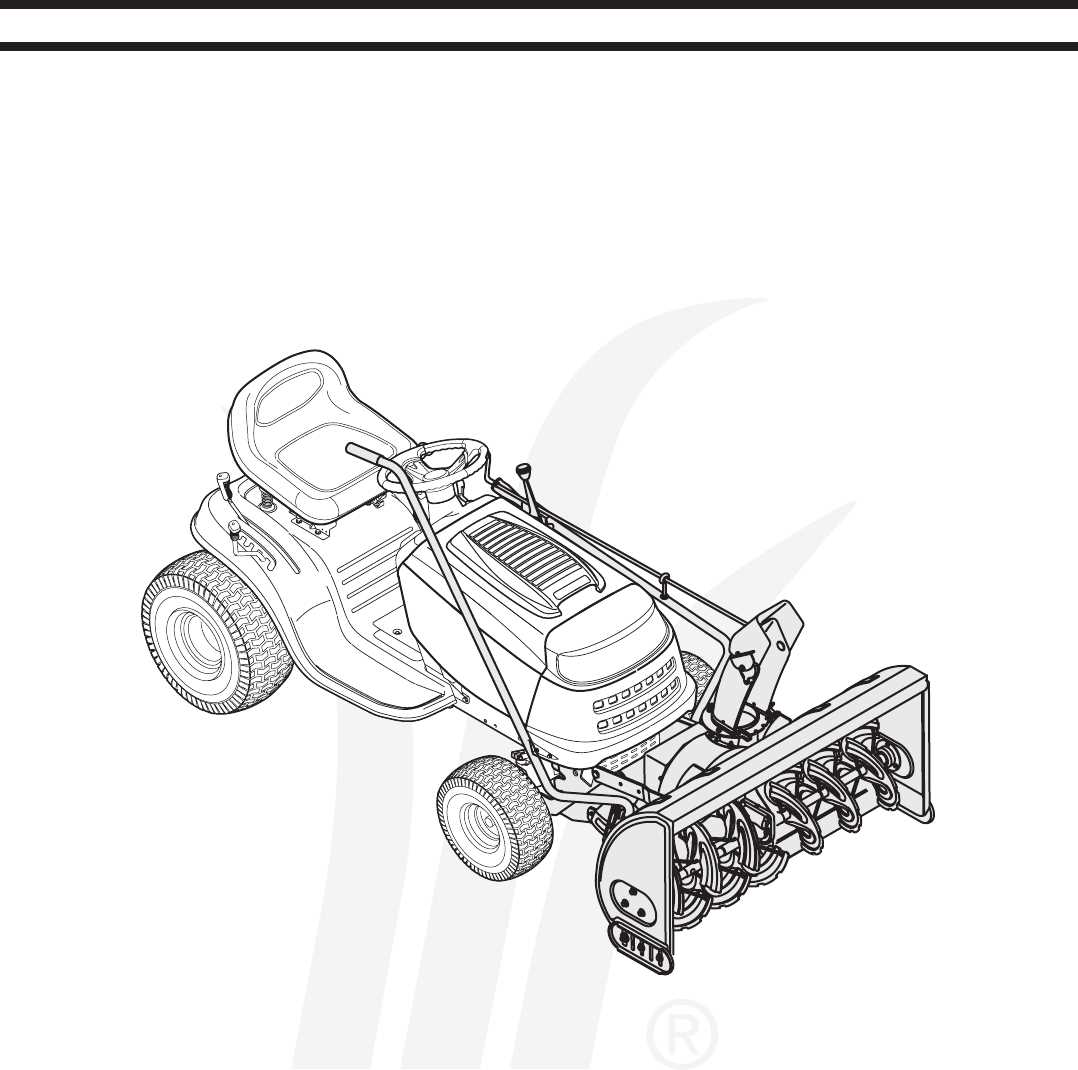

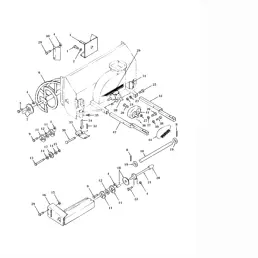

Yard Machine Snow Blower Parts Diagram Overview

In regions where winter precipitation is a common occurrence, having an efficient device to remove accumulated snow is essential. Understanding the various elements that constitute this equipment can significantly enhance its functionality and longevity. This section aims to elucidate the intricate details involved in the assembly and operation of these essential tools.

Recognizing the individual elements is vital for anyone looking to maintain or repair their equipment. Each component plays a specific role, contributing to the overall performance and efficiency of the clearing process. By familiarizing oneself with these crucial aspects, users can ensure their device remains in optimal working condition throughout the harsh winter months.

Moreover, being knowledgeable about the various features enables users to make informed decisions regarding upgrades and replacements. Whether one is considering enhancing performance or simply ensuring proper maintenance, understanding the layout of these components is a significant step toward achieving satisfactory results. Investing time in this knowledge can lead to a more reliable and effective tool for tackling winter’s challenges.

Yard Machine Snow Blower Overview

This section offers an insight into a versatile tool designed for efficiently managing cold weather conditions. With its robust design and innovative features, this equipment is essential for homeowners looking to maintain clear pathways and driveways during winter months.

Key Features

Equipped with powerful engines and advanced propulsion systems, this unit ensures reliable performance in various snow depths. Its adjustable chute allows for precise direction control, making it easy to direct debris where needed. Additionally, the ergonomic handle design promotes user comfort, reducing fatigue during extended use.

Maintenance and Care

To ensure optimal functionality, regular maintenance is crucial. Routine checks of the engine, fuel system, and belts can prolong the life of the equipment. Cleaning the exterior after each use helps prevent rust and wear. Following the manufacturer’s guidelines for servicing will keep the tool in top condition throughout its lifespan.

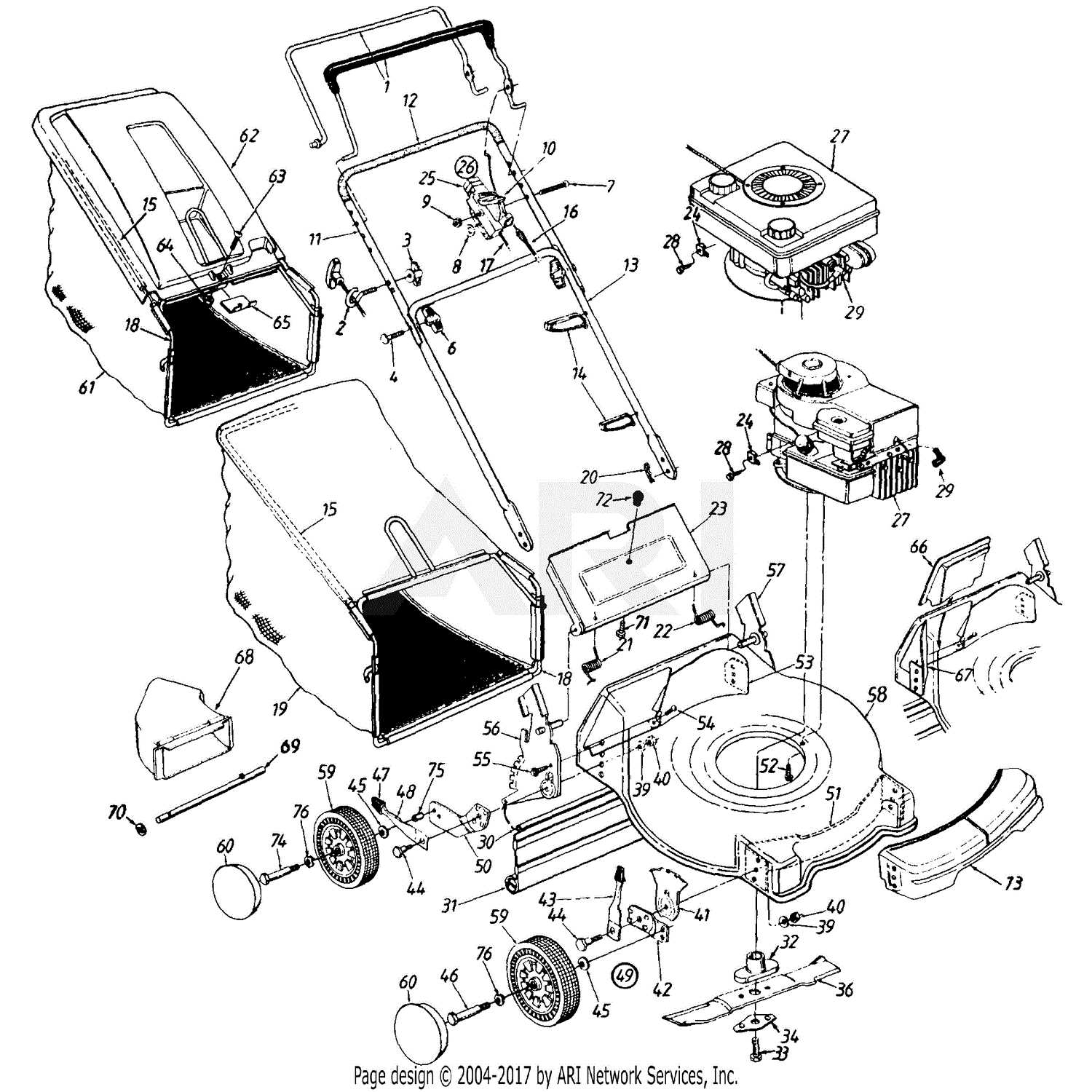

Key Components of Snow Blowers

Understanding the essential elements of a clearing device can significantly enhance its functionality and efficiency. Each component plays a crucial role in ensuring optimal performance during harsh winter conditions. Below are some of the primary features to consider when examining these devices.

- Engine: The power source that drives the entire unit, providing the necessary force to move and clear snow effectively.

- Auger: A spiral blade that collects and churns the accumulated snow, breaking it down for easier expulsion.

- Impeller: This component works in tandem with the auger, helping to propel the cleared snow away from the device.

- Chassis: The main structure that houses all components, providing stability and durability to withstand harsh conditions.

- Handlebars: Allow the operator to maneuver the equipment with ease, often featuring controls for speed and direction.

Each of these features contributes to the overall effectiveness of the device, making them indispensable for efficient snow removal. Understanding how they work together can help users maximize their performance and longevity.

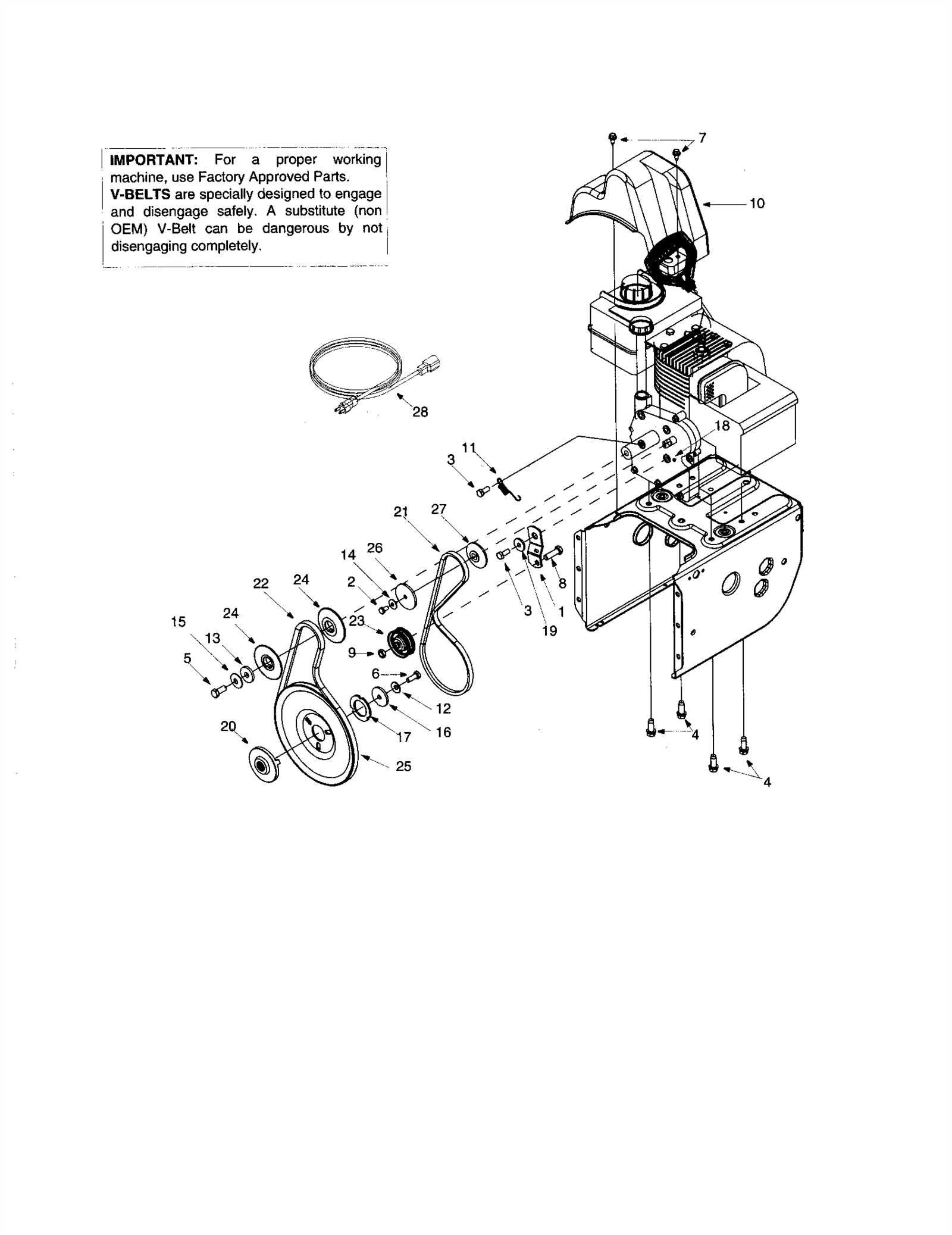

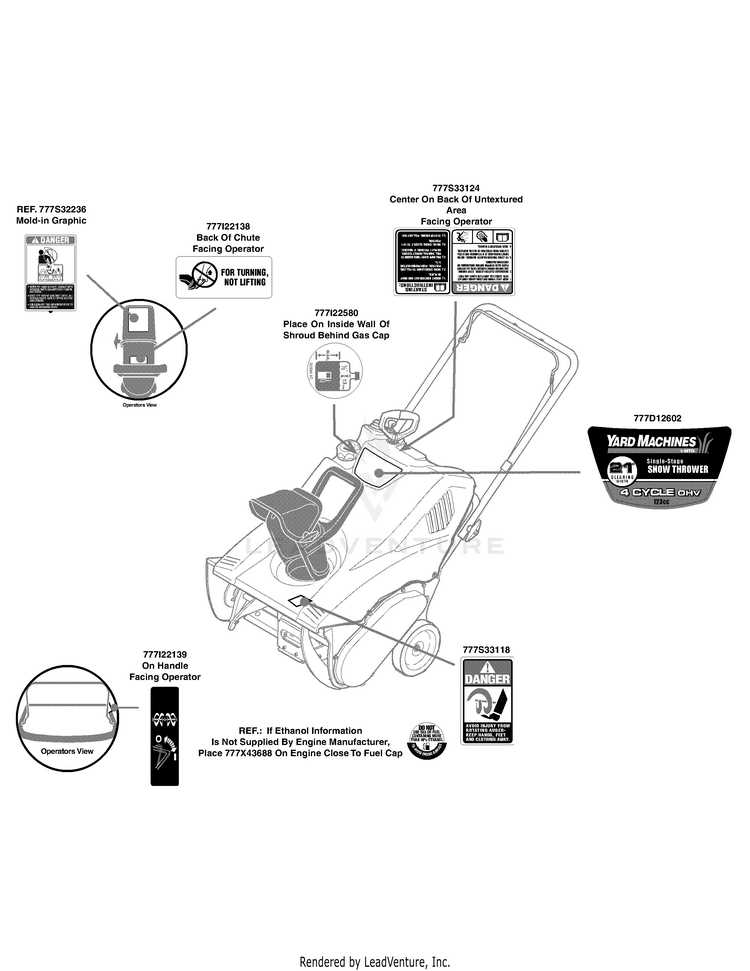

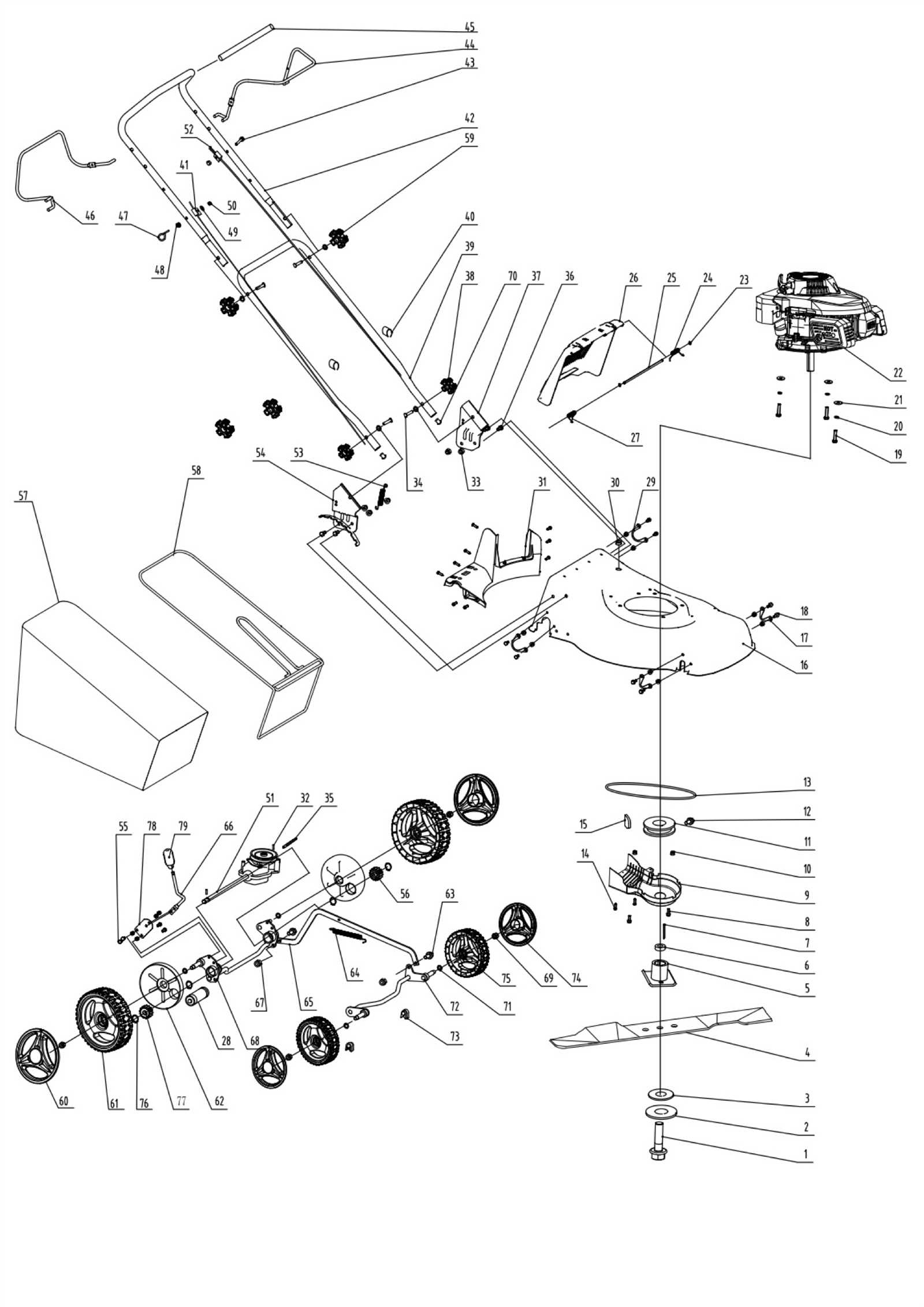

Importance of Parts Diagrams

Understanding the components of any mechanical device is essential for effective maintenance and repair. Visual representations of these components serve as invaluable resources, allowing users to identify individual elements and their interconnections. Such illustrations not only enhance comprehension but also streamline troubleshooting processes.

Facilitating Maintenance and Repairs

Visual aids play a crucial role in the upkeep of complex devices. By offering a clear overview of each component, these resources enable users to locate specific items quickly and assess their condition. This efficiency significantly reduces the time spent on repairs and fosters a deeper understanding of the overall structure.

Enhancing Communication

When collaborating with technicians or discussing issues with service providers, having a visual reference can greatly improve communication. Illustrations help convey specific problems more clearly, ensuring that all parties are on the same page regarding repairs or replacements. This shared understanding minimizes misunderstandings and leads to more effective resolutions.

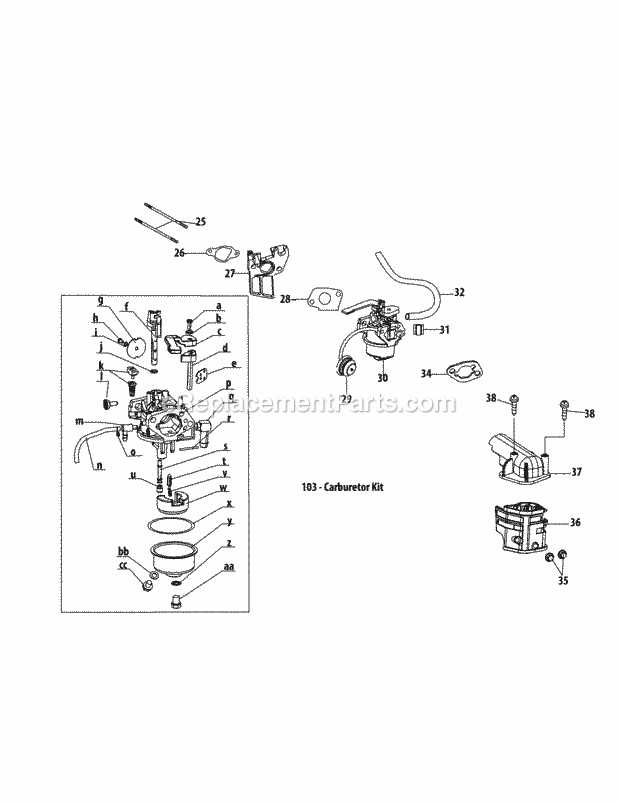

Identifying Common Snow Blower Issues

Understanding the typical complications that arise during winter operations is essential for maintaining optimal performance. By recognizing these challenges early, users can ensure smooth functioning and prolong the lifespan of their equipment.

Common Complications

- Starting Difficulties: Problems initiating the equipment may stem from fuel issues, spark plug malfunctions, or battery failures.

- Ineffective Performance: Insufficient clearing power can result from dull blades, improper adjustments, or clogs in the chute.

- Excessive Vibration: This may indicate loose components or imbalance within the system.

- Unusual Noises: Sounds like grinding or rattling can signify worn-out parts or misalignments.

Troubleshooting Steps

- Check fuel levels and ensure quality.

- Inspect and replace spark plugs if necessary.

- Examine the blades for wear and sharpen or replace them as needed.

- Ensure all bolts and screws are securely fastened.

- Listen for abnormal sounds and investigate their source.

Regular inspections and addressing these common issues can significantly enhance reliability and efficiency during usage. Taking proactive measures will lead to a more effective and enjoyable experience during the winter months.

Maintenance Tips for Snow Blower Parts

Proper upkeep of your winter clearing equipment is essential for ensuring optimal performance and longevity. By regularly checking and maintaining various components, you can prevent potential issues and enhance efficiency during operation.

Here are some crucial maintenance tips to keep in mind:

| Component | Maintenance Tips |

|---|---|

| Engine | Change the oil regularly and replace the air filter to promote efficient combustion and reduce wear. |

| Fuel System | Use fresh fuel and consider adding a stabilizer to prevent degradation, especially during off-seasons. |

| Auger | Inspect for any damage or wear and ensure it is clear of debris to maintain effective snow displacement. |

| Chassis | Check for loose bolts and rust; clean and touch up any damaged areas to prevent corrosion. |

| Skids and Shoes | Regularly inspect and replace these components to ensure optimal height adjustment and ground contact. |

By following these guidelines, you can enhance the reliability of your winter equipment, ensuring that it remains in prime condition for the cold months ahead.

Replacement Parts for Yard Machines

Maintaining optimal performance in outdoor equipment often requires sourcing various components. Whether you’re dealing with wear and tear or simply seeking to upgrade functionality, understanding the available replacements is crucial. This section explores essential replacements that ensure longevity and reliability in your outdoor apparatus.

Identifying Key Components

When considering alternatives, it’s important to identify the main components that may require attention. Elements such as motors, belts, and control systems can significantly impact overall performance. Regular inspections and timely replacements can prevent further issues, ensuring that your equipment remains in top shape throughout the season.

Where to Find Quality Alternatives

Numerous suppliers offer quality alternatives for outdoor equipment. Reputable retailers provide both original and aftermarket components, catering to various budgets and preferences. It’s advisable to research suppliers and read reviews to guarantee the authenticity and quality of the parts you choose.

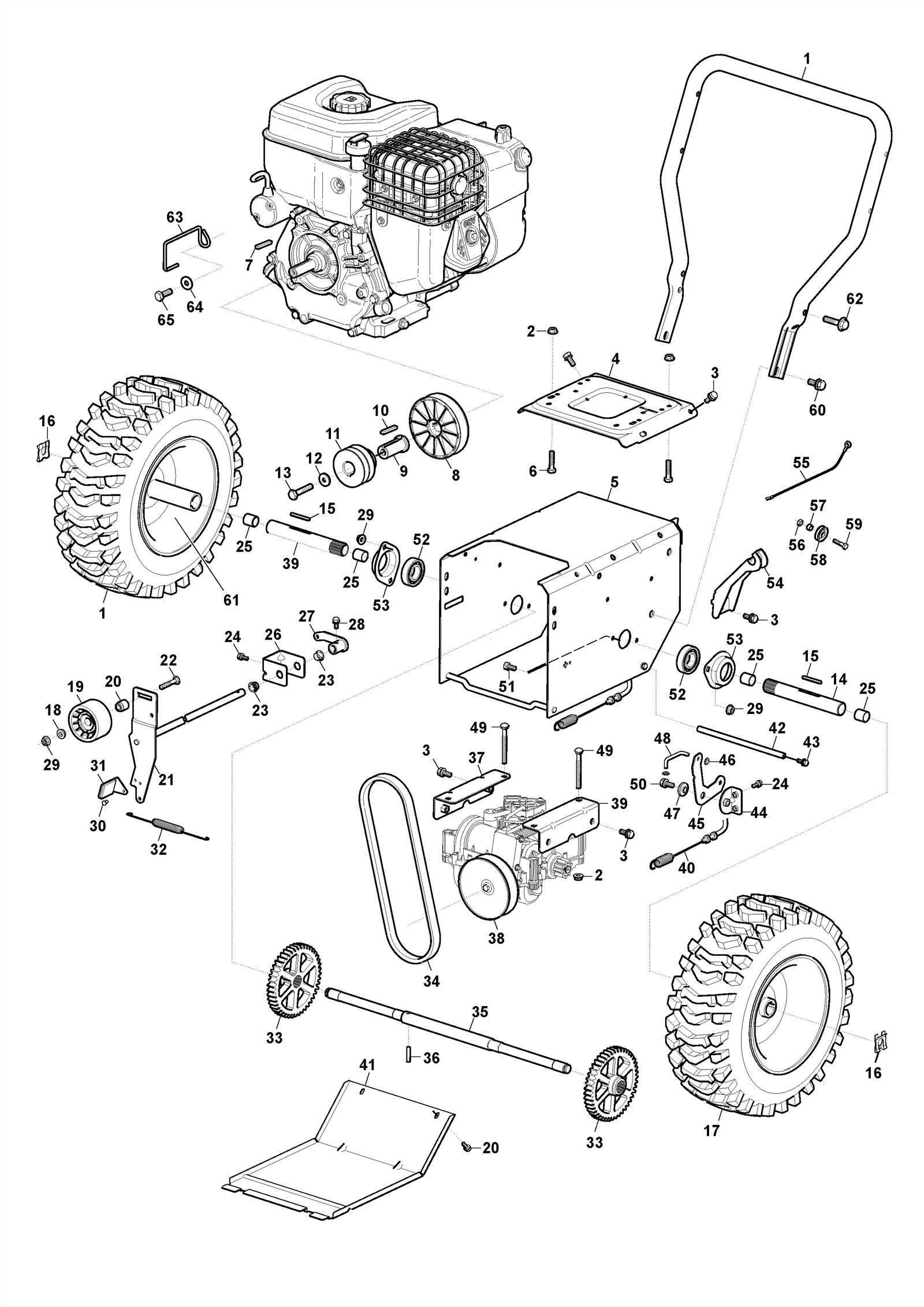

Understanding the Auger System

The auger system plays a crucial role in the effective operation of outdoor clearing equipment. This mechanism is designed to efficiently gather and transport material, ensuring smooth performance during operation. By comprehending how this system works, users can better appreciate its significance in achieving optimal results.

Components of the Auger System

The auger system consists of several essential components, each contributing to its overall functionality. The primary element is the rotating screw blade, which is responsible for breaking up and collecting the material. Additionally, a housing structure encases the auger, directing the flow of debris toward the discharge chute. Understanding these elements helps in recognizing the importance of regular maintenance and potential troubleshooting.

Operation Principles

The operation of the auger system relies on a simple yet effective mechanism. As the screw blade rotates, it engages with the material, pulling it into the housing. The continuous motion creates a steady flow, allowing for efficient clearing. Regular inspection of the auger system can prevent blockages and ensure consistent performance, making it an essential aspect of upkeep for any operator.

Engine Specifications for Yard Blowers

This section explores the essential characteristics and features of the power units used in outdoor clearing equipment. Understanding these specifications is crucial for selecting the right model and ensuring optimal performance during use.

Power units typically vary in design, with several key aspects to consider:

- Engine Type: Commonly available engines include two-stroke and four-stroke options, each offering unique advantages in terms of power delivery and maintenance.

- Displacement: This measurement, often expressed in cubic centimeters (cc), indicates the engine’s size and its ability to generate power. Larger displacement usually results in greater output.

- Power Output: Typically rated in horsepower (HP) or kilowatts (kW), this figure denotes the engine’s capability to perform tasks effectively.

- Fuel Type: Many engines utilize gasoline, while some may operate on alternative fuels. This choice affects performance, efficiency, and environmental impact.

- Starting Mechanism: Options include manual recoil starters and electric start systems, providing convenience depending on user preferences.

When selecting a unit, it is essential to assess these specifications in relation to your specific needs and conditions. Proper understanding will aid in maximizing efficiency and effectiveness during operation.

Winter Preparation for Snow Equipment

As the cold season approaches, ensuring that your equipment is ready for the challenges ahead is essential. Proper maintenance and readiness can significantly enhance performance and extend the lifespan of your tools. Taking the time to prepare can make all the difference when winter weather strikes.

Essential Maintenance Tasks

- Check fuel levels and quality to ensure optimal performance.

- Inspect and replace worn or damaged components as necessary.

- Sharpen blades or cutting edges for improved efficiency.

- Clean the equipment thoroughly to prevent rust and corrosion.

- Examine belts and cables for signs of wear and tension.

Storage Considerations

- Store in a dry, sheltered location to protect against moisture.

- Use a cover to shield from dust and debris.

- Ensure that all movable parts are lubricated to prevent seizing.

- Check for any leaks or drips that may indicate maintenance issues.

Taking these steps will help ensure that your equipment is ready to tackle the challenges of winter weather effectively. A well-maintained tool not only performs better but also provides peace of mind during harsh conditions.

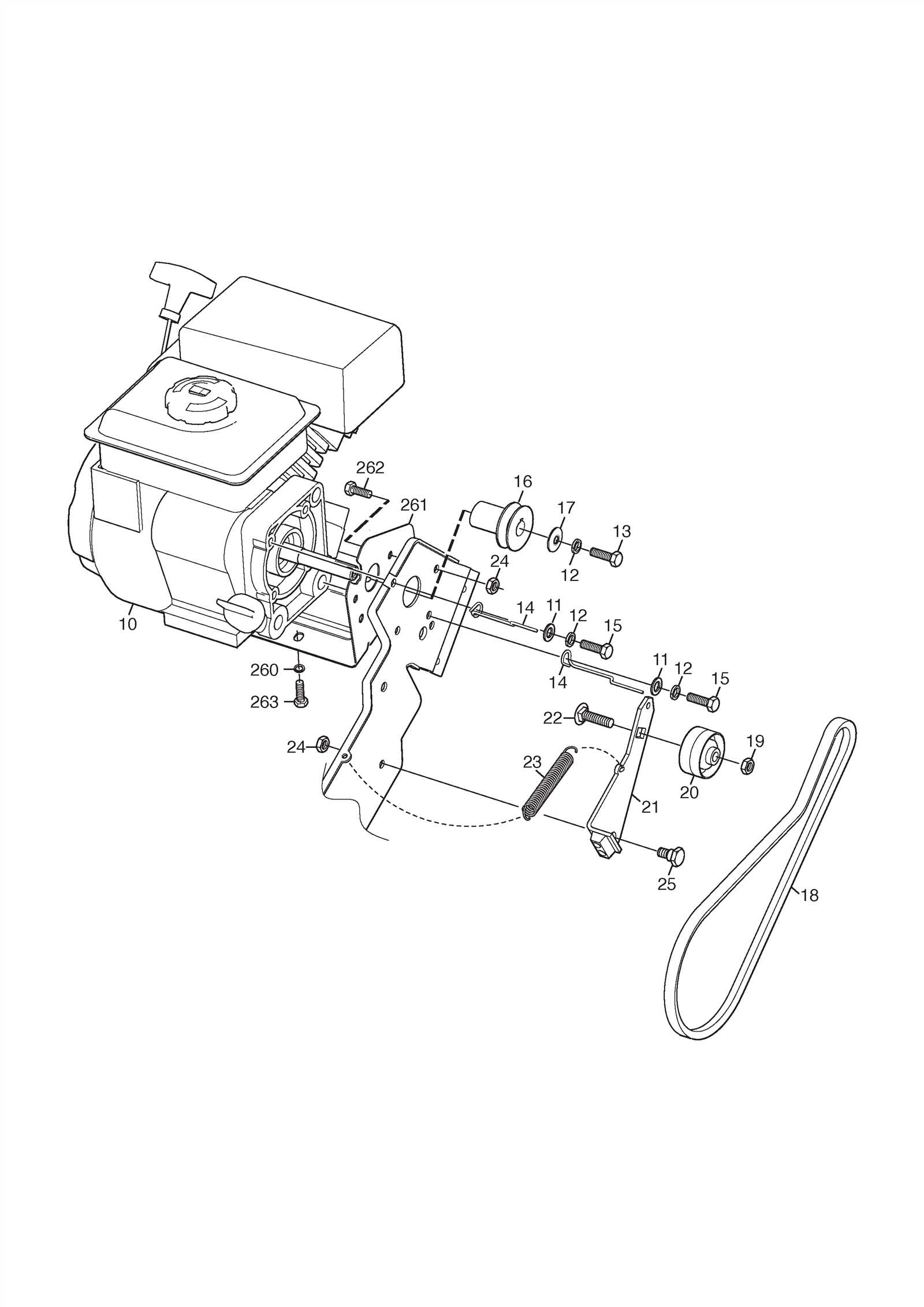

How to Read Parts Diagrams

Understanding component illustrations is crucial for effective maintenance and repair of various equipment. These visual guides provide insights into the arrangement and functionality of each element, enabling users to identify the necessary replacements or adjustments. By familiarizing oneself with the symbols and layout of these illustrations, one can enhance their repair skills and extend the lifespan of their equipment.

Familiarize Yourself with Symbols

Each illustration typically employs a set of symbols and notations that convey specific information about the components. Taking the time to learn these symbols can greatly improve comprehension. Common symbols may indicate sizes, material types, and even connection points. Familiarity with these representations allows users to make informed decisions about what to order or replace.

Follow the Assembly Sequence

Another vital aspect of interpreting these illustrations is understanding the sequence of assembly. By examining the order in which components are arranged, one can better visualize the assembly process. This understanding is especially beneficial when reassembling equipment after repairs, as it reduces the likelihood of errors and ensures that everything fits together seamlessly.

Tools Needed for Repairs

When it comes to performing maintenance and fixing equipment, having the right tools is essential. The correct instruments not only enhance efficiency but also ensure that tasks are executed safely and accurately. A well-equipped workspace can make all the difference in the repair process, leading to successful outcomes and prolonging the lifespan of the equipment.

Essential Hand Tools

Begin with a collection of basic hand tools. These include wrenches, screwdrivers, and pliers, which are vital for loosening and tightening various components. Having a variety of sizes ensures that you can tackle different tasks effectively. Additionally, consider using a magnetic tray to keep small parts organized and within reach during your work.

Power Tools and Equipment

For more complex repairs, power tools can significantly expedite the process. A drill, for instance, is invaluable for removing and installing fasteners quickly. If you encounter stubborn bolts or nuts, an impact wrench can provide the extra torque needed to loosen them. Always prioritize safety by wearing appropriate protective gear when using these tools.

Where to Buy Replacement Parts

Finding the right components for your outdoor equipment is essential for maintaining optimal performance and extending its lifespan. Fortunately, various avenues are available for acquiring the necessary elements, ensuring you can keep your equipment running smoothly. Whether you prefer shopping online or visiting a local store, there are numerous options to consider.

Below is a table highlighting some reliable sources for purchasing components:

| Source | Type | Website |

|---|---|---|

| Local Hardware Store | Physical Retailer | N/A |

| Online Retailer | Website | www.example.com |

| Manufacturer’s Website | Official Online Store | www.manufacturer.com |

| Specialty Parts Suppliers | Online Retailer | www.partsupplier.com |

| Second-Hand Stores | Physical Retailer | N/A |

Consider exploring these options to find the components you need efficiently. Each source offers its advantages, allowing you to select the best fit for your needs.