Understanding the Throttle Body Parts Diagram

In the intricate world of automotive engineering, the components responsible for managing airflow play a crucial role in engine performance and efficiency. These mechanisms ensure that the right amount of air enters the combustion chamber, impacting fuel combustion and overall vehicle operation.

By examining the various elements involved in this system, one can appreciate how each piece contributes to optimal functionality. Analyzing these components not only helps in diagnosing potential issues but also enhances the understanding of how they work in unison to achieve the desired outcome.

For enthusiasts and professionals alike, delving into the specifics of airflow management can reveal the ultimate secrets of enhancing engine output and efficiency. This exploration will clarify how each component interacts, providing insights into maintenance and upgrades for improved performance.

Understanding Throttle Body Functionality

The component in question plays a critical role in regulating airflow within an internal combustion engine. Its design and operation are essential for optimal performance, affecting how efficiently the engine operates under varying conditions.

Key functions include:

- Controlling air intake based on the driver’s input.

- Regulating engine speed and power output.

- Ensuring proper fuel mixture for combustion.

Understanding the mechanics behind this component can lead to enhanced vehicle performance and responsiveness. The interaction between the driver’s commands and the engine’s requirements illustrates the importance of precision in this system.

To delve deeper into its operation, consider the following aspects:

- How airflow is modulated during acceleration.

- The impact of electronic control systems on functionality.

- Common issues that can affect performance and efficiency.

Ultimately, mastering the intricacies of this mechanism is vital for anyone looking to improve their understanding of automotive engineering and performance tuning.

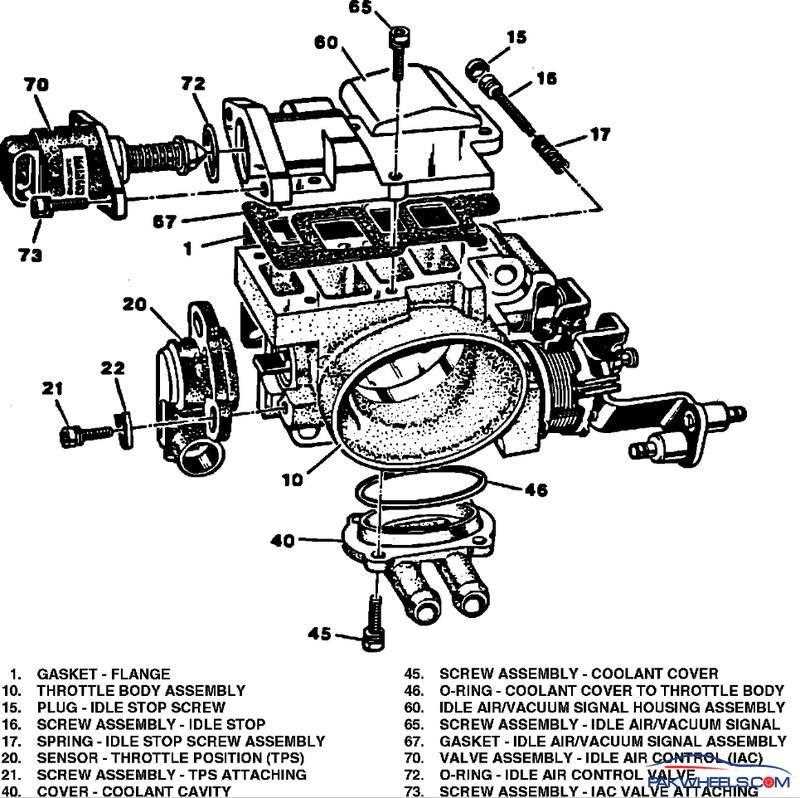

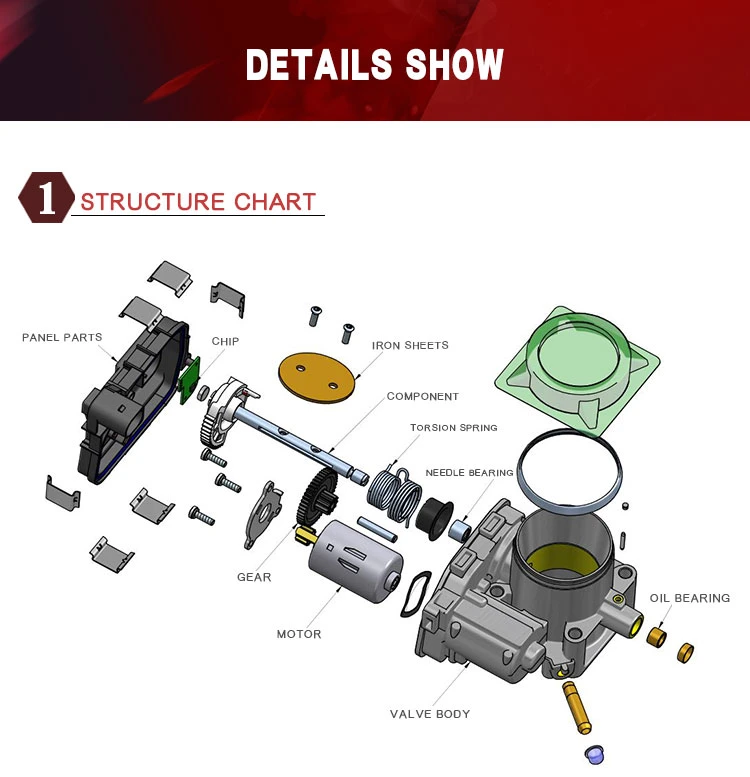

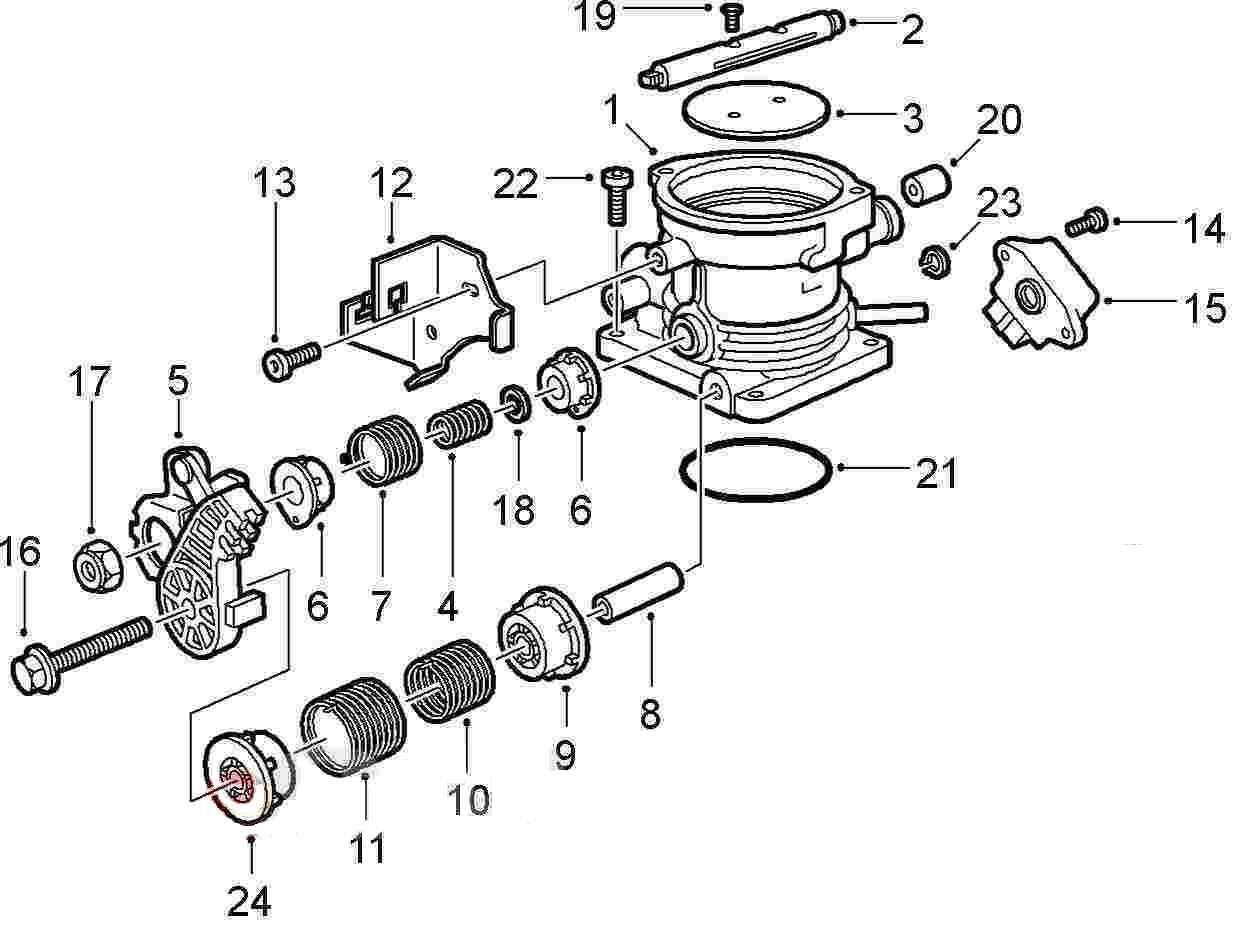

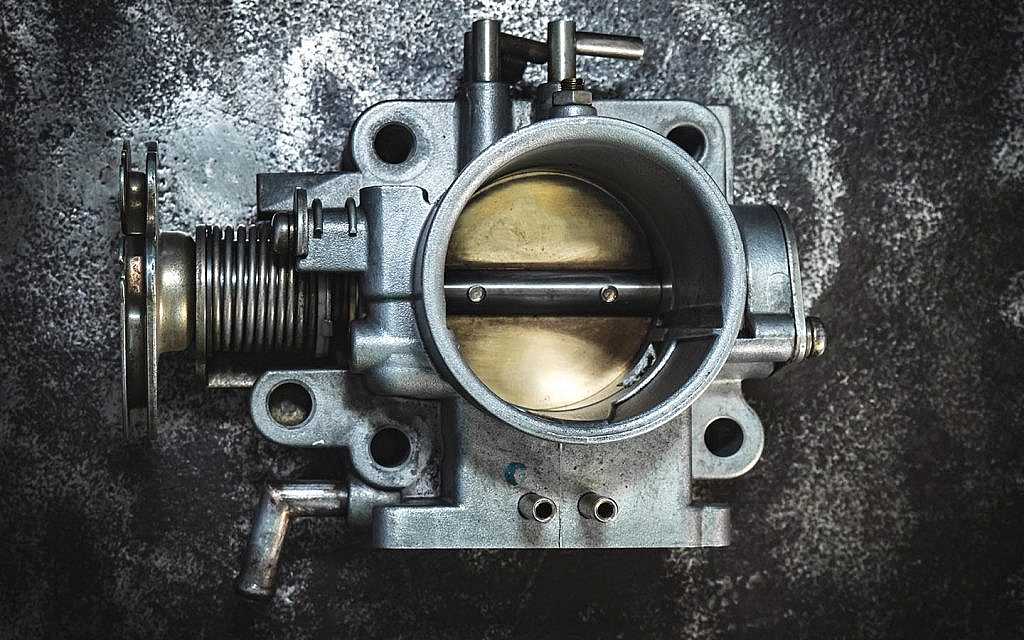

Key Components of Throttle Bodies

The intricate assembly that regulates air intake plays a vital role in optimizing engine performance. Understanding its essential elements is crucial for effective maintenance and enhancement of overall functionality. Each component contributes uniquely to the efficiency and responsiveness of the system.

Airflow Regulator

The airflow regulator is fundamental in controlling the volume of air entering the engine. Its precise operation ensures that the right amount of air mixes with fuel, leading to optimal combustion. Any malfunction here can directly affect performance and fuel efficiency.

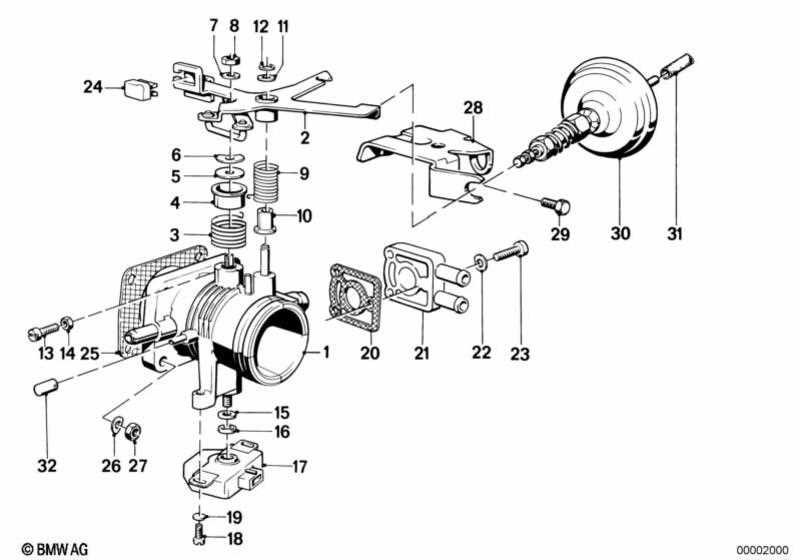

Position Sensor

The position sensor monitors the opening angle of the airflow regulator. This information is relayed to the engine control unit, allowing for real-time adjustments to maintain desired performance levels. A failure in this sensor can lead to erratic engine behavior.

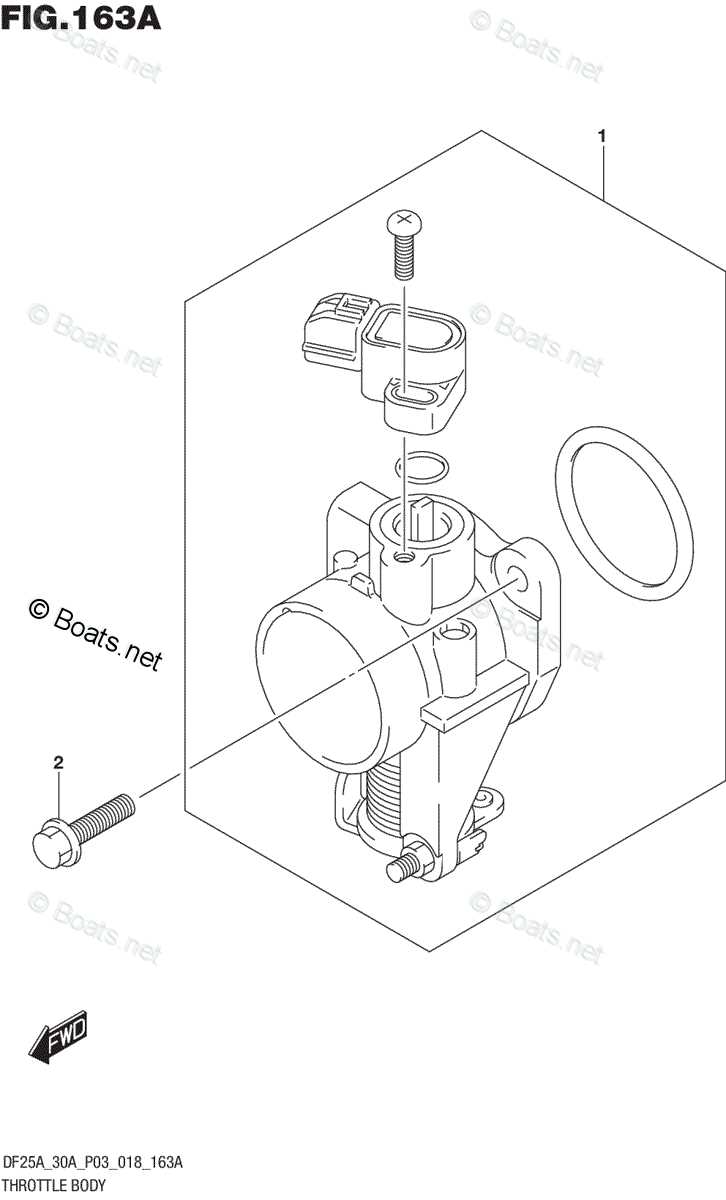

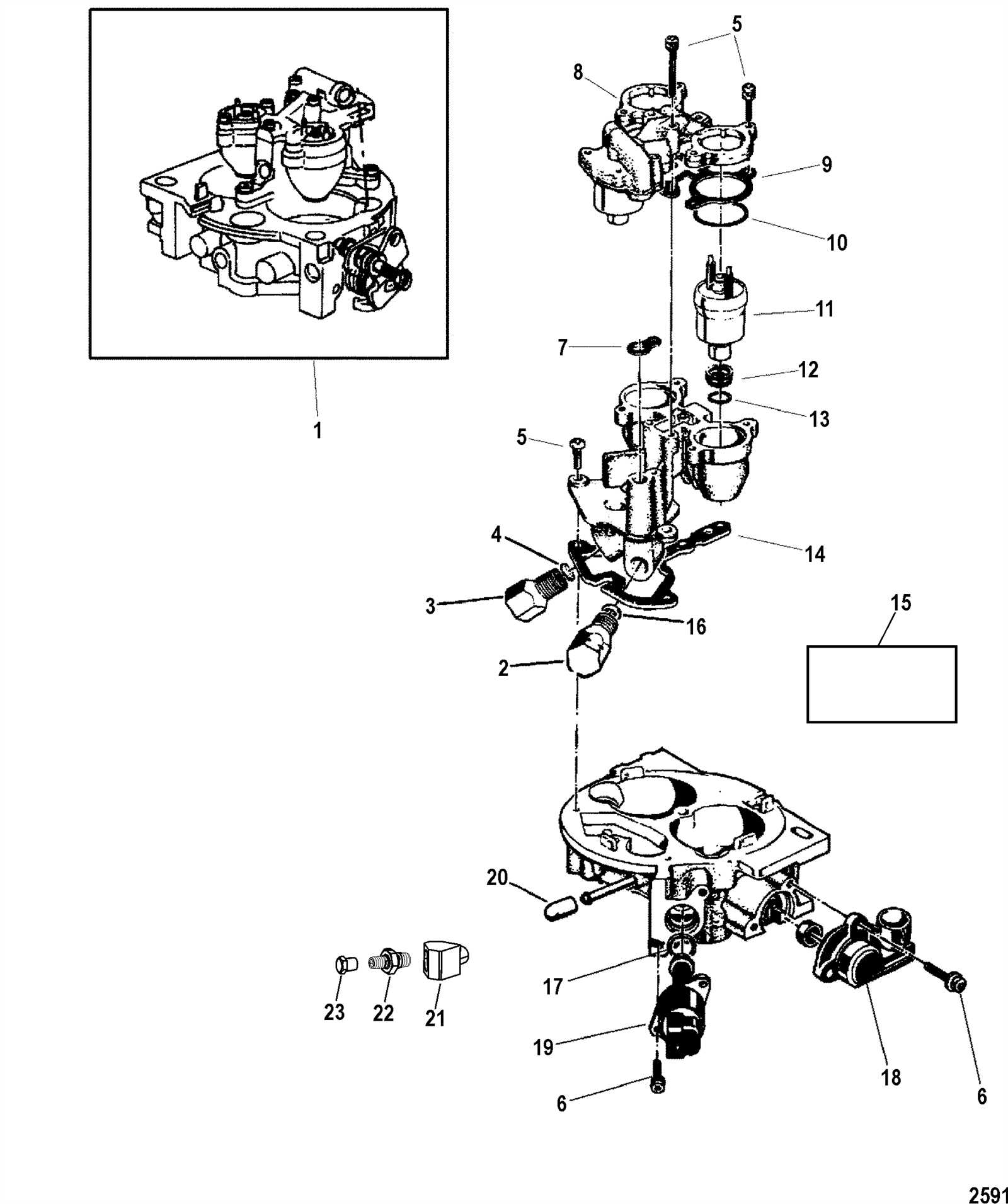

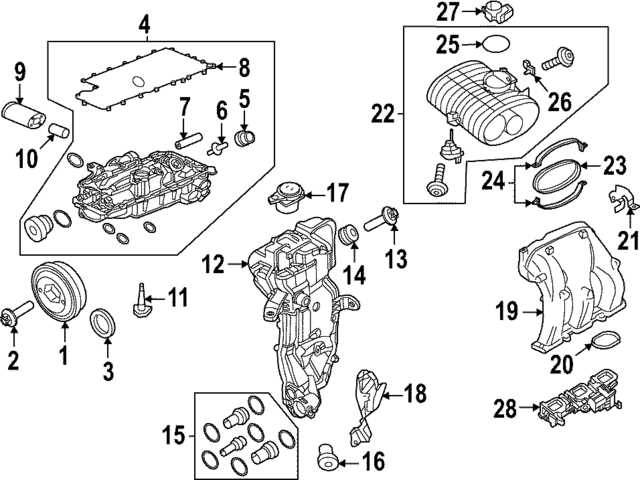

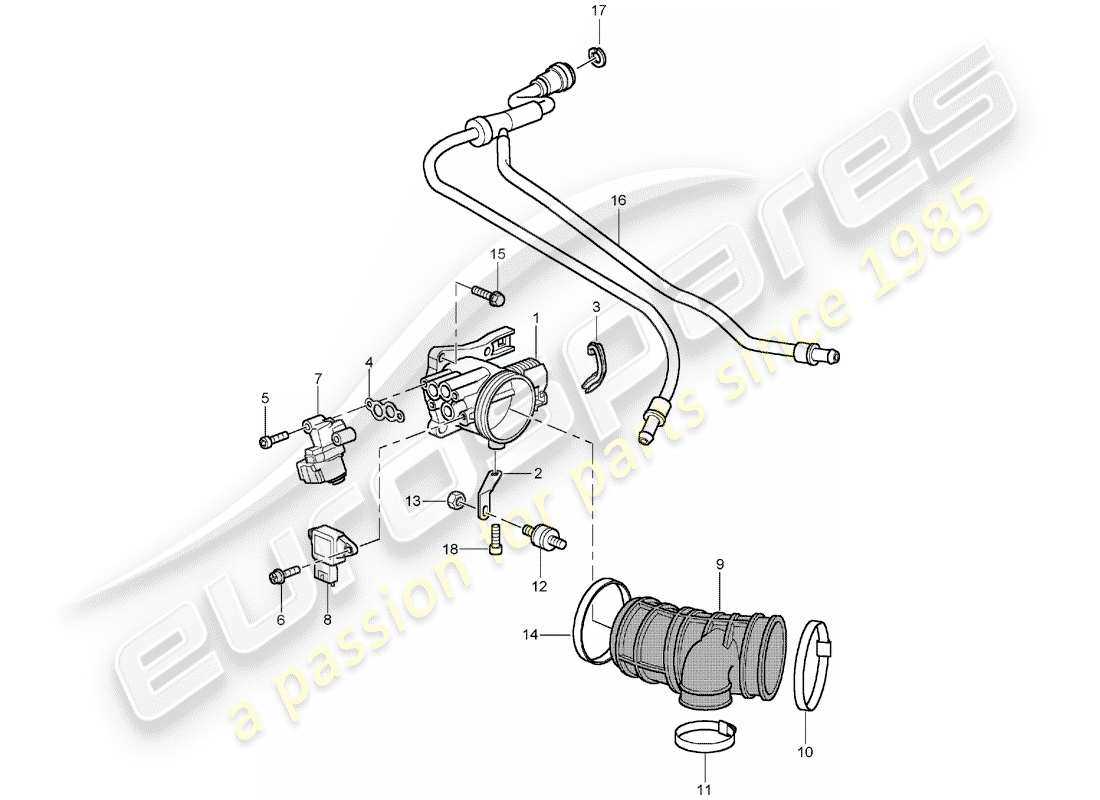

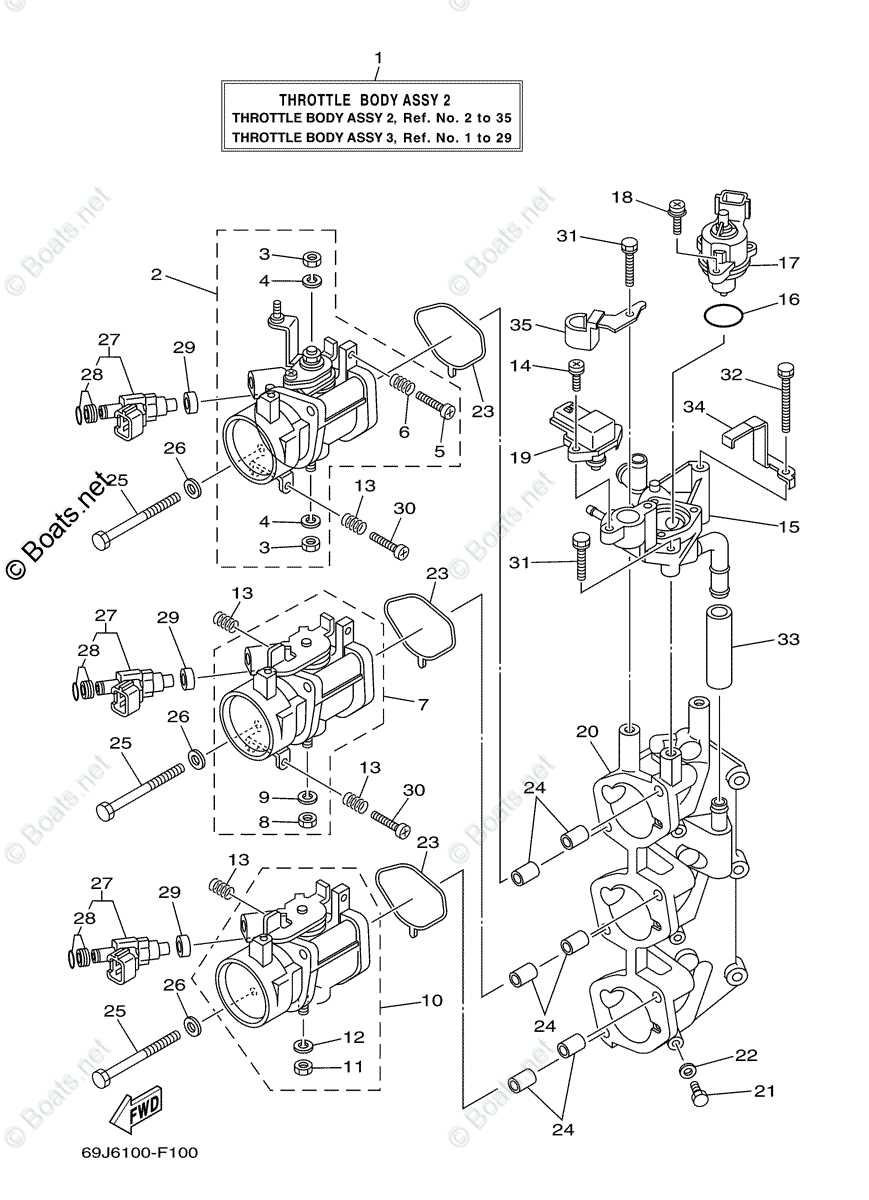

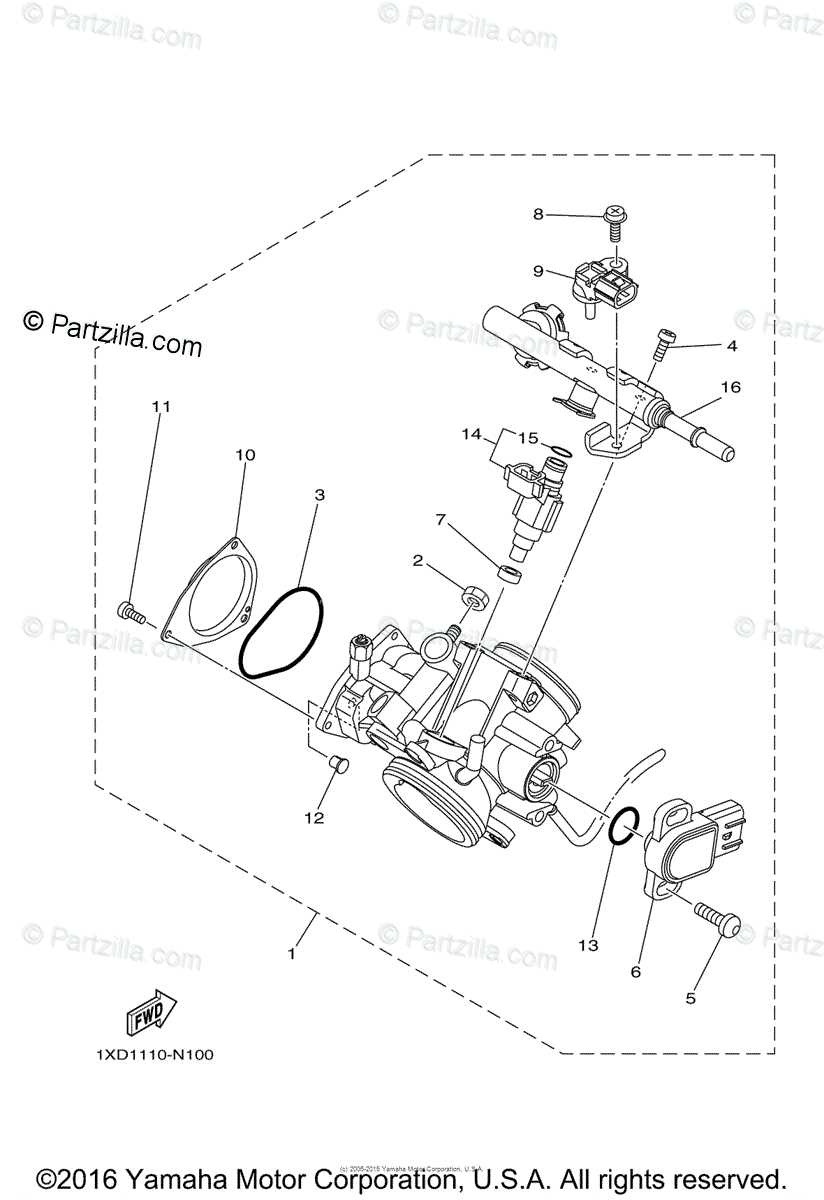

Throttle Body Diagrams Explained

Understanding the intricate layouts of air control mechanisms is essential for automotive enthusiasts and technicians alike. These schematics reveal how air flows into the engine, showcasing the components that regulate this process. By analyzing these visual representations, one can grasp the relationship between various elements and their functions in maintaining optimal engine performance.

Each component plays a critical role in managing airflow, with designs tailored to enhance efficiency and response. Recognizing the significance of these arrangements can aid in troubleshooting and optimizing vehicle performance. The diagrams not only illustrate physical placements but also convey the operational dynamics essential for a well-functioning engine system.

Types of Throttle Body Designs

Various designs serve crucial roles in managing airflow within combustion engines, impacting performance and efficiency. Understanding these configurations is essential for optimizing vehicle functionality and achieving desired outcomes.

Common Design Types

- Single Throttle Valve

- Dual Throttle Valves

- Electronic Control Systems

Factors Influencing Design Choice

- Engine Size and Type

- Desired Performance Characteristics

- Fuel Efficiency Goals

Importance of Airflow Control

Effective regulation of airflow is crucial for optimizing engine performance and ensuring efficiency. This control mechanism allows for the precise management of the air-fuel mixture, directly influencing power output and fuel consumption. Understanding the significance of this regulation helps in appreciating the overall functioning of an engine.

Key Benefits

- Enhanced Performance: Proper airflow management contributes to improved acceleration and responsiveness.

- Fuel Efficiency: A well-regulated air supply ensures optimal combustion, reducing unnecessary fuel consumption.

- Emissions Control: Efficient airflow helps minimize harmful emissions, supporting environmental sustainability.

- Engine Longevity: Consistent airflow regulation can prevent engine knocking and overheating, extending the lifespan of engine components.

Factors Influencing Airflow Regulation

- Engine Design: Different configurations impact how airflow is managed and utilized.

- Driving Conditions: Variations in speed and load require dynamic adjustments to airflow.

- Altitude: Changes in elevation affect air density, necessitating recalibrations for optimal performance.

- Maintenance: Regular checks and cleaning of related systems ensure effective operation and prevent blockages.

Throttle Position Sensor Overview

The component discussed plays a crucial role in monitoring the position of a critical mechanism within an engine. By providing real-time data to the vehicle’s control unit, it ensures optimal performance and responsiveness. Understanding its function is essential for anyone interested in automotive technology.

Functionality: This sensor measures the angle of the mechanism, translating it into an electrical signal. This information is vital for adjusting fuel delivery and ignition timing, which directly impacts engine efficiency and power output.

Importance: A malfunctioning sensor can lead to various issues, such as poor acceleration, stalling, or increased emissions. Therefore, regular diagnostics and maintenance are necessary to keep the vehicle operating smoothly.

In summary, this sensor serves as a key element in ensuring the engine runs effectively, highlighting the importance of monitoring and maintaining its condition for optimal vehicle performance.

Common Throttle Body Issues

Several complications can arise in the component responsible for regulating air intake in an engine, affecting performance and efficiency. Understanding these common challenges is essential for maintaining optimal vehicle operation. Here are some frequent problems encountered with this critical mechanism.

1. Contamination and Buildup

Over time, carbon deposits and grime can accumulate, hindering airflow and creating an imbalance in the air-fuel mixture. This can lead to rough idling, stalling, or sluggish acceleration. Regular cleaning can help mitigate these issues and enhance performance.

2. Sensor Malfunction

Integrated sensors play a vital role in monitoring airflow and adjusting fuel delivery accordingly. A malfunctioning sensor can send incorrect readings to the engine control unit, resulting in poor fuel efficiency and increased emissions. Diagnosing and replacing faulty sensors is crucial for restoring proper function.

Maintenance Tips for Throttle Bodies

Proper upkeep of essential engine components is crucial for optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents potential issues that could lead to costly repairs. Here are some practical suggestions to ensure your system operates smoothly.

Regular Cleaning

Accumulation of dirt and carbon deposits can hinder airflow and affect performance. Periodically, it is advisable to clean the inner surfaces using a suitable cleaner. Make sure to follow the manufacturer’s guidelines to avoid damaging sensitive elements.

Inspection of Seals and Gaskets

Wear and tear on seals can lead to air leaks, negatively impacting engine efficiency. Inspect these components regularly for signs of cracking or deterioration. If any damage is detected, replace them promptly to maintain optimal performance.

Additionally, always keep an eye on the connection points for signs of corrosion or looseness, which could also compromise functionality. Regular maintenance will ensure that your engine remains responsive and efficient.

Signs of Throttle Body Failure

Identifying the signs of malfunction in this critical component can help prevent further issues in your vehicle’s performance. A range of symptoms may indicate that the unit is not functioning optimally, leading to a decrease in efficiency and potential engine complications.

Common Symptoms

Drivers may experience erratic acceleration or a noticeable decrease in power when pressing the accelerator. Additionally, unexpected stalling or rough idling can be indicative of trouble. Unusual noises from the engine compartment may also signal that the unit is struggling to operate as intended.

Diagnostic Indicators

Check engine lights may illuminate, often accompanied by error codes related to air intake management. Poor fuel economy and increased emissions are other critical signs that the system is failing. Regular monitoring and prompt attention to these issues can significantly extend the life of your engine.

Upgrading Your Throttle Body

Enhancing the air intake system of your vehicle can lead to improved performance and responsiveness. By upgrading the key components that regulate airflow, enthusiasts can achieve greater efficiency and power. This section explores the benefits and considerations involved in making such modifications.

Benefits of Upgrading

One of the primary advantages of enhancing the airflow mechanism is increased horsepower. By allowing a more significant volume of air to enter the engine, the combustion process becomes more efficient, resulting in a noticeable boost in performance. Additionally, improved throttle response can lead to a more engaging driving experience, especially in high-performance scenarios.

Choosing the Right Upgrade

When selecting a suitable enhancement, it’s essential to consider compatibility with your vehicle’s make and model. Some modifications may require additional tuning to optimize performance, ensuring that the engine operates smoothly without compromising reliability. It’s advisable to consult with professionals or refer to detailed guides specific to your vehicle.

Installation Tips

Installing a new air intake component typically involves straightforward procedures, but careful attention to detail is crucial. Ensure that all connections are secure, and utilize quality gaskets to prevent air leaks. Proper installation not only enhances performance but also contributes to the longevity of the system.

Conclusion

Upgrading the components that manage airflow can significantly enhance your vehicle’s performance. With careful consideration and the right choices, drivers can experience improved efficiency and responsiveness, making every journey more exhilarating.

Throttle Body and Fuel Efficiency

The performance of an engine is closely linked to how effectively it manages the flow of air and fuel. A crucial component in this system plays a significant role in optimizing combustion, thereby impacting overall energy consumption. Ensuring this element operates smoothly can lead to improved mileage and reduced emissions.

Efficient air intake is vital for achieving the ideal fuel-to-air ratio. When this mechanism is functioning properly, it allows for precise control over the mixture entering the combustion chamber. This precision enhances the efficiency of the combustion process, resulting in better fuel economy.

Moreover, maintenance of this component can prevent issues such as clogging or wear, which can lead to inefficient operation. Regular cleaning and inspection can help maintain optimal airflow, ensuring that the engine performs at its best. In turn, this translates to savings at the pump and a lower environmental footprint.

In summary, understanding the significance of this essential component can aid vehicle owners in making informed decisions regarding maintenance and upgrades, ultimately enhancing fuel efficiency and performance.

Throttle Body Replacement Process

Replacing the intake manifold component is an essential procedure to ensure optimal engine performance. This task involves several steps that require careful attention and proper tools to achieve a successful outcome. Understanding the process can help vehicle owners maintain their engines effectively and avoid unnecessary complications.

Preparation and Tools

Before starting the replacement, gather all necessary tools, including wrenches, screwdrivers, and a gasket scraper. It’s crucial to have a clean workspace and to disconnect the battery to prevent any electrical issues. Ensure you have the correct replacement unit that fits your vehicle model to avoid compatibility problems.

Removal and Installation

Begin by removing any components obstructing access to the manifold assembly. Carefully detach the old unit, paying attention to the connected hoses and wiring. Inspect the mounting surface for any debris or old gasket material before installing the new component. Securely attach the new unit, reconnect all hoses and wiring, and finally, test the system to confirm proper functionality.

Future Trends in Throttle Technology

As the automotive industry continues to evolve, innovations in air management systems are becoming increasingly important. Enhanced performance, fuel efficiency, and environmental considerations are driving the development of advanced mechanisms that control airflow. The focus is shifting towards greater precision and integration of electronic controls, which promise to revolutionize how engines respond to driver inputs.

Integration with Hybrid Systems

The rise of hybrid and electric vehicles is shaping new approaches to air management. Future systems are expected to seamlessly integrate with electric powertrains, allowing for improved energy efficiency. This synergy will enhance overall vehicle performance while reducing emissions, marking a significant step forward in sustainable automotive technology.

Smart Technologies and Connectivity

Emerging smart technologies are set to transform traditional airflow control. Connectivity features will enable real-time data exchange between vehicles and cloud-based systems, allowing for adaptive adjustments based on driving conditions and individual driver preferences. This level of sophistication not only enhances performance but also contributes to the overall safety and efficiency of modern vehicles.