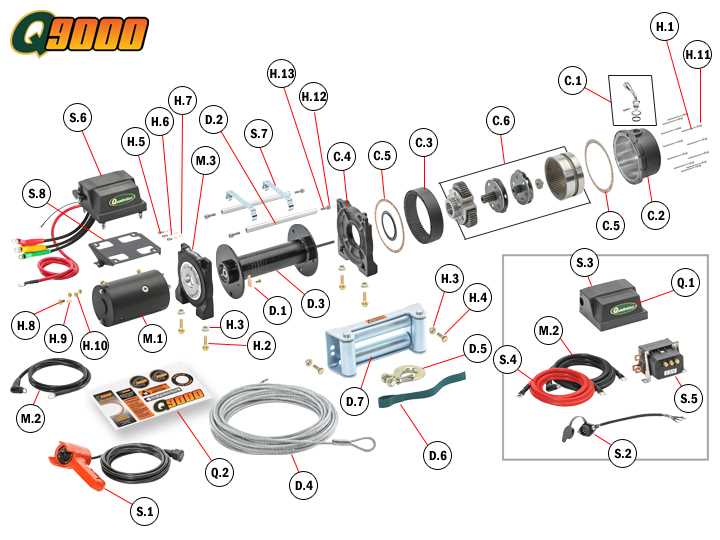

Mile Marker Winch Parts Diagram Explained

The intricate machinery used in towing and recovery operations relies on various crucial elements that ensure optimal performance and reliability. A comprehensive knowledge of these components can enhance your ability to maintain and troubleshoot your system effectively. By breaking down each part’s function, users can gain insight into how everything works together to achieve ultimate efficiency.

When examining these mechanisms, it’s important to explore their roles and interactions. Understanding the layout of these components not only aids in repairs but also boosts the overall effectiveness of the equipment. Each piece plays a vital role in the system’s operation, contributing to its functionality and durability.

Through this exploration, you will delve into the specifics of each item, allowing you to make informed decisions regarding upgrades or replacements. A well-rounded grasp of these elements empowers users to optimize their equipment for various applications, ensuring they are always ready for any challenge.

Mile Marker Winch Overview

This section provides an insightful look into a renowned device designed for enhancing off-road experiences. With a focus on reliability and performance, these tools are essential for adventurers seeking to navigate challenging terrains.

Key features that make this equipment stand out include:

- Durability: Constructed from robust materials to withstand harsh conditions.

- Efficiency: Engineered for optimal pulling power, allowing users to overcome obstacles with ease.

- Versatility: Suitable for various applications, from recreational use to recovery operations.

Understanding the components that contribute to its functionality is crucial. Here are the primary elements:

- Drivetrain: Ensures smooth operation and effective torque transfer.

- Control System: Offers user-friendly interfaces for precise management.

- Spooling Mechanism: Facilitates efficient winding and unwinding of the cable.

In summary, this device exemplifies a perfect blend of strength and technology, making it a favored choice among outdoor enthusiasts and professionals alike.

Understanding Winch Components

Exploring the various elements that make up a pulling mechanism is essential for grasping its functionality and efficiency. Each component plays a critical role in the overall performance, contributing to the system’s ability to handle different loads and terrains. By delving into the individual parts, one can gain a deeper appreciation for how they work together to achieve seamless operation.

Key Elements

- Drum: The central cylinder around which the rope is wound, crucial for the mechanism’s capability to store and release tension.

- Motor: The driving force that provides the necessary power to operate the system, available in various types for different applications.

- Rope: The strong, flexible line that transmits force and can be made from different materials to suit specific tasks.

- Gearbox: A set of gears that modifies the motor’s output to increase torque or speed as needed for the task at hand.

- Remote Control: The device that allows for safe operation from a distance, enhancing user convenience and safety.

Supportive Components

- Fairlead: Guides the rope as it unwinds from the drum, minimizing wear and ensuring smooth operation.

- Mounting Bracket: The structural element that secures the mechanism in place, ensuring stability during operation.

- Clutch: Enables the operator to disengage the drum from the motor, allowing for free-spooling of the rope when necessary.

- Brake System: Provides safety by preventing the load from falling unexpectedly, especially during operation.

Importance of Quality Parts

Using high-quality components is crucial for the optimal performance and longevity of any machinery. These elements ensure reliability and efficiency, significantly reducing the risk of failure during operation. Investing in superior materials ultimately enhances overall functionality and safety.

Durability and Reliability

Durable components withstand wear and tear, minimizing the likelihood of breakdowns. Reliability is essential, especially in demanding environments where performance is non-negotiable. High-quality materials provide peace of mind, knowing that they will perform as expected over time.

Cost-Effectiveness

While premium components may have a higher initial cost, they often lead to lower long-term expenses. Quality parts reduce maintenance frequency and replacement needs, ultimately saving money and time. Investing in excellence pays off by ensuring sustained operational success.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These illustrations provide a visual guide to the various elements and their interconnections, enabling users to grasp how each component functions within the larger assembly.

Begin by familiarizing yourself with the layout. Identify the different sections and how they relate to one another. Look for labels or numbers that indicate specific elements, which often correspond to a list or legend.

Pay attention to the scale and orientation. Ensure you understand the size relationships between parts, as this can affect installation and compatibility. Recognizing the direction of arrows or lines can also clarify movement or flow within the system.

Finally, cross-reference with manuals or guides for detailed descriptions. This step is crucial for troubleshooting or when ordering replacements, as it provides context and ensures accuracy in identifying necessary components.

Common Issues with Winch Parts

Understanding the typical challenges associated with these mechanical devices can greatly enhance their longevity and effectiveness. Frequent complications can arise from various components, impacting performance and reliability. Identifying these issues early can prevent more significant failures.

| Issue | Description |

|---|---|

| Corrosion | Exposure to moisture can lead to rust and deterioration of metal components. |

| Overheating | Excessive strain can cause motor overheating, risking permanent damage. |

| Gear Wear | Continuous use can result in worn gears, affecting the efficiency of the device. |

| Electrical Issues | Faulty wiring or connections can interrupt power supply, leading to malfunctions. |

| Improper Lubrication | Insufficient lubrication can increase friction, causing parts to wear out faster. |

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. Regular maintenance not only extends the lifespan of components but also enhances performance and safety. Here are some essential practices to keep in mind.

- Conduct regular inspections to identify wear and tear early.

- Lubricate moving parts as recommended by the manufacturer.

- Clean all surfaces to prevent rust and debris accumulation.

- Check electrical connections for corrosion and tightness.

In addition, follow these steps:

- Keep a maintenance log to track services performed.

- Replace worn components promptly to avoid further damage.

- Store equipment in a dry, protected environment to minimize exposure to harsh elements.

By implementing these strategies, you can significantly enhance the ultimate longevity of your equipment.

Upgrading Your Winch System

Enhancing your pulling apparatus can significantly improve its performance and reliability. Whether you’re looking to tackle tougher tasks or simply want to increase efficiency, understanding the components and potential upgrades is essential. This section will guide you through the various options available for elevating your system.

Assessing Your Current Setup

Before making any enhancements, evaluate the existing equipment’s capabilities. Identify any limitations and consider how these might impact your needs. This assessment will help in selecting the most suitable upgrades.

Choosing Upgrades Wisely

Focus on high-quality components such as improved motors, durable cables, and advanced control systems. Investing in reliable gear can lead to a significant boost in functionality, ensuring that your apparatus meets the demands of challenging environments.

Installing Replacement Parts Safely

Ensuring the secure installation of components is crucial for maintaining functionality and safety. Taking the right precautions not only extends the lifespan of the equipment but also minimizes the risk of accidents during operation. Understanding the essential steps involved in this process is vital for both novices and experienced individuals alike.

Preparation is key before commencing any replacement work. Gather all necessary tools and materials, and make sure you are in a clean, well-lit environment. It is advisable to read the manufacturer’s instructions thoroughly to familiarize yourself with the specific requirements for the task at hand.

Next, disconnect power sources to eliminate the risk of accidental engagement while working. This could involve unplugging devices or turning off relevant switches. Wearing appropriate safety gear, such as gloves and goggles, is also essential to protect yourself from potential hazards.

When handling the new components, ensure they are compatible with your equipment. Check for any visible damage before installation. Following the guidelines for fitting will help in avoiding common pitfalls that could lead to malfunction or failure.

Finally, test the system once the new components are in place. Gradually restore power and monitor for any irregularities. This final step is vital to confirm that everything operates smoothly and safely, providing peace of mind during usage.

Differences Between Manual and Electric Winches

Understanding the distinctions between different types of pulling systems is essential for selecting the right tool for specific tasks. Each type offers unique benefits and limitations that cater to various applications and user preferences.

Power Source

- Manual: Operated by physical effort, typically using a hand crank.

- Electric: Powered by a battery or electrical source, providing automatic operation.

Ease of Use

- Manual: Requires significant physical strength and can be labor-intensive.

- Electric: Offers convenience and ease, allowing users to operate with minimal effort.

Ultimately, the choice depends on the intended use, available power sources, and user preference.

Identifying Parts by Model Number

Recognizing components through their model identifiers is crucial for ensuring compatibility and optimal performance. This process not only streamlines maintenance but also enhances the efficiency of repairs and upgrades. Here’s how to effectively identify components using their designated numbers.

To begin with, understanding the significance of the model number is essential. Each identifier serves as a unique reference that connects to specific characteristics and specifications. Follow these steps for accurate identification:

- Locate the model number on the equipment. It is often found on a label or engraved on the body.

- Refer to the manufacturer’s catalog or website. This resource usually contains detailed information about the various models.

- Cross-reference the model number with online databases or forums. Many communities provide insights and support for identifying components.

In addition, keeping a list of frequently used model numbers can be helpful for future reference. Consider the following tips:

- Organize your list by category for easy access.

- Update the list regularly to include new acquisitions or changes.

- Share the list with team members to improve collaboration and efficiency.

By employing these strategies, you can confidently identify the components necessary for your projects, leading to smoother operations and reduced downtime.

Where to Buy Authentic Parts

Finding genuine components for your equipment is crucial to ensure optimal performance and longevity. With numerous options available in the market, selecting the right source can make a significant difference in the reliability of your machinery.

Online Retailers: One of the most convenient ways to acquire authentic components is through reputable online retailers. Websites that specialize in industrial and mechanical equipment often offer a wide selection of genuine items. Ensure to verify the seller’s credibility through reviews and ratings.

Authorized Dealers: Another reliable option is to purchase from authorized distributors. These dealers are officially recognized by manufacturers, guaranteeing that you receive authentic goods. They often provide excellent customer support and can assist with installation and maintenance advice.

Manufacturer Websites: For those seeking the utmost assurance of authenticity, consider purchasing directly from the manufacturer’s website. Many companies provide a dedicated section for genuine products, along with detailed descriptions and specifications to help you make an informed choice.

Local Retail Stores: Visiting local retail stores can also be beneficial. Establishments that specialize in machinery and tools typically stock authentic components and can offer personalized assistance. Additionally, building a relationship with local suppliers can lead to valuable insights and recommendations.

Ensuring you acquire legitimate components is essential for maintaining the functionality and safety of your equipment. By exploring these options, you can confidently source the items you need.

Frequently Asked Questions About Winches

This section addresses common inquiries related to hoisting mechanisms, providing clarity on various aspects and ensuring users can make informed decisions. Whether you’re a novice or experienced operator, understanding these essentials will enhance your knowledge and confidence.

What should I consider when choosing a hoisting device?

When selecting a lifting mechanism, it’s important to assess factors such as load capacity, type of application, and power source. Additionally, consider the environment in which it will be used, as this can impact functionality and safety.

How can I maintain my lifting equipment?

Regular maintenance is crucial for optimal performance. Inspect cables, lubricate moving parts, and check for wear or damage. Following the manufacturer’s guidelines will help ensure longevity and safe operation.