Understanding the Bosch GCM12SD Parts Diagram for Better Maintenance

In the realm of power equipment, grasping the intricate structure of various tools is essential for both maintenance and effective usage. Each device comprises numerous elements, each serving a specific purpose, contributing to the overall functionality. A detailed examination of these components can enhance one’s ability to troubleshoot and optimize performance.

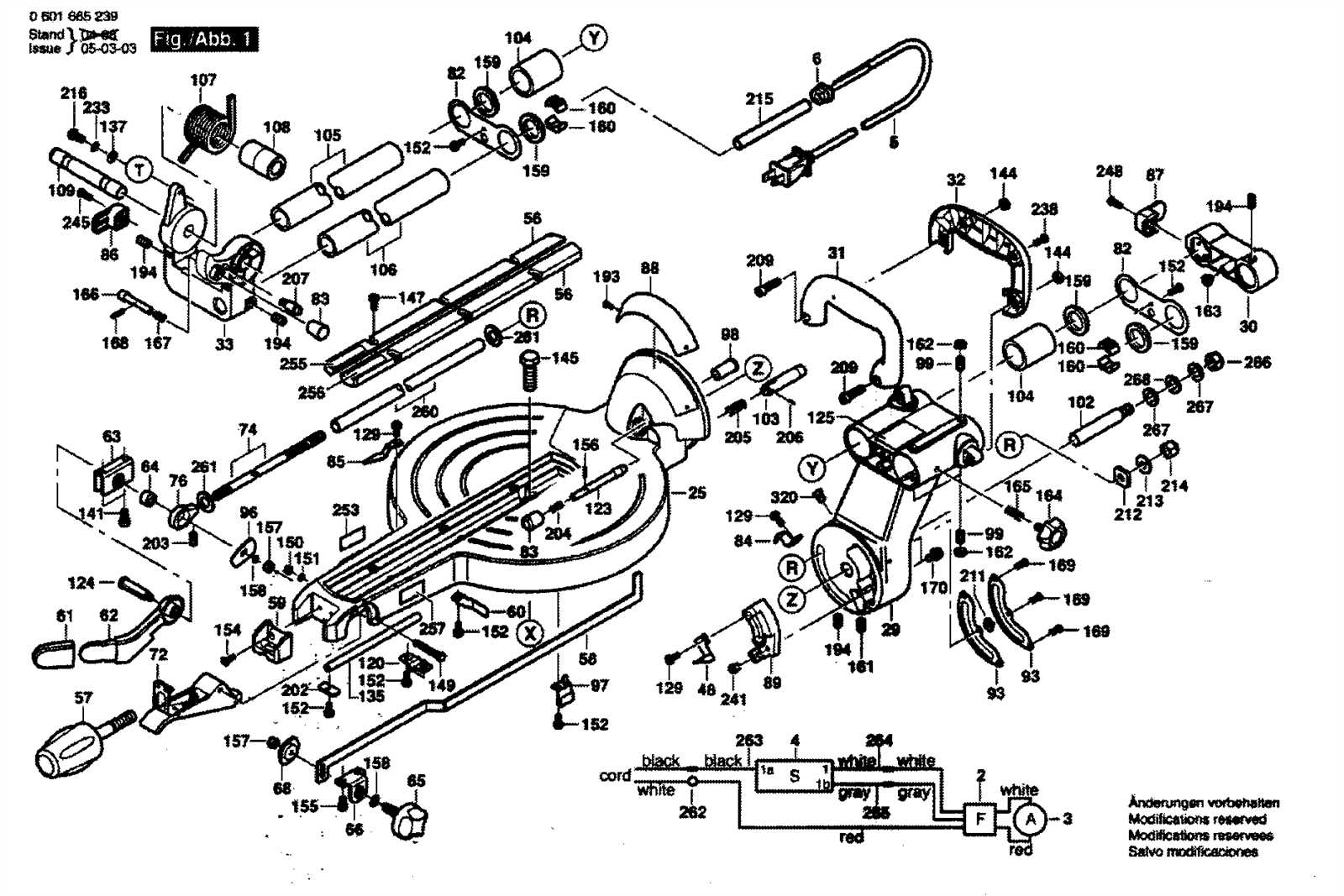

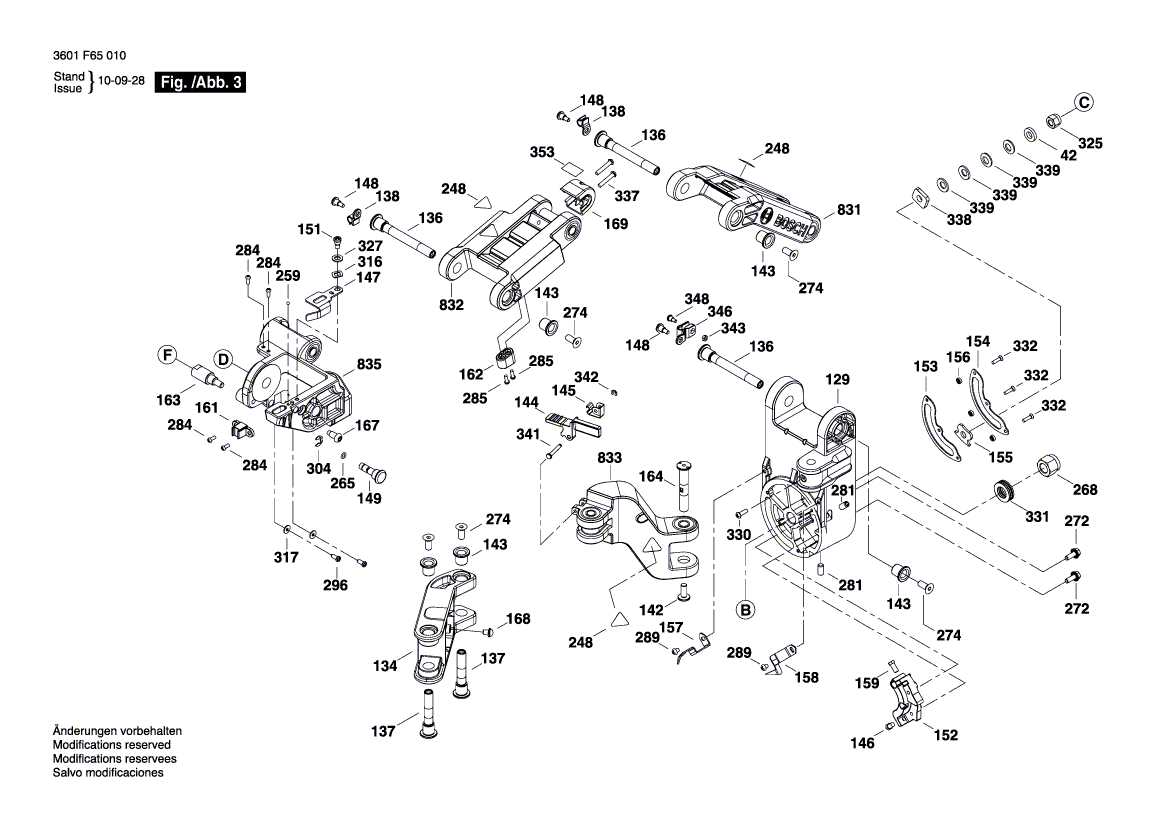

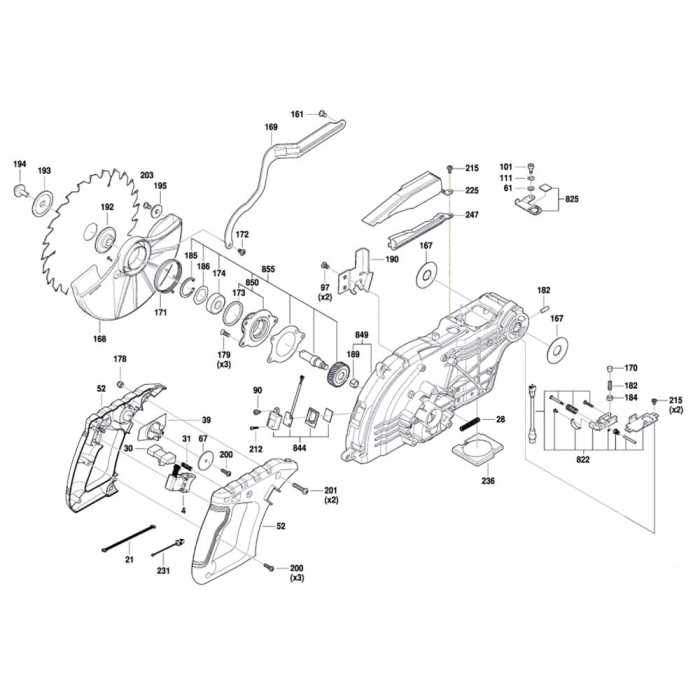

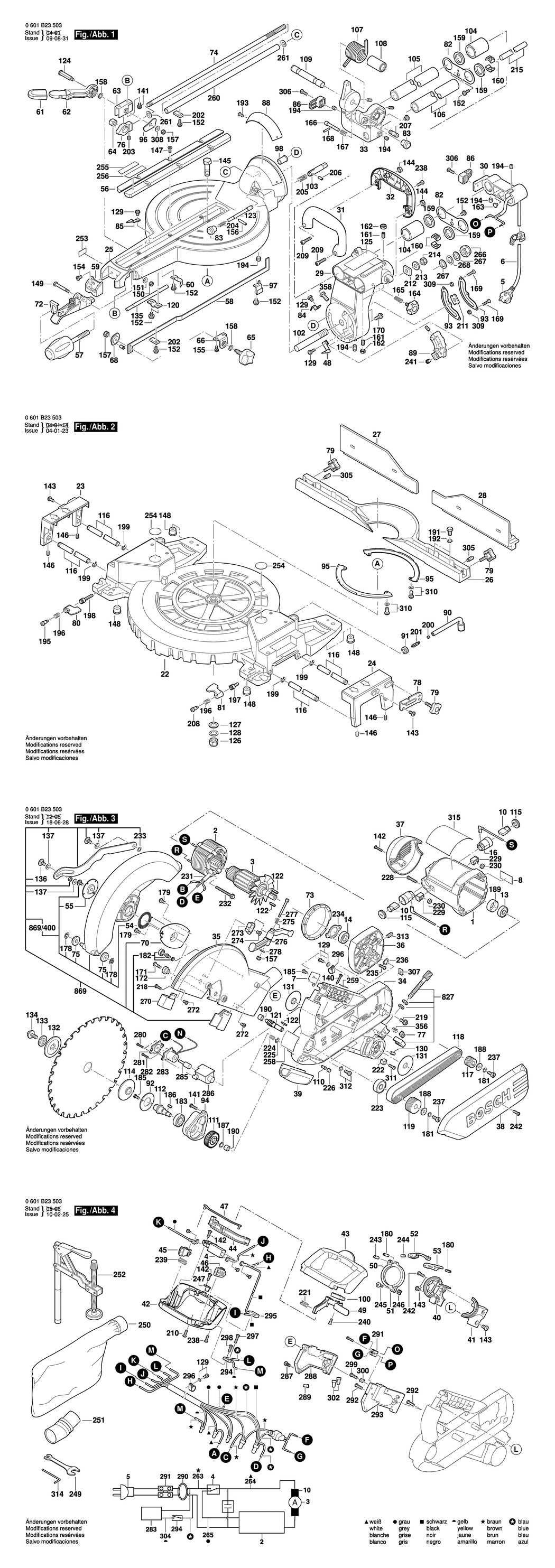

Visual representations of tool assemblies play a crucial role in this understanding. By exploring comprehensive layouts, users can identify individual parts, gaining insight into how each fits into the larger mechanism. Such knowledge is invaluable for repairs, upgrades, and routine inspections.

Furthermore, familiarizing oneself with these configurations not only aids in efficient operation but also empowers enthusiasts and professionals alike to handle equipment with confidence. This exploration encourages a deeper appreciation for the craftsmanship and engineering that goes into creating reliable, high-performance tools.

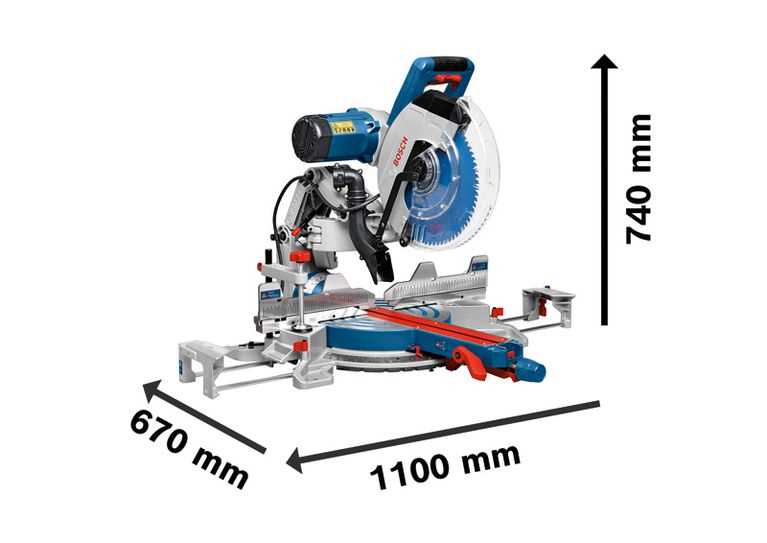

Overview of the Mitre Saw

This cutting tool stands out for its precision and versatility, making it a popular choice among both professionals and DIY enthusiasts. Designed to deliver clean cuts in various materials, it integrates advanced features that enhance usability and efficiency in any woodworking project.

Key Features

- Dual-bevel functionality for angled cuts

- Large cutting capacity to handle wider materials

- High-performance motor for robust operation

- Integrated dust collection for a cleaner workspace

Applications

- Framing and carpentry tasks

- Trim and molding installation

- Furniture making and renovation projects

Key Features of Bosch GCM12SD

This tool combines advanced engineering with practical design to enhance user experience and efficiency. It is built to meet the demands of both professional tradespeople and serious DIY enthusiasts, ensuring reliability and precision in every cut.

Precision Cutting: The innovative design allows for highly accurate and smooth cuts, making it ideal for intricate woodworking projects.

Enhanced Stability: Its robust construction offers superior stability, reducing vibrations and ensuring a steady performance throughout use.

Versatile Capabilities: This model excels in handling various materials and can accommodate a range of cutting tasks, from simple to complex.

User-Friendly Features: Equipped with easy-to-use controls and adjustments, it facilitates quick setup and operation, catering to both beginners and experts.

Portability: Despite its powerful capabilities, the lightweight design allows for effortless transport between job sites, enhancing overall convenience.

Understanding Parts Diagram Importance

Comprehending the layout of components in machinery is crucial for effective maintenance and repair. A visual representation serves as a valuable guide, allowing users to identify and locate each element within a complex assembly. This knowledge not only aids in troubleshooting but also ensures that replacements are accurate and efficient.

Benefits of a Visual Representation

A schematic illustration offers numerous advantages, including:

| Advantage | Description |

|---|---|

| Enhanced Clarity | Visuals simplify understanding by providing a clear view of component relationships. |

| Efficient Repairs | Quick identification of parts reduces downtime during maintenance tasks. |

| Improved Training | New users can learn faster with a graphical reference for component functions. |

Application in Maintenance

Utilizing an illustrated guide can streamline the repair process. By following a systematic approach to assembly and disassembly, technicians can minimize errors and enhance safety. Understanding the layout ensures that every part is correctly installed and functioning, ultimately prolonging the life of the equipment.

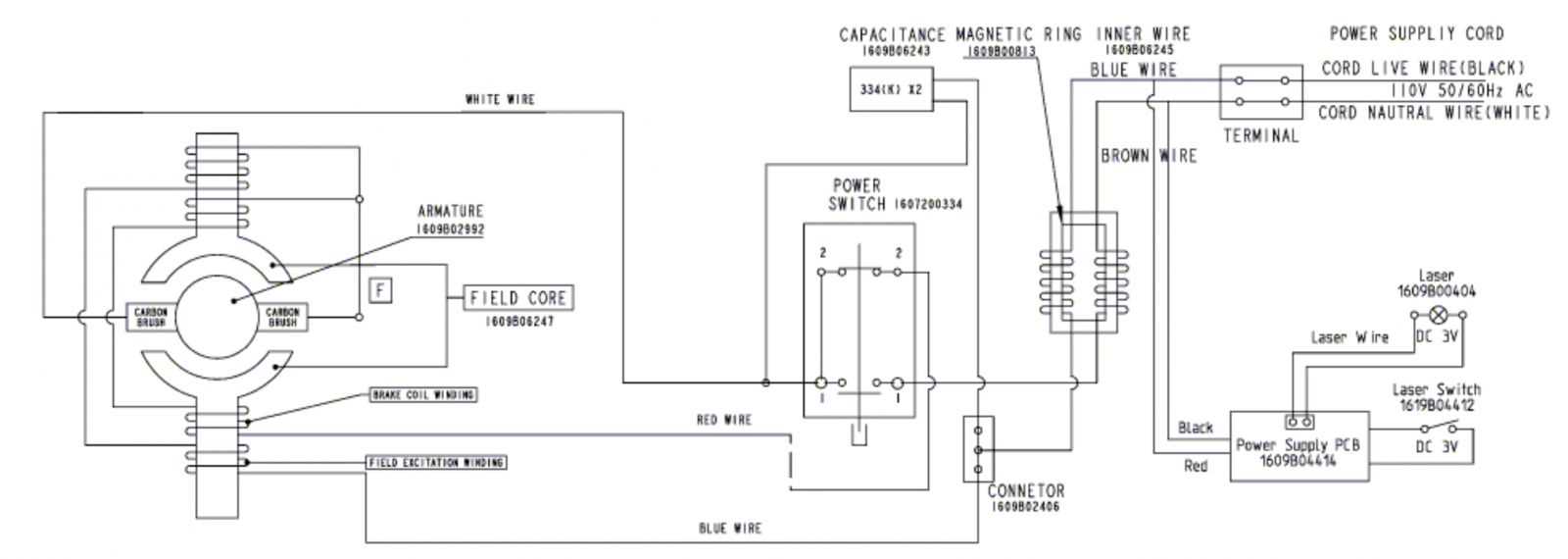

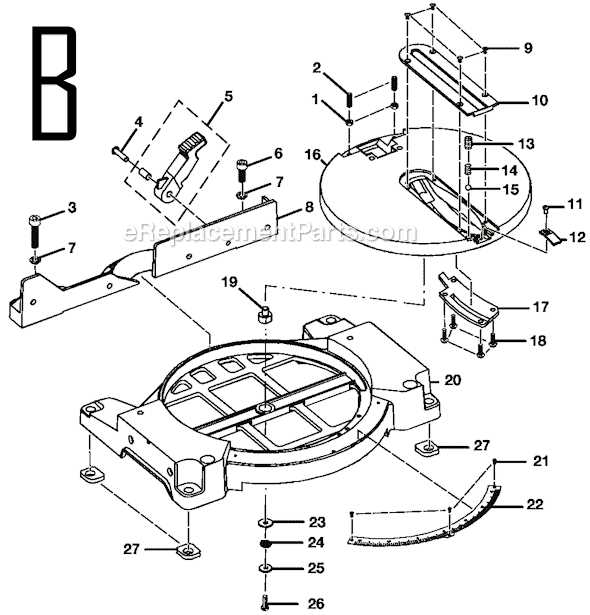

Common Components of the GCM12SD

This section explores the essential elements that make up the tool, highlighting their functionality and importance in ensuring optimal performance.

- Main Body: The foundation that houses all key mechanisms and provides stability during operation.

- Cutting Blade: The primary element used for making precise cuts, available in various sizes for different applications.

- A pivotal structure that allows for smooth movement and adjustment of the cutting angle.

- Table: The surface that supports materials being cut, often equipped with measurement guides.

- Motor: The power source that drives the cutting blade, ensuring efficient performance.

- Safety Guard: A crucial feature that protects the user from accidental contact with the blade.

Understanding these components will help users to maximize the tool’s potential and enhance their overall experience.

Identifying Replacement Parts

When it comes to maintaining your tools, recognizing the components that may require substitution is essential for optimal performance. Whether you are a professional or a DIY enthusiast, knowing how to pinpoint the necessary elements ensures that your equipment remains reliable and efficient. This process can save time and money, preventing unnecessary delays in your projects.

To start, familiarize yourself with the various segments of your tool. Each component plays a critical role, and understanding their functions can help you identify which ones might need replacement due to wear or damage. Regular inspections can reveal signs of deterioration such as cracks, fraying, or unusual noises during operation.

Utilizing reference materials can be incredibly beneficial. Instruction manuals often include detailed information about each part, including its specifications and recommended replacements. Additionally, online resources and community forums provide valuable insights and guidance from fellow users who may have faced similar challenges.

Moreover, consulting with knowledgeable professionals at local retailers can offer practical advice. They can assist in ensuring you select the correct items, thus enhancing the longevity and efficiency of your equipment. Remember, proper identification of the necessary components is a key step in effective maintenance and repair.

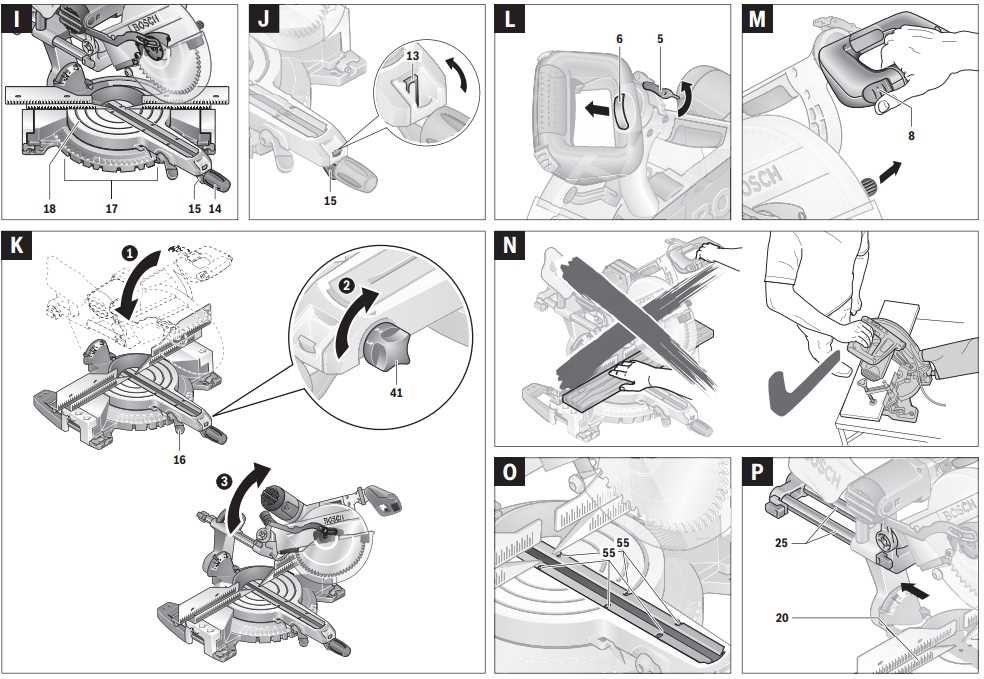

Assembly and Disassembly Instructions

This section provides essential guidance for assembling and disassembling your cutting tool effectively. Understanding these procedures ensures proper maintenance and functionality, enhancing your overall experience.

Assembly Steps

- Gather all components and necessary tools.

- Begin by securing the base to a stable surface.

- Attach the arm to the base, ensuring it pivots smoothly.

- Install the cutting blade, following safety guidelines.

- Connect any additional features, such as the dust collection system.

- Perform a final inspection to confirm all parts are securely attached.

Disassembly Steps

- Disconnect the power source to ensure safety.

- Remove any accessories or attachments first.

- Carefully detach the blade, using appropriate tools.

- Unfasten the arm from the base.

- Finally, disassemble the base and any remaining components.

Following these instructions will help maintain your equipment in optimal condition.

Troubleshooting Common Issues

When operating precision cutting equipment, encountering problems is not uncommon. Recognizing and resolving these issues quickly can enhance performance and prolong the lifespan of your tool. This section outlines frequent challenges users may face and offers practical solutions.

1. Inaccurate Cuts

If you find that your cuts are not aligning as expected, consider the following factors:

- Blade Alignment: Ensure the blade is properly aligned with the cutting fence.

- Blade Sharpness: Dull blades can lead to uneven cuts; replace them if necessary.

- Material Placement: Verify that the material is securely positioned against the fence before cutting.

2. Excessive Vibration

Vibration during operation can be a sign of several underlying issues:

- Loose Components: Check for any loose screws or parts that may need tightening.

- Unbalanced Blade: Inspect the blade for damage or warping that could cause imbalance.

- Improper Setup: Ensure the equipment is placed on a stable, level surface to minimize movement.

By addressing these common concerns, users can maintain efficient operation and ensure reliable results from their cutting equipment.

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the extended lifespan and optimal performance of your equipment. Regular attention to various components can prevent common issues and enhance reliability over time.

- Regular Cleaning: Dust and debris can accumulate and interfere with performance. Clean the surfaces and moving parts frequently to maintain functionality.

- Lubrication: Apply appropriate lubricants to all necessary areas as specified in the manual. This reduces friction and prevents wear and tear.

- Inspect for Damage: Routinely check for any signs of wear, cracks, or other damage. Addressing minor issues promptly can prevent larger problems later.

- Calibration: Ensure that the settings are adjusted correctly. Regular calibration helps maintain accuracy and efficiency.

- Proper Storage: When not in use, store the equipment in a dry, clean place. Protect it from extreme temperatures and moisture to avoid corrosion.

By following these maintenance practices, you can enhance the durability and performance of your tools, ensuring they remain reliable for years to come.

Where to Find Original Parts

Finding authentic components for your tools is essential for maintaining their performance and longevity. Here are some reliable sources to consider when searching for genuine replacements:

- Manufacturer’s Website: Check the official site for a dedicated section on replacements.

- Authorized Dealers: Locate nearby vendors who are recognized by the manufacturer.

- Online Marketplaces: Use reputable e-commerce platforms that specialize in tool supplies.

- Local Hardware Stores: Visit physical shops that often stock original items or can order them for you.

- Tool Repair Centers: Inquire at repair facilities, as they usually have access to genuine components.

Ensuring that you obtain the correct items from these trusted sources will help you keep your equipment in optimal condition.

Comparing Aftermarket Options

When exploring alternatives to original equipment, it’s crucial to assess the various aftermarket solutions available on the market. These options can often provide comparable performance at a more attractive price point, but the quality and longevity can vary significantly. Understanding the pros and cons of these substitutes is essential for making an informed decision.

Quality Assessment: One of the primary factors to consider is the quality of the components. Many manufacturers offer aftermarket products that claim to meet or exceed the specifications of the originals. It’s important to read reviews and check ratings from other users to gauge reliability.

Price Comparison: Cost is often a significant advantage when opting for alternatives. However, a lower price doesn’t always equate to better value. Evaluating the overall lifespan and performance of the substitute is necessary to determine if it truly saves money in the long run.

Compatibility: Ensuring compatibility with existing tools is vital. Some aftermarket products may not fit as seamlessly as their original counterparts, leading to potential issues during use. Checking specifications and consulting user feedback can help mitigate this risk.

Warranty and Support: Aftermarket items may not come with the same level of support or warranty as original products. Investigating the manufacturer’s customer service reputation and warranty policies can provide insights into the potential risks involved.

In conclusion, while aftermarket options can present significant savings and performance benefits, thorough research is essential to ensure you select a product that meets your needs without compromising quality.

Safety Precautions During Repairs

When engaging in maintenance or fixing equipment, prioritizing safety is crucial. Proper precautions not only protect the individual performing the task but also ensure that the equipment remains functional and reliable. Adhering to guidelines can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment

Always wear appropriate personal protective gear. This includes safety goggles to shield your eyes, gloves to protect your hands, and ear protection if working with loud machinery. Each piece of equipment should be selected based on the specific risks involved in the repair process.

Work Environment Safety

Maintain a clean and organized workspace. Remove any unnecessary items that could pose a tripping hazard. Ensure proper lighting and ventilation, and keep all tools in designated areas to minimize distractions. Regularly inspecting the area for potential hazards can help maintain a safe environment throughout the repair process.

Utilizing the Parts Diagram Effectively

Understanding the intricate components of a tool is essential for efficient maintenance and repairs. A visual representation of these elements serves as a valuable resource, enabling users to identify, locate, and replace any necessary parts with ease. By familiarizing oneself with this resource, one can enhance their operational efficiency and extend the lifespan of their equipment.

To maximize the benefits of this visual guide, consider the following strategies:

| Strategy | Description |

|---|---|

| Familiarization | Spend time studying the visual representation to understand the layout and relationships between different components. |

| Identification | Use the visual guide to quickly identify parts that may require maintenance or replacement during routine checks. |

| Replacement | Refer to the guide when ordering new components, ensuring the correct items are acquired for repairs. |

| Assembly | Utilize the visual reference during reassembly to ensure all components are correctly positioned and secured. |

By applying these approaches, one can navigate the complexities of tool maintenance with greater confidence and efficiency, leading to improved performance and durability of the equipment.