Understanding the Blower Motor Parts Diagram

In the realm of climate control and air distribution, grasping the inner workings of essential components is crucial. These mechanisms play a pivotal role in ensuring optimal airflow, maintaining comfort within various environments. An insightful exploration of these elements reveals their interconnectivity and functionality, which ultimately contributes to the overall efficiency of the system.

Delving deeper into the specifics, we can uncover the various sections that contribute to the effective movement of air. Each element, from the source of propulsion to the intricate network of connections, serves a distinct purpose. By visualizing these components, one can appreciate how they collaboratively function to enhance air circulation and regulate temperature.

Understanding these systems not only aids in troubleshooting and maintenance but also empowers individuals to make informed decisions regarding their performance. A comprehensive grasp of these elements equips users with the knowledge necessary to optimize their environment, ensuring both comfort and efficiency.

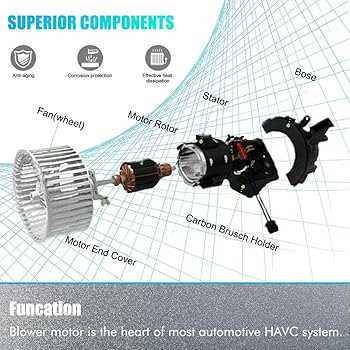

Understanding Blower Motor Components

In the realm of heating and cooling systems, various elements work together to ensure optimal airflow and temperature regulation. Each component plays a crucial role, contributing to the overall efficiency and functionality of the system. Gaining insight into these essential elements can enhance both performance and maintenance practices.

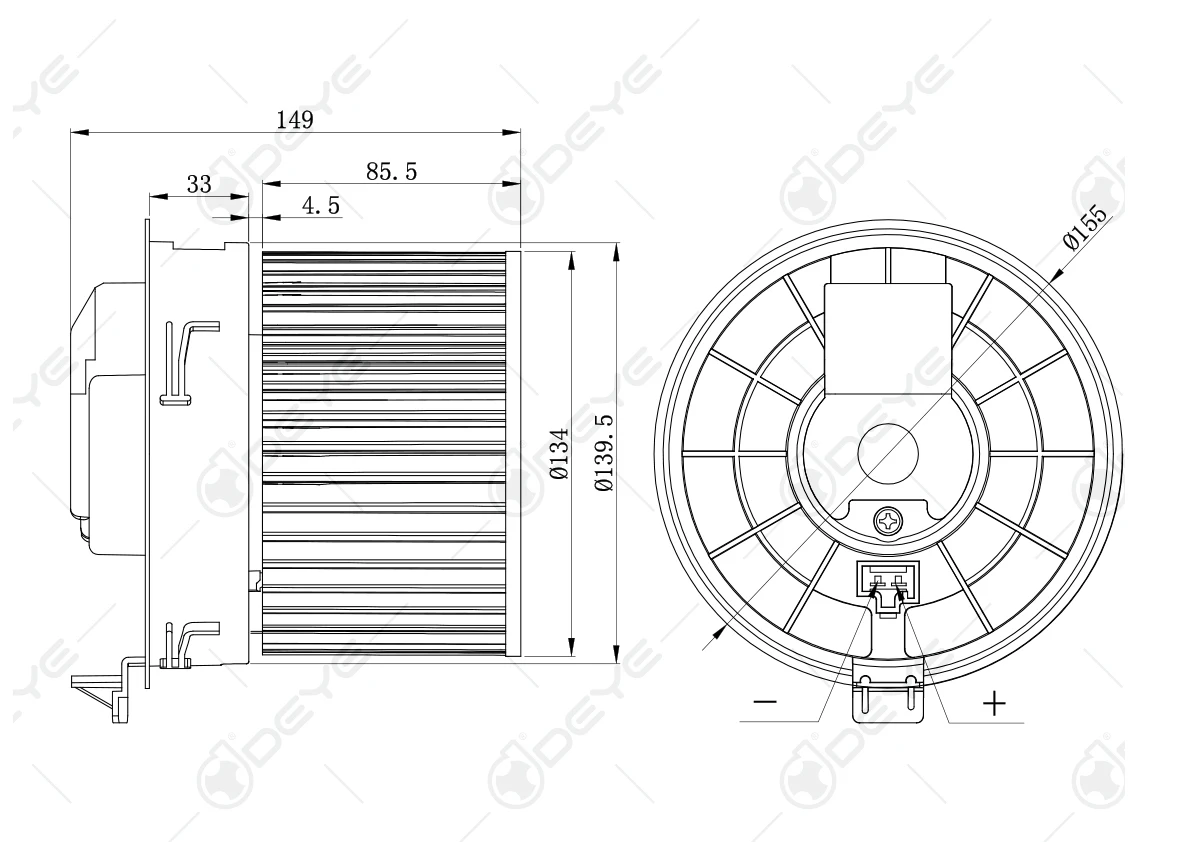

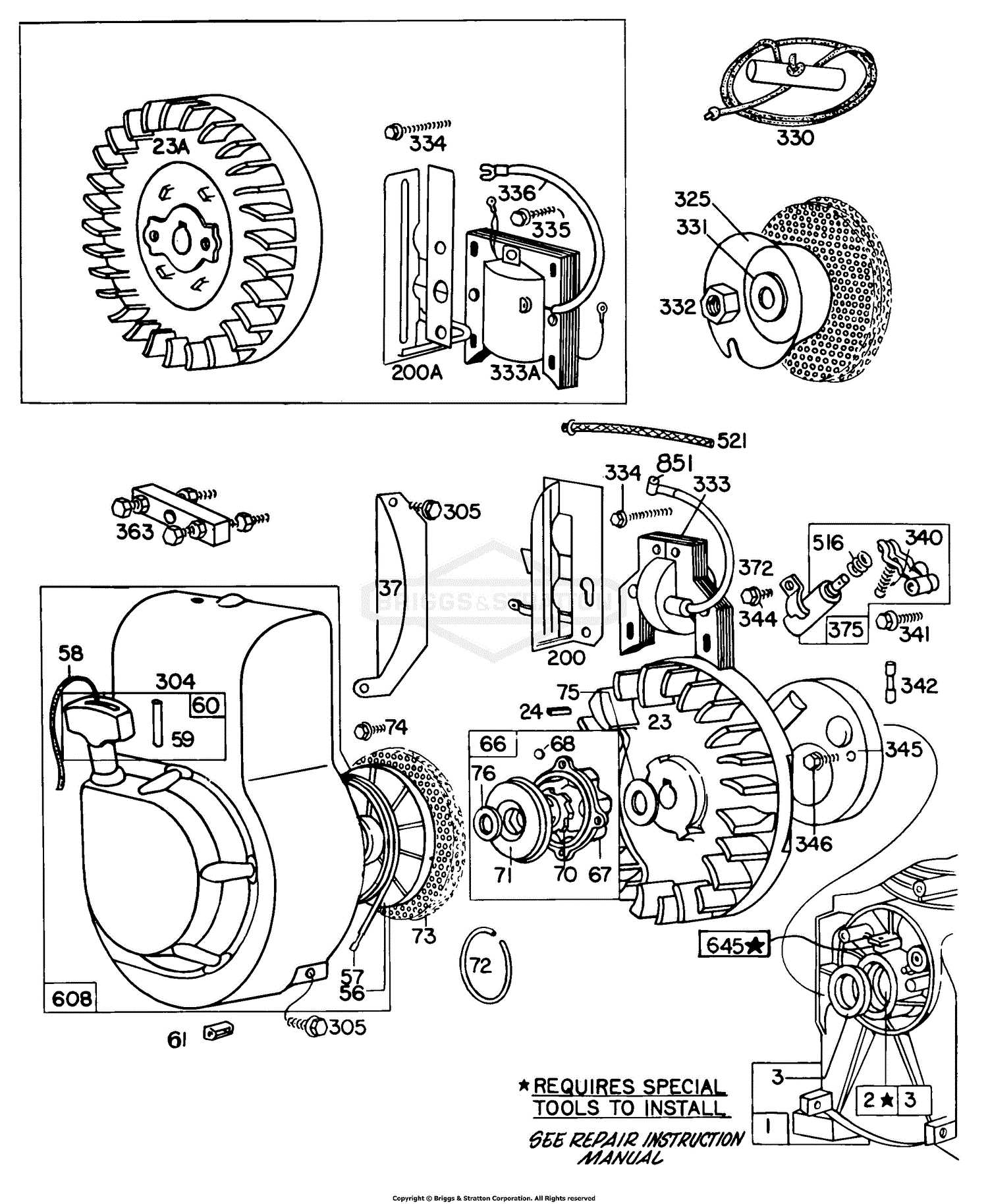

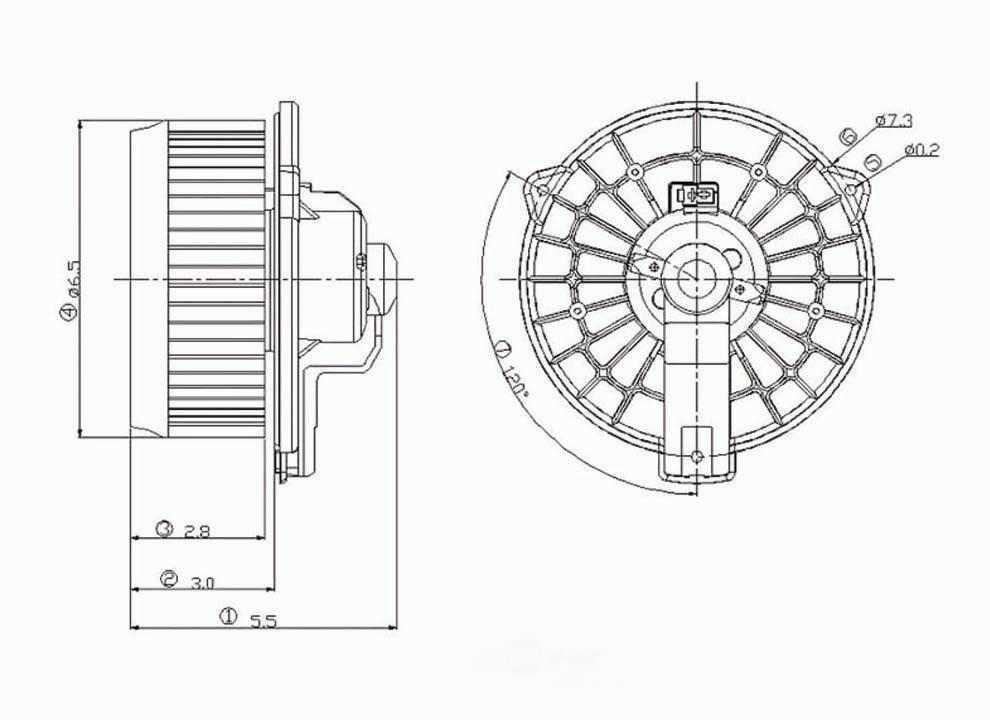

Core Elements: At the heart of the system lies a critical unit responsible for driving air through ducts and into living spaces. This unit often consists of a housing that protects its internal components, ensuring durability and longevity. Inside, one can find a rotor that spins to create airflow, combined with blades designed for maximum efficiency.

Power Source: The operation of this assembly relies heavily on electrical input. An effective energy supply is vital for the rotation of the rotor, and various connectors facilitate this electrical flow. A reliable power source ensures that the entire system functions smoothly, responding promptly to temperature adjustments.

Control Mechanisms: To maintain desired conditions, control systems regulate the speed and operation of the airflow unit. These mechanisms can include thermostats and variable speed drives, which allow for precise adjustments based on the environment’s needs. Proper calibration of these controls is essential for achieving energy efficiency.

Maintenance Considerations: Regular upkeep of each component can significantly impact performance. Dust accumulation can hinder airflow, while wear and tear on moving parts can lead to inefficiencies. Ensuring that all elements are clean and well-maintained will prolong the lifespan of the entire assembly and enhance its operational capabilities.

Understanding these integral components provides a clearer picture of how airflow systems function. By recognizing their roles and the importance of regular maintenance, one can ensure optimal performance and energy efficiency in any climate control system.

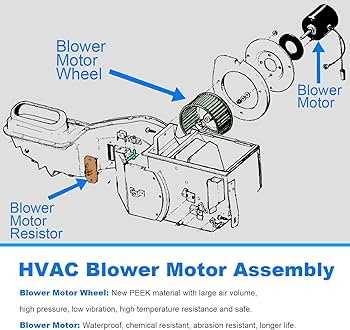

Function of the Blower Motor

The primary role of this essential component is to circulate air within a system, ensuring optimal performance and comfort. By facilitating airflow, it helps in regulating temperatures and maintaining a pleasant environment in various applications, including vehicles and HVAC systems.

Air Circulation

This device plays a critical role in moving air efficiently. It draws in ambient air, mixes it with heated or cooled air, and distributes it throughout the designated space. The effective circulation of air prevents hotspots and cold areas, enhancing overall comfort for occupants.

Temperature Regulation

Another vital function involves managing temperature levels. By adjusting the airflow rate, it contributes to maintaining the desired climate, whether it’s cooling during hot weather or heating in colder conditions. This functionality not only improves comfort but also supports energy efficiency by reducing the load on other components in the system.

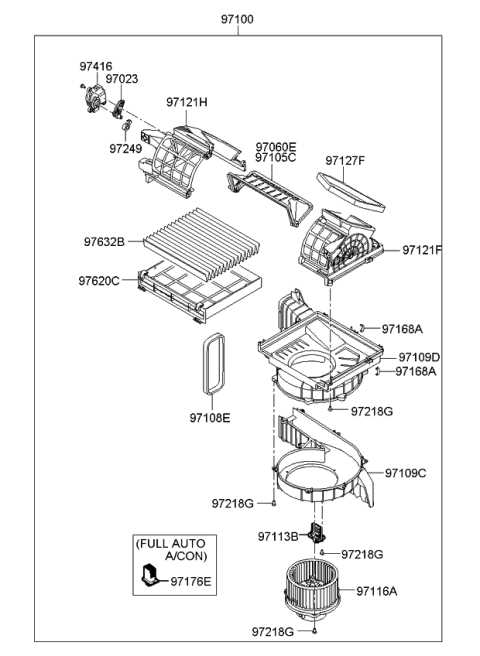

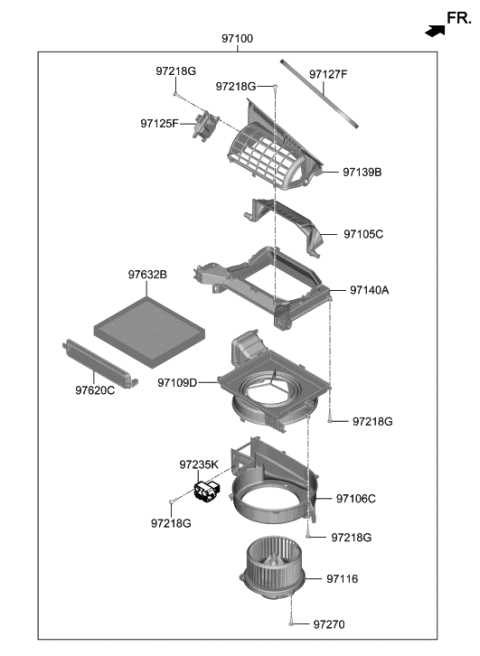

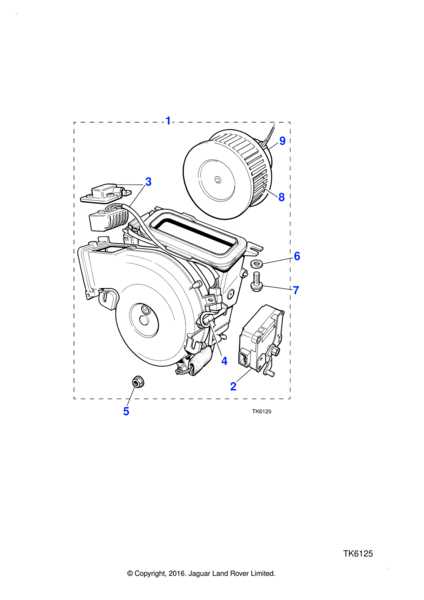

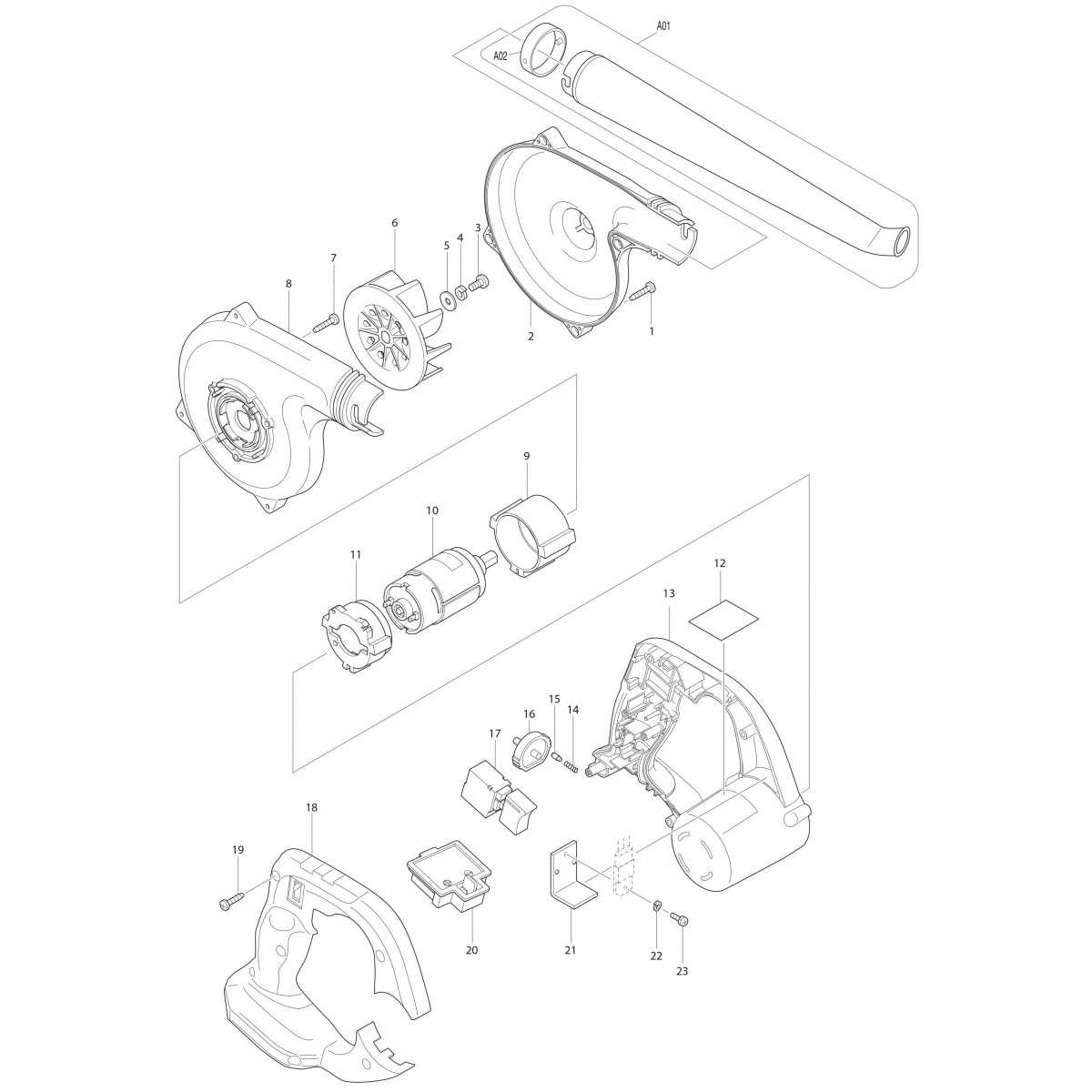

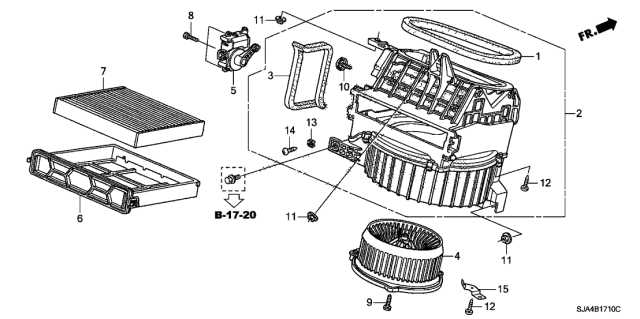

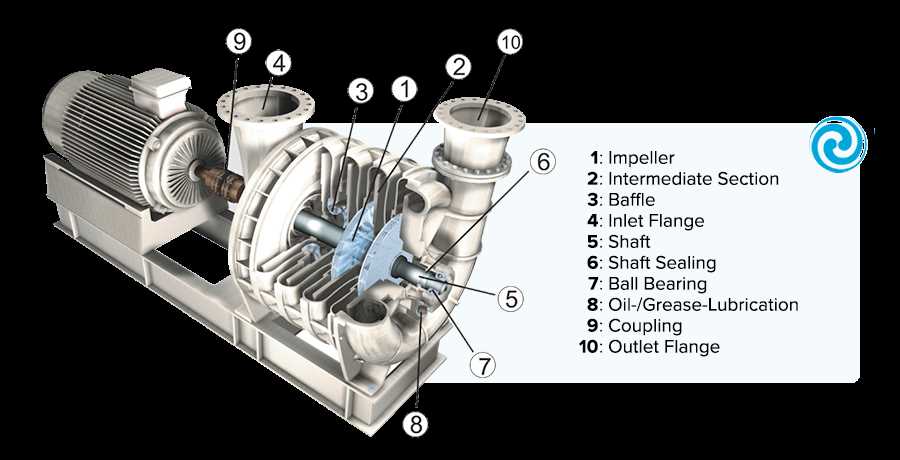

Key Parts of the System

The functionality of a ventilation mechanism relies on several crucial components that work together seamlessly. Each element plays a significant role in ensuring efficient air circulation, contributing to overall system performance and reliability.

1. Housing: This structure encases the entire assembly, providing protection and support. It is designed to withstand environmental factors while allowing for optimal airflow.

2. Impeller: Serving as the driving force, this component moves air through the system. Its design and material directly influence the efficiency and effectiveness of air movement.

3. Shaft: This rod connects the impeller to the power source, facilitating motion. The quality and alignment of the shaft are essential for reducing wear and ensuring smooth operation.

4. Bearings: These components support the rotating shaft, minimizing friction and wear. Proper maintenance of the bearings is critical for prolonging the lifespan of the assembly.

5. Electrical Connections: The wiring and connectors are vital for providing power to the mechanism. Secure and reliable connections are necessary to prevent disruptions in performance.

6. Control Module: This system manages the operation, allowing for adjustments in speed and functionality based on user requirements. A responsive control module enhances the overall efficiency of the setup.

Electrical Connections Explained

Understanding how electrical components interact is crucial for maintaining optimal performance in various systems. This section delves into the intricate web of connections that facilitate power distribution and functionality.

Connections are essential for ensuring that electricity flows seamlessly between components. Each link serves a specific purpose, contributing to the overall efficiency of the setup.

- Wiring Types:

- Copper: Known for its excellent conductivity.

- Aluminum: Lightweight and cost-effective, though less conductive than copper.

- Connection Methods:

- Soldering: A permanent connection that provides stability.

- Crimping: A reliable method that allows for easy disconnection.

- Plug-in: Facilitates quick and simple assembly or disassembly.

- Types of Connectors:

- Spade Connectors: Ideal for quick connections.

- Ring Terminals: Provide a secure and stable connection.

- Wire Nuts: Commonly used for joining multiple wires.

Understanding the nuances of these connections helps in troubleshooting and improving the reliability of electrical systems. Proper maintenance ensures longevity and optimal operation.

Common Issues with Blower Motors

Understanding the typical challenges that can arise in ventilation systems is essential for maintaining optimal performance. These issues often lead to inefficiencies and can affect the overall comfort and air quality in a space. Below are some frequently encountered problems and their potential causes.

- No Airflow:

This issue can occur due to several reasons:

- Clogged filters

- Obstructed ducts

- Faulty electrical connections

- Unusual Noises:

Strange sounds can indicate mechanical failures, such as:

- Worn bearings

- Loose components

- Debris interference

- Inconsistent Temperature:

Fluctuations in temperature may arise from:

- Malfunctioning sensors

- Improper calibration

- Insufficient airflow due to blockages

- Excessive Heat:

Overheating can be a sign of:

- Overworked components

- Inadequate lubrication

- Electrical issues

Regular maintenance and timely inspections can help identify these issues early, ensuring the system operates efficiently and prolonging its lifespan.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires a proactive approach to care and upkeep. By following essential maintenance practices, you can enhance performance and avoid premature wear. This section highlights key strategies that contribute to durability and reliability.

Regular Inspections

Routine assessments can help identify potential issues before they escalate. Look for signs of wear, unusual noises, or irregular operation. Timely intervention can save both time and resources.

Cleaning and Lubrication

Keeping components clean and well-lubricated is crucial for optimal functioning. Dust and debris can hinder performance, while proper lubrication reduces friction and wear. Schedule regular cleaning sessions and apply suitable lubricants as needed.

| Task | Frequency | Benefits |

|---|---|---|

| Visual Inspection | Monthly | Early detection of issues |

| Cleaning | Every 3 months | Enhanced airflow and efficiency |

| Lubrication | Biannually | Reduced wear and noise |

How to Identify Faulty Components

Recognizing defective elements within a system is crucial for maintaining efficiency and ensuring longevity. A systematic approach to diagnosis can help pinpoint issues before they escalate, thereby minimizing downtime and repair costs. This section outlines key indicators and methods for identifying malfunctioning components.

Start by observing any irregularities in performance. Symptoms such as unusual noises, overheating, or inconsistent operation can suggest underlying problems. Additionally, visual inspections can reveal signs of wear or damage, such as cracks or corrosion. For a more thorough assessment, utilizing diagnostic tools can provide valuable insights into the functionality of each element.

| Indicator | Description | Possible Cause |

|---|---|---|

| Unusual Noises | Grinding, squealing, or rattling sounds | Worn bearings or loose connections |

| Overheating | Excessive heat generation | Electrical overload or inadequate airflow |

| Inconsistent Operation | Fluctuating speeds or failures to start | Faulty controls or electrical issues |

| Visible Damage | Cracks, burns, or corrosion | Environmental exposure or age-related deterioration |

In conclusion, a proactive approach in identifying defective components will not only enhance performance but also extend the lifespan of the entire system. Regular maintenance and timely diagnostics play a significant role in achieving optimal functionality.

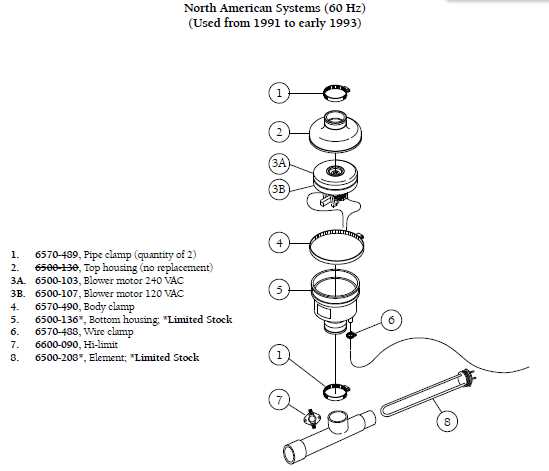

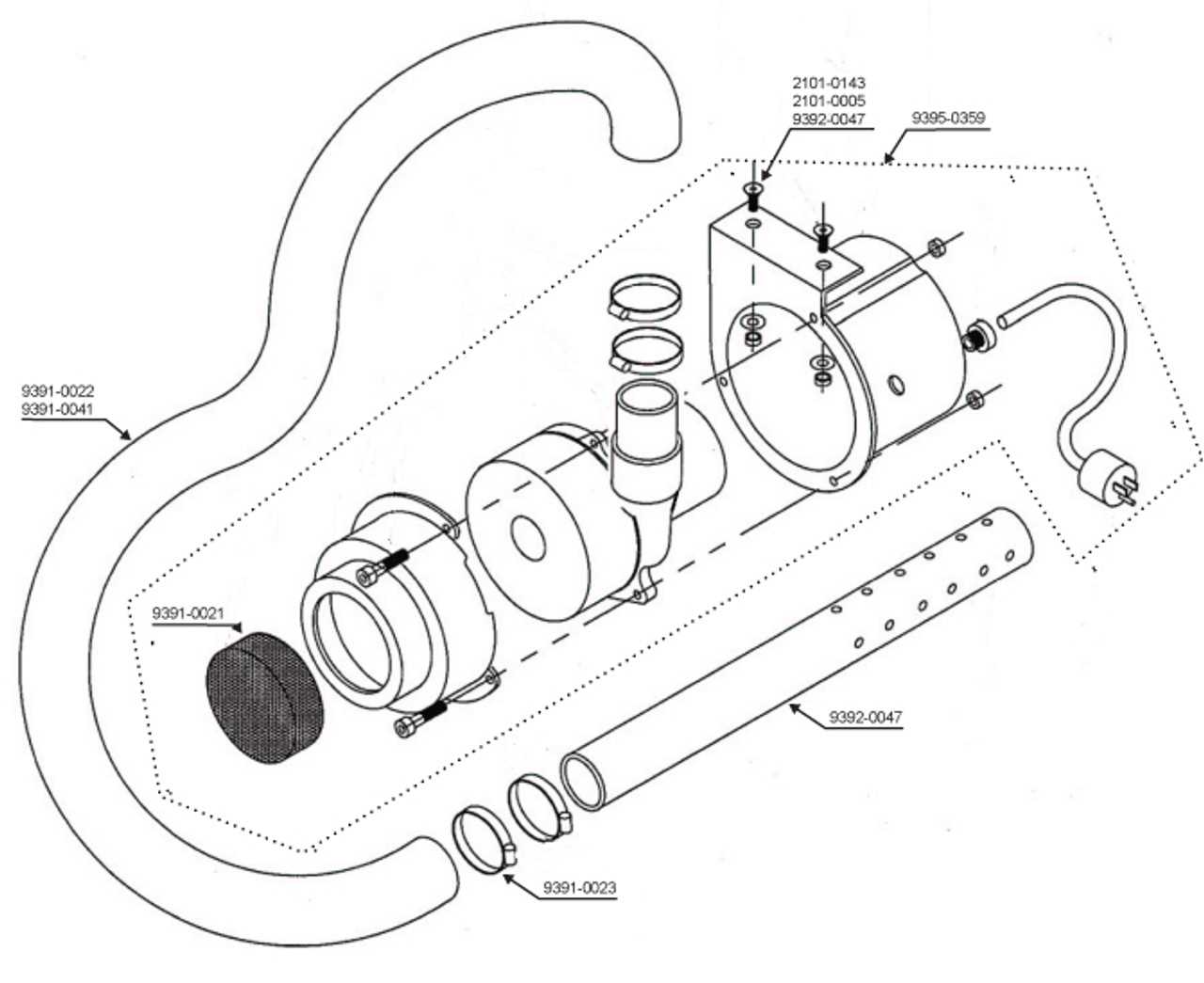

Step-by-Step Replacement Guide

This guide provides a clear and concise approach for replacing the essential components of your heating and cooling system. Following these steps will help ensure a successful installation, allowing for optimal performance and longevity.

Before beginning, gather all necessary tools and materials to streamline the process. It’s crucial to follow safety precautions to avoid any hazards.

| Step | Action |

|---|---|

| 1 | Turn off the power supply to the unit to prevent any electrical hazards. |

| 2 | Remove the access panel to gain entry to the internal components. |

| 3 | Carefully disconnect any electrical connections attached to the unit. |

| 4 | Remove the existing component by unscrewing or unclipping it from its housing. |

| 5 | Install the new component by aligning it properly and securing it in place. |

| 6 | Reconnect all electrical connections, ensuring they are secure. |

| 7 | Replace the access panel and restore power to the unit. |

| 8 | Test the system to confirm that the replacement was successful and everything is functioning correctly. |

By adhering to this structured approach, you can confidently replace the necessary components, enhancing the efficiency of your system.

Tools Needed for Repair Work

Effective repair tasks require a selection of essential instruments to ensure efficiency and precision. Having the right equipment not only streamlines the process but also enhances the quality of the outcomes. Below is a compilation of the fundamental tools that should be part of any repair toolkit.

- Wrenches: Various sizes for loosening and tightening fasteners.

- Screwdrivers: Both flat-head and Phillips for different types of screws.

- Pliers: Useful for gripping, twisting, and cutting wires.

- Socket Set: Essential for reaching nuts and bolts in tight spaces.

- Utility Knife: Handy for cutting through various materials.

In addition to these primary tools, a few specialized items may also be beneficial:

- Multimeter: For testing electrical components and circuits.

- Torque Wrench: To ensure fasteners are tightened to specified settings.

- Heat Gun: Useful for softening materials or removing adhesive.

- Work Light: To illuminate the workspace for better visibility.

By equipping yourself with these tools, you will be well-prepared to tackle various repair challenges efficiently and effectively.

Safety Precautions to Follow

When working with mechanical systems, it is essential to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks and ensure a secure working environment.

Here are some vital precautions to consider:

- Always disconnect power before starting any maintenance or repairs.

- Wear appropriate personal protective equipment, such as gloves, goggles, and masks.

- Ensure that your workspace is clean and organized to avoid tripping hazards.

Furthermore, consider these additional recommendations:

- Read the manufacturer’s instructions thoroughly before beginning any work.

- Never bypass safety features or warnings installed on the equipment.

- Keep all tools in good condition and store them safely after use.

- Be aware of your surroundings and avoid distractions while working.

By following these safety measures, you can create a safer environment and minimize the likelihood of incidents during your tasks.

Differences Between Motor Types

Understanding the distinctions among various types of drive systems is crucial for effective application and maintenance. Each variety possesses unique characteristics that cater to specific operational needs, impacting efficiency, performance, and longevity. Recognizing these differences allows users to select the most suitable option for their requirements.

Types of Drive Systems

There are several categories of drive systems, including AC and DC variants. AC systems are commonly known for their simplicity and reliability, often utilized in stationary applications. In contrast, DC systems offer better control over speed and torque, making them ideal for portable and variable-load scenarios. The choice between these types can significantly influence overall system functionality.

Efficiency and Performance

The efficiency of these systems varies greatly based on their design and application. For instance, AC variants generally operate at higher efficiency levels, particularly in fixed-speed applications, while DC counterparts excel in environments requiring variable speed. Additionally, the performance metrics, such as response time and heat generation, differ based on the underlying technology used in each type.

Resources for Further Learning

Expanding your knowledge on mechanical components and their functionalities can enhance your understanding of various systems. This section provides valuable materials that will aid in deepening your expertise and practical skills.

-

Books:

- “Automotive Technology: A Systems Approach” by Jack Erjavec

- “Understanding Automotive Electronics” by William B. Ribbens

- “The Art of Electronics” by Paul Horowitz and Winfield Hill

-

Online Courses:

-

Websites:

-

YouTube Channels:

Utilizing these resources will provide a comprehensive foundation for mastering the intricacies of mechanical systems and their operation.