Cantilever Brake Components Illustrated Guide

The intricate design of a suspension system plays a crucial role in ensuring smooth and safe navigation across various terrains. Understanding the various elements involved in this assembly can greatly enhance the knowledge of how vehicles maintain stability and comfort. This section delves into the essential components that contribute to the overall functionality of this mechanism.

Within this framework, each component serves a specific purpose, working in harmony to provide optimal performance. Recognizing the relationships between these elements allows for a deeper appreciation of their engineering and the impact they have on handling and safety. The visualization of these components aids in grasping their arrangement and interconnections.

In this exploration, we will outline the key features and roles of each constituent element, illuminating their significance in the larger context of vehicle dynamics. By dissecting this assembly, readers will gain insights into the mechanisms that underpin effective motion control and rider experience.

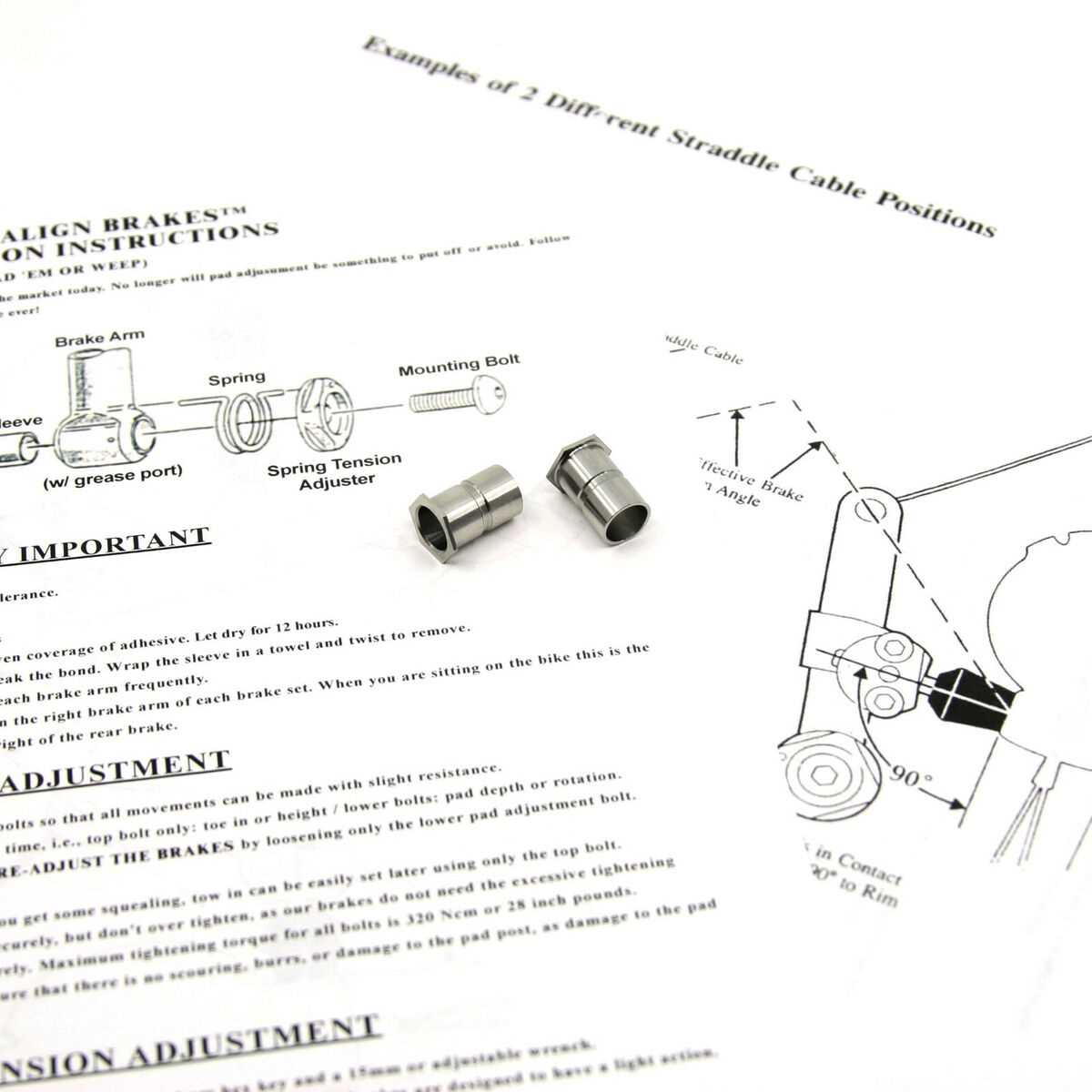

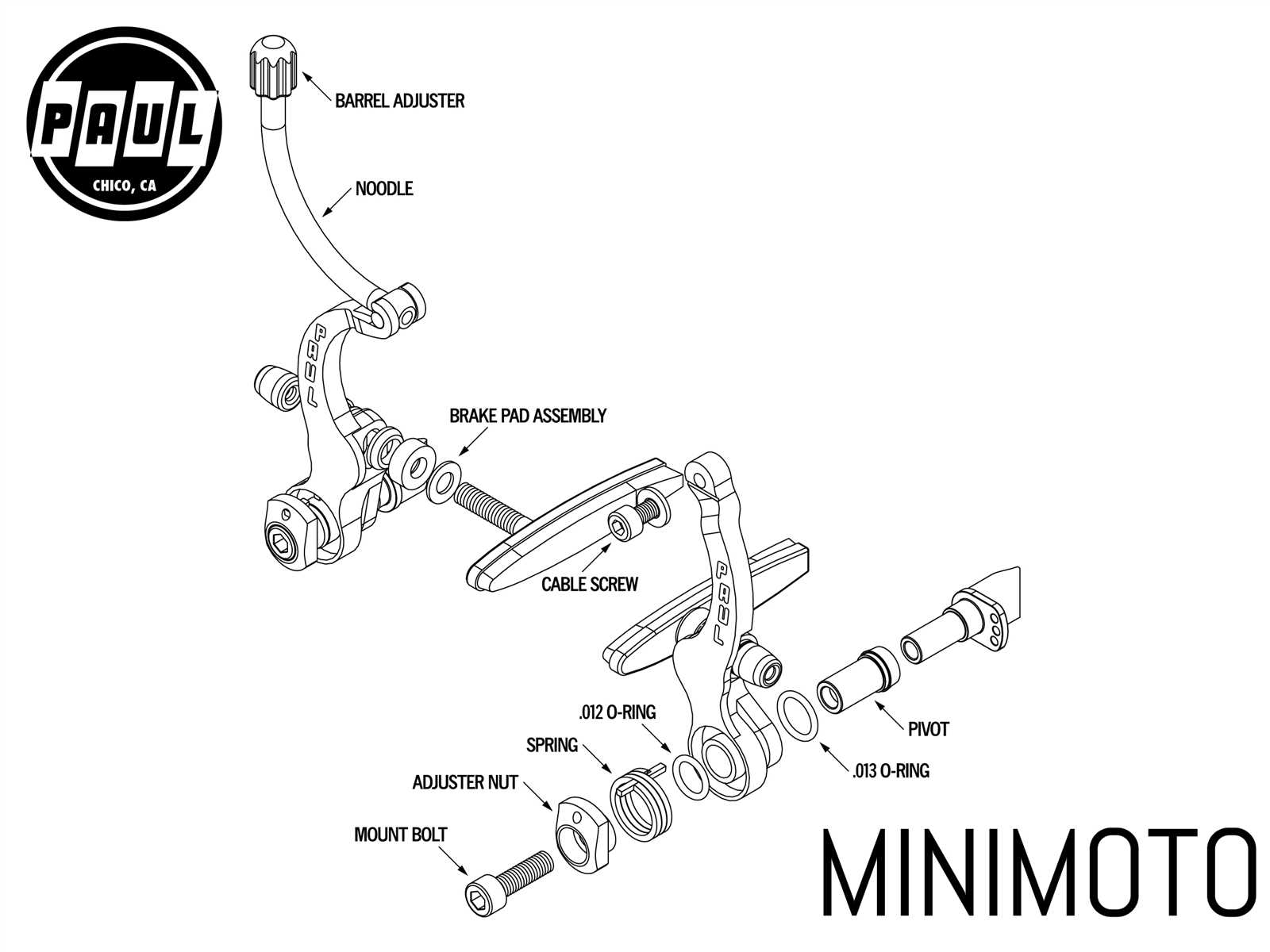

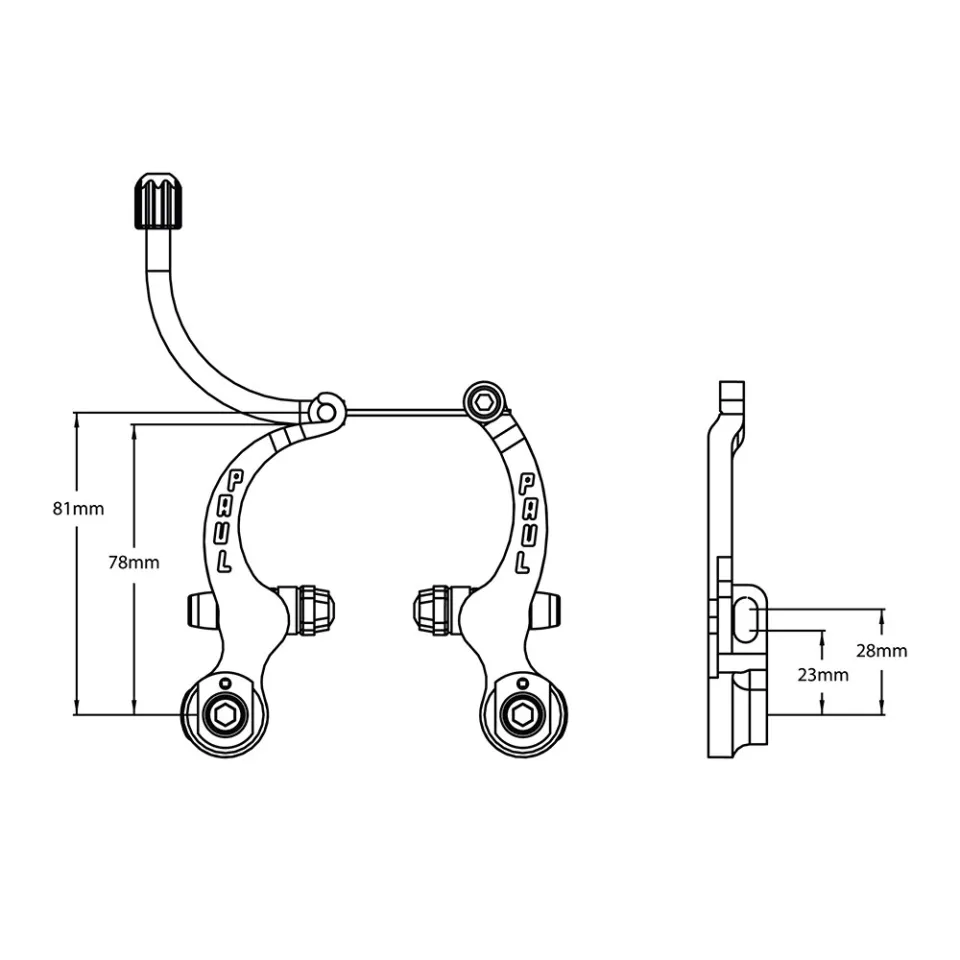

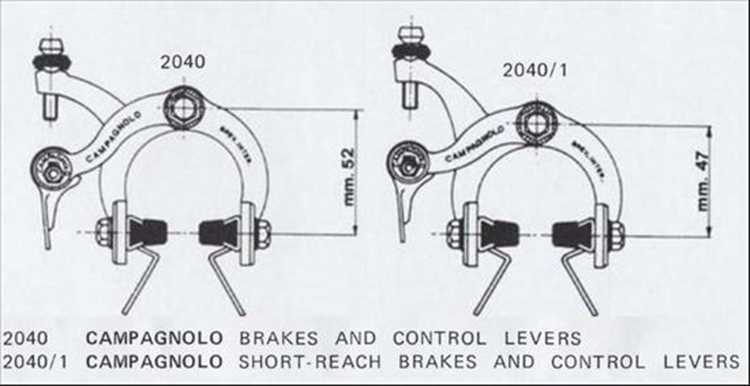

Cantilever Brake Parts Diagram

This section provides a detailed overview of the components involved in a specific stopping mechanism commonly used in cycling and other applications. Understanding these elements is crucial for effective maintenance and performance optimization. Each piece plays a vital role in the overall functionality, ensuring smooth operation and safety during use.

Below is a table illustrating the key components and their respective functions:

| Component | Description |

|---|---|

| Lever | Responsible for initiating the stopping action by applying force. |

| Cable | Transmits force from the lever to the mechanism that engages the stopping elements. |

| Arm | Connects the mechanism to the stopping surface, allowing movement and application of pressure. |

| Housing | Encloses the mechanism, providing support and protection for internal parts. |

| Adjustment Screw | Facilitates fine-tuning of the alignment and effectiveness of the mechanism. |

| Stopping Surface | Contacts the wheel, creating the necessary friction to slow or halt movement. |

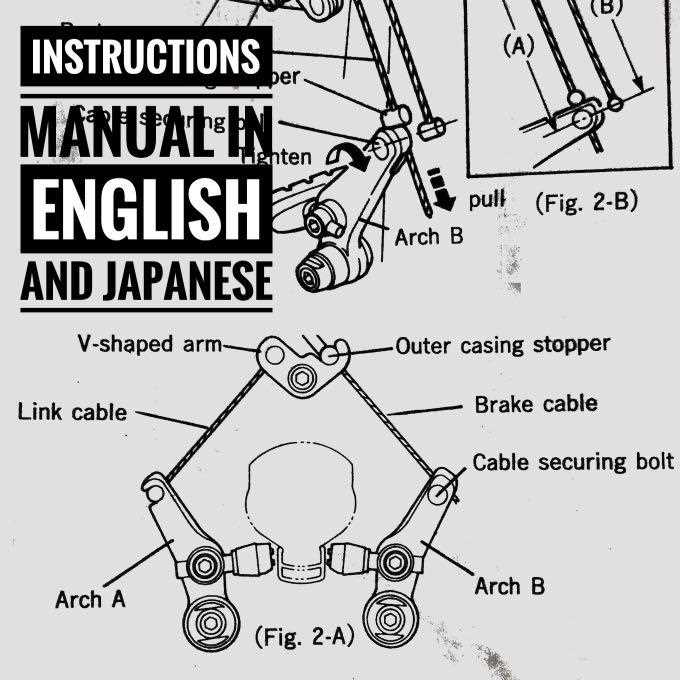

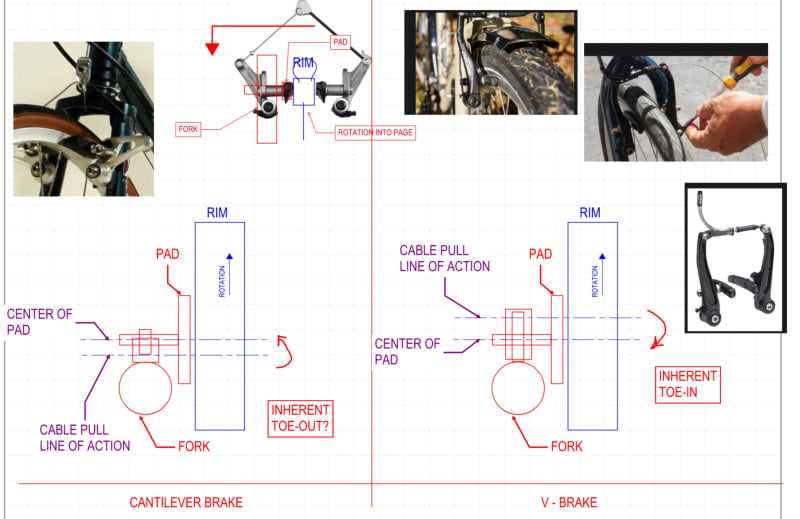

Understanding Cantilever Brake Mechanism

The mechanism under discussion is a crucial component in various transport systems, providing effective deceleration and control. It operates through a unique arrangement of levers and cables that facilitate smooth engagement and disengagement during operation. This setup enhances responsiveness and stability, making it suitable for diverse applications, from bicycles to specialized vehicles.

At its core, this mechanism employs a dual-arm design that allows for efficient force distribution. When pressure is applied, the arms pivot, activating the friction surfaces to create the necessary stopping force. This innovative arrangement not only improves performance but also offers advantages in terms of maintenance and adjustability.

Additionally, the geometry of this system plays a significant role in its functionality. By adjusting the alignment and positioning of the arms, users can fine-tune the response and efficiency according to their specific requirements. This adaptability is one of the reasons why this design remains popular among enthusiasts and professionals alike.

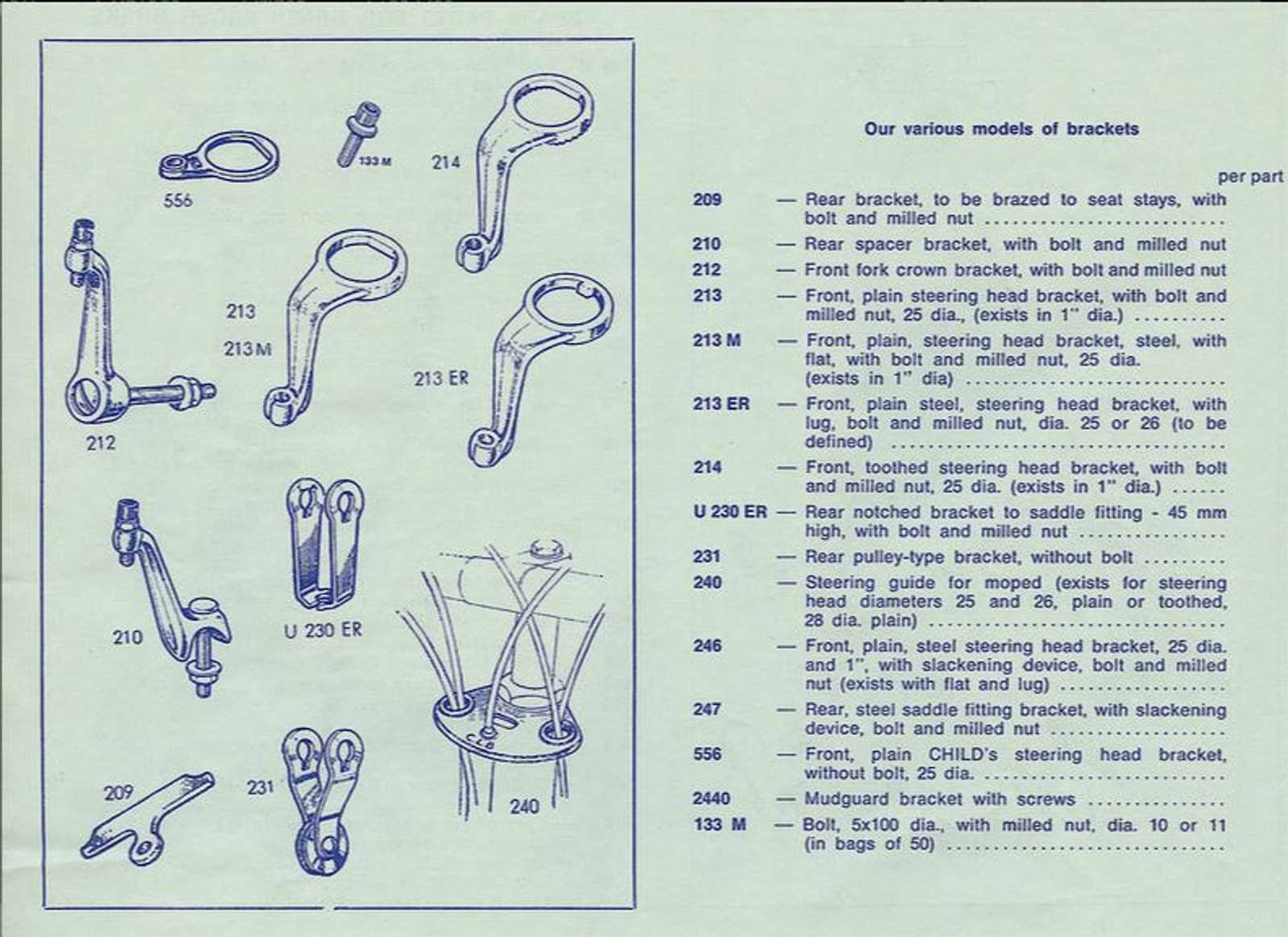

Key Components of Brake System

The efficient operation of a stopping mechanism relies on several crucial elements that work together to ensure safety and responsiveness. Understanding these integral components provides insight into how this system functions and enhances overall vehicle performance. Each part plays a specific role, contributing to the effective slowing down or halting of motion.

Essential Elements

Among the vital elements, the friction materials are paramount, providing the necessary grip to decelerate the motion. The connecting structures facilitate the transmission of force, ensuring that the action initiated by the driver is effectively executed. Additionally, the hydraulic system is critical, allowing for smooth and consistent pressure application across various components.

Supportive Structures

Supportive frameworks are also significant, as they maintain the alignment and stability of the overall assembly. Furthermore, sensors and indicators enhance the user experience by providing feedback on the system’s status, alerting the operator to any potential issues. A thorough comprehension of these elements is essential for anyone involved in the maintenance or design of these systems.

Functionality of Brake Arms

The components responsible for initiating the stopping action of a vehicle play a critical role in ensuring safety and control during operation. These mechanisms, often positioned strategically within the overall system, work by exerting force on the moving elements, effectively slowing or halting their motion. Understanding their operation provides insights into the overall effectiveness and responsiveness of the stopping system.

Mechanics of Operation

When engaged, these mechanisms leverage a mechanical advantage that amplifies the force applied by the user. This amplification is crucial, as it allows for effective engagement even with minimal effort. The design typically incorporates pivot points and levers, which optimize the force distribution across the entire system, enhancing performance and reliability.

Importance in Overall System Performance

The proper functioning of these components directly influences the overall efficiency of the stopping mechanism. Any malfunction or misalignment can lead to diminished performance, increasing the risk of accidents. Therefore, regular maintenance and checks are essential to ensure that these elements operate seamlessly, providing a reliable response in critical situations.

Role of Brake Pads Explained

Components responsible for generating friction play a crucial role in ensuring safe and effective stopping power in various transportation systems. Their function is vital for maintaining control and safety while navigating different terrains.

These essential elements consist of several key features:

- Friction Material: This surface is designed to create resistance against the wheel, allowing the system to slow down or stop.

- Backing Plate: This sturdy base provides support and helps attach the friction material securely.

- Wear Indicator: Some models are equipped with this feature to signal when replacement is necessary, ensuring optimal performance.

The effectiveness of these components is influenced by various factors, including:

- Material Quality: The composition of the friction surface affects longevity and stopping power.

- Temperature Resistance: High-quality materials can withstand heat generated during use, preventing performance loss.

- Environmental Conditions: Factors like moisture and dirt can impact effectiveness, making maintenance essential.

Understanding the significance of these components helps users appreciate their importance in maintaining safe and reliable operation across different types of vehicles.

Importance of Cables and Housing

The significance of flexible conduits and protective casings in a mechanical system cannot be overstated. These components play a crucial role in ensuring that forces are transmitted effectively while maintaining the overall integrity of the structure. They not only facilitate smooth operation but also protect against wear and environmental factors that could compromise functionality.

Flexible conduits are essential for transmitting force and enabling movement. Their design allows for flexibility, accommodating various angles and positions, which is vital in dynamic systems. A well-designed conduit ensures minimal friction, enhancing performance and longevity.

Protective casings serve as the first line of defense against external elements. They safeguard the conduits from dust, moisture, and mechanical damage, which can lead to malfunction. By preserving the condition of the conduits, these casings contribute significantly to the system’s reliability and safety.

Overall, the interplay between flexible conduits and protective casings is fundamental to the efficient operation of mechanical systems. Neglecting the importance of these components can lead to premature wear and costly repairs, highlighting the need for regular maintenance and quality materials.

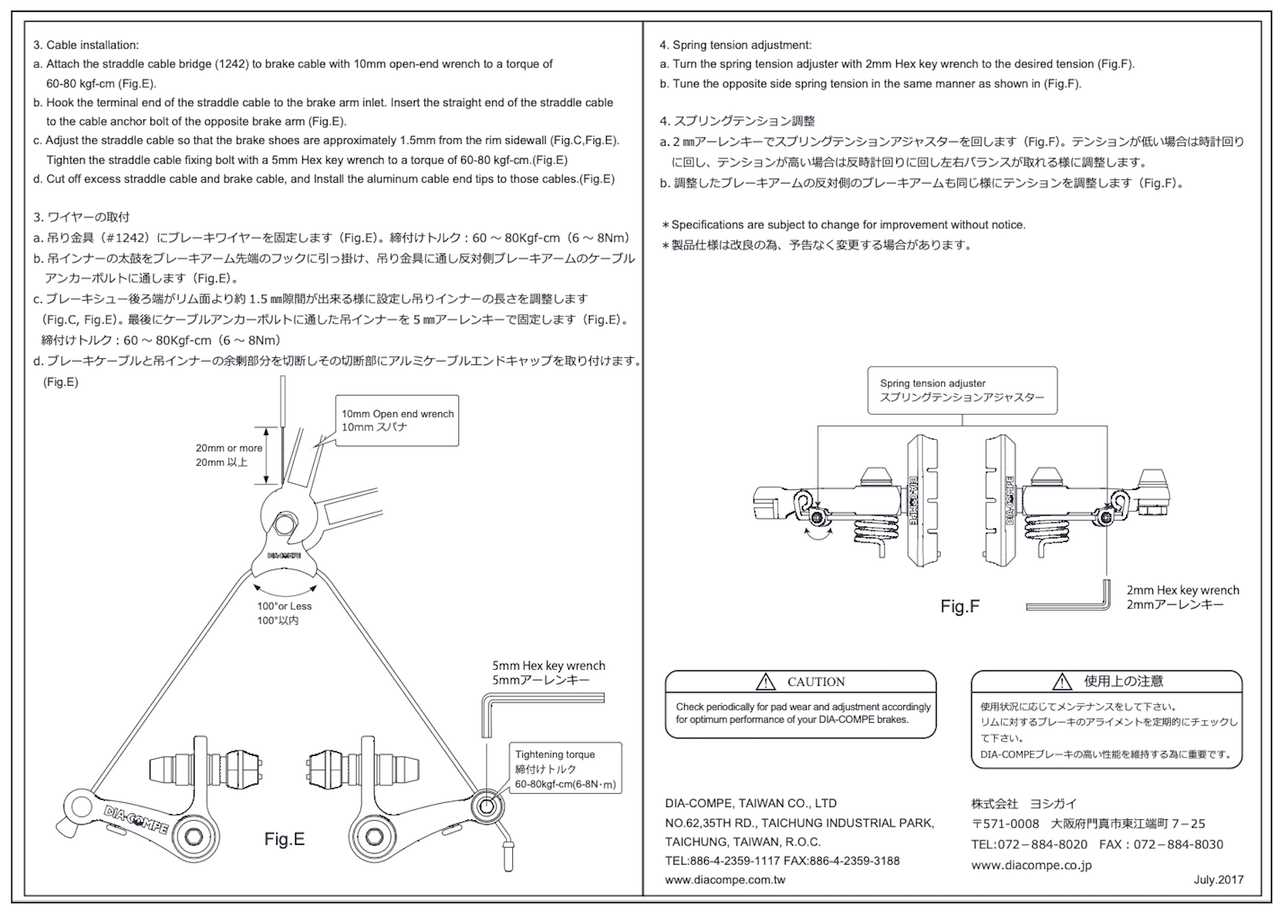

Adjustment Techniques for Optimal Performance

Achieving peak functionality in a mechanical system requires careful calibration and fine-tuning. This process involves adjusting various components to ensure they work harmoniously, providing the user with a reliable and efficient experience. By focusing on precision and consistency, one can enhance overall performance and extend the lifespan of the system.

Key Adjustment Methods

Several techniques can be employed to optimize the functionality of the assembly. Understanding the mechanics behind each adjustment will help in achieving the desired outcomes. The following table outlines essential methods along with their purposes and potential effects:

| Adjustment Method | Purpose | Potential Effects |

|---|---|---|

| Alignment | Ensures components are positioned correctly | Improved accuracy and reduced wear |

| Tension Adjustment | Modifies the tightness of cables or components | Enhanced responsiveness and control |

| Angle Settings | Alters the angle of engagement | Optimized interaction and decreased friction |

| Clearance Optimization | Adjusts the gap between moving parts | Minimized slippage and improved efficiency |

Regular Maintenance Practices

In addition to the adjustment techniques mentioned above, regular maintenance is vital to sustaining optimal performance. Inspecting components for wear and tear, lubricating moving parts, and ensuring all connections are secure can prevent potential issues before they arise. By implementing these practices, one can maintain the system’s integrity and functionality over time.

Maintenance Tips for Brake Longevity

To ensure the longevity of your stopping mechanism, regular care and attention are essential. Proper upkeep not only improves performance but also extends the lifespan of key components. Following a consistent schedule for cleaning, inspecting, and adjusting the system helps maintain its efficiency over time.

Below are some essential maintenance practices that will help keep the system running smoothly:

| Maintenance Task | Recommended Frequency |

|---|---|

| Cleaning the mechanism | After every ride in wet or dusty conditions |

| Lubricating pivot points | Monthly or after heavy use |

| Inspecting for wear and tear | Every 2-3 months |

| Checking cable tension | Every ride |

By following these tips, you can enhance the performance and lifespan of your stopping mechanism, ensuring consistent reliability.

Common Issues and Troubleshooting Steps

When maintaining your bike’s stopping system, you may encounter several recurring problems. These can range from improper alignment of components to difficulties in achieving smooth and consistent performance. Understanding the root cause of these issues is key to ensuring optimal functionality and safe riding.

| Issue | Possible Cause | Solution | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Uneven or weak response | Misaligned setup or worn elements | Adjust the positioning of key parts and check for wear. Replace any damaged elements. | ||||||||||

Sque

Benefits of Using Cantilever Brakes

One of the main advantages of this type of stopping system is its efficiency in various conditions. It provides reliable control and ensures a smooth and predictable halt even in challenging environments. The unique structure of the mechanism allows for enhanced modulation, giving the user better control over the stopping force. Increased Stopping Power

This system is designed to deliver superior halting force, especially when navigating difficult terrains. The optimized layout enhances leverage, resulting in more effective slowing down with minimal effort from the rider. Improved VersatilityDue to its adaptable design, this stopping solution can be applied across different bicycle types, making it a popular choice for both off-road and urban cyclists. Its durability ensures long-term performance with minimal need for maintenance.

Comparison with Other Brake TypesUnderstanding the differences between various stopping mechanisms is essential for selecting the best system for your bicycle. This section provides a detailed analysis, comparing the effectiveness, maintenance, and performance of different types of stopping devices. Effectiveness and PerformanceEach type of stopping mechanism has its own strengths and weaknesses. Some systems provide excellent stopping power in dry conditions, while others perform better in wet environments. The modulation, or how smoothly the force is applied, also varies significantly between systems, affecting the rider’s control and confidence. Maintenance and DurabilityMaintenance requirements differ among the various types of stopping devices. Some systems are known for their durability and low maintenance, requiring only occasional adjustments. Others might need more frequent care to ensure optimal performance. Understanding these differences can help in making an informed decision based on how much time and effort you’re willing to invest in upkeep.

|