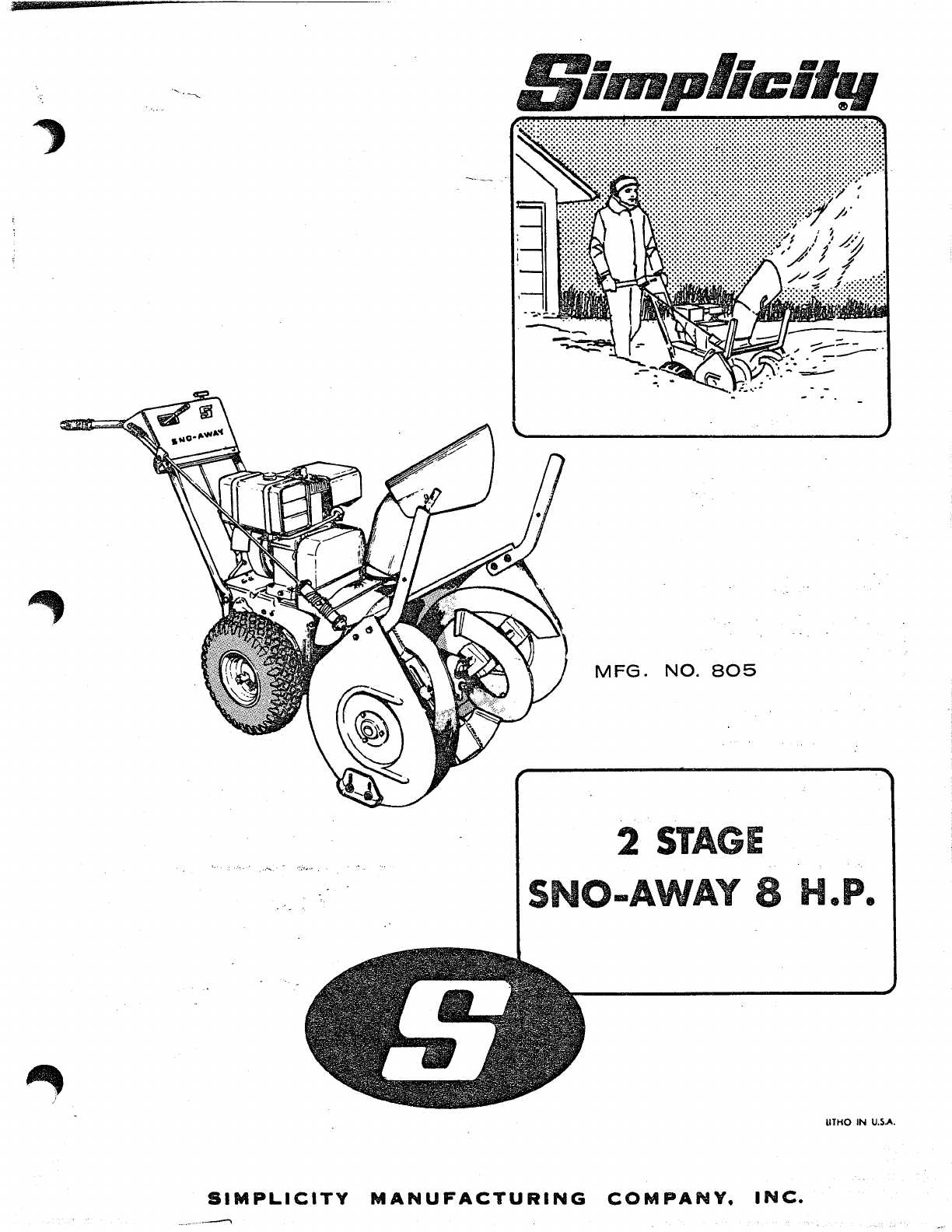

Simplicity Snow Blower Parts Overview

Maintaining and troubleshooting outdoor machinery requires a clear understanding of its internal structure and how the various elements function together. Whether you are repairing or upgrading, knowing how each part contributes to the overall operation is essential. This guide will help you identify the crucial elements, providing insight into their interactions and functionality.

Every machine relies on an intricate system of components working in harmony to perform efficiently. By familiarizing yourself with the specific pieces, you can make more informed decisions about care and repairs. A comprehensive breakdown allows for easier identification of potential issues and ensures smoother operation in the long run.

When you’re equipped with this knowledge, you can approach tasks with confidence, knowing exactly what you’re dealing with. This understanding simplifies the repair process and helps maintain optimal performance for an extended period.

Understanding Snow Blower Assembly Parts

When maintaining or repairing outdoor equipment designed to clear frozen precipitation, it’s crucial to have a clear understanding of the key components that make up the machine. These components work together to ensure effective operation, so familiarity with each element and how they interact is essential. Recognizing the function of each section will help in troubleshooting issues or performing regular upkeep.

Main Components Overview

- Engine: The powerhouse of the system, responsible for driving the machine’s movements.

- Auger: The mechanism that breaks down the frozen material for easy removal.

- Chute: Directs the cleared material away from the work area, allowing for efficient disposal.

- Drive system: Ensures the smooth movement of the equipment over different terrains.

- Skid shoes: Protect the machine from direct contact with the ground, adjusting the clearance height.

Key Considerations When Assembling

- Ensure proper alignment of the components to avoid unnecessary wear or malfunction.

- Check that all bolts and fasteners are securely tightened to maintain stability during use.

- Verify that the chute is correctly positioned for optimal snow discharge.

- Inspect the auger blades for damage or wear, replacing them as needed.

- Confirm that the drive system is functioning smoothly and that the machine is responsive to controls.

Essential Components of a Snow Blower

Understanding the key elements of a cold weather clearing machine is crucial for proper maintenance and efficient operation. These vital components ensure the device functions seamlessly during harsh conditions, helping users tackle even the most challenging winter tasks.

Power System

The power system is the heart of the machine, providing the necessary energy to operate all other components. It typically includes:

- Engine: Responsible for powering the entire unit, often fueled by gasoline or electricity.

- Starter: Allows the user to ignite the engine, either manually or with an electric start option.

Clearing Mechanism

The clearing mechanism is designed to move ice and debris effectively. Key parts include:

- Auger: A rotating component that pulls in and shreds accumulated material.

- Chute: Directs the cleared material out, allowing users to control the discharge location.

Other auxiliary elements, such as wheels and controls, complement these core systems, ensuring optimal performance. Keeping these essential pieces in good working order is key to long-lasting and effective use.

How to Identify Key Mechanisms

Understanding the essential components of your equipment is crucial for proper maintenance and efficient functioning. By recognizing the primary parts, you can easily spot potential issues and perform necessary repairs. This section will guide you through identifying the core mechanisms that ensure smooth operation.

Visual Inspection

One of the simplest methods for recognizing key components is through a visual inspection. Look for larger assemblies and moving parts that play an integral role in the machinery’s performance.

- Check the housing for signs of wear or damage.

- Identify the handles and control mechanisms for any loose or faulty connections.

- Locate the chute and auger mechanisms, which are typically essential for movement and discharge.

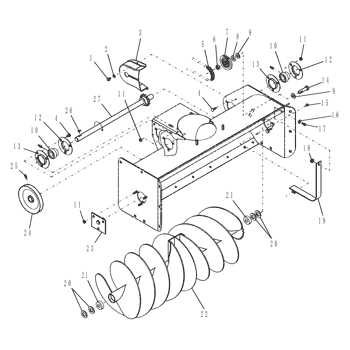

Reference Manuals and Guides

Using reference materials, such as user manuals or manufacturer guides, can significantly aid in identifying key mechanisms. These documents usually contain labeled illustrations and descriptions, helping you better understand how parts interact.

- Consult the product manual for part descriptions.

- Look for exploded views that break down each section.

- Pay attention to the list of maintenance tasks associated with each component.

Common Troubleshooting for Blower Parts

When facing issues with your equipment, understanding the typical malfunctions can help resolve them quickly. Problems with components can arise from wear, improper maintenance, or external factors. Below are some common issues and their solutions that you can follow to get your machine working efficiently again.

- Clogging: If the unit isn’t performing as expected, clogging is often the culprit. Ensure that nothing is obstructing the intake or exhaust areas. Remove debris and check for any blockages in the intake funnel.

- Uneven Operation: If the machine operates unevenly, inspect the blades for damage or imbalance. Check that all moving parts are properly aligned and that nothing is stuck within the mechanism.

- No Start: If the unit fails to start, check the fuel and ignition system. Ensure that the fuel is fresh and that the spark plug is functioning correctly. Sometimes, cleaning or replacing the spark plug may solve the issue.

- Excessive Vibration: This could be caused by loose or damaged components. Tighten all fasteners and inspect for any parts that may have worn down or broken over time.

- Noise Issues: Excessive noise may indicate that a bearing or another moving part is worn out. Inspect and replace parts that show signs of wear or damage to restore quiet operation.

These steps should help you address most common challenges. Regular maintenance and proper storage can reduce the likelihood of these issues occurring and extend the lifespan of your equipment.

Maintenance Tips for Snow Blower Efficiency

Keeping your equipment in top shape ensures it runs smoothly and extends its lifespan. Regular attention to key components can prevent costly breakdowns and enhance performance, especially during harsh conditions. Below are essential tips to maintain your machine’s efficiency throughout the season.

Regular Inspections and Cleanings

Routine inspections allow you to catch potential issues before they become significant problems. Keeping the machine clean from debris and dirt prevents clogging and maintains optimal operation.

| Component | Recommended Maintenance |

|---|---|

| Engine | Check oil levels regularly, and change the oil after every 25 hours of operation. |

| Air Filter | Inspect and clean every 10 hours of use. Replace if damaged or excessively dirty. |

| Auger and Impeller | Remove any ice or debris buildup and check for any loose fasteners. |

Storage Tips for Longevity

Proper storage ensures that your equipment remains functional during the off-season. It’s crucial to store it in a dry, sheltered space to prevent rust and corrosion. Additionally, topping off the fuel tank before storage can prevent fuel degradation.

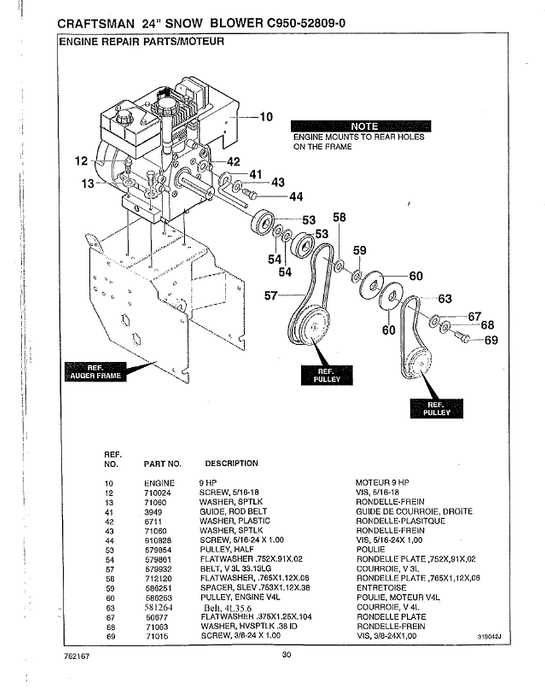

Replacing Worn-out Snow Blower Parts

Maintaining the efficiency of your equipment requires attention to worn or damaged components. Over time, regular use can lead to wear and tear, diminishing the machine’s performance. It is essential to recognize the signs of wear and replace necessary items promptly to ensure optimal functioning during the colder months.

Before proceeding with any replacements, it is important to identify the most common components that require attention:

- Cutting mechanism blades

- Drive belts

- Skid shoes

- Impeller fan

- Auger assembly

Here is a basic guide to follow when replacing these components:

- Turn off the engine and disconnect any power sources to ensure safety during maintenance.

- Inspect each part for visible damage or signs of wear.

- Remove the old component carefully, using appropriate tools, and discard it properly.

- Install the new part by aligning it with the corresponding attachment points.

- Test the equipment to ensure that the new part is functioning correctly and that the machine operates smoothly.

By following these steps, you can extend the life of your equipment and maintain its effectiveness in clearing paths. Regular maintenance and timely replacements ensure that you are ready for the harsh winter conditions.

Snow Blower Parts and Their Functions

When operating a machine designed to clear ice and debris, understanding its key components is essential for optimal performance. Each element of the equipment has a specific role that contributes to its overall efficiency. The following breakdown explains how different sections work together to ensure effective operation during colder months.

Main Components

- Auger: This rotating component gathers the material from the ground and moves it towards the discharge chute.

- Impeller: Located behind the auger, it expels the gathered material out through the chute, helping with the machine’s throwing distance.

- Chassis: The frame that holds all components in place and ensures the machine stays sturdy while in use.

Control and Power System

- Throttle: Allows the user to regulate the engine speed, providing greater control over the unit’s power.

- Drive Mechanism: Engages the wheels or tracks to move the unit forward or backward, depending on the user’s needs.

- Handlebars: Equipped with controls for ease of maneuvering and adjusting speed settings.

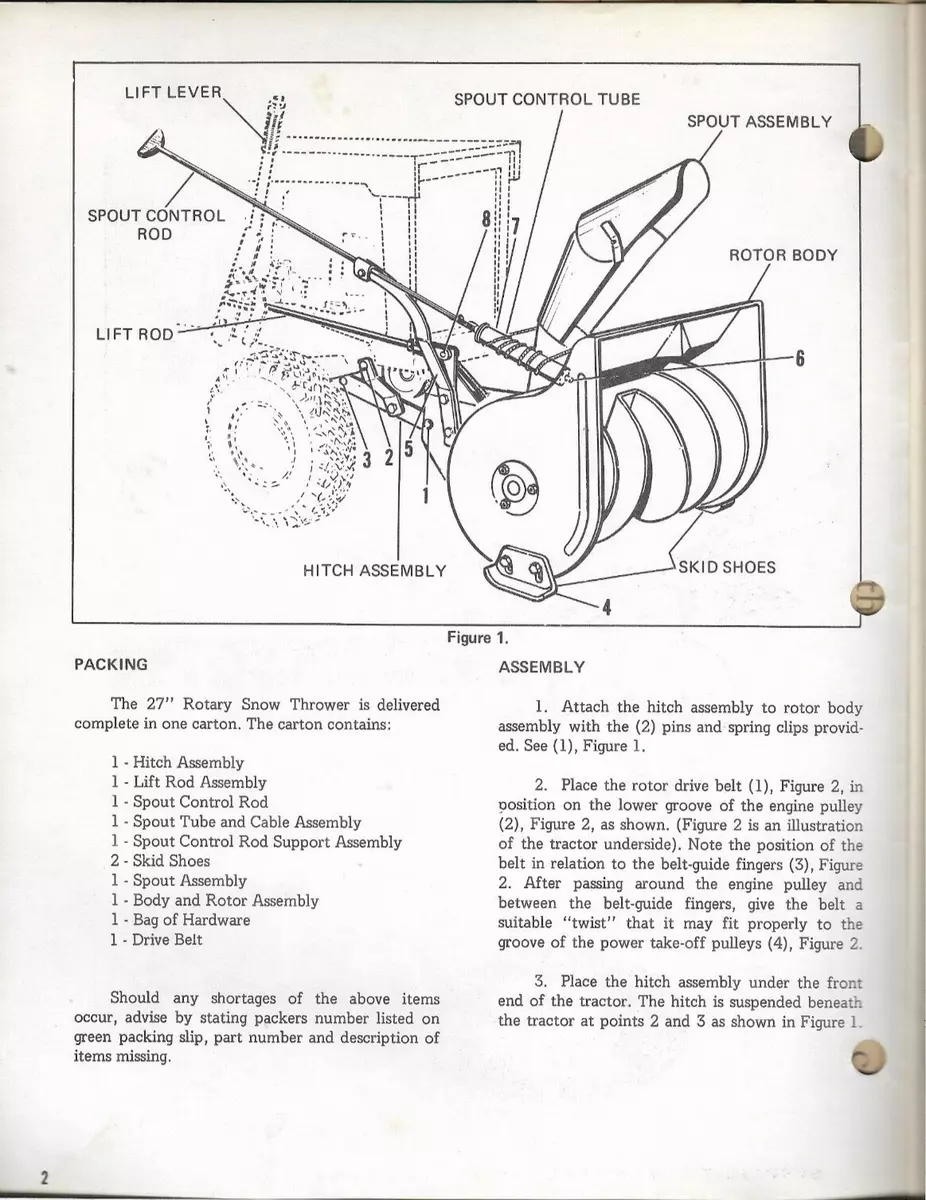

Step-by-Step Assembly Instructions

Assembling a snow clearing machine can seem daunting, but with a systematic approach, the process becomes straightforward. This guide will walk you through each step to ensure proper assembly, enabling efficient operation and long-lasting performance.

Tools and Preparation

Before beginning, make sure you have all necessary tools and components ready. Organizing these in advance can help save time and prevent mistakes during the assembly process.

- Socket set

- Wrenches

- Grease for lubrication

- Owner’s manual

Assembly Steps

- Start by attaching the base frame to the main unit. Align the holes properly and secure them with bolts and nuts. Tighten the connections to ensure stability.

- Install the wheels or tracks, depending on your model. Make sure they are positioned correctly to maintain balance during operation.

- Next, attach the chute and auger assembly. Be careful to align all components so that they rotate freely without obstruction.

- Connect the handlebar to the main frame. Ensure that all cables for control mechanisms are properly routed and do not interfere with the machine’s movement.

- Finally, check all bolts and fasteners to ensure they are tight. Lubricate moving parts for smoother operation.

Following these steps will help you assemble the unit efficiently, ensuring it is ready for use in clearing pathways and driveways.

Safety Precautions When Handling Parts

When working with machinery components, safety should always be the top priority. Proper handling of each element ensures both personal safety and the longevity of the equipment. It is essential to take necessary precautions to avoid injury and damage during maintenance or repairs.

Always wear protective gloves to prevent cuts, abrasions, and other injuries that can occur when handling sharp or heavy items. Additionally, eye protection is recommended to safeguard against flying debris or accidental contact with moving parts.

Ensure that all equipment is turned off and disconnected from power sources before starting any work. This precaution minimizes the risk of electrical shocks or mechanical injuries. Be cautious when lifting heavy objects; consider using lifting aids or seeking help to avoid strain or injury.

Before proceeding with any repairs or maintenance, familiarize yourself with the tools and components involved. Proper understanding of the assembly and disassembly process can greatly reduce risks and increase efficiency during the task.

Top Brands and Parts Compatibility

When choosing equipment for winter clearing, it’s important to ensure that the components are compatible with your machine. Various brands offer a wide range of products, but not all parts are interchangeable. Understanding the compatibility between different manufacturers is crucial to maintaining optimal performance and efficiency.

Each brand designs its machines with specific components that may vary in size, shape, or functionality. It is vital to check the specifications before purchasing any replacement or upgrade parts. Below is a table highlighting the compatibility between popular brands and their components.

| Brand | Compatible Parts | Notes |

|---|---|---|

| Brand A | Drive belts, auger assemblies, control cables | Mostly compatible with similar model ranges |

| Brand B | Engine components, chute assemblies | Check model-specific recommendations for best performance |

| Brand C | Scraper bars, shear pins, skid shoes | Compatible across a wide range of models |

| Brand D | Drive systems, control levers | Limited compatibility, verify before purchase |

How to Find the Correct Parts Diagram

When maintaining or repairing equipment, it is essential to have a clear visual reference to ensure the right components are identified and ordered. A detailed schematic is invaluable for determining which pieces are needed for specific tasks. Understanding how to access and interpret these visuals can save time and reduce errors.

Identify the Model and Manufacturer

Before diving into the search for a schematic, confirm the exact model and brand of your machine. This step is crucial, as it allows you to narrow down the possibilities and avoid confusion. Each version may have slight variations, so having the correct identification is key to finding the accurate visual guide.

Search Through Authorized Sources

Many manufacturers provide digital copies of these visuals on their official websites. These resources are typically well-organized and updated to reflect any changes in design or part numbers. Additionally, third-party sites that specialize in machine repairs may also offer helpful references. Be sure to use trustworthy sources to ensure the information is current and accurate.

Note: Always verify part numbers before ordering to avoid unnecessary delays and costs.