Understanding the Components of a Boat Engine Diagram

Delving into the intricacies of maritime mechanics reveals a fascinating interplay of elements essential for smooth navigation. Each element plays a crucial role in the overall functionality, ensuring that vessels operate efficiently and effectively. This exploration not only highlights their significance but also illustrates how they work in harmony to support the vessel’s performance.

Grasping the complexities of these mechanical structures involves recognizing their distinct functions and interrelations. Each section contributes uniquely to the overall system, influencing everything from power generation to propulsion. Analyzing these components provides insight into their importance in maintaining operational integrity and safety on the water.

By examining these elements closely, one can appreciate the sophistication of maritime technology. Understanding their arrangement and interaction can illuminate the engineering principles that keep vessels afloat and performing at their best. This knowledge serves as a foundation for anyone looking to deepen their comprehension of marine operations and mechanics.

Understanding Boat Engine Components

Gaining insight into the essential elements of marine propulsion systems is crucial for any enthusiast. Each component plays a significant role in ensuring optimal performance and efficiency. A comprehensive understanding allows for better maintenance and troubleshooting, ultimately enhancing the overall experience on the water.

Key elements to consider include:

- Power Source: The heart of the mechanism, providing the necessary energy for operation.

- Cooling System: Maintains optimal temperatures to prevent overheating and ensures longevity.

- Fuel Delivery: Responsible for transferring energy-rich substances to the combustion area.

- Exhaust Mechanism: Channels waste gases away, ensuring efficient operation and safety.

- Lubrication System: Reduces friction between moving parts, promoting smooth operation and reducing wear.

When examining each element, it is essential to recognize how they interact and contribute to the overall functionality. A well-maintained system not only enhances performance but also extends the lifespan of the entire assembly.

- Regular inspections can prevent unexpected failures.

- Understanding the role of each element aids in effective troubleshooting.

- Knowledge of maintenance requirements helps in planning routine care.

Ultimately, familiarizing oneself with these critical components paves the way for a deeper appreciation and more enjoyable experiences in maritime ventures.

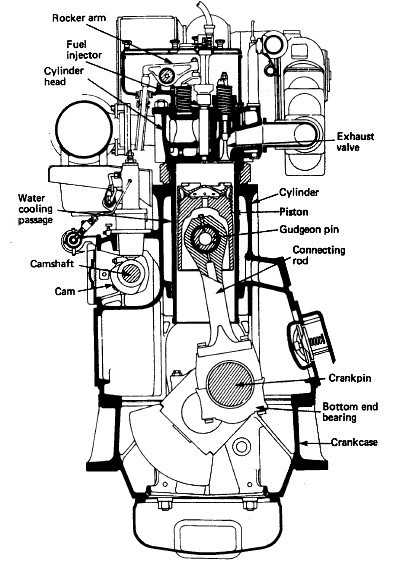

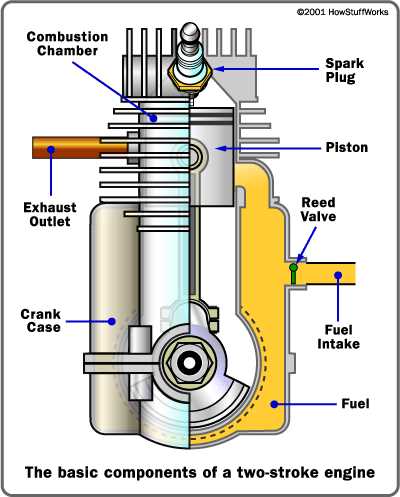

Key Parts of an Inboard Engine

Understanding the essential components of a watercraft’s power unit is crucial for efficient operation and maintenance. Each element plays a significant role in ensuring optimal performance, reliability, and longevity. Familiarity with these components can enhance both safety and enjoyment on the water.

Crankshaft is a vital component that converts linear motion into rotational motion, driving the propulsion system. This transformation of energy is fundamental for generating thrust.

Cylinder head houses the valves and spark plugs, facilitating the combustion process. Its design influences the efficiency and power output of the unit, making it a key focus during upgrades or repairs.

Intake and exhaust manifolds manage the flow of air and fuel into the combustion chamber while directing exhaust gases out. Proper functioning of these elements is essential for maintaining performance and reducing emissions.

Cooling system plays a critical role in regulating temperature, ensuring that the machinery does not overheat during operation. This system typically involves a heat exchanger or raw water intake to dissipate excess heat effectively.

Fuel system is responsible for delivering the right mixture of fuel and air to the combustion chamber. Components such as fuel pumps and injectors are essential for optimal performance and efficiency.

Transmission connects the power unit to the propeller or drive shaft, translating rotational energy into thrust. The design and condition of the transmission can significantly affect handling and responsiveness.

Each of these components contributes to the overall functionality of the power unit. Understanding their roles helps in identifying maintenance needs and ensuring reliable operation on the water.

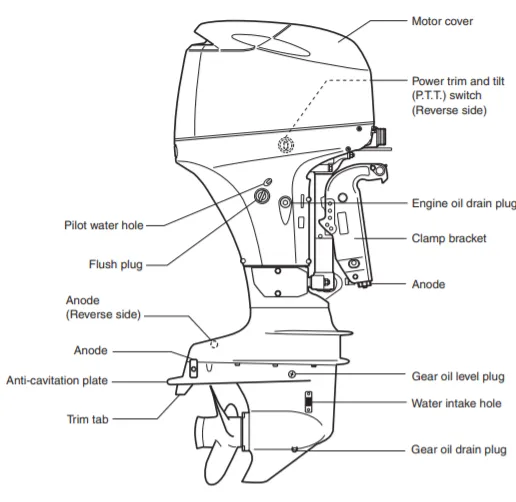

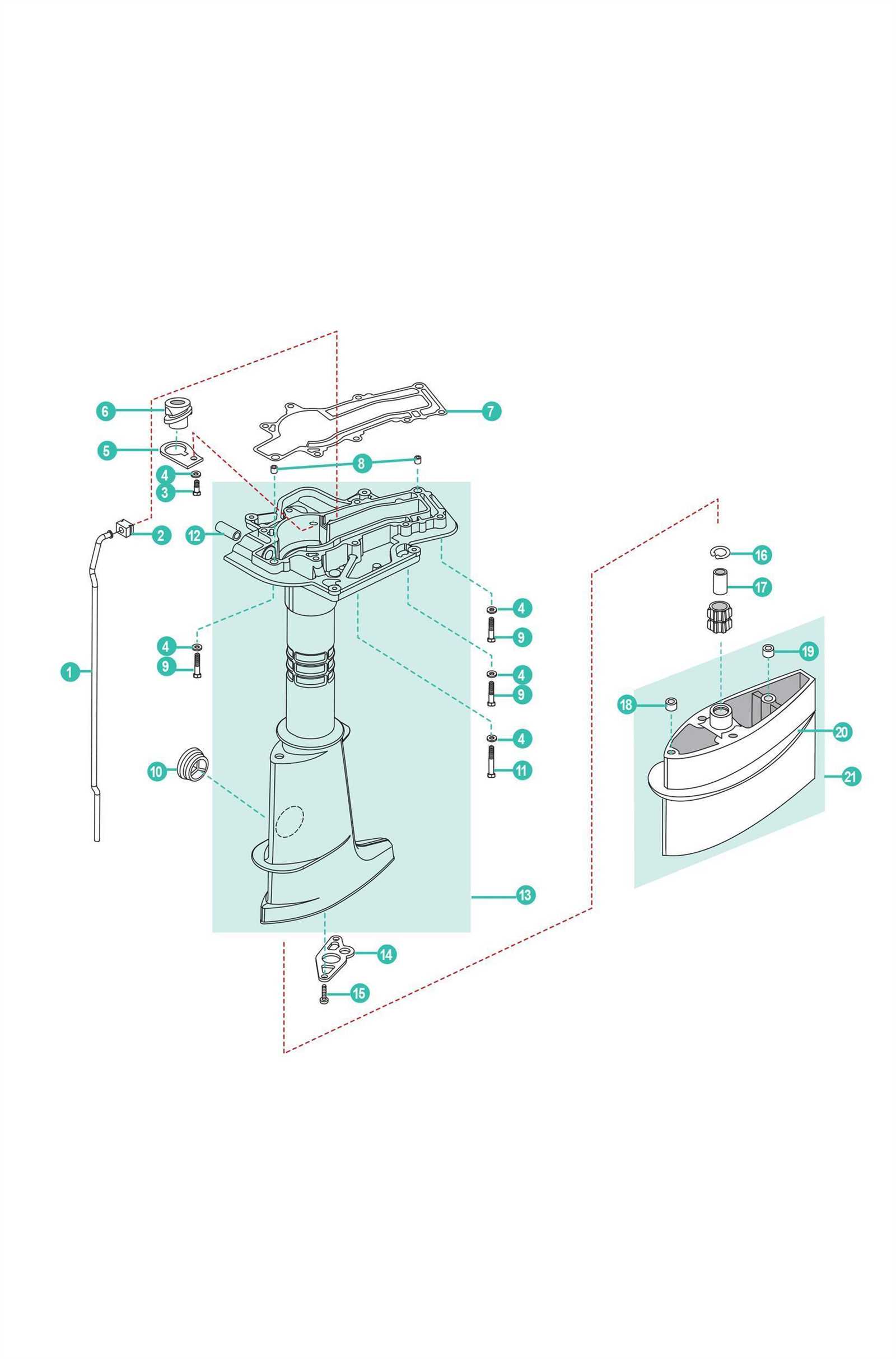

Identifying Outboard Motor Elements

Understanding the various components of an outboard motor is essential for maintenance and effective operation. Each element plays a vital role, contributing to the overall functionality and efficiency of the system. By familiarizing yourself with these components, you can ensure better performance and longevity.

Key Components to Recognize

- Powerhead: The main assembly where combustion occurs, housing the cylinders and other crucial elements.

- Gearcase: This section contains the gears and driveshaft, responsible for transferring power to the propeller.

- Propeller: A rotating blade that propels the vessel through water by converting rotational motion into thrust.

- Fuel System: Comprising the fuel tank, lines, and carburetor or injectors, this system delivers fuel to the combustion area.

- Cooling System: Essential for preventing overheating, this system typically includes water intakes and thermostats.

Importance of Familiarization

Recognizing these key elements not only aids in troubleshooting but also enhances overall boating experience. Regular inspection and understanding of each component’s function contribute to smoother operation and can prevent costly repairs.

Fuel System Overview in Engines

The fuel mechanism plays a critical role in the overall functionality of any propulsion system. It is responsible for managing the flow and delivery of energy sources, ensuring optimal performance and efficiency. Understanding its components and their interactions is essential for maintaining reliability and enhancing power output.

Key Functions of the Fuel Mechanism

- Storage: Safeguarding the energy source until needed.

- Delivery: Transporting fuel from the storage unit to the combustion chamber.

- Mixing: Combining fuel with air to create a combustible mixture.

- Control: Regulating the amount of fuel supplied based on demand.

Components of the Fuel Mechanism

- Tank: The reservoir where fuel is held.

- Pump: A device that moves fuel from the tank to the necessary components.

- Filter: Ensures that impurities are removed before the fuel reaches the combustion area.

- Injector: Sprays the fuel into the combustion chamber in a precise manner.

Each of these elements contributes to the overall efficiency and performance, making the fuel system a vital aspect of any propulsion mechanism.

Cooling Mechanisms in Boat Motors

Effective thermal management is crucial for optimal performance in marine propulsion systems. The regulation of temperature prevents overheating and ensures that machinery operates within safe limits. Various techniques are employed to dissipate heat generated during operation, each contributing uniquely to the longevity and reliability of the machinery.

The most common cooling methods involve the use of water or air to absorb and carry away excess heat. These systems not only enhance efficiency but also protect vital components from thermal damage. Understanding these mechanisms can help in selecting the right approach for specific applications.

| Cooling Method | Description | Advantages |

|---|---|---|

| Raw Water Cooling | Utilizes water from the surrounding environment to absorb heat. | Efficient and cost-effective; widely available. |

| Freshwater Cooling | Employs a closed-loop system using coolant fluid to transfer heat. | Provides better temperature control and prevents corrosion. |

| Air Cooling | Uses airflow to dissipate heat without liquid coolant. | Lightweight and reduces risk of leaks. |

Each of these cooling strategies has its own set of benefits and drawbacks. Selecting the appropriate method depends on various factors, including the type of vessel, operating conditions, and maintenance capabilities. Careful consideration of these elements ensures reliable and efficient operation on the water.

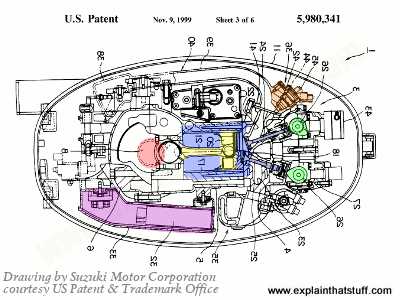

Electrical System and Wiring Basics

The electrical network of a maritime vessel plays a crucial role in ensuring smooth operations and functionality. Understanding the components and layout of this system is essential for maintaining performance and safety. Proper wiring and connectivity are key to enabling various functions, from navigation to communication.

Wiring Fundamentals involve the arrangement and connection of conductors that facilitate the flow of electricity. Each connection must be secure and appropriately insulated to prevent short circuits or failures. Using the correct gauge of wire is vital, as it affects the efficiency and safety of the entire network.

Electrical Components include batteries, switches, fuses, and various instruments. Each component must be selected based on the specific demands of the vessel. For instance, the choice of battery impacts not only the starting power but also the overall energy management during operation.

Understanding Voltage and Current is essential for anyone working with electrical systems. It’s important to recognize how these two factors interact and affect performance. Properly designed circuits must balance load and capacity to ensure reliability and longevity.

Lastly, regular Maintenance of the electrical system cannot be overstated. Periodic inspections help identify wear and potential issues before they escalate, ensuring that all systems remain operational and safe for navigation.

Transmission and Propulsion Details

The intricacies of motion systems play a vital role in the overall functionality and performance of marine vessels. Understanding how these mechanisms work together is essential for optimizing efficiency and ensuring smooth navigation. This section delves into the essential components that contribute to the movement and control of a maritime craft.

Transmission is the crucial link that transfers power from the power source to the moving elements. It involves various components that work in harmony to manage speed and torque, allowing for precise maneuvering. Among these elements, gear systems are fundamental, enabling adjustments in speed while maintaining stability under different conditions.

Propulsion systems are responsible for generating the thrust needed to propel the vessel through water. This can involve various mechanisms, such as propellers or jets, each with unique characteristics that influence performance. The choice of propulsion type significantly affects speed, fuel efficiency, and overall handling.

In summary, a comprehensive understanding of these essential systems is crucial for anyone involved in marine activities. By mastering the intricacies of transmission and propulsion, operators can significantly enhance the performance and safety of their maritime experiences.

Maintenance Tips for Engine Parts

Regular upkeep is essential for ensuring the longevity and efficiency of your mechanical systems. By focusing on key elements, you can prevent issues before they arise and enhance overall performance. Here are some valuable suggestions to help maintain these crucial components.

1. Routine Inspections: Schedule consistent check-ups to identify any signs of wear or damage. Look for leaks, cracks, or corrosion that may compromise functionality. Early detection can save time and resources.

2. Cleanliness is Key: Keep all areas free of dirt and debris. Use appropriate cleaning agents to remove grease and grime, which can hinder performance. A clean workspace contributes to better operation and reduces the risk of malfunctions.

3. Lubrication: Ensure that all moving elements are properly lubricated. This reduces friction and minimizes the risk of overheating. Follow manufacturer guidelines for the type and frequency of lubricants used.

4. Monitor Fluid Levels: Regularly check and maintain optimal fluid levels. This includes oils and coolants, which are vital for efficient functioning. Low levels can lead to severe damage and costly repairs.

5. Seasonal Care: Prepare your equipment for seasonal changes. For instance, winterizing measures can prevent freezing and other weather-related issues. Be proactive in your maintenance to avoid unexpected breakdowns.

6. Follow Manufacturer Recommendations: Adhere to guidelines provided by the manufacturer for maintenance schedules and servicing. This ensures that your components operate within their designed parameters and helps maintain warranty coverage.

By incorporating these practices into your routine, you can extend the lifespan of critical elements and ensure reliable performance when you need it most.

Common Issues in Engine Components

Understanding the typical challenges faced by critical components is essential for ensuring optimal performance. Various elements can experience wear and tear, leading to reduced efficiency and potential failures. Identifying these issues early can save time and costs associated with repairs.

Frequent Problems

- Overheating: Excessive temperatures can damage components, leading to reduced functionality.

- Leaks: Fluid leaks can compromise performance and indicate underlying faults.

- Corrosion: Exposure to moisture and salt can result in deterioration, affecting longevity.

- Vibration: Unusual vibrations may signal misalignment or imbalance, potentially causing severe damage.

- Clogging: Blockages in systems can impede flow, resulting in decreased efficiency.

Maintenance Tips

- Regularly inspect for signs of wear and tear.

- Monitor fluid levels and check for leaks frequently.

- Keep components clean to prevent buildup and corrosion.

- Address unusual noises or vibrations immediately.

- Schedule routine maintenance to ensure all systems function optimally.

Performance Enhancements for Boat Engines

Improving the capabilities of maritime propulsion systems is essential for achieving higher speeds, better fuel efficiency, and enhanced overall reliability. Various strategies can be implemented to optimize performance and ensure a smoother sailing experience.

- Tuning and Calibration:

Adjusting the settings of the propulsion mechanism can lead to significant improvements. This includes fine-tuning the fuel-to-air ratio and ignition timing for optimal combustion.

- Upgrading Components:

Investing in high-quality elements such as propellers, exhaust systems, and intake manifolds can drastically enhance performance. These upgrades often lead to reduced drag and improved thrust.

- Weight Reduction:

Minimizing unnecessary weight can result in better acceleration and handling. Utilizing lightweight materials for construction and equipment can have a noticeable impact.

- Regular Maintenance:

Consistent upkeep, including oil changes and filter replacements, ensures optimal functioning. Well-maintained systems are less prone to malfunctions and can perform at peak levels.

- Fuel Quality:

Using high-octane fuel can improve performance by enabling more efficient combustion, leading to enhanced power output and efficiency.

Implementing these enhancements can significantly improve the functionality and performance of maritime vessels, making for a more enjoyable and efficient experience on the water.

Choosing the Right Engine for Your Boat

When it comes to selecting the ideal power source for your vessel, several factors come into play. Understanding your requirements and preferences is crucial to ensure optimal performance and efficiency on the water. The choice can significantly influence your experience, from speed to fuel consumption and overall reliability.

Assessing Your Needs

Start by considering how you intend to use your watercraft. Are you planning leisurely excursions, high-speed adventures, or perhaps fishing trips? Identifying your primary activities will help determine the necessary specifications for the propulsion system. Additionally, consider the size and weight of your craft, as these factors greatly impact the performance of the chosen power unit.

Fuel Type and Efficiency

Another vital aspect is the type of fuel that best suits your lifestyle and budget. Diesel engines typically offer better fuel efficiency and longevity, while gasoline units may provide quicker acceleration and lower initial costs. Weighing the benefits of each fuel type in relation to your intended use will lead to a more informed decision.