Complete Guide to 2008 Saturn Vue Body Parts Diagram

Exploring the intricate design of automotive constructions reveals a fascinating interplay of components that work harmoniously to ensure functionality and safety. This visual guide aims to enhance your knowledge of the various segments that comprise a specific model, enabling a deeper appreciation for the engineering behind everyday vehicles.

In this section, we will break down the essential elements that make up the exterior framework of the automobile. By examining these components, readers will gain insight into their roles and significance in the overall performance and aesthetics of the vehicle. This understanding not only aids in maintenance but also fosters a greater connection with the machine itself.

Acquiring familiarity with these segments can empower vehicle owners to make informed decisions regarding repairs and enhancements. Whether you are a seasoned mechanic or an enthusiastic car owner, this exploration serves as a valuable resource for anyone looking to delve into the mechanics of their ride.

Understanding the 2008 Saturn Vue Design

The design of this compact SUV reflects a blend of functionality and aesthetics, catering to the needs of modern drivers. With a focus on both form and performance, the exterior features a streamlined silhouette that enhances aerodynamics while providing a sturdy presence on the road.

Attention to detail is evident in the choice of materials and finishes, ensuring durability and a polished look. The layout offers an inviting interior space, equipped with user-friendly controls and ample storage options. Comfort is prioritized, making it suitable for both short commutes and long journeys.

Incorporating safety features and technology, this vehicle aims to create a secure driving environment. The overall structure is engineered to provide a balance of power and efficiency, appealing to a wide range of drivers looking for reliability and style.

Overview of Saturn Vue Components

This section provides a comprehensive look at the essential elements that make up a particular model of an automobile. Understanding these components is crucial for anyone interested in maintenance, repairs, or modifications. Each part plays a vital role in ensuring the vehicle operates efficiently and safely.

Key Elements

The primary components of a vehicle can be categorized into several main groups, each serving distinct functions that contribute to the overall performance and reliability. Below are some of the critical categories:

| Component Category | Function |

|---|---|

| Chassis | Provides structural support and stability. |

| Engine | Generates power to propel the vehicle. |

| Transmission | Transfers power from the engine to the wheels. |

| Brakes | Ensures safe stopping and control. |

| Electrical System | Supplies power to various components and systems. |

Maintenance Considerations

Key Features of Body Parts

Understanding the essential components of a vehicle’s exterior is crucial for maintenance and performance. Each element plays a significant role in not only aesthetics but also in structural integrity and safety. This section outlines the primary attributes that characterize these components, providing insights into their functionality and importance.

| Feature | Description |

|---|---|

| Durability | Designed to withstand various environmental conditions and impacts, ensuring longevity. |

| Aerodynamics | Shapes are optimized to reduce air resistance, enhancing fuel efficiency and performance. |

| Weight | Lightweight materials are often used to improve handling and efficiency without compromising strength. |

| Safety Features | Incorporation of crumple zones and reinforcement enhances occupant protection during collisions. |

| Corrosion Resistance | Coatings and materials are selected to minimize rust and degradation over time. |

Importance of Accurate Diagrams

Precise illustrations play a crucial role in the automotive industry, serving as essential tools for both professionals and enthusiasts. They provide a clear representation of complex structures, facilitating a better understanding of assembly and repair processes.

Key reasons for relying on accurate illustrations include:

- Clarity: Clear visuals help in identifying components and their locations, reducing confusion during maintenance.

- Efficiency: Well-crafted illustrations enable quicker assembly or disassembly, saving valuable time in repairs.

- Safety: Accurate visuals can highlight critical safety features, ensuring that essential parts are properly handled and maintained.

- Cost-Effectiveness: Reducing the likelihood of errors during repairs can minimize costly mistakes and rework.

In summary, reliable visuals are vital for effective vehicle maintenance and repair, promoting efficiency and safety while reducing potential costs.

Common Issues with Body Parts

Vehicles often experience various challenges related to their exterior components. Understanding these common problems can help owners identify issues early and maintain their vehicles effectively. From wear and tear to environmental damage, several factors contribute to the degradation of these elements over time.

Frequent Problems

Below are some of the typical concerns that arise with exterior components:

| Issue | Description |

|---|---|

| Rust | Corrosion can develop on metal surfaces, particularly in areas exposed to moisture and salt. |

| Cracks | Plastic components may develop fissures due to temperature fluctuations and impact. |

| Paint Fading | Exposure to sunlight can cause the color to fade, diminishing the vehicle’s aesthetic appeal. |

| Dents | Minor collisions or hail can create depressions in the surface, impacting both appearance and value. |

Prevention and Maintenance

Regular maintenance and protective measures can significantly extend the lifespan of exterior elements. Routine inspections, waxing, and prompt repairs are essential to avoid costly replacements in the future.

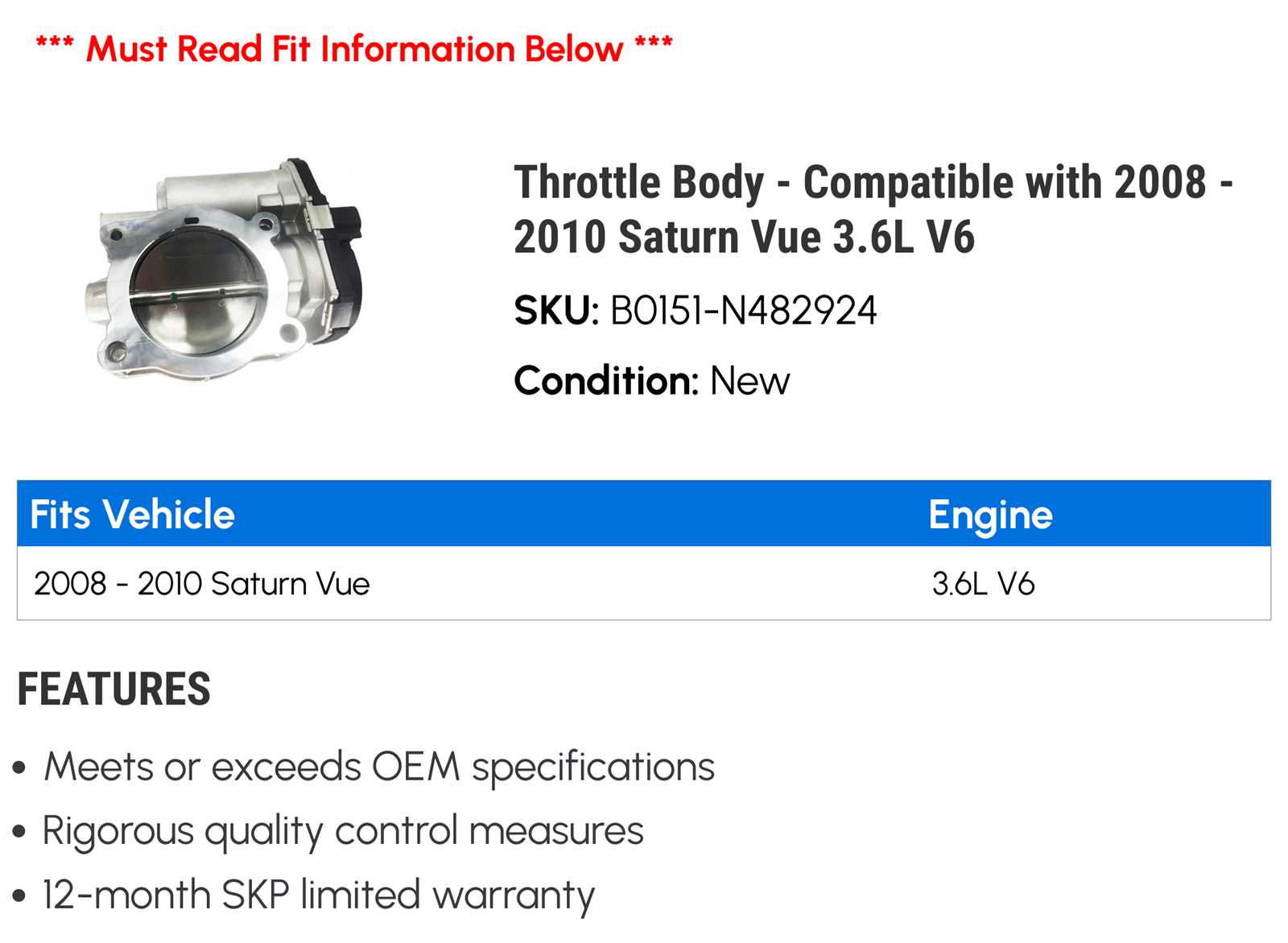

Replacement Procedures for Components

When it comes to maintaining your vehicle, knowing how to effectively replace various elements is crucial. Understanding the steps involved can save time, reduce costs, and enhance overall vehicle performance. This section outlines essential procedures for swapping out different components, ensuring you can tackle repairs with confidence.

Preparation Steps

Before initiating any replacement, proper preparation is vital. Begin by gathering all necessary tools and components. Ensure the vehicle is parked on a level surface, and always engage the parking brake. Wearing safety gear, such as gloves and goggles, is recommended to protect yourself during the process. Additionally, consult the vehicle’s manual for specific instructions related to the component being replaced.

Replacement Process

Once prepared, follow these general steps for replacing components:

- Remove Fasteners: Start by loosening and removing any screws or bolts securing the component. Keep these fasteners organized for reinstallation.

- Detach the Component: Carefully disconnect any electrical connectors or hoses attached to the part. Take care not to damage surrounding components during this process.

- Install the New Component: Position the new part in place, ensuring it aligns correctly with mounting points. Reattach any connectors or hoses, ensuring a secure fit.

- Refasten: Replace the screws or bolts to secure the component firmly. Follow the specified torque settings if available.

Finally, it’s essential to conduct a thorough inspection to confirm that everything is properly installed and functioning. By adhering to these guidelines, you can ensure a successful replacement, contributing to the longevity and reliability of your vehicle.

Materials Used in Body Construction

The selection of materials for vehicle exteriors plays a crucial role in determining overall performance, safety, and aesthetic appeal. Each component is carefully crafted from specific substances that offer unique properties, contributing to the durability and functionality of the automobile. Understanding the materials involved helps in appreciating their impact on the vehicle’s design and efficiency.

Common Materials

Aluminum is frequently employed due to its lightweight characteristics and resistance to corrosion, making it ideal for enhancing fuel efficiency while maintaining structural integrity. Steel, on the other hand, is valued for its strength and impact resistance, providing essential safety features. Additionally, advanced composite materials are increasingly utilized, offering a blend of strength and reduced weight, which aids in performance without sacrificing safety.

Innovations in Material Usage

Recent advancements have introduced new materials such as high-strength steel and thermoplastics, which enhance performance while minimizing environmental impact. These innovations not only improve energy efficiency but also allow for greater design flexibility, enabling manufacturers to create more aerodynamic shapes. As technology evolves, the integration of innovative substances continues to redefine standards in vehicle construction.

Differences Between Trim Levels

When exploring various configurations of a vehicle, it’s essential to understand how the different trim options can significantly influence the overall experience. Each level presents a unique set of features and enhancements, catering to diverse preferences and needs.

Base Trim typically offers essential functionalities, focusing on practicality and affordability. It serves as a solid choice for those prioritizing budget without sacrificing reliability.

Mid-Level Trim introduces additional comfort and convenience features, such as upgraded audio systems, enhanced seating materials, and improved technology. This option appeals to buyers looking for a balance between cost and luxury.

Top Trim represents the pinnacle of luxury and performance, often including premium features like advanced safety systems, superior infotainment technology, and high-quality interior finishes. This choice is ideal for individuals seeking the utmost in comfort and style.

Understanding these distinctions allows potential owners to make informed decisions that align with their preferences and lifestyle requirements.

Tools Required for Repairs

When undertaking maintenance or restoration tasks on a vehicle, having the right instruments at your disposal is essential. Proper tools not only facilitate the process but also ensure safety and precision during repairs. Below is a list of essential equipment that every enthusiast should consider for effective work.

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening and tightening bolts and nuts. |

| Wrench Set | Provides leverage for turning fasteners in tight spaces. |

| Screwdriver Set | Essential for removing and installing screws of various types. |

| Jack and Jack Stands | Used for lifting the vehicle safely to access the underside. |

| Pliers | Useful for gripping, twisting, and cutting wires or other materials. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications. |

| Multimeter | For diagnosing electrical issues and measuring voltage. |

| Shop Manual | Provides detailed instructions and specifications for repairs. |

Where to Find Diagrams Online

Locating detailed illustrations for automotive components has become increasingly accessible thanks to the vast resources available on the internet. Enthusiasts and professionals alike can benefit from a variety of websites that offer comprehensive visuals and manuals. These resources not only aid in understanding vehicle assembly but also assist in troubleshooting and repair tasks.

Recommended Websites

| Website | Description |

|---|---|

| AutoZone | Provides free repair guides and diagrams for a wide range of vehicles. |

| Haynes Manuals | Offers detailed manuals with illustrations for various car models. |

| RepairPal | Features a collection of diagrams and repair information tailored to different makes and models. |

| Alldata | A subscription-based service that delivers extensive repair documentation and diagrams. |

Tips for Effective Searches

To enhance your search experience, consider using specific terms related to the vehicle in question. Including model year, make, and other relevant keywords can yield more accurate results. Joining automotive forums and communities can also provide valuable insights and recommendations on where to find high-quality resources.

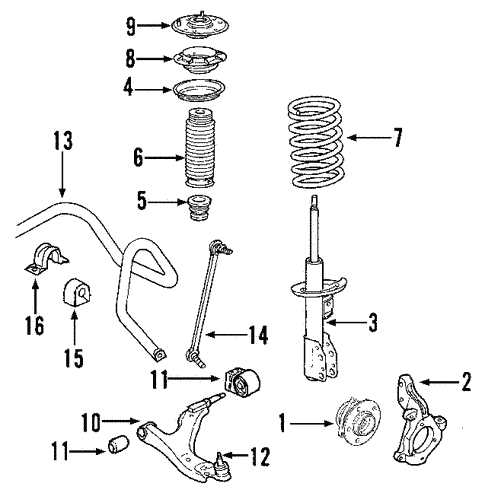

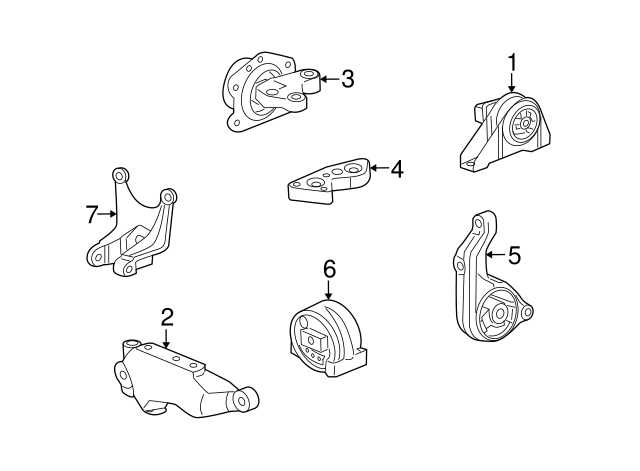

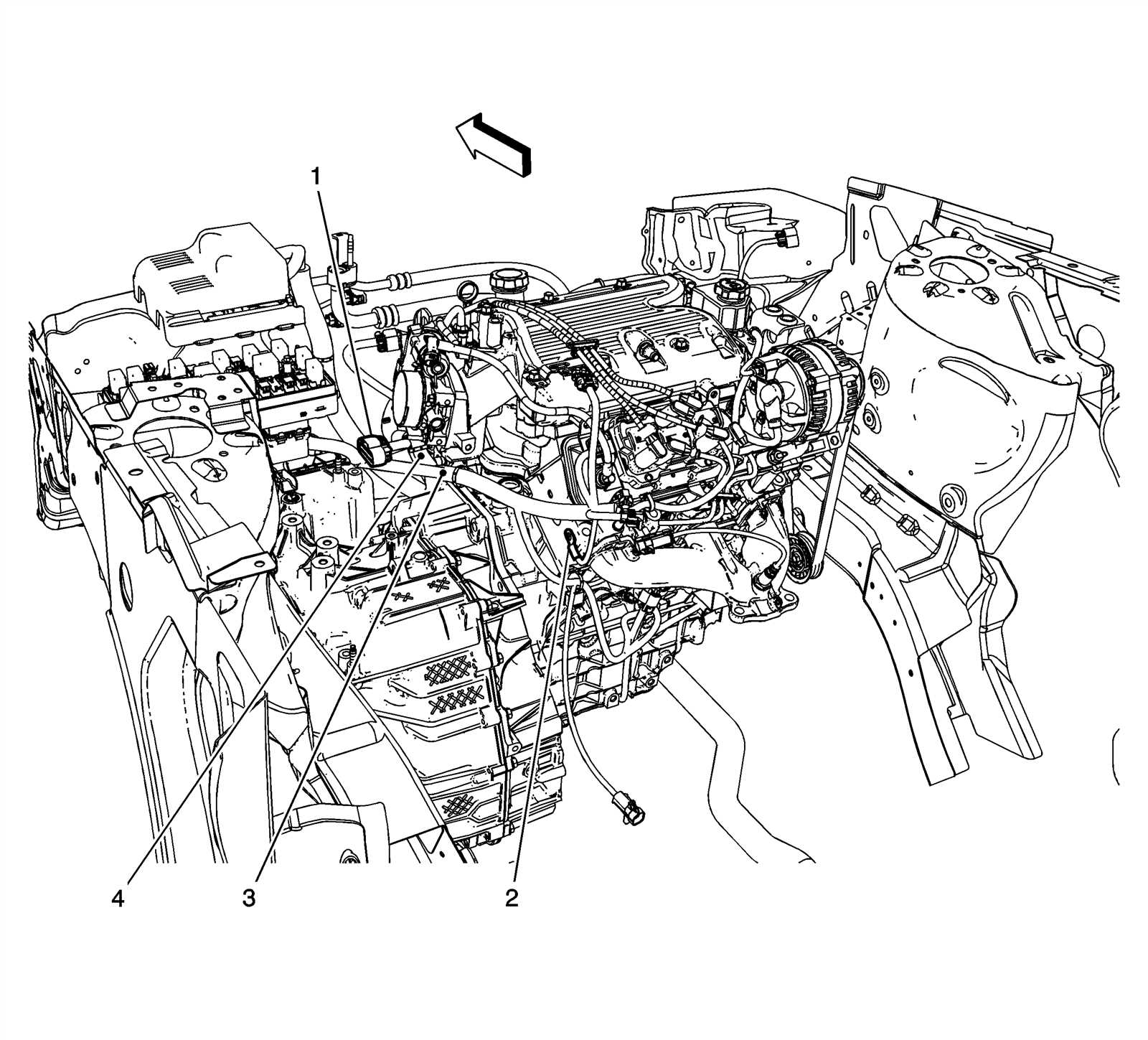

Visual Aids for Assembly

Effective visual tools play a crucial role in the assembly process, enhancing understanding and ensuring accuracy. These aids can significantly streamline the workflow and help users visualize complex procedures.

- Illustrative Diagrams: Clear graphics that depict each step can minimize confusion.

- Step-by-Step Guides: Sequential instructions accompanied by images help in following the correct order.

- 3D Models: Interactive representations allow for a comprehensive view of the components and their interactions.

Utilizing these resources can reduce errors and improve overall efficiency during the assembly task. Each tool offers distinct advantages that cater to different learning styles.

- Preparation: Gather all necessary tools and components before starting.

- Familiarization: Study the visual aids to understand the process thoroughly.

- Execution: Follow the guides step by step, referencing visuals as needed.

Incorporating visual support not only simplifies assembly but also empowers users, providing them with the confidence to tackle the project effectively.

Maintenance Tips for Saturn Vue

Ensuring the longevity and performance of your vehicle requires regular attention and care. A proactive approach to upkeep can prevent issues and enhance your driving experience. Below are essential practices to consider for optimal maintenance.

- Regular Oil Changes: Changing the oil periodically is crucial. It lubricates engine components and removes impurities.

- Tire Care: Monitor tire pressure and tread depth. Rotating tires regularly promotes even wear and extends their lifespan.

- Brake Inspection: Keep an eye on brake pads and rotors. Addressing any unusual sounds early can prevent costly repairs.

- Fluid Levels: Check and top off all essential fluids, including coolant, brake fluid, and transmission fluid, to ensure optimal performance.

Additionally, consider the following recommendations:

- Battery Maintenance: Inspect terminals for corrosion and ensure a secure connection. Replace the battery as needed.

- Filter Replacements: Change air and cabin filters periodically to improve air quality and engine efficiency.

- Belts and Hoses: Regularly inspect belts and hoses for wear and tear to avoid breakdowns.

- Scheduled Inspections: Follow the manufacturer’s recommended service schedule for comprehensive check-ups.

Adopting these maintenance practices can significantly enhance the reliability and safety of your vehicle, allowing you to enjoy smooth journeys for years to come.