Massimo Snow Blower Parts Layout Overview

When it comes to maintaining your outdoor machinery, a thorough grasp of its individual elements is crucial. Each component plays a significant role in ensuring optimal functionality and longevity of the entire system. By familiarizing yourself with these parts, you can not only enhance performance but also simplify the repair process when issues arise.

In this guide, we will explore the intricate layout of essential elements that comprise your equipment. We will break down the functionality and interconnection of each piece, providing clarity on how they work together to achieve efficient operation. This knowledge empowers users to diagnose problems and implement effective solutions with confidence.

Moreover, understanding the structure of your machinery can lead to better decision-making when it comes to upgrades and replacements. Armed with this information, you’ll be well-prepared to tackle any maintenance challenges and keep your equipment in prime condition throughout the seasons.

Understanding Massimo Snow Blower Parts

When tackling the challenges of winter weather, having a reliable machine is essential. Familiarity with the individual components of this equipment enhances its performance and ensures efficient operation. By grasping the roles of various elements, users can maintain their machinery better and troubleshoot issues effectively.

Key Components and Their Functions

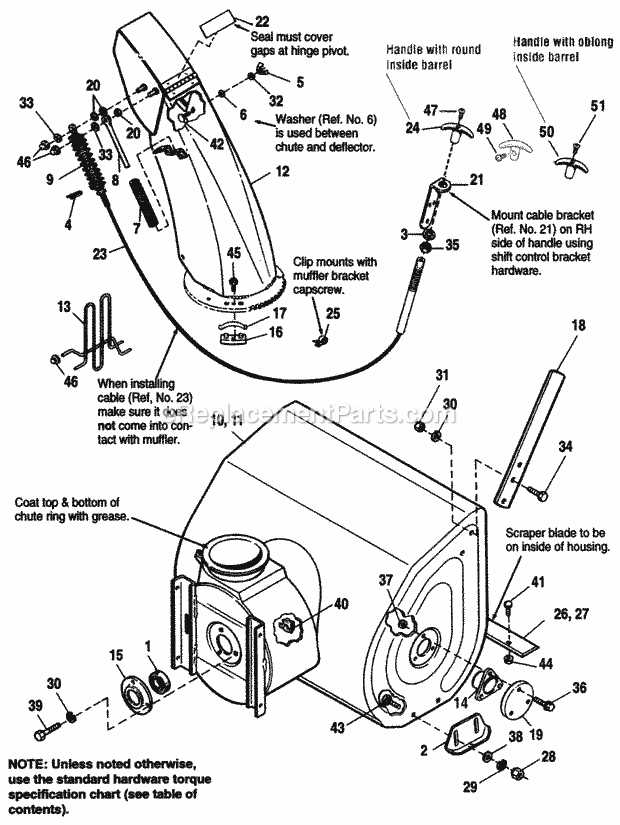

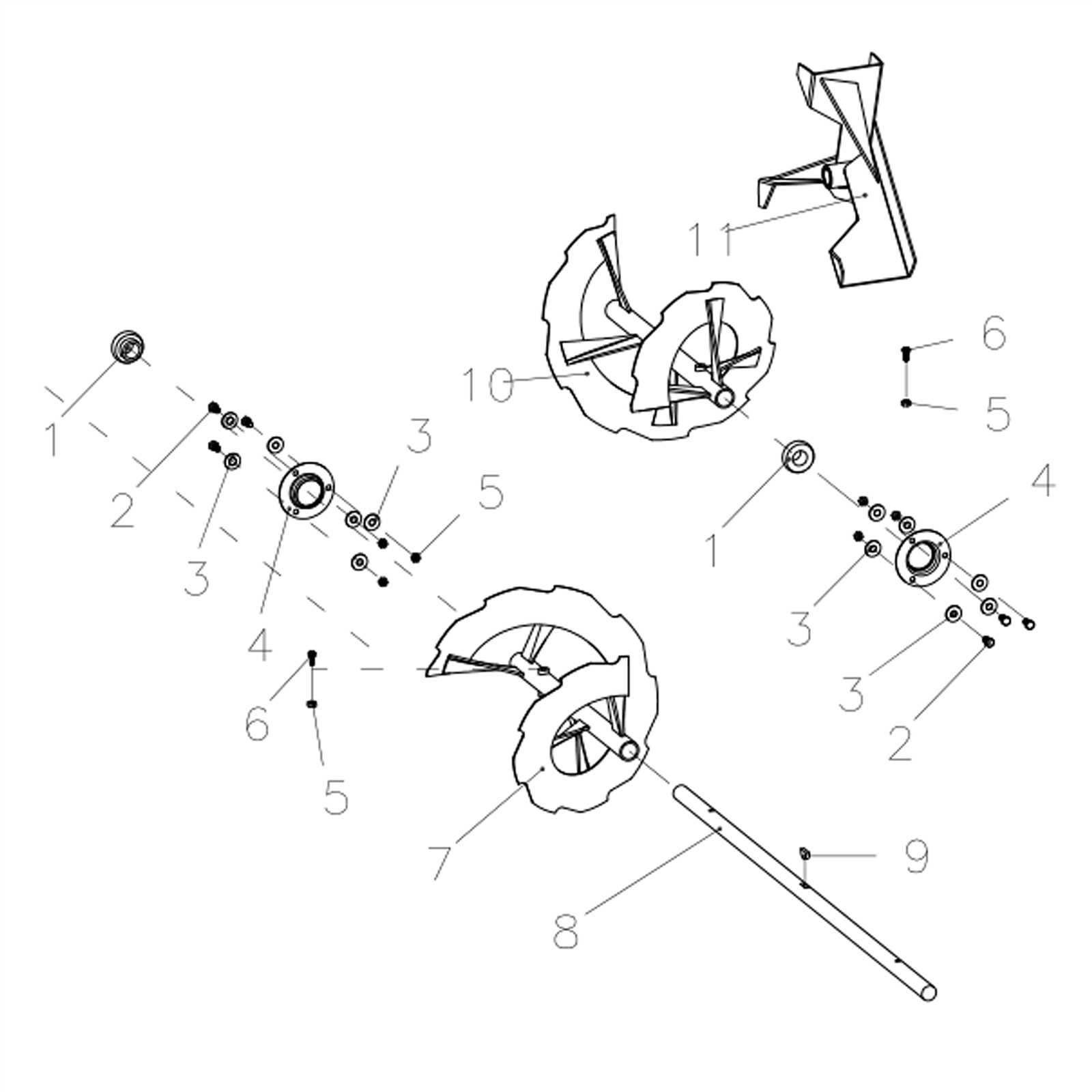

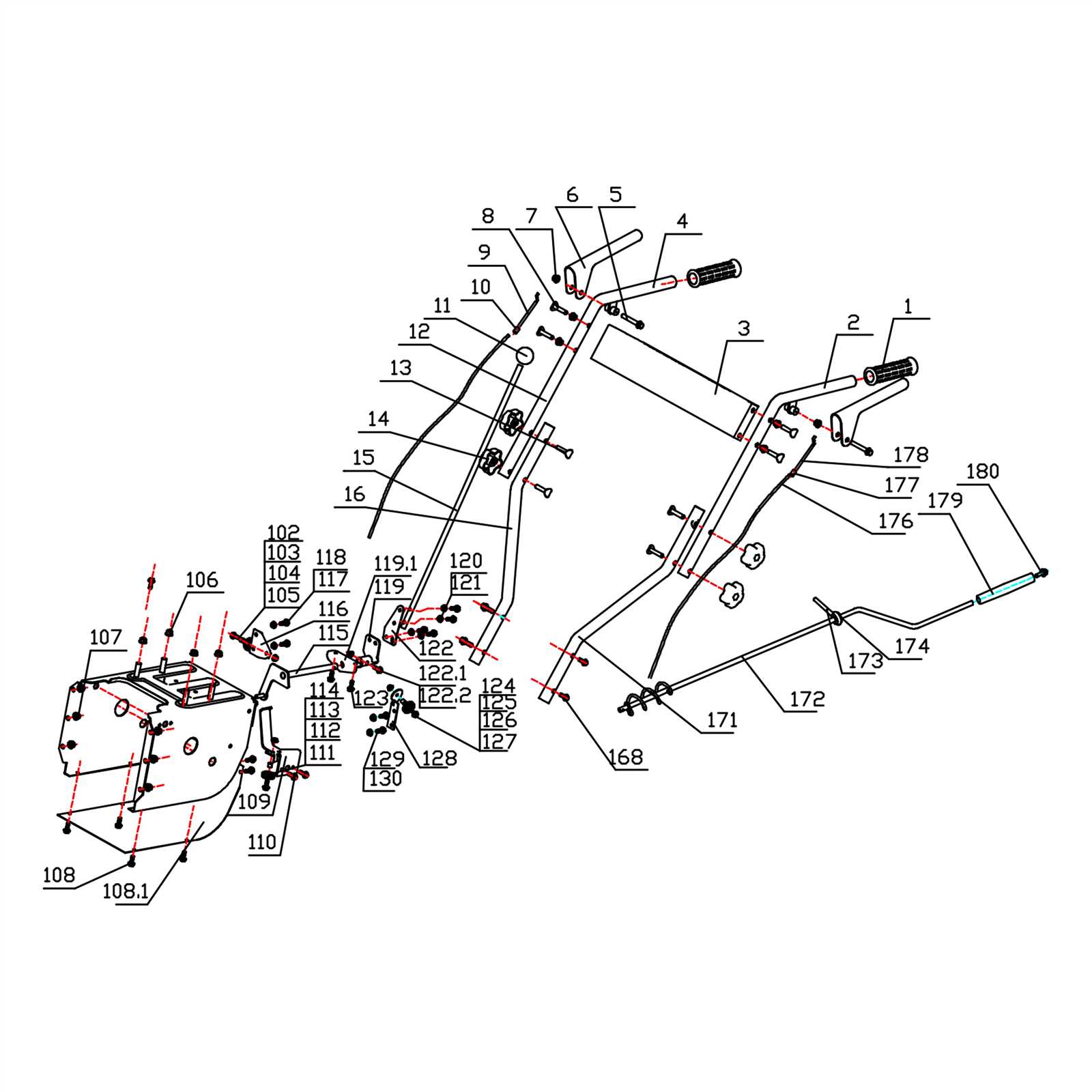

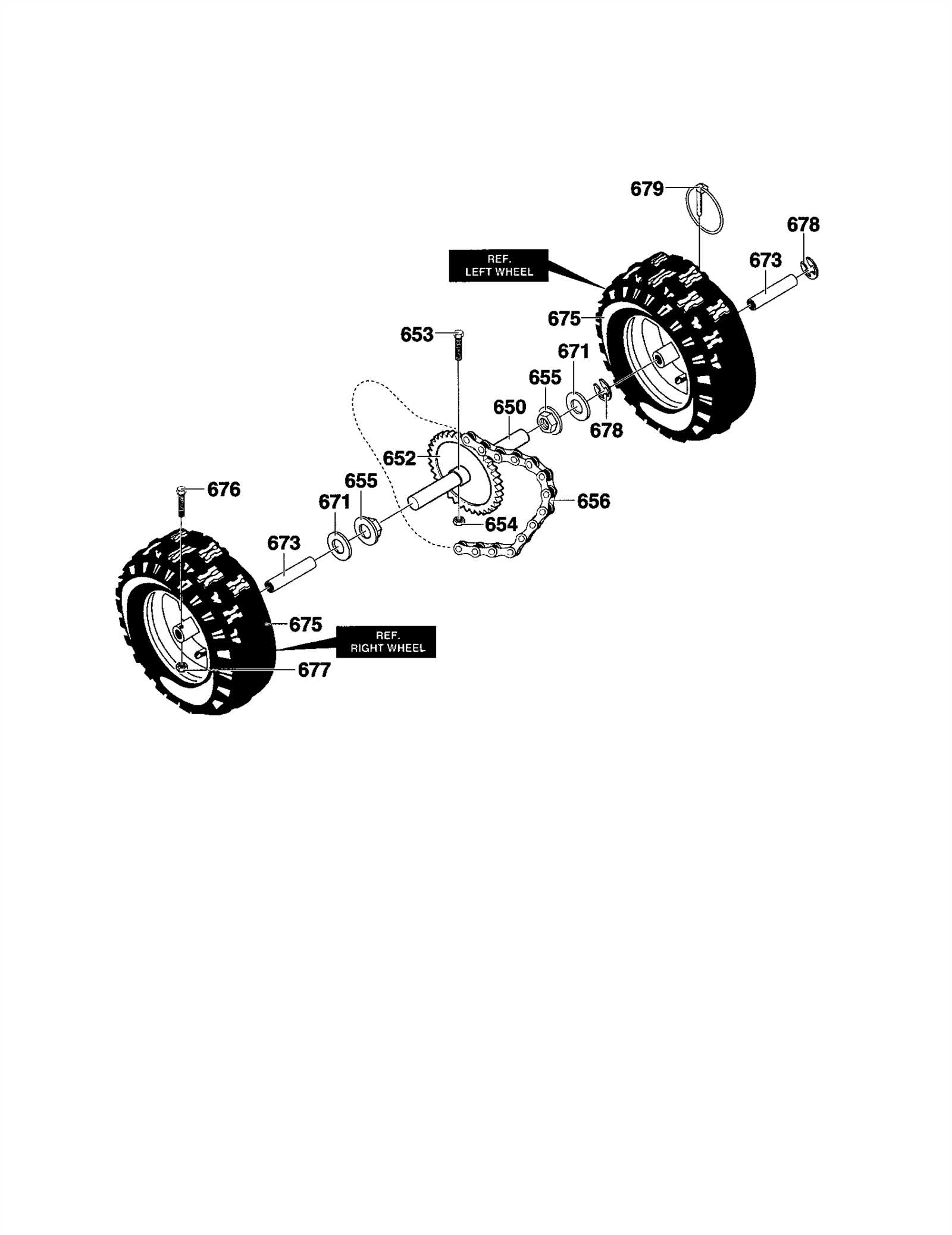

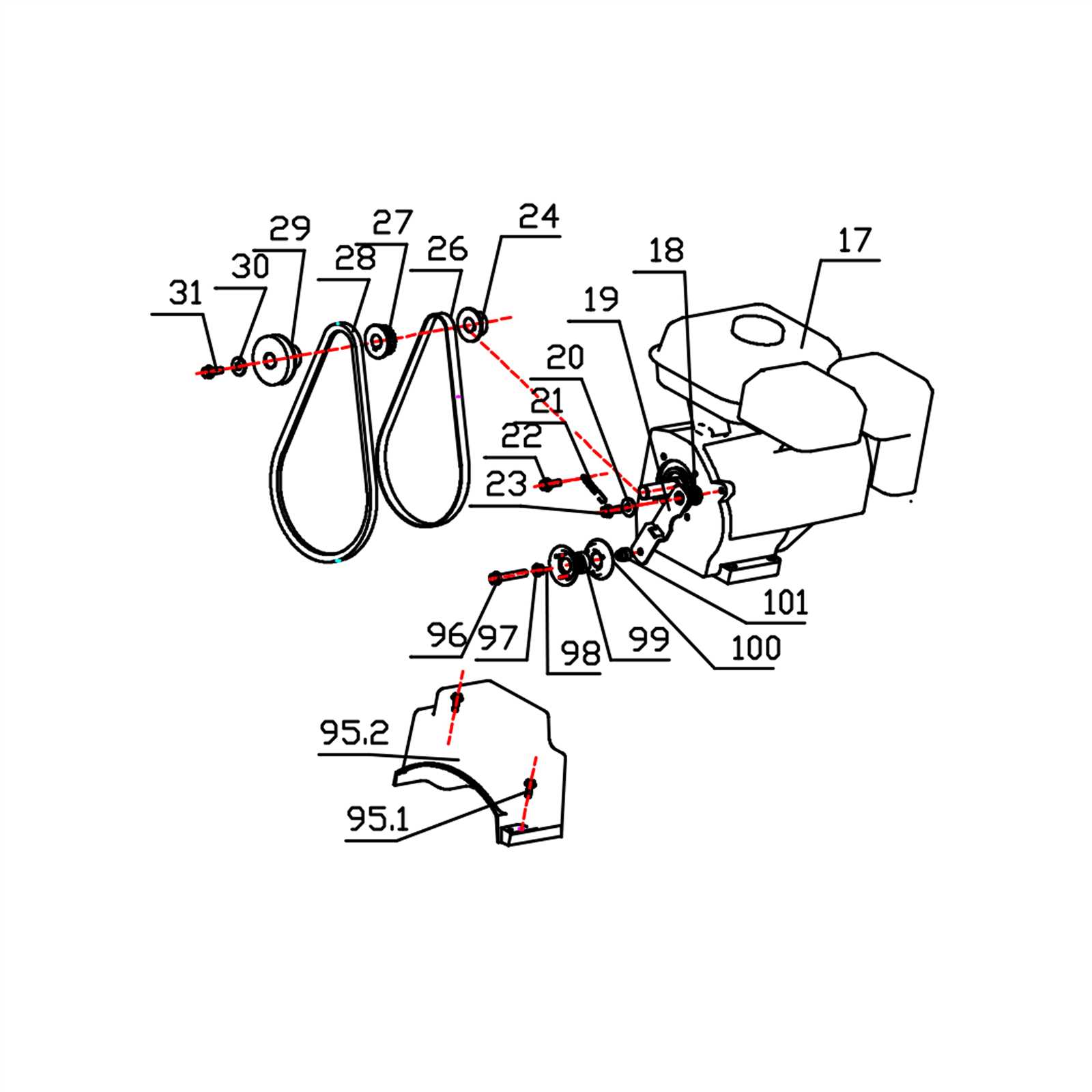

Each element of the equipment plays a crucial role in its overall functionality. For instance, the engine is the powerhouse, providing the necessary energy to operate various mechanisms. Meanwhile, the auger is responsible for gathering material and directing it towards the discharge chute. Understanding these roles enables users to appreciate how each piece contributes to the machine’s effectiveness.

Maintenance and Troubleshooting Tips

Regular upkeep is vital for optimal performance. Pay attention to components such as the belts and blades, as wear and tear can significantly impact functionality. Performing routine checks allows for timely replacements and adjustments, preventing minor issues from escalating into major repairs. Additionally, recognizing common problems can aid in swift troubleshooting, ensuring your equipment remains operational when needed most.

Importance of Snow Blower Maintenance

Regular upkeep of your winter equipment is crucial for ensuring its efficiency and longevity. Proper maintenance not only enhances performance but also prevents costly repairs down the line. By following a consistent care routine, users can maximize the lifespan of their machinery and enjoy reliable operation throughout the cold season.

Benefits of Routine Maintenance

- Improved Performance: Regular checks and adjustments ensure that the machine operates at peak efficiency, reducing the risk of unexpected breakdowns.

- Increased Safety: Well-maintained equipment is less likely to malfunction, which minimizes the risk of accidents during operation.

- Cost Savings: Investing time in maintenance can prevent larger issues that often lead to expensive repairs or replacements.

Key Maintenance Tasks

- Check and replace the fuel as necessary to keep the engine running smoothly.

- Inspect and sharpen blades to ensure effective clearing of surfaces.

- Examine belts and cables for signs of wear and replace them if needed.

- Clean the exterior and remove any debris that could affect performance.

- Store the machine properly during off-seasons to protect it from the elements.

Common Issues with Snow Blower Components

When it comes to the efficient operation of winter equipment, understanding the potential problems that may arise with various elements is crucial. From mechanical failures to wear and tear, recognizing these issues early can significantly enhance performance and prolong the lifespan of the machinery.

Mechanical Failures

One of the primary concerns is the failure of moving parts. Gear and belt malfunctions often occur due to overexertion or insufficient lubrication. Regular maintenance, including checking for wear, can prevent these issues from escalating. Inspections should be routine to identify any abnormal sounds or vibrations that could indicate trouble.

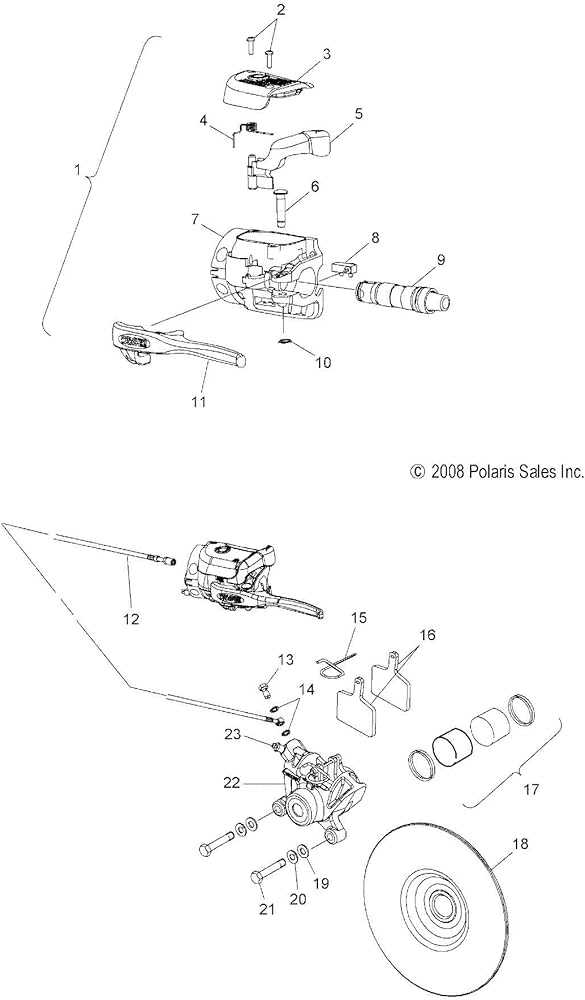

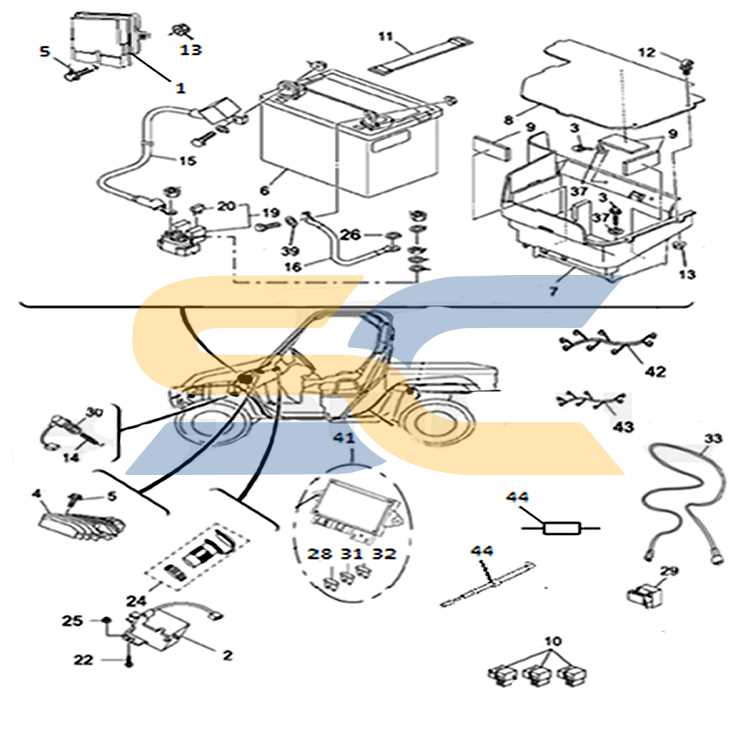

Electrical Problems

Another area to monitor is the electrical system. Problems such as faulty wiring or dead batteries can hinder functionality. If the equipment doesn’t start, it’s essential to examine connections and ensure power sources are fully charged. Timely replacements of defective components can restore operational capability without extensive downtime.

How to Identify Broken Parts

Recognizing malfunctioning components in your equipment is essential for maintaining optimal performance. A keen eye for detail can help you spot wear and tear, ensuring that repairs are made promptly to avoid further issues. In this section, we will explore effective strategies for identifying problematic elements in your machinery.

Visual Inspection

Start with a thorough visual examination. Look for signs of damage such as cracks, corrosion, or unusual wear. Pay close attention to moving parts, as they are often the most susceptible to failure. If any component appears out of alignment or shows signs of excessive friction, it may indicate a problem that needs addressing.

Functional Testing

After the visual inspection, conduct functional tests. Operate the equipment and observe its performance. Listen for abnormal sounds, such as grinding or rattling, which can signal internal damage. Additionally, assess the overall efficiency; any decrease in power or responsiveness may point to failing elements that require further investigation.

Finding Replacement Parts Online

Locating suitable components for your outdoor equipment can be a straightforward process if you know where to look. The internet offers a plethora of resources that simplify the search, ensuring that you can keep your machinery running smoothly. By using specific terms and filters, you can efficiently navigate through available inventories to find what you need.

When embarking on your search, it’s beneficial to have detailed information about the item you’re looking for. Knowing the model number and any relevant specifications can significantly enhance your ability to find the correct replacement. Additionally, consider the reliability of the online retailer, as quality varies widely.

| Resource Type | Examples |

|---|---|

| Manufacturer Websites | Official sites often provide direct access to genuine components. |

| Online Marketplaces | Platforms like eBay and Amazon offer a variety of choices from multiple sellers. |

| Specialty Retailers | Stores dedicated to outdoor equipment may have a more focused selection. |

| Forums and Communities | Online discussion boards can provide recommendations and links to reliable sources. |

By utilizing these resources and approaches, you can successfully find the necessary components to maintain and repair your machinery, ensuring optimal performance for years to come.

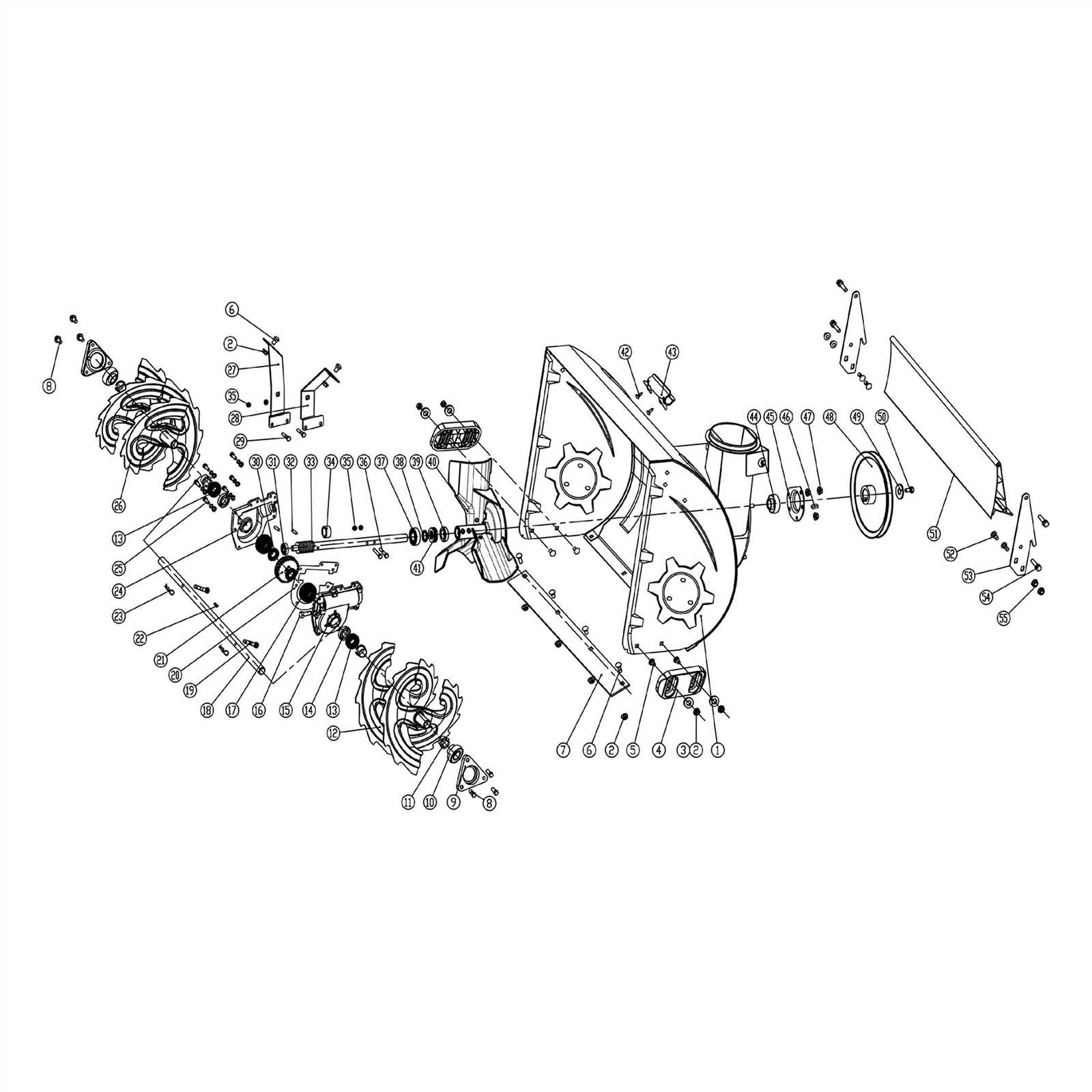

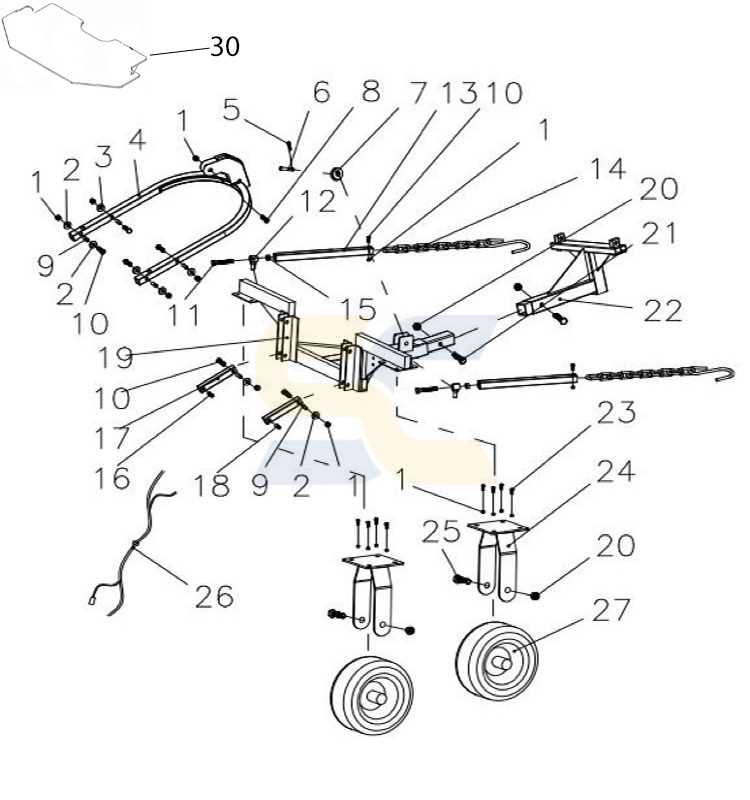

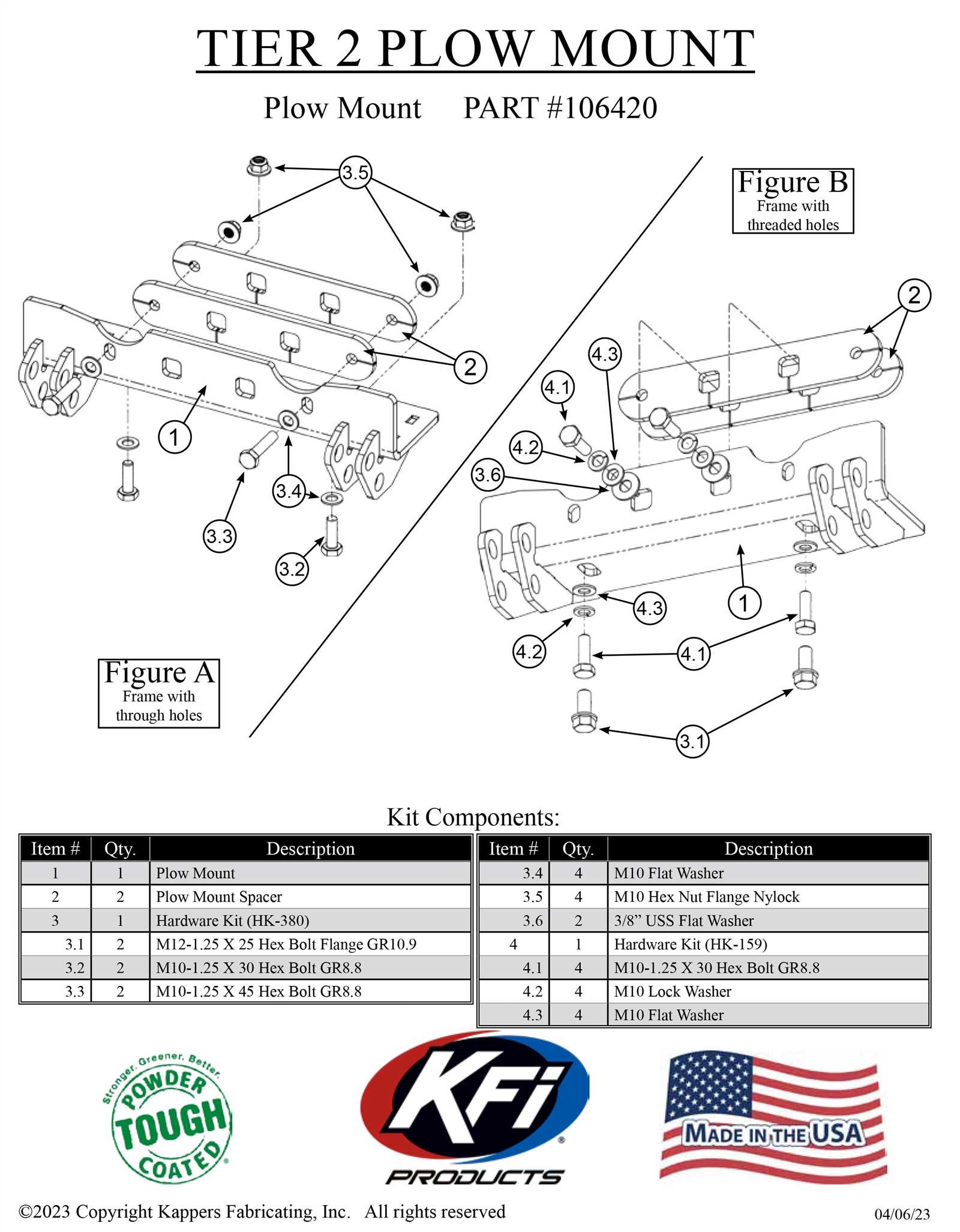

Massimo Snow Blower Parts Catalog

Understanding the components of your outdoor equipment is crucial for optimal performance and maintenance. This section aims to provide a comprehensive overview of various elements involved in your machinery, ensuring that you can easily identify and source what you need for repairs or upgrades.

Each item plays a specific role in the overall functionality, contributing to efficiency and reliability. By familiarizing yourself with these components, you can make informed decisions about replacements or enhancements, ultimately extending the lifespan of your equipment.

Whether you’re looking for the engine assembly, auger system, or any other integral parts, having a detailed catalog can significantly simplify the process. This organized collection allows for quick reference and helps in locating the exact pieces necessary for maintenance or troubleshooting.

Key components to consider include:

- Engine components – Essential for powering the machine.

- Chassis and frame – Providing structural support and durability.

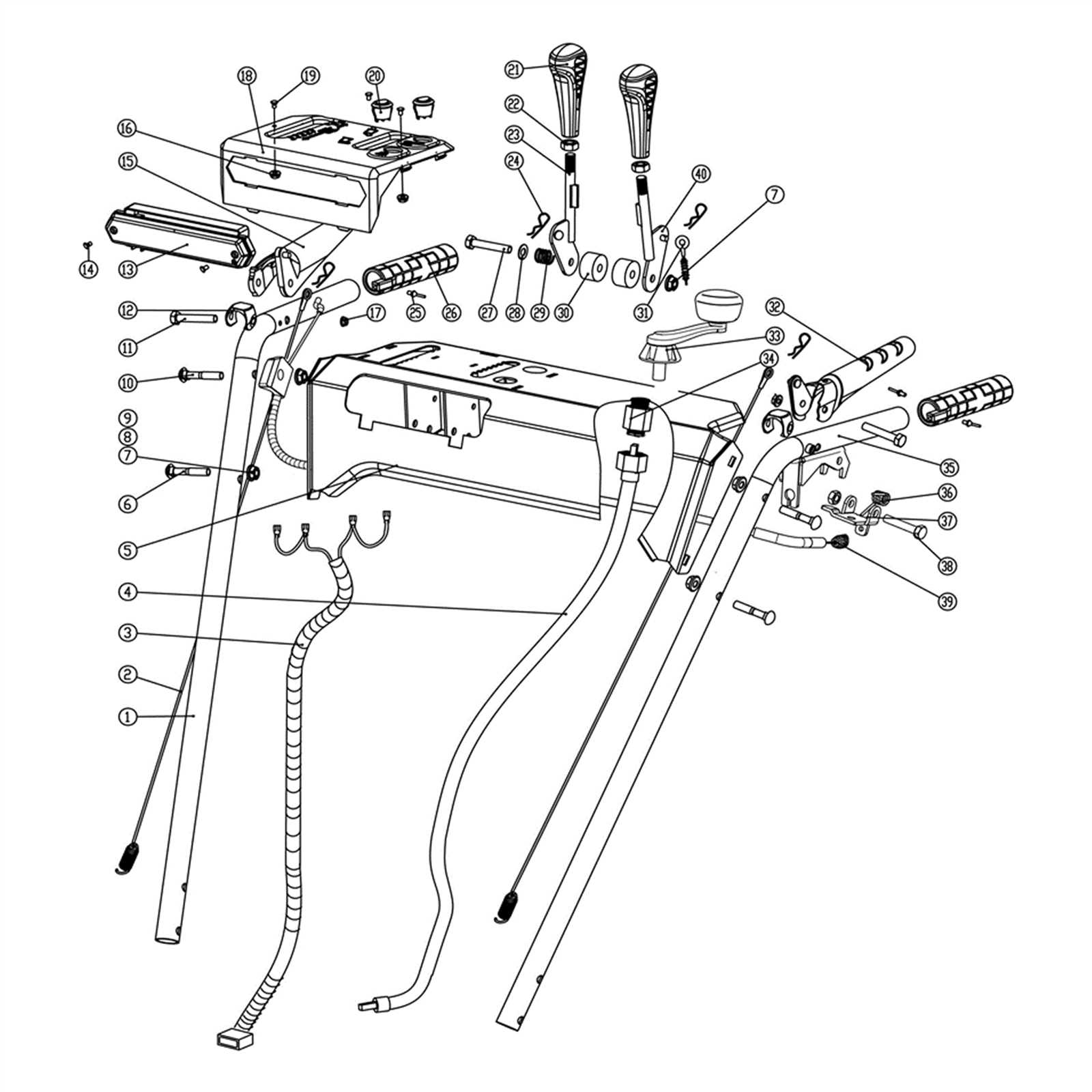

- Control systems – Ensuring user interface and operational efficiency.

- Transmission parts – Vital for movement and speed regulation.

Utilizing this resource will not only aid in quick repairs but also enhance your understanding of how each piece interacts within the larger system, empowering you to take better care of your equipment.

Step-by-Step Repair Guide

This guide will provide you with a systematic approach to fixing common issues with your outdoor equipment. By following these steps, you can ensure that your machine operates efficiently and effectively, extending its lifespan and maintaining optimal performance.

-

Identify the Problem: Start by diagnosing the issue. Listen for unusual noises and observe any performance irregularities. Common problems include:

- Reduced power

- Difficulty starting

- Unusual vibrations

-

Gather Necessary Tools: Ensure you have the right tools for the job. Essential items may include:

- Screwdrivers

- Wrenches

- Replacement components

-

Consult the Manual: Refer to the manufacturer’s manual for specific instructions related to your model. This resource will guide you on:

- Assembly and disassembly

- Maintenance tips

- Safety precautions

-

Disassemble Carefully: Follow the manual’s instructions to dismantle the equipment. Keep track of all screws and parts to avoid losing them.

-

Inspect Components: Check each part for wear and damage. Look for:

- Cracks or breaks

- Corrosion

- Loose connections

-

Replace or Repair: If you identify any damaged parts, replace them with new ones or repair them as needed. Ensure compatibility with your equipment model.

-

Reassemble the Equipment: Once repairs are complete, carefully put everything back together. Refer to your notes and the manual to ensure accuracy.

-

Test the Equipment: Start the machine and observe its performance. If issues persist, reassess your repairs and check for overlooked problems.

Following these steps will help you effectively address common issues, ensuring that your outdoor machine remains in top condition for years to come.

Essential Tools for Snow Blower Repairs

When it comes to maintaining and fixing winter machinery, having the right instruments at hand can make all the difference. Whether you’re performing routine upkeep or addressing specific issues, being equipped with the proper tools ensures efficiency and effectiveness in your tasks.

Basic Toolkit Essentials

- Wrenches: A set of adjustable wrenches and socket wrenches is crucial for loosening and tightening various components.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will help tackle different types of fasteners.

- Pliers: Needle-nose and standard pliers are handy for gripping and manipulating smaller parts.

- Torque Wrench: This tool is essential for applying the correct amount of torque to bolts and screws.

Specialized Instruments

- Fuel Stabilizer: Helps maintain fuel quality, preventing clogging and other issues.

- Spark Plug Wrench: A dedicated tool for easily removing and replacing spark plugs.

- Oil Filter Wrench: Simplifies the process of changing oil filters during maintenance.

- Multimeter: Useful for diagnosing electrical issues and ensuring proper functioning of components.

Equipping yourself with these essential tools not only streamlines the repair process but also enhances the longevity and performance of your winter equipment. Being prepared will save time and prevent frustration when winter conditions arrive.

Comparing OEM and Aftermarket Parts

When maintaining machinery, the choice between original components and alternative solutions often arises. Each option presents its own set of advantages and challenges, influencing both performance and cost-effectiveness. Understanding these differences can greatly assist in making an informed decision.

Original components, typically produced by the manufacturer, are designed to meet specific quality and performance standards. They often ensure a perfect fit and reliability, which can lead to longer-lasting efficiency. However, this comes at a higher price, which some users might find prohibitive.

On the other hand, alternative solutions can offer more affordable choices, potentially providing similar functionality at a fraction of the cost. These components may be produced by third-party manufacturers, and while they can deliver satisfactory results, the variability in quality can sometimes lead to concerns regarding longevity and compatibility. It is essential for users to weigh these factors when deciding which route to pursue.

Ultimately, the decision between original and alternative components should consider budget constraints, performance needs, and long-term maintenance plans. Thorough research and assessment of both options can help ensure optimal performance and value.

Winter Prep: Ensuring Functionality

As the colder months approach, it’s essential to prepare your outdoor equipment for optimal performance. Ensuring that all components are in working order can prevent unexpected issues when you need them the most. This section highlights key considerations for maintenance and readiness, allowing you to tackle winter challenges efficiently.

| Action | Description |

|---|---|

| Inspection | Examine all machinery for wear and tear, checking belts, cables, and any moving parts. |

| Lubrication | Apply appropriate oils and greases to reduce friction and ensure smooth operation. |

| Fuel Check | Ensure the fuel system is clean and filled with fresh fuel to avoid performance issues. |

| Battery Care | Test and maintain the battery, ensuring it holds a charge for reliable starting. |

| Cleaning | Remove any debris or dirt that may obstruct operation, promoting longevity. |

Taking these proactive steps will help guarantee that your equipment is ready to perform at its best when winter arrives. Regular maintenance not only enhances efficiency but also prolongs the life of your machines.

Safety Tips for Using Snow Blowers

When operating outdoor equipment designed for clearing winter precipitation, it’s crucial to prioritize safety to prevent accidents and injuries. Understanding the inherent risks and following best practices can ensure a safe and efficient experience.

Here are some essential precautions to keep in mind:

| Tip | Description |

|---|---|

| Read the Manual | Familiarize yourself with the equipment’s specifications and safety features by thoroughly reviewing the user manual before operation. |

| Wear Protective Gear | Always wear appropriate clothing, including sturdy footwear, gloves, and goggles, to protect against flying debris and cold conditions. |

| Clear the Area | Remove any obstacles, such as branches or toys, from the work area to prevent accidents during operation. |

| Check for Damage | Inspect the machinery for any signs of wear or damage before use, ensuring that all components are functioning properly. |

| Keep Hands Clear | Avoid placing hands near the discharge area or rotating parts. If a clog occurs, turn off the machine and use a tool to clear it. |

| Stay Alert | Maintain focus while operating the equipment and avoid distractions, as they can lead to mishaps. |

| Follow Weather Conditions | Be aware of the weather and avoid using the equipment during severe storms or poor visibility conditions. |

By adhering to these guidelines, operators can significantly reduce the risk of injury and enhance their overall effectiveness in managing winter weather challenges.

Upgrading Your Snow Blower Equipment

Enhancing your winter equipment can significantly improve its efficiency and effectiveness during the cold months. Whether you’re looking to boost performance or increase durability, investing in the right upgrades is essential for tackling harsh conditions with ease.

Assessing Your Current Setup is the first step in the upgrade process. Examine your existing machinery to identify areas that may benefit from enhancement. This could include upgrading the engine for more power, improving the auger system for better snow handling, or even enhancing the chassis for increased stability.

Consider accessories that can complement your machinery. Items such as improved tires or specialized attachments can provide better traction and versatility. Investing in high-quality components can lead to a noticeable difference in performance and user experience.

Finally, always refer to reliable guides and diagrams for installation and compatibility. Understanding how each upgrade integrates with your equipment ensures optimal performance and longevity. By strategically enhancing your machinery, you can make the most out of winter challenges.

Frequently Asked Questions about Repairs

This section addresses common inquiries regarding maintenance and troubleshooting for outdoor machinery. Whether you’re facing performance issues or need guidance on specific components, these FAQs aim to provide clarity and support for effective repairs.

Common Issues and Solutions

- What should I do if the machine won’t start?

- Check the fuel level and ensure it’s fresh.

- Inspect the spark plug for wear or damage.

- Verify that all safety switches are engaged.

- How can I fix poor performance?

- Clean or replace the air filter.

- Examine the fuel system for blockages.

- Ensure that all belts and cables are in good condition.

Maintenance Tips

- Regularly check and change the oil to maintain engine health.

- Inspect and tighten all bolts and screws periodically.

- Store the unit in a dry place to prevent rust and corrosion.