Understanding the John Deere JE75 Parts Diagram for Efficient Maintenance

In the realm of agricultural equipment, comprehending the intricacies of machinery can significantly enhance operational efficiency. Proper knowledge of individual elements and their relationships ensures that operators can maintain and repair their equipment effectively, minimizing downtime and maximizing productivity.

Every complex system relies on a well-structured layout of its components. Familiarizing oneself with the arrangement and functionality of these elements not only aids in troubleshooting but also promotes informed decision-making during maintenance. Recognizing how each segment interacts can lead to a more seamless operational experience.

Access to comprehensive visuals and technical illustrations provides valuable insights into machinery assembly. These resources serve as essential guides, helping users navigate the various sections and understand the significance of each part. By leveraging such tools, operators can ensure their equipment remains in optimal condition, ready to tackle the demands of modern agricultural practices.

Understanding the John Deere JE75

This section delves into the intricacies of a specific agricultural machine that has gained popularity for its efficiency and versatility. Understanding its components and functionality is crucial for both operators and technicians, ensuring optimal performance in various farming tasks.

Key Features and Benefits

This machine is designed with a range of features that enhance productivity and ease of use. Its robust engine and advanced technology contribute to reliable operation, making it suitable for a variety of agricultural applications. Additionally, its user-friendly interface allows for seamless handling, even for those new to the equipment.

Maintenance and Care

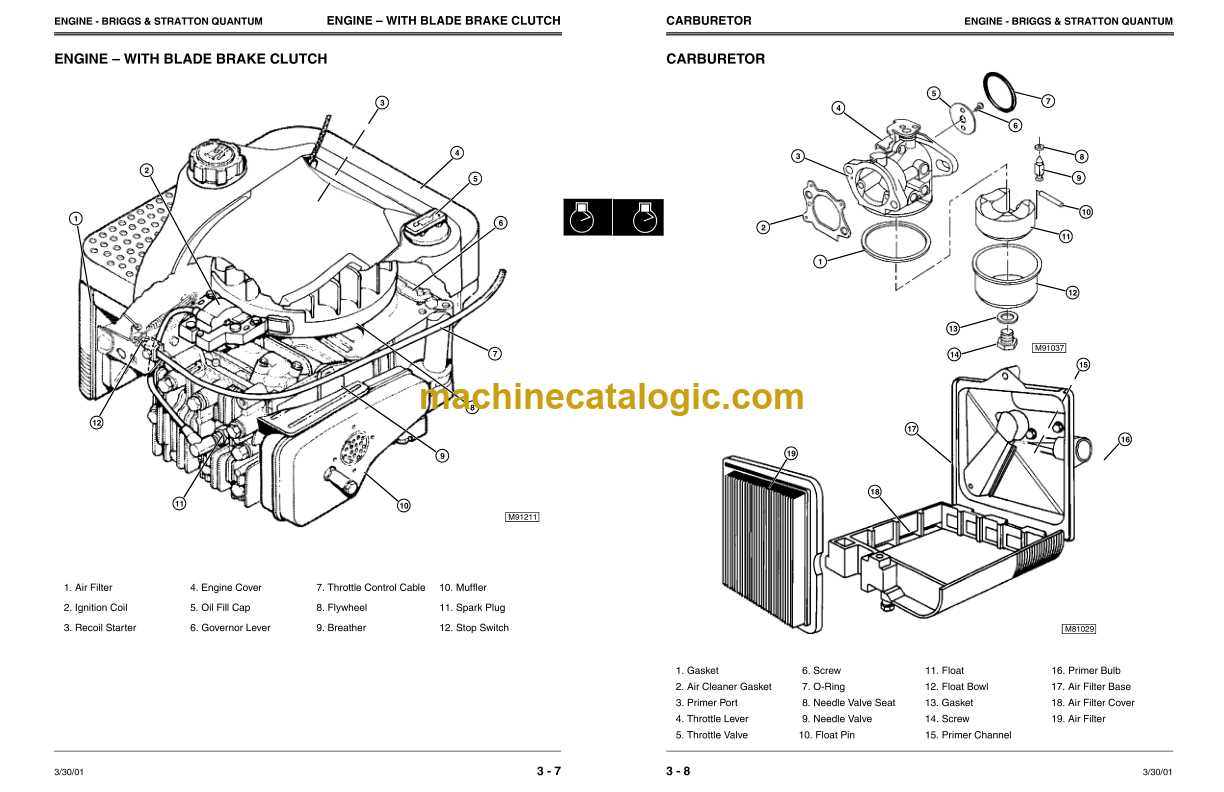

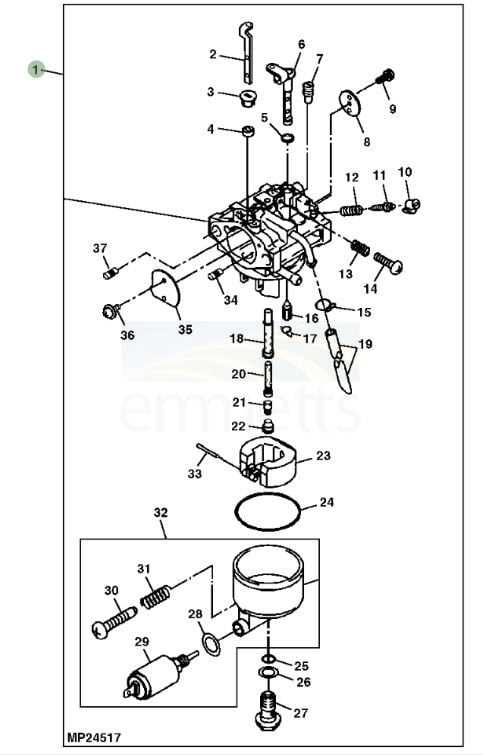

Overview of Key Components

This section focuses on essential elements that constitute the machinery, providing insights into their functions and interrelationships. Understanding these components is crucial for effective maintenance and optimal performance, ensuring that the equipment operates smoothly under various conditions.

Main Assembly Features

The primary assembly of the equipment includes several critical features that work together to deliver reliable operation. Each part plays a vital role, contributing to the overall efficiency and effectiveness of the machine.

| Component | Description |

|---|---|

| Engine | Provides the necessary power for operation, converting fuel into mechanical energy. |

| Transmission | Transfers power from the engine to the wheels, allowing for speed adjustments and directional changes. |

| Hydraulic System | Facilitates movement and operation of various attachments, utilizing fluid power for efficiency. |

| Chassis | The structural framework that supports all components and provides stability during operation. |

Operational Enhancements

Enhancements integrated into the machinery serve to improve functionality and ease of use. These upgrades can include advanced control systems and ergonomic designs, which contribute to better handling and efficiency.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as valuable tools, providing insights into the intricate relationships between various elements. By simplifying complex structures, these illustrations enable technicians to identify and address issues with confidence.

Enhanced Clarity: Visual aids significantly improve comprehension. They break down information into digestible parts, making it easier for users to locate specific elements. This clarity is essential for efficient troubleshooting and repairs, reducing the risk of errors.

Time Efficiency: Having a clear visual reference saves time during maintenance tasks. Technicians can quickly pinpoint the required components, leading to faster resolution of problems and minimizing downtime for the equipment.

Educational Resource: These visual guides also serve as educational tools. They help newcomers familiarize themselves with machinery layouts and components, promoting better understanding and skill development within the workforce.

Facilitating Communication: When discussing repairs or modifications, having a visual reference enhances communication among team members. It ensures everyone is on the same page, reducing misunderstandings and improving collaboration.

In summary, visual representations of machinery components play a vital role in maintenance and repair processes. They enhance clarity, save time, educate users, and facilitate effective communication, ultimately contributing to the longevity and efficiency of equipment.

Finding Genuine Replacement Parts

When it comes to maintaining machinery, sourcing authentic components is crucial for optimal performance and longevity. Using reliable replacements ensures that your equipment runs efficiently and reduces the risk of malfunctions. The market is flooded with various options, making it essential to identify the right sources for quality items.

Researching Trusted Suppliers is the first step in this process. Look for authorized dealers or manufacturers who offer guarantees on their products. This not only provides peace of mind but also ensures compatibility with your machine.

Understanding Specifications is equally important. Each model has unique requirements, and being informed about these can help you avoid potential issues. Referencing your machine’s manual can provide valuable insights into the exact specifications needed for effective replacements.

Lastly, reading reviews and seeking recommendations from fellow operators can guide you to reliable options. Feedback from others who have faced similar challenges can be invaluable in making informed choices.

Common Issues with JE75 Machinery

Equipment in this category often faces a range of challenges that can affect performance and efficiency. Understanding these common problems is essential for maintenance and troubleshooting, ensuring longevity and optimal operation.

Overheating is a frequent issue that can arise from inadequate cooling or blocked air vents. Regularly checking fluid levels and ensuring proper airflow can mitigate this problem.

Electrical Failures may occur due to worn-out wiring or poor connections. Inspecting the electrical system for signs of corrosion or damage is crucial to prevent sudden shutdowns.

Hydraulic Leaks can significantly impact functionality. Keeping an eye on hydraulic fluid levels and inspecting hoses for cracks will help in early detection and repair.

Mechanical Wear is another concern, often resulting from prolonged use. Regularly examining moving parts and replacing worn components is vital to maintain performance.

By being aware of these common issues, operators can take proactive steps to ensure their machinery runs smoothly and efficiently.

How to Use the Parts Diagram

Understanding the visual representation of components is crucial for efficient maintenance and repairs. A clear illustration helps users identify individual elements, ensuring accurate assembly and disassembly processes. By utilizing such a visual aid, you can streamline your workflow and minimize potential errors.

Identifying Components

The first step in utilizing this illustration is to familiarize yourself with each labeled section. By cross-referencing the numbers or letters indicated, you can easily locate specific items within the machinery. This knowledge is essential for ordering replacements or understanding the layout of your equipment.

Guided Assembly and Maintenance

Once you have a solid grasp of the individual components, the next phase involves following the guide for reassembly or maintenance tasks. This resource serves as a roadmap, allowing you to tackle repairs systematically. Paying close attention to the arrangement of parts can prevent mistakes and enhance overall functionality.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of essential components. By implementing a systematic approach, you can minimize downtime and maximize efficiency.

Regular Inspections

Frequent examinations are crucial for identifying potential issues before they escalate. Pay close attention to critical areas such as:

| Component | Inspection Frequency | Common Issues |

|---|---|---|

| Hydraulic System | Every 100 hours | Leaks, fluid quality |

| Engine | Every 50 hours | Oil levels, filters |

| Belts and Hoses | Every 200 hours | Cracks, wear |

Proper Lubrication

Lubrication is vital for reducing friction and wear on moving parts. Ensure you use the correct type of lubricant and follow the manufacturer’s guidelines for application intervals. This practice not only prevents overheating but also promotes smoother operation.

Identifying Part Numbers Efficiently

Efficiently pinpointing the correct component identifiers is crucial for maintaining and repairing machinery. A clear understanding of how to navigate various resources can significantly enhance your ability to find the necessary items without unnecessary delays.

Utilizing comprehensive resources such as catalogs and online databases can streamline the identification process. Familiarizing yourself with these tools will allow you to quickly cross-reference and verify the numbers you need.

| Step | Description |

|---|---|

| 1 | Gather all relevant documentation related to the equipment. |

| 2 | Use online resources to search for specific identifiers based on the equipment type. |

| 3 | Cross-reference found identifiers with existing records to ensure accuracy. |

| 4 | Consult with experts or customer service if discrepancies arise. |

By following these steps, you can enhance your efficiency in locating the correct component identifiers, ensuring smoother operations and maintenance tasks.

Comparing JE75 with Similar Models

This section explores the distinctions and similarities between the specified model and its counterparts in the same category. Understanding these variations can assist users in making informed decisions regarding performance, features, and overall value.

Performance Metrics

When evaluating performance, it is essential to consider engine output, efficiency, and operational capabilities. The analyzed unit showcases a robust power-to-weight ratio, making it suitable for a variety of tasks. In contrast, other models may offer different strengths, such as enhanced fuel efficiency or superior handling, appealing to specific user needs.

Features and Functionality

The highlighted equipment stands out due to its innovative features that enhance usability and comfort. Comparatively, similar models may include alternative functionalities or attachments that provide versatility in diverse applications. Users should assess which features align best with their requirements, ensuring optimal performance for their specific tasks.

Resources for DIY Repairs

Engaging in self-repair projects can be both fulfilling and cost-effective. By utilizing the right materials and references, individuals can confidently tackle various mechanical challenges. This section will provide a wealth of information to support those who prefer a hands-on approach to maintenance and restoration.

Online Communities: Numerous forums and social media groups exist where enthusiasts share their experiences, tips, and troubleshooting advice. Engaging with these communities can enhance your knowledge and provide solutions to common problems.

Instructional Videos: Platforms like YouTube host a vast array of tutorials that guide users through specific repair processes step by step. Visual aids can greatly simplify complex tasks and offer practical insights that written guides might overlook.

Manuals and Guides: Accessing comprehensive manuals and repair guides can prove invaluable. These documents often contain detailed schematics, assembly instructions, and maintenance schedules, ensuring that DIY enthusiasts have all the necessary information at their fingertips.

Specialized Retailers: Many stores offer parts and tools specifically tailored for various machines. These retailers often provide expert advice and recommendations, ensuring that you have the right equipment for your repair projects.

Local Workshops: Participating in hands-on workshops can enhance your skill set. Many community centers and technical schools offer classes that cover basic to advanced repair techniques, providing a great opportunity to learn from professionals.

With these resources at your disposal, embarking on DIY repairs can become an enjoyable and empowering journey.

Where to Buy JE75 Parts Online

Finding high-quality components for your equipment can be a challenge, especially when searching online. However, several reliable platforms specialize in offering a wide range of accessories and replacements that ensure your machinery operates smoothly. This section outlines the best options for sourcing these essential items from the comfort of your home.

| Website | Description |

|---|---|

| OEM Parts Store | This site provides original manufacturer components, ensuring perfect compatibility and durability for your machine. |

| Aftermarket Supplier | Offering a variety of alternatives at competitive prices, this option can be ideal for budget-conscious users looking for reliable substitutes. |

| Local Dealer Website | Many local distributors have online catalogs, allowing you to order directly and often providing regional expertise on the best solutions. |

| E-commerce Platforms | Popular online marketplaces feature a wide selection from various sellers, making it easy to compare prices and find what you need. |

When purchasing online, ensure that you verify the credibility of the seller and check customer reviews. This diligence will help you make informed decisions and secure the best items for your equipment.