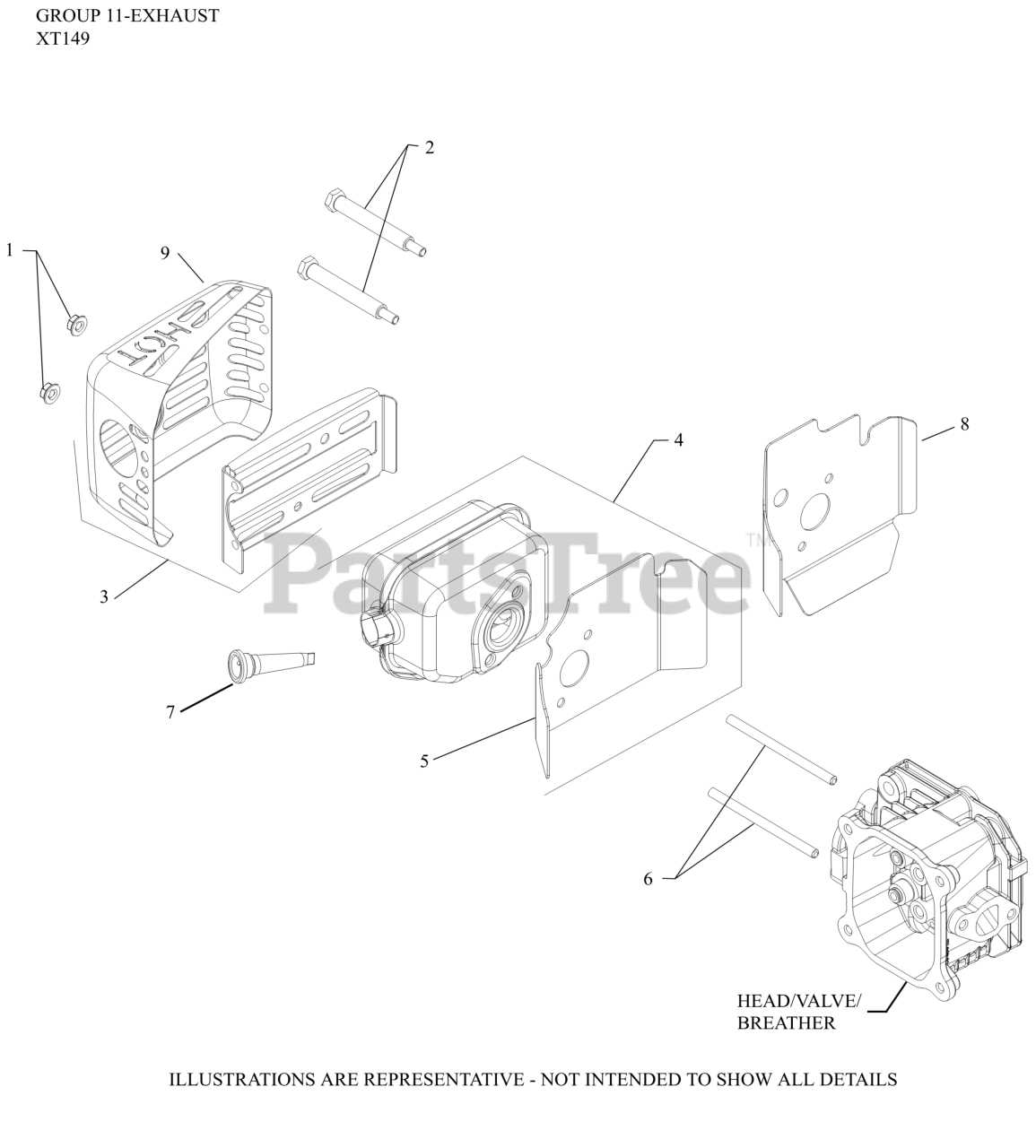

Kohler XT-6 Parts Diagram Overview

The intricate workings of an engine are best understood through detailed illustrations that showcase each component’s placement and function. These visual aids serve as essential tools for both enthusiasts and professionals in the field, providing clarity on how various parts interact within the system.

By examining a comprehensive visual representation, one can gain valuable insights into the design and functionality of essential elements. This understanding not only aids in maintenance and repairs but also enhances overall performance knowledge.

Whether you’re troubleshooting issues or planning an upgrade, having access to well-structured representations of engine components can significantly simplify the process. Engaging with these resources empowers users to make informed decisions and ensures efficient handling of their machinery.

Kohler XT-6 Parts Overview

This section provides an insight into the various components essential for optimal performance. Understanding the functionality of each element is crucial for effective maintenance and repairs.

Key Components

- Engine Block

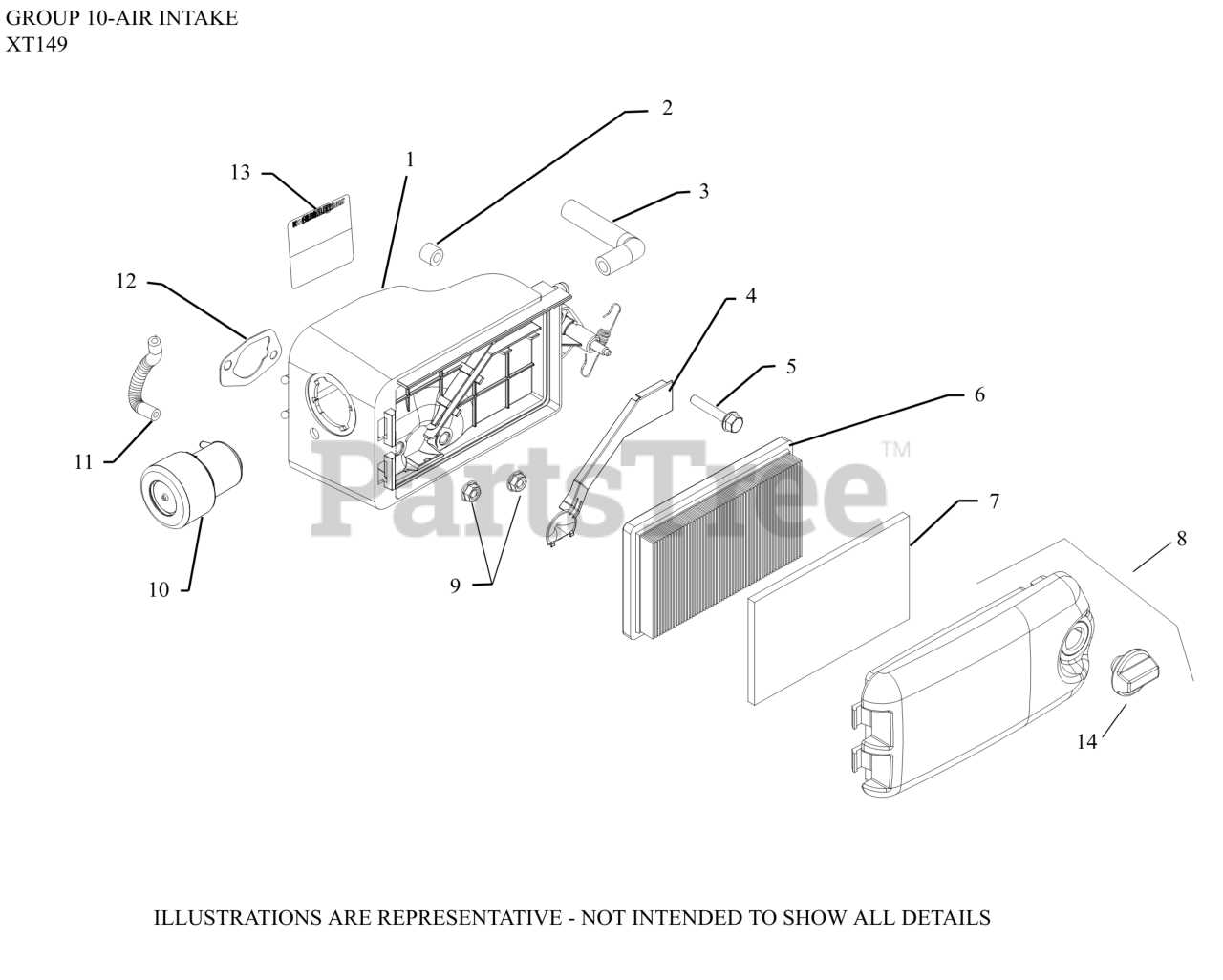

- Fuel System

- Ignition System

- Cooling System

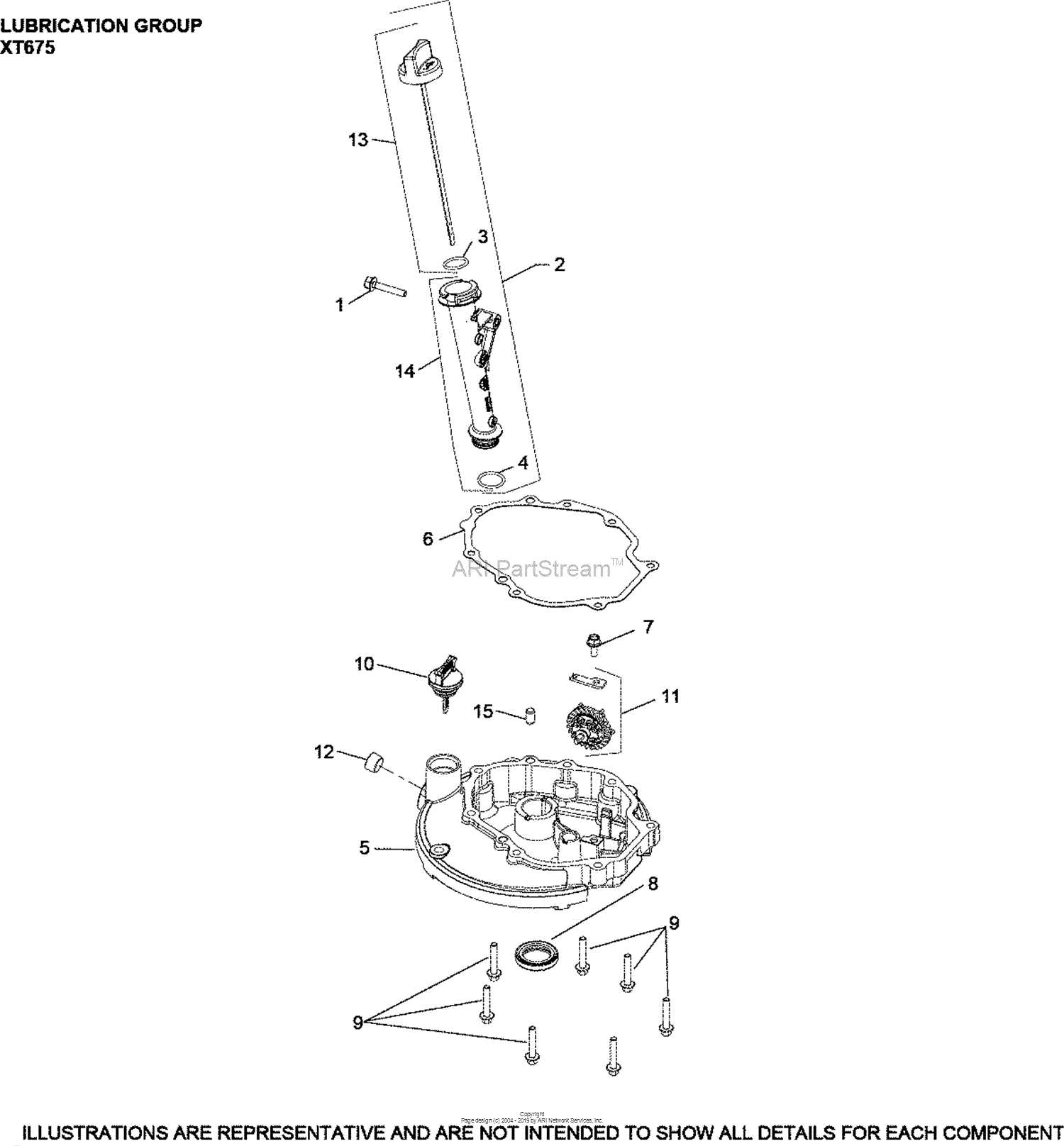

- Lubrication System

Maintenance Tips

- Regularly check the oil level.

- Replace filters as recommended.

- Inspect the spark plug for wear.

- Ensure the cooling system is functioning properly.

- Keep all connections secure and free of debris.

Understanding Engine Components

Engines are intricate systems composed of various elements that work together to produce power. Each part has a unique function that contributes to the overall performance and efficiency of the machine. Understanding these components is essential for maintenance and repair, as well as for optimizing operation.

Main Components

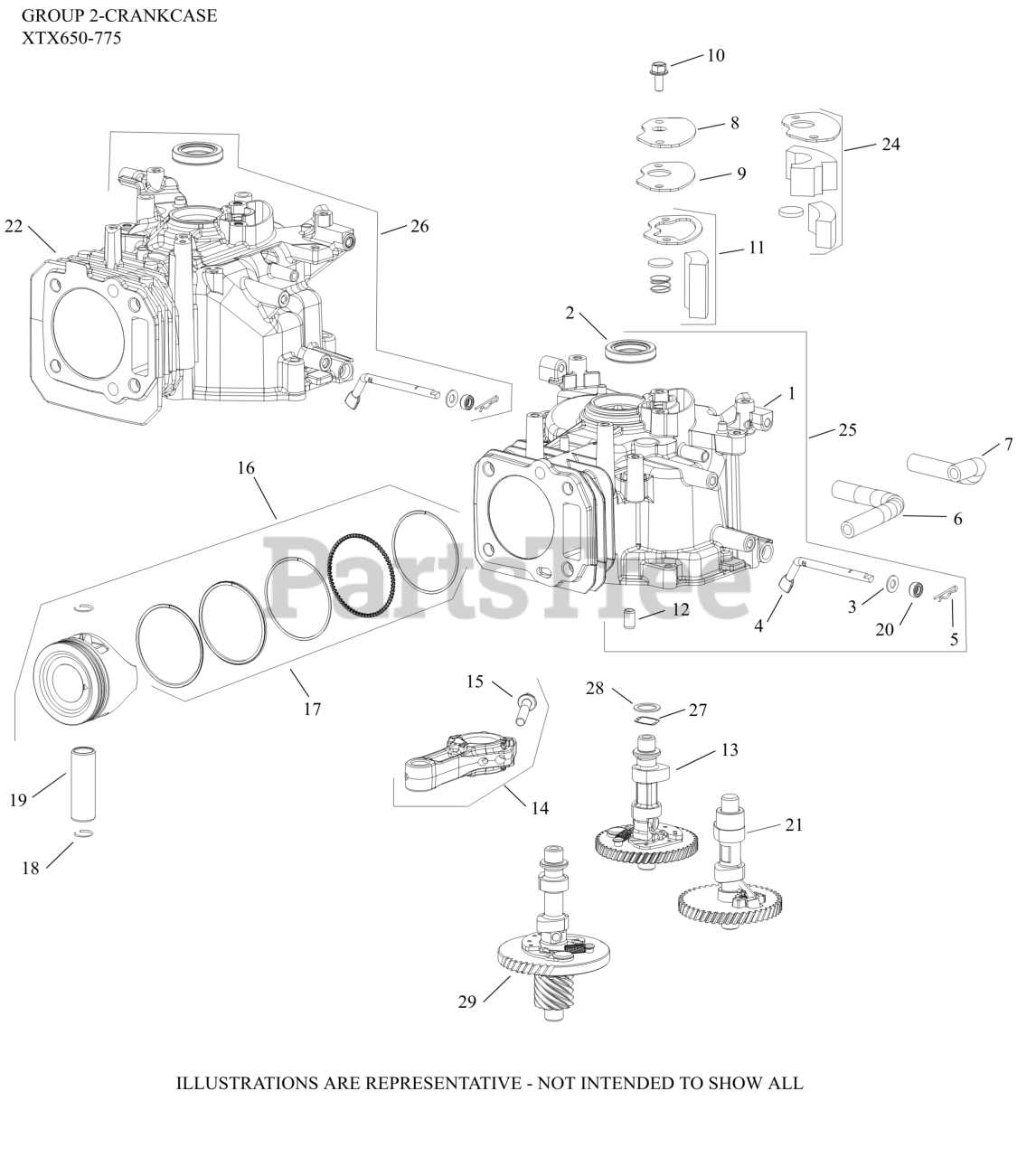

- Block: The core structure housing the cylinders and various other components.

- Cylinder: The space where fuel combustion occurs, generating power.

- Piston: Moves up and down within the cylinder, converting combustion energy into mechanical work.

- Crankshaft: Transforms the linear motion of the pistons into rotational motion.

- Valves: Control the intake of air and fuel and the exhaust of combustion gases.

Supporting Elements

- Camshaft: Operates the valves at the right timing for efficient combustion.

- Fuel System: Delivers fuel to the engine, including pumps and injectors.

- Ignition System: Initiates the combustion process through spark generation.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

By familiarizing oneself with these essential components, operators can enhance their understanding of engine mechanics, leading to better maintenance practices and improved performance.

Identifying Common Issues

Recognizing frequent problems in small engines can significantly enhance maintenance and performance. Various factors can lead to operational difficulties, and understanding these can help in troubleshooting effectively.

One common issue is difficulty starting the engine, often attributed to fuel supply problems or electrical malfunctions. Checking the fuel system for clogs or leaks is essential, as well as ensuring that the ignition components are functioning properly.

Another prevalent concern is irregular operation or stalling. This can result from an imbalance in the air-fuel mixture or dirty filters. Regular inspections and cleanings can mitigate these issues, promoting smoother performance.

Additionally, unusual noises during operation may indicate mechanical wear or failure. Listening carefully to the engine’s sounds can provide valuable clues about underlying issues that need immediate attention.

Maintenance Tips for Longevity

Ensuring the durability of your machinery involves a series of crucial practices that enhance its performance and lifespan. Regular care and attention can prevent common issues and promote smooth operation over time.

- Regular Inspections: Conduct frequent checks for any signs of wear or damage.

- Clean Components: Keep all parts free from dirt and debris to maintain optimal function.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear.

- Replace Worn Parts: Timely replacement of damaged components prevents further issues.

- Follow Manufacturer Guidelines: Adhere to maintenance schedules and recommendations to ensure proper care.

By implementing these strategies, you can significantly extend the life of your equipment and enhance its reliability in various applications.

Parts Replacement Guidelines

When it comes to maintaining your equipment, understanding the process of component exchange is crucial for optimal performance. This section provides essential tips for effectively replacing various elements to ensure longevity and reliability.

Assessment: Before starting, carefully evaluate the components that need replacement. Identify any signs of wear or damage that may affect functionality.

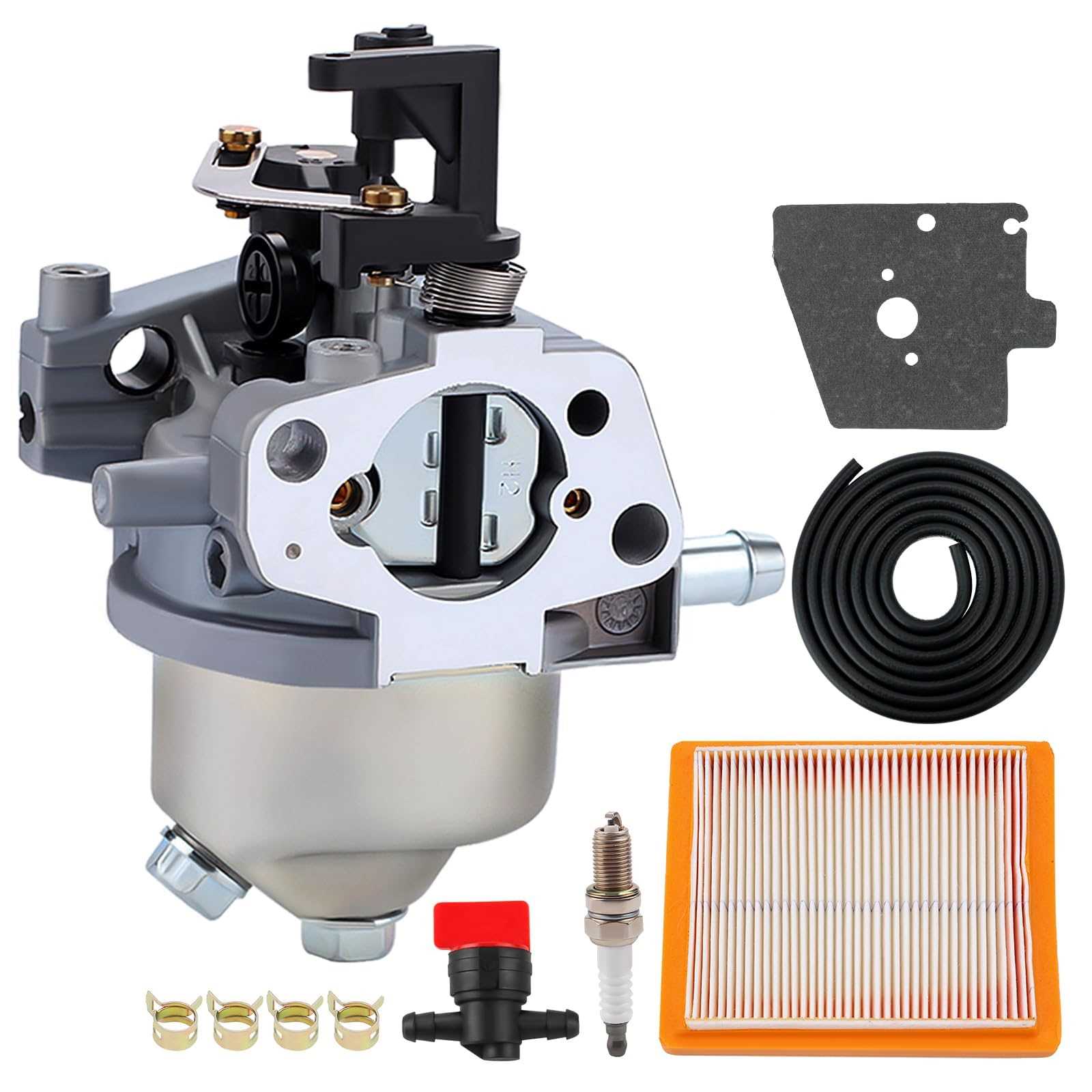

Tools and Materials: Gather the necessary tools and replacement items before you begin. Having everything on hand will streamline the process and reduce downtime.

Step-by-Step Process: Follow a systematic approach when replacing components. Begin by safely removing the faulty part, ensuring that any residual energy sources are disconnected. Install the new item following the manufacturer’s guidelines, and verify that it is securely fastened.

Testing: Once the replacement is complete, conduct a thorough test to confirm that everything operates correctly. Address any issues immediately to prevent further complications.

Regular Maintenance: Establish a routine for checking and replacing components as needed. Proactive maintenance helps avoid unexpected failures and extends the life of your equipment.

Tools Required for Repairs

Having the right equipment is crucial for effective maintenance and fixing tasks. Proper tools not only streamline the process but also ensure safety and precision during repairs.

Essential tools include a variety of wrenches, screwdrivers, and pliers. These items are fundamental for loosening and tightening components efficiently. Additionally, a socket set can provide better access to hard-to-reach areas.

For more intricate jobs, a torque wrench is vital to ensure that connections are secured to the correct specifications. A multimeter can help diagnose electrical issues, while a work light improves visibility in dark spaces.

Investing in quality tools is key, as they enhance both the experience and outcome of repair projects. Always keep your toolkit organized to quickly locate the necessary items when needed.

Exploring Manufacturer Recommendations

Understanding the guidance provided by producers is crucial for maintaining optimal performance and longevity of any equipment. Manufacturers often offer valuable insights regarding the selection of components, maintenance routines, and troubleshooting techniques, ensuring that users can maximize their machinery’s efficiency.

Importance of Following Guidelines

Adhering to the recommendations set forth by the manufacturer helps prevent potential issues that may arise from using incompatible parts or neglecting maintenance. These guidelines are developed based on extensive research and testing, making them an essential resource for users.

Recommended Maintenance Practices

Regular maintenance is vital for the longevity of your equipment. Following the suggested intervals for servicing and using the correct tools can significantly enhance performance. It’s advisable to consult the manufacturer’s documentation for detailed schedules and practices tailored to your specific machinery.

Safety Precautions During Maintenance

Ensuring a safe working environment during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions should be taken to protect both the individual performing the maintenance and the equipment being serviced. Familiarity with safety protocols and the appropriate use of protective gear can significantly reduce risks associated with maintenance activities.

Use of Personal Protective Equipment

Wearing suitable personal protective equipment (PPE) is essential. This includes gloves, safety goggles, and sturdy footwear to shield against potential hazards. The choice of PPE should be based on the specific tasks at hand and the materials being handled. Regular inspection of safety gear ensures that it remains effective and in good condition.

Proper Tools and Equipment Handling

Utilizing the correct tools for each task not only enhances efficiency but also minimizes the likelihood of accidents. Tools should be inspected before use to ensure they are in proper working order. Additionally, following manufacturer instructions for handling and operation can help maintain safety throughout the maintenance process.

How to Access Parts Diagram

Understanding the components of a machine is crucial for effective maintenance and repairs. To gain insight into the assembly, one can refer to visual representations that illustrate the various elements involved.

Step 1: Start by visiting the manufacturer’s official website, where resources and manuals are often provided.

Step 2: Look for a section dedicated to technical documents or support, which typically houses these visual guides.

Step 3: If available, utilize the search feature to enter the model name to streamline your search.

Step 4: Once you locate the relevant document, download or view it online to explore the layout of the equipment.

Step 5: For additional help, consider reaching out to customer support, which can assist in obtaining the necessary illustrations.

Ordering Replacement Parts Online

When it comes to maintaining machinery, sourcing components online has become a convenient option for many users. With just a few clicks, you can find the necessary items to ensure your equipment operates smoothly.

Steps to Order Components

- Identify the required component by checking your equipment specifications or user manual.

- Visit reputable online retailers that specialize in mechanical parts.

- Use the search function to locate the specific item needed.

- Compare prices and reviews to ensure quality and reliability.

- Add the chosen component to your cart and proceed to checkout.

Benefits of Online Ordering

- Convenience: Shop from the comfort of your home at any time.

- Wide Selection: Access to a vast inventory of components that may not be available locally.

- Competitive Pricing: Often, online prices are more favorable due to lower overhead costs.

- Customer Reviews: Read experiences from other buyers to make informed decisions.

Understanding Warranty Information

Warranty information is essential for consumers to know their rights and protections regarding products. It outlines what is covered, the duration of coverage, and the steps required to make a claim. Understanding these details helps ensure that users can seek assistance if any issues arise with their equipment.

What to Look For

When reviewing warranty documents, pay attention to the following:

- Coverage Details: Understand what parts or services are included.

- Duration: Note how long the warranty is valid.

- Claim Process: Familiarize yourself with the steps needed to file a claim.

Common Exclusions

Many warranties come with exclusions that limit their scope. These may include:

- Damage due to misuse or neglect

- Normal wear and tear

- Unauthorized repairs or modifications

Being aware of these factors can help prevent misunderstandings and ensure satisfaction with the product.

Connecting with Professional Services

Engaging with expert services is essential for ensuring optimal functionality and longevity of machinery. Professionals offer valuable insights and tailored solutions that can enhance performance and prevent potential issues. Establishing a relationship with qualified technicians can lead to efficient maintenance and timely repairs, ultimately saving time and resources.

Benefits of Professional Support

Utilizing specialized services provides numerous advantages, including:

| Advantage | Description |

|---|---|

| Expertise | Professionals possess in-depth knowledge and experience in their field. |

| Time-Saving | Outsourcing tasks allows for quicker resolutions and minimal downtime. |

| Preventative Maintenance | Regular inspections can identify issues before they escalate. |

Finding the Right Professionals

When seeking expert services, consider the following tips:

- Research credentials and reviews.

- Ask for referrals from trusted sources.

- Evaluate service offerings and pricing structures.