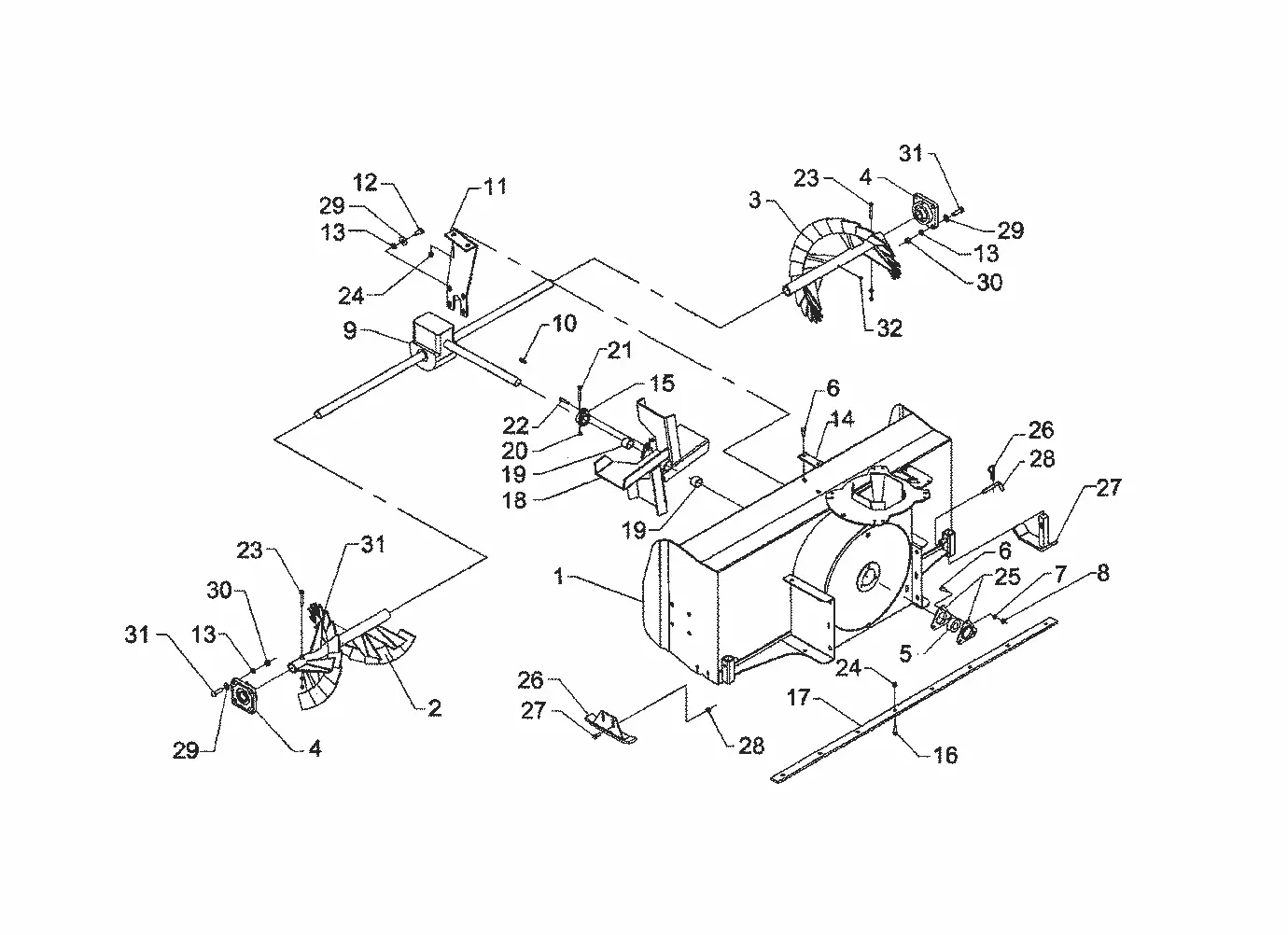

Mtd Snow Blower Parts Diagram for Easy Maintenance

When it comes to maintaining outdoor machinery, a comprehensive grasp of its components is essential. This knowledge not only facilitates effective repairs but also enhances the overall efficiency of the device. Having a clear representation of how these elements fit together can save both time and effort during troubleshooting.

Visual aids play a crucial role in understanding complex systems. By examining detailed illustrations, users can easily identify specific elements and their functions. This approach empowers individuals to tackle issues with confidence, ensuring that every aspect of their machinery is well taken care of.

Whether you are a seasoned technician or a casual user, familiarizing yourself with the intricacies of your equipment can significantly improve its longevity and performance. Engaging with these visuals transforms the repair process from a daunting task into a manageable endeavor, allowing for a smoother experience in maintaining outdoor tools.

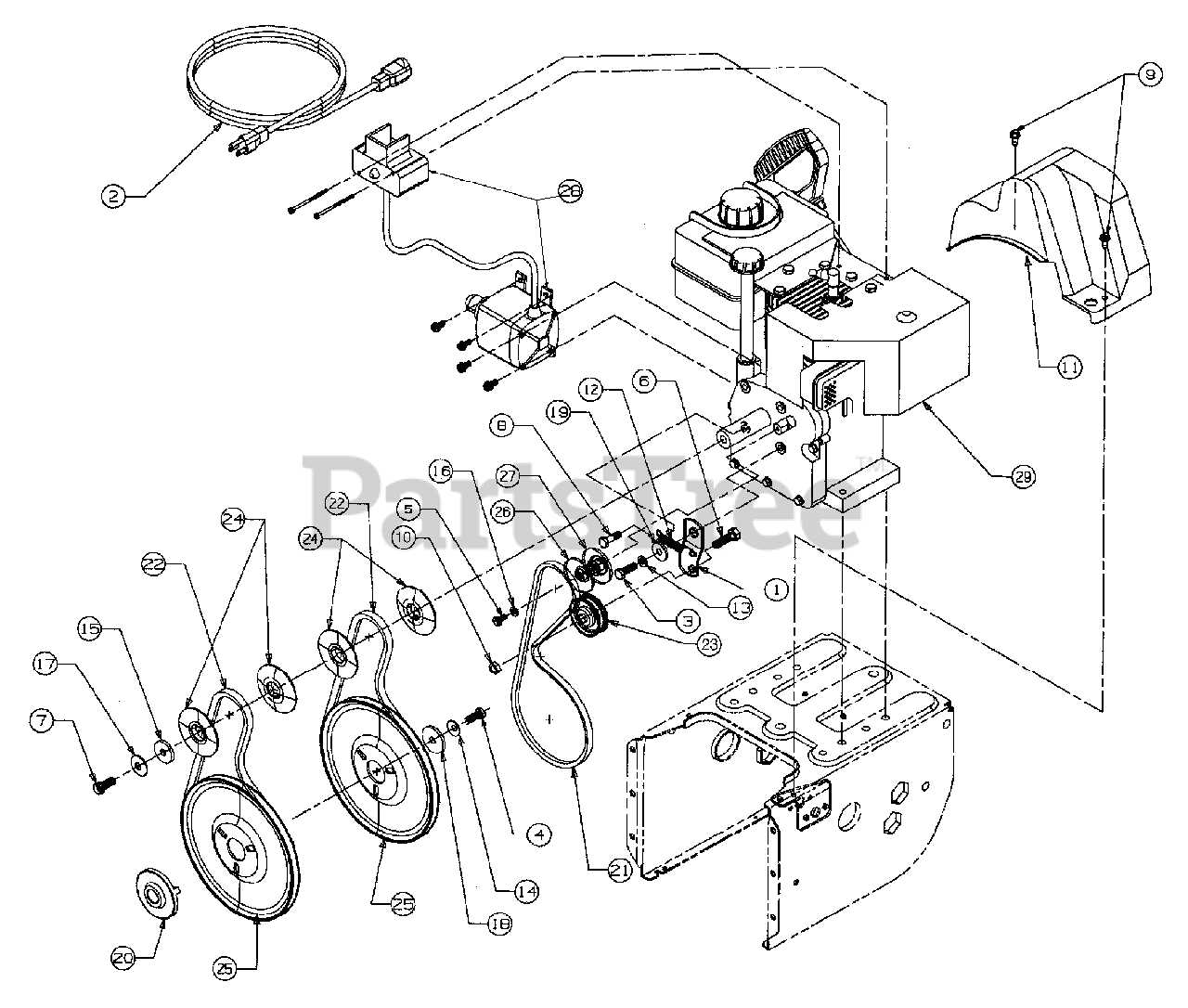

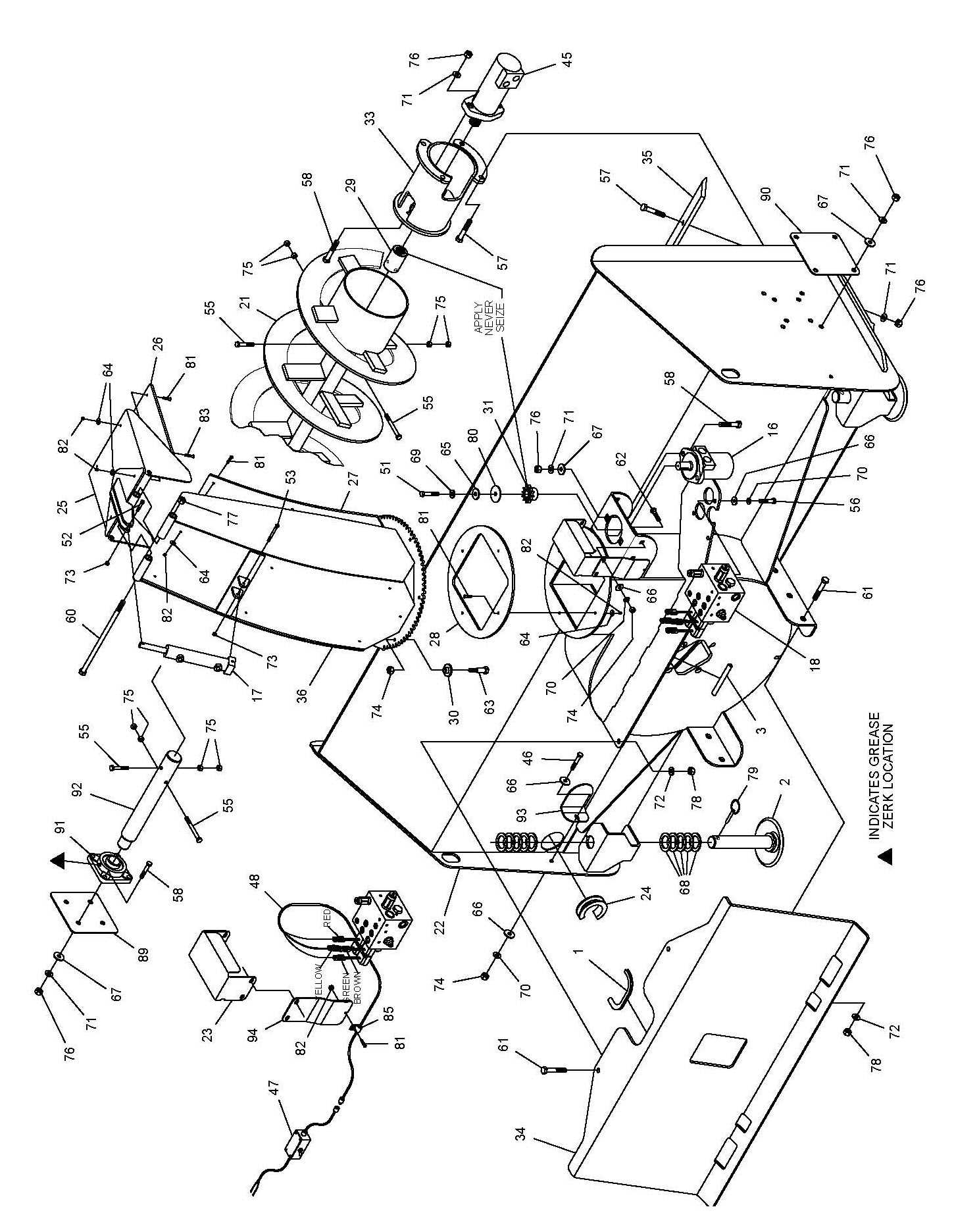

Understanding MTD Snow Blower Components

When exploring the various elements that make up a winter clearing machine, it’s essential to recognize the functionality and interaction of each component. These essential pieces work in unison to ensure optimal performance, making understanding their roles critical for effective maintenance and troubleshooting.

Power System: This is the heart of the machine, providing the necessary energy for operation. It typically includes a motor and transmission, which convert fuel or electric power into mechanical energy.

Clearing Mechanism: The primary feature for removing snow, this system comprises rotating blades or augers designed to efficiently gather and direct snow away from the pathway.

Chassis: The structural framework supports all other components. A robust chassis contributes to stability and durability, allowing the machine to withstand harsh winter conditions.

Controls: User interfaces are vital for operating the machine effectively. They allow the operator to adjust speed, direction, and other settings to optimize performance according to varying conditions.

Safety Features: Essential for protecting the user, these include mechanisms that prevent accidental starts and systems designed to manage the risk of injuries while in operation.

By delving into these components, operators can gain a deeper understanding of their equipment, leading to improved maintenance practices and enhanced performance during winter challenges.

Key Parts of MTD Snow Blowers

This section highlights the essential components that contribute to the functionality and efficiency of winter clearing equipment. Understanding these elements is crucial for maintenance and optimal performance during harsh weather conditions.

| Component | Description |

|---|---|

| AUGER | Designed to gather and direct the material towards the discharge chute. |

| DISCHARGE CHUTE | Controls the direction in which the cleared material is expelled. |

| ENGINE | Powers the entire unit, providing the necessary force for operation. |

| CHASSIS | The frame that supports all other components, ensuring stability and durability. |

| CONTROL PANEL | Interface for the operator to manage settings and adjustments during use. |

How to Read a Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to identify and acquire necessary items for repairs. This guide will help you navigate such illustrations effectively, ensuring you grasp the relationships and functions of each element involved.

| Symbol | Description |

|---|---|

| A | Main component |

| B | Connector or fastener |

| C | Support structure |

| D | Optional accessory |

By familiarizing yourself with common symbols and their meanings, you can more easily locate what you need for your maintenance tasks.

Importance of Regular Maintenance

Routine upkeep is crucial for ensuring the longevity and efficiency of your equipment. Neglecting this essential practice can lead to a decline in performance and potentially costly repairs. Regular attention not only helps in identifying minor issues before they escalate but also enhances the overall safety and reliability of the machinery.

Proactive care allows users to maintain optimal functionality, ensuring that every component operates harmoniously. This can result in improved efficiency, ultimately saving both time and resources. Additionally, a well-maintained machine tends to have a higher resale value, providing a return on investment.

Furthermore, adhering to a scheduled maintenance routine fosters a better understanding of the equipment. This knowledge empowers users to operate their machines with confidence and awareness, reducing the risk of accidents. In summary, consistent maintenance is not merely a chore; it is a wise investment in performance and safety.

Common Issues and Solutions

When operating outdoor equipment, encountering challenges is not uncommon. Understanding these frequent problems can help users maintain optimal performance and ensure longevity.

- Engine Won’t Start:

- Check fuel levels and ensure it is fresh.

- Inspect spark plug for damage or wear.

- Examine the battery connections for corrosion.

- Inefficient Performance:

- Clear any blockages in the intake or discharge areas.

- Ensure the blades are sharp and properly aligned.

- Check for loose or damaged belts and replace if necessary.

- Unusual Noises:

- Investigate for foreign objects lodged in the machinery.

- Inspect bearings and other moving parts for wear.

- Tighten any loose screws or components to reduce rattling.

- Overheating:

- Ensure proper airflow around the engine.

- Change the oil if it is dark or contaminated.

- Regularly clean air filters to maintain efficiency.

Identifying Wear and Tear Signs

Recognizing the indicators of deterioration is essential for maintaining optimal functionality of outdoor machinery. Over time, components may show signs of fatigue due to various factors such as prolonged use, environmental conditions, and lack of maintenance. Awareness of these signs can help in timely interventions, preventing further damage and ensuring efficient performance.

Common symptoms include unusual noises, which may suggest misalignment or damage to moving parts. Additionally, leaks around connections or seals can indicate wear, affecting overall efficiency. Visual inspections for cracks, corrosion, or excessive wear on surfaces can also reveal critical issues that require immediate attention.

Another important aspect is monitoring performance changes. A noticeable decrease in effectiveness, such as reduced power output or inconsistent operation, often points to underlying problems. Regularly checking these aspects will contribute to the longevity and reliability of your equipment.

Replacement Parts Availability Guide

Ensuring the functionality of your outdoor equipment is essential for optimal performance. This section offers insights into the sourcing and availability of components that may require replacement over time. Understanding where to find these essential elements can greatly enhance the longevity and reliability of your machinery.

When seeking replacements, consider checking local retailers, online marketplaces, and authorized dealers. Availability may vary, so exploring multiple channels can provide the best options. Additionally, verifying compatibility with your specific model is crucial to ensure proper fit and functionality.

It’s also beneficial to familiarize yourself with common components that often require attention, such as belts, blades, and engines. Keeping an eye on wear and tear will help you proactively address issues before they escalate.

Lastly, consulting manuals or manufacturer websites can provide detailed information about the necessary replacements and their specifications, helping you make informed decisions for maintenance and repairs.

Assembly and Disassembly Instructions

This section provides essential guidance for the correct assembly and disassembly of your equipment. Understanding these steps ensures not only efficient operation but also prolongs the lifespan of the machine. Following these instructions meticulously will help you maintain optimal performance.

Disassembly Steps

Begin by ensuring the unit is powered off and disconnected from any power source. Carefully remove any attachments or accessories. Next, identify and unscrew the fasteners that hold the main components together. Make sure to keep track of all screws and parts during this process. Once disassembled, inspect each part for wear or damage before proceeding to reassemble.

Assembly Steps

To reassemble, start by placing the main components in their original positions. Secure them using the fasteners you previously removed, ensuring they are tightened properly but not overly so, to avoid damage. Reattach any accessories or attachments, checking that all connections are secure. Finally, conduct a thorough inspection to confirm that everything is in place and ready for operation.

Seasonal Preparation Tips

As the seasons change, ensuring your outdoor equipment is ready for the challenges ahead is essential. Proper preparation not only enhances performance but also extends the lifespan of your machinery, making it more reliable when you need it most.

Inspect and Maintain

Before the onset of winter, thoroughly examine your equipment. Check for any signs of wear or damage, and replace components as necessary. Regular maintenance keeps your machinery functioning optimally and can prevent costly repairs later.

Fuel and Lubrication

Ensure that fuel systems are clean and filled with fresh fuel to avoid issues during operation. Additionally, applying the right lubricants to moving parts reduces friction and wear, improving efficiency when the equipment is in use.

Safety Precautions When Operating

Ensuring a safe working environment is crucial when using outdoor equipment. Adhering to specific guidelines can prevent accidents and injuries, allowing for an efficient and secure experience. Operators should familiarize themselves with essential safety measures to minimize risks associated with machinery operation.

General Safety Guidelines

Before starting any equipment, it’s important to review and understand the manufacturer’s instructions. Always wear appropriate protective gear, including gloves, eye protection, and sturdy footwear. Additionally, ensure that the area is clear of obstacles and bystanders to maintain a safe working zone.

Operational Safety Tips

During operation, remain focused and avoid distractions. Never bypass safety features or attempt to clear blockages while the equipment is running. If maintenance is required, ensure the machinery is powered down and disconnected from any power source.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Use gloves, safety glasses, and appropriate footwear. |

| Inspect Equipment | Check for damage or wear before operation. |

| Clear Work Area | Remove obstacles and ensure bystanders are at a safe distance. |

| Follow Instructions | Read and understand the user manual before use. |

| Power Off for Maintenance | Always shut down and disconnect power before servicing. |

Enhancing Performance with Upgrades

Improving the efficiency and effectiveness of outdoor equipment can significantly enhance user experience and productivity. By implementing specific enhancements, one can optimize functionality, extend lifespan, and increase overall reliability. These modifications can range from simple replacements to advanced upgrades, all aimed at boosting performance.

One of the most impactful areas for enhancement is the engine. Upgrading to a more powerful motor can lead to increased output and reduced strain during operation. This allows for smoother handling of tough tasks, ensuring that the machinery performs optimally even in challenging conditions.

Another essential upgrade involves the cutting and moving mechanisms. Investing in higher-quality blades or augers can improve cutting efficiency, allowing for quicker and cleaner results. Additionally, enhancing the drive system with better belts or chains can ensure consistent power delivery and responsiveness.

Don’t overlook the importance of accessories and add-ons. Features like improved traction systems, adjustable handles, or ergonomic grips can significantly enhance usability and comfort during operation. These enhancements not only make the machinery easier to handle but also contribute to safer and more enjoyable experiences.

Regular maintenance also plays a crucial role in performance enhancement. Keeping components clean and well-lubricated ensures that everything operates smoothly and efficiently, prolonging the life of the equipment and maintaining peak performance.

In conclusion, investing in upgrades and maintenance is a wise strategy for anyone looking to maximize the potential of their outdoor machinery. Each improvement, no matter how small, contributes to a more efficient and satisfying experience.

Cost-Effective Repair Strategies

When it comes to maintaining outdoor equipment, implementing budget-friendly repair methods can significantly enhance longevity and performance. By utilizing resourceful techniques and exploring alternative solutions, owners can minimize expenses while ensuring their machinery remains functional.

Assessing Damage: Begin by thoroughly evaluating the condition of the equipment. Identify the specific issues that require attention and prioritize them based on urgency and cost.

DIY Solutions: Embrace do-it-yourself repairs whenever possible. Online resources and community forums often provide invaluable guidance on fixing common problems, allowing owners to save on labor costs.

Quality Aftermarket Alternatives: Consider high-quality aftermarket options instead of brand-name replacements. Many of these alternatives provide comparable performance at a fraction of the price.

Regular Maintenance: Preventative care can drastically reduce repair costs. Establish a routine maintenance schedule to clean, lubricate, and inspect components, helping to catch minor issues before they escalate.

Networking: Join local groups or online communities focused on equipment upkeep. Sharing tips and experiences can lead to discovering cost-effective strategies and resources.

Resources for DIY Enthusiasts

For those who enjoy hands-on projects, having access to reliable resources is essential. Whether you are fixing equipment or creating something new, the right materials and information can make all the difference in achieving successful outcomes. Below are some valuable resources that can enhance your DIY experience.

Online Communities

Joining forums and social media groups dedicated to DIY projects provides a platform for sharing experiences and advice. Engagement with fellow enthusiasts can inspire creativity and offer solutions to common challenges. Websites like Reddit and specialized DIY forums are great places to delve into discussions and gather insights.

Tutorial Videos and Guides

Video tutorials and step-by-step guides can be extremely helpful for visual learners. Platforms like YouTube host countless instructional videos that cover a wide range of topics, from basic repairs to advanced techniques. Utilizing these resources allows you to follow along and enhance your skills with practical demonstrations.