Understanding the Columbia Snow Blower Parts Diagram for Efficient Repairs

When it comes to maintaining outdoor machinery, a comprehensive grasp of its various elements is essential. This knowledge not only facilitates efficient repairs but also enhances the overall lifespan of the equipment. Familiarizing oneself with the intricate layout of these components can empower users to troubleshoot issues with confidence.

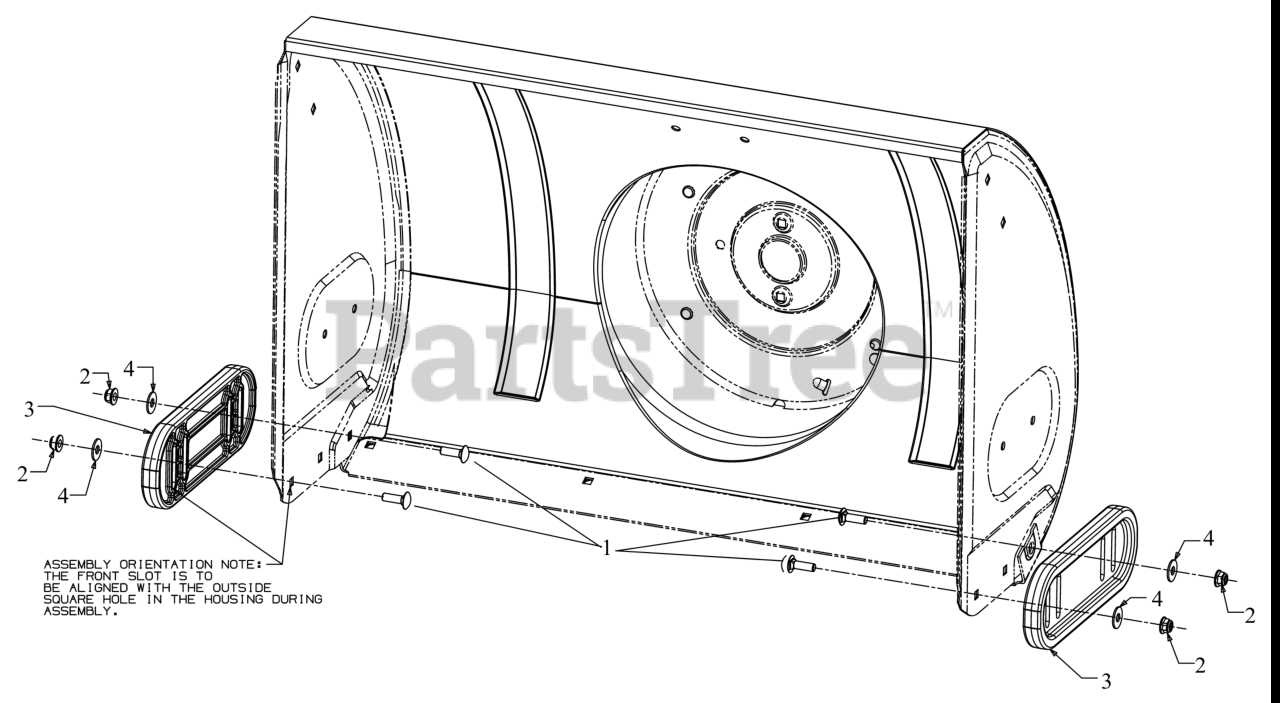

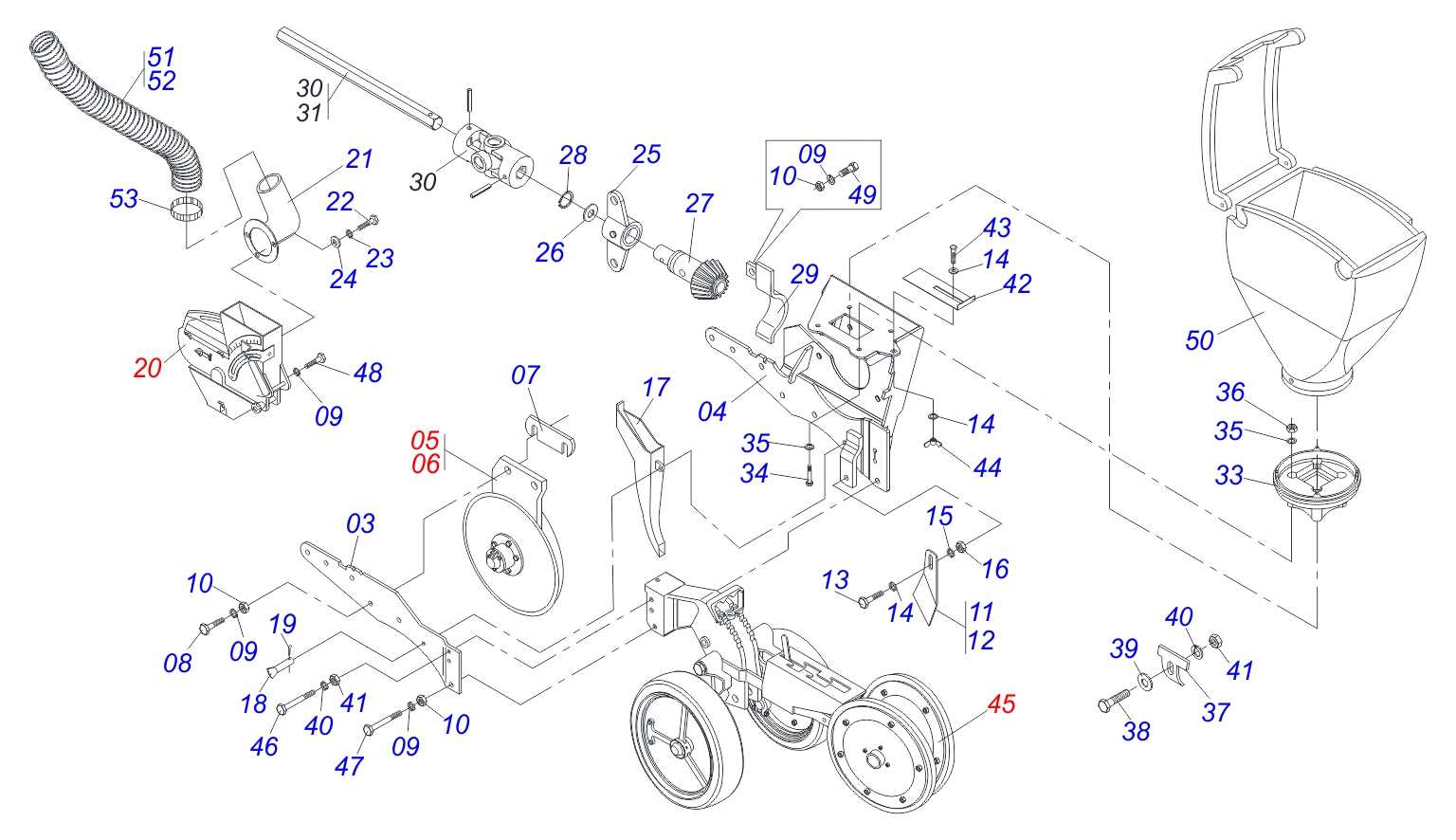

Visual representations of mechanical assemblies serve as invaluable tools for both novice and experienced operators. They illustrate the interconnectedness of each segment, providing clarity on how they work together to achieve optimal performance. By dissecting these visuals, one can easily identify potential wear and tear, ensuring timely interventions before minor issues escalate into major malfunctions.

In the realm of maintenance, having access to precise and detailed layouts is crucial. They not only guide repair efforts but also foster a deeper understanding of the machinery’s operation. This insight can lead to more informed decisions regarding upgrades and replacements, ultimately contributing to a smoother and more efficient experience in managing outdoor tasks.

Understanding Columbia Snow Blowers

Efficient equipment for managing winter weather can make a significant difference in maintaining safe and accessible spaces. Familiarity with these machines enhances their operation and prolongs their lifespan. Knowledge about their components and functionality is crucial for both novice and experienced users.

| Component | Function |

|---|---|

| Engine | Powers the entire unit, providing the necessary force to operate effectively. |

| Auger | Breaks up and collects the material, facilitating smooth discharge. |

| Chute | Directs the flow of the expelled material, allowing for precise placement. |

| Controls | Enables the operator to adjust settings and maneuver the machine easily. |

| Frame | Provides structural integrity and stability during operation. |

Understanding these elements ensures optimal use and maintenance, ultimately leading to effective performance in challenging weather conditions.

Overview of Snow Blower Components

This section provides a comprehensive look at the essential elements that contribute to the effective operation of a winter clearing machine. Understanding these components is crucial for maintenance and troubleshooting.

Main Elements

- Engine: Powers the entire mechanism, providing necessary force.

- Auger: Collects and moves the frozen precipitation toward the discharge chute.

- Discharge Chute: Directs the expelled material away from the clearing area.

- Impeller: Assists in propelling the collected material out of the chute.

Support Systems

- Frame: The structural backbone, ensuring stability and durability.

- Skids: Control the height above the ground, preventing damage to surfaces.

- Controls: Allow the operator to manage speed and direction with ease.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and maintenance of machinery. They provide a clear overview of individual elements, ensuring that users can easily identify and locate each section. This clarity is essential for effective troubleshooting and repairs, enabling users to maintain optimal performance and prolong the lifespan of their equipment.

Additionally, such illustrations facilitate communication between manufacturers and users. When a breakdown occurs, having a detailed visual reference simplifies the process of ordering replacements and ensures that the correct items are obtained swiftly. This efficiency minimizes downtime and enhances user satisfaction.

Moreover, these visual aids support educational efforts, helping individuals learn about the functionality and interaction of various components. They serve as valuable tools for both novices and experienced operators, fostering a deeper understanding of the machinery and its operational principles.

Common Issues with Snow Blower Parts

When operating a winter machine, various challenges can arise, affecting its efficiency and performance. Understanding these common difficulties can help users identify problems early and ensure smooth operation during harsh weather conditions.

Wear and Tear: Over time, components may experience degradation due to regular use. Signs of wear often include decreased performance and unusual noises. Regular inspections can help catch these issues before they escalate.

Blockages: Accumulations of ice and debris can hinder functionality, leading to frustrating stoppages. Clearing these obstructions promptly is crucial to maintaining optimal operation.

Fuel System Issues: Problems within the fuel delivery system can manifest as starting difficulties or poor performance. Keeping the fuel system clean and well-maintained can prevent these inconveniences.

Electrical Failures: Electrical components may fail, causing issues such as ignition troubles or malfunctioning controls. Regular checks can ensure that wiring and connections remain intact and functional.

Improper Maintenance: Neglecting routine maintenance can lead to a host of problems. Regular cleaning, lubrication, and part replacement are essential to prolong the life of the equipment.

By being aware of these typical concerns, operators can take proactive measures to address them, ensuring reliable performance even in the most challenging conditions.

How to Read Parts Diagrams

Understanding technical illustrations can significantly enhance your ability to service machinery effectively. These visual representations break down components and their relationships, making it easier to identify what you need for maintenance or repair tasks.

To navigate these illustrations successfully, consider the following key points:

- Familiarize Yourself with Symbols: Each component often has a specific symbol or label. Take time to learn what these mean.

- Check the Key: Most visuals include a key or legend that clarifies what each part is. This will help you avoid confusion.

- Follow the Flow: Diagrams usually present parts in a logical sequence. Following this can aid in understanding how everything fits together.

- Pay Attention to Numbers: Parts are often numbered for easy reference. Make sure to match these numbers to the parts list for accuracy.

By keeping these tips in mind, you can more effectively interpret technical illustrations and ensure that your maintenance tasks are completed correctly and efficiently.

Identifying Parts for Replacement

Understanding the components of your machine is crucial for effective maintenance and ensuring optimal performance. When a particular element fails, recognizing it among various options can streamline the repair process.

To assist in identifying the necessary components, consider the following steps:

- Refer to the user manual for specific part names and descriptions.

- Examine the machine closely for any visible damage or wear.

- Take note of any numbers or labels on components that may indicate their model or type.

Additionally, familiarizing yourself with common elements can be beneficial:

- Engines and their essential mechanisms

- Chassis and structural supports

- Control systems and their functionalities

- Transmission elements

Utilizing these strategies will enhance your ability to find suitable replacements effectively.

Where to Find Columbia Parts Diagrams

Locating schematics for equipment components can significantly simplify maintenance and repair tasks. Understanding the layout of various elements not only enhances the efficiency of service but also aids in troubleshooting. There are several reliable sources where these valuable resources can be accessed.

Online Resources

- Manufacturer’s Website: Many companies provide official documentation directly on their websites. Searching the support or resources section can yield precise drawings and manuals.

- Parts Retailers: Online retailers often host a variety of schematics for the products they sell, making it easier to find necessary illustrations.

- Forums and Community Groups: Engaging with online communities can lead to shared resources, including diagrams and repair tips from experienced users.

Physical Locations

- Local Dealers: Authorized dealers typically maintain archives of technical documentation and can provide assistance in finding specific schematics.

- Repair Shops: Professional repair services often have access to comprehensive manuals and diagrams, offering guidance or copies upon request.

Maintenance Tips for Snow Blowers

Proper upkeep of your winter equipment is essential for optimal performance and longevity. Regular maintenance not only ensures reliable operation but also helps prevent unexpected breakdowns during critical times. Implementing a consistent care routine can enhance efficiency and save you from costly repairs.

1. Regular Inspection: Frequently check your machine for any signs of wear or damage. Inspect belts, cables, and other components to ensure they are functioning correctly. Address any issues immediately to prevent further complications.

2. Clean After Use: After each session, clear any accumulated debris and ice. This practice prevents rust and corrosion, which can shorten the life of your equipment.

3. Oil Changes: Just like any machinery, changing the oil at regular intervals is vital. Follow the manufacturer’s recommendations for oil type and frequency to maintain engine health.

4. Fuel Quality: Use high-quality fuel and consider adding a fuel stabilizer, especially if the equipment will sit unused for long periods. This helps prevent gumming and clogging of the fuel system.

5. Check the Blades: Inspect and sharpen the cutting edges as needed. Dull blades can hinder performance and lead to additional strain on the engine.

6. Storage Practices: Store your equipment in a dry, sheltered area to protect it from the elements. Covering it with a tarp or using a dedicated storage space can help prevent moisture buildup.

By following these tips, you can ensure that your winter machinery operates efficiently and lasts through many seasons to come.

Safety Precautions When Repairing

Ensuring a safe environment during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions not only protect the individual but also extend the lifespan of the equipment being serviced. Understanding and following safety measures can significantly reduce risks associated with mechanical repairs.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear. Protective gear is essential to guard against sharp objects, flying debris, and other hazards that may arise during repairs. Additionally, ensure that your work area is well-lit and organized to minimize tripping or falling.

Proper Tool Handling

Familiarize yourself with the tools you are using, and always handle them with care. Using tools incorrectly can lead to serious injuries. Make sure to keep tools in good condition and store them safely when not in use. Moreover, always disconnect the power source before starting any maintenance to avoid unexpected activation.

Comparing Columbia with Other Brands

In the competitive landscape of winter equipment, evaluating various manufacturers reveals key distinctions in performance, durability, and technology. Each brand offers unique features that cater to different user needs and preferences, making it essential to analyze what sets them apart.

When assessing quality, some brands emphasize robust construction and longevity, while others focus on innovative functionalities that enhance user experience. Understanding these differences can guide consumers in making informed decisions.

Price points also vary significantly; certain brands may offer budget-friendly options without compromising basic functionality, whereas others justify higher costs with advanced engineering and superior materials. Ultimately, identifying the best fit requires a thorough examination of individual requirements and priorities.

Upgrading Snow Blower Components

Enhancing the efficiency and performance of your winter equipment can lead to a smoother experience during harsh conditions. By replacing or improving specific elements, you can ensure better functionality and longevity. This section explores various components that can be upgraded for optimal results.

Here are some key areas to consider for enhancement:

- Engine Performance: Upgrading to a more powerful engine can provide increased efficiency and speed.

- Impeller Design: A high-performance impeller can improve the throw distance and reduce clogging.

- Skid Shoes: Opting for durable skid shoes can protect your surfaces while enhancing maneuverability.

- Auger Blades: Sharp, robust blades can improve cutting efficiency and reduce wear and tear.

- Drive System: A more advanced drive system can enhance traction and handling in slippery conditions.

When planning upgrades, consider the compatibility of new components with your existing machinery. Investing in quality materials and parts will yield better performance and reliability, ensuring your equipment remains effective through the winter months.

Resources for DIY Repairs

Engaging in home repairs can be a rewarding experience, providing an opportunity to enhance skills while saving costs. Having access to the right resources is crucial for successfully tackling projects, ensuring that each task is completed efficiently and effectively.

Online Forums and Communities

Participating in online communities allows enthusiasts to exchange tips, ask questions, and share experiences. Websites dedicated to repair discussions can offer valuable insights and troubleshooting advice from seasoned users, fostering a collaborative environment.

Instructional Videos and Tutorials

Visual guides can significantly ease the learning curve associated with repairs. Platforms like video-sharing sites host a plethora of tutorials that walk users through various procedures step-by-step. These resources not only clarify the process but also provide practical examples that can enhance understanding.

Additional resources, such as user manuals and maintenance guides, can further assist in making informed decisions and ensuring that repairs are conducted safely and correctly. Always remember to stay organized and document each step to facilitate future projects.