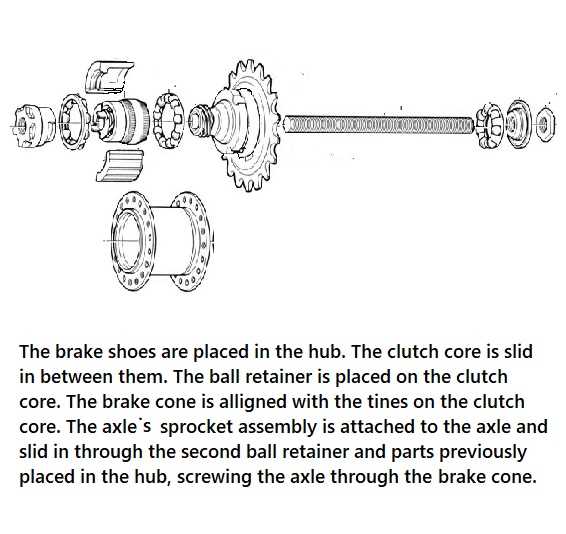

Coaster Brake Parts Diagram Overview

The functionality of bicycles relies on various elements working in harmony to ensure a safe and efficient ride. Among these components, the stopping mechanism plays a crucial role in controlling speed and ensuring the rider’s safety. This section delves into the intricate design and operation of these vital elements, shedding light on how they interact during use.

By exploring the various features of this mechanism, one can gain a deeper appreciation for the engineering that contributes to a smooth and reliable cycling experience. This insight not only enhances the understanding of the device but also highlights the importance of proper maintenance for optimal performance.

Whether you are an avid cyclist or a casual rider, familiarizing yourself with the intricacies of this mechanism will empower you to make informed decisions about repairs and upgrades. Embracing knowledge about these components will ultimately lead to a more enjoyable and safer cycling journey.

This section delves into the fundamental workings of a specific stopping mechanism commonly found in bicycles. It explores the critical components that contribute to its functionality, highlighting how each element interacts within the overall system. By understanding these interactions, one can better appreciate the engineering behind this reliable braking solution.

- Introduction to the Mechanism: Overview of how this braking system operates.

- Components Overview: Summary of essential elements involved.

- Functionality Explained: Insight into the mechanism’s operation.

- Importance of Maintenance: Tips for keeping the system in optimal condition.

- Common Issues: Identification of frequent problems and their solutions.

- Assembly and Disassembly: Step-by-step guide to handling the components.

- Performance Factors: Analysis of elements affecting efficiency.

- Safety Considerations: Guidelines to ensure secure operation.

- Upgrading Components: Suggestions for enhancements and modifications.

- Comparative Analysis: Comparison with other braking mechanisms.

- Conclusion: Recap of the significance and reliability of this braking solution.

Essential Components of Coaster Brakes

The functionality of a certain stopping mechanism relies on several crucial elements that work in harmony. Each component plays a vital role in ensuring efficient operation, contributing to the overall performance and reliability of the system.

One of the primary elements is the rotating mechanism that interacts with the wheel, allowing for engagement when pressure is applied. This interaction is facilitated by an attached lever, which, when actuated, creates the necessary friction to slow down or halt movement.

Additionally, a robust housing encases these mechanisms, providing protection from external elements and ensuring durability over time. Inside this enclosure, a series of springs and tension devices maintain optimal pressure, allowing for smooth activation and retraction.

Finally, connecting rods and linkage systems ensure that the forces applied are effectively transmitted throughout the assembly, enhancing responsiveness and control. Each of these components, working together seamlessly, exemplifies the intricate design of efficient stopping systems.

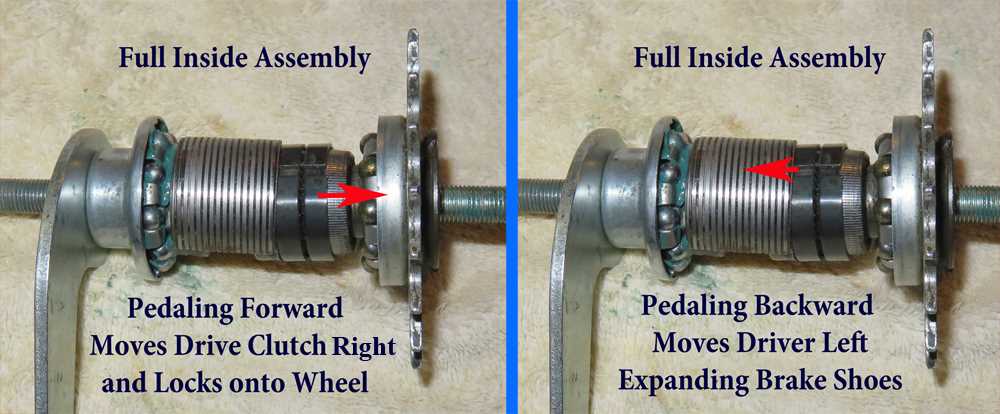

How Coaster Brakes Function

The mechanism responsible for slowing down a vehicle operates through a simple yet effective design, relying on friction to create resistance. When the user applies pressure to the pedals in reverse, this action initiates a series of movements that engage the internal system, enabling the vehicle to decelerate smoothly.

At the core of this system lies a series of components that work together seamlessly. When the pedals are reversed, a component within the assembly pushes against a drum, generating friction. This interaction is crucial as it converts the kinetic energy of the moving vehicle into heat, allowing it to slow down effectively. The design ensures that this process occurs without the need for complex levers or external mechanisms, making it user-friendly and reliable.

Additionally, this type of slowing mechanism provides an intuitive experience for riders. The simplicity of operation means that less maintenance is required, allowing users to focus on their journey rather than on mechanical issues. Moreover, the compact design enhances the overall aesthetics of the vehicle, making it a popular choice among cyclists.

Benefits of Using Coaster Brakes

Utilizing a certain type of stopping mechanism offers numerous advantages for riders of all skill levels. This system, known for its simplicity and reliability, provides an effective solution for various cycling conditions. Its design enhances safety and ease of use, making it an appealing choice for many enthusiasts.

One significant advantage is the reduced maintenance required compared to more complex systems. Riders can enjoy a smoother experience with fewer adjustments and repairs needed over time. This feature is particularly beneficial for those who prefer low-maintenance options.

Another key benefit lies in the intuitive operation. Engaging the stopping mechanism is straightforward, allowing users to focus on their ride without distractions. This ease of use makes it suitable for beginners and casual riders, as well as seasoned cyclists seeking a reliable alternative.

Furthermore, this type of mechanism offers effective performance in various weather conditions, providing consistent stopping power regardless of the environment. This reliability ensures that riders can feel confident and secure during their journeys, whether on city streets or rugged trails.

Common Issues with Coaster Brakes

Understanding frequent challenges associated with specific stopping mechanisms can enhance overall riding safety and performance. These problems often stem from wear and tear, improper installation, or inadequate maintenance. Identifying these issues early can prevent accidents and prolong the lifespan of the components.

Wear and Tear

Wear and tear is a prevalent concern, as friction over time can diminish the efficiency of the stopping system. Riders may notice a decrease in responsiveness or unusual noises when engaging the mechanism. Regular inspections can help detect signs of deterioration before they escalate into more significant failures.

Improper Installation

Improper installation can lead to various operational issues, including misalignment and ineffective stopping power. Ensuring that components are fitted correctly is crucial for optimal functionality. If a system is not set up according to manufacturer specifications, it may not perform as intended, compromising rider safety.

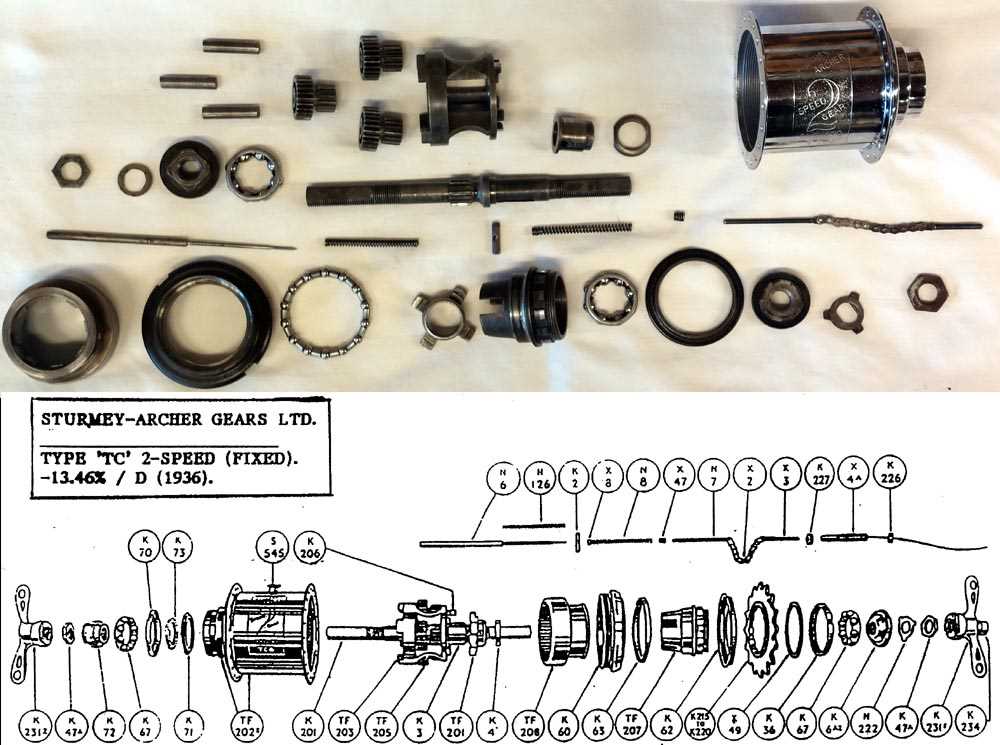

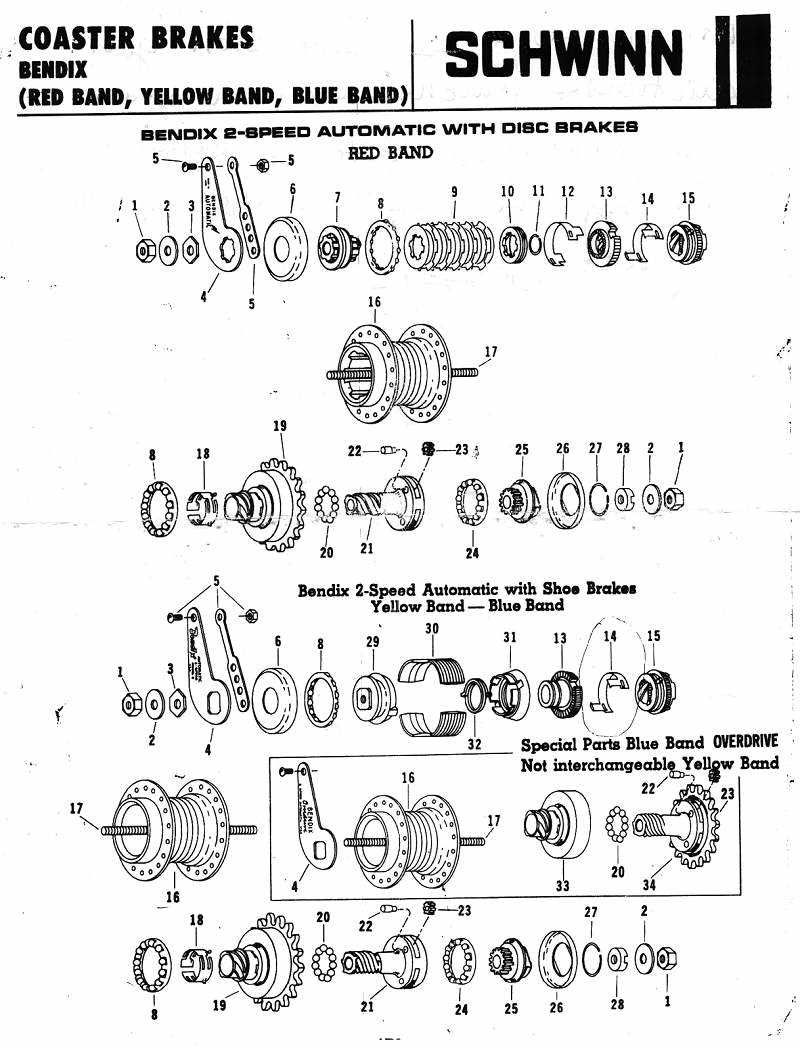

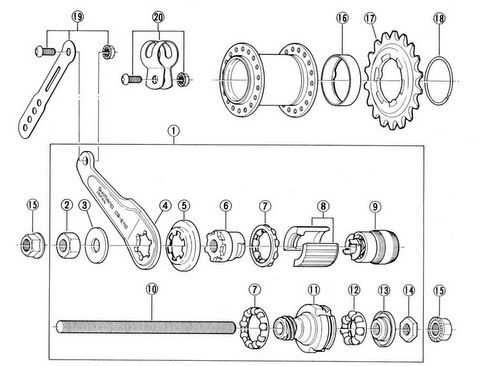

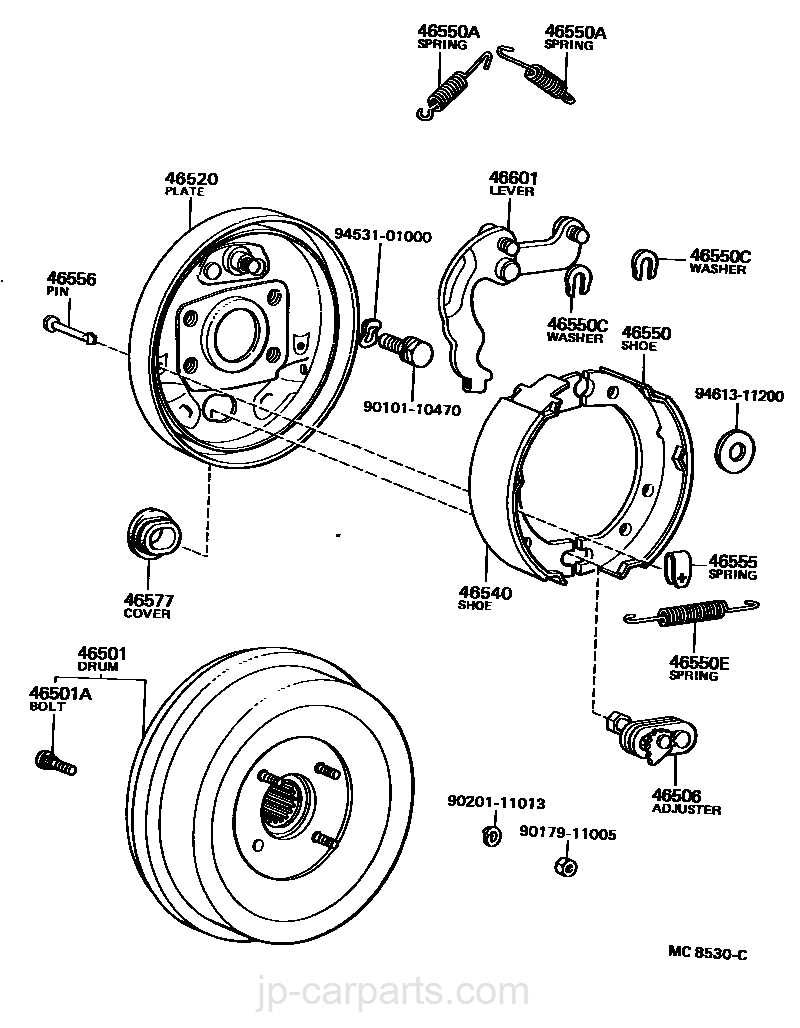

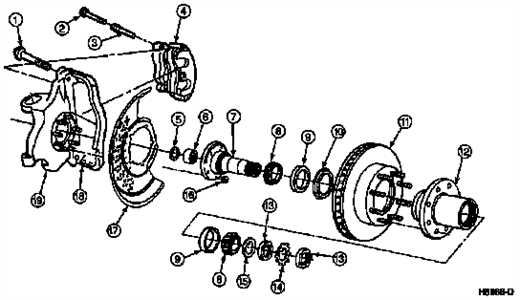

Identifying Coaster Brake Parts

Understanding the components of a bicycle’s stopping mechanism is crucial for maintenance and repairs. Familiarity with the various elements involved in this system ensures optimal functionality and safety during rides. This section provides an overview of the essential components that make up this system, aiding in recognition and troubleshooting.

Main Components Overview

The stopping mechanism consists of several key elements that work together seamlessly. Each component has a distinct role, contributing to the overall effectiveness of the system.

| Component | Description |

|---|---|

| Hub | The central part that houses the internal mechanisms, allowing rotation. |

| Lever | A handle connected to the stopping mechanism, used to activate the system. |

| Friction Pads | Materials that create resistance against the inner surface for effective stopping. |

| Spring | Provides tension, ensuring that the stopping mechanism resets after use. |

Common Issues and Recognition

Awareness of common problems associated with these elements is vital for prompt repairs. Recognizing signs of wear or malfunction can prevent further complications and enhance safety.

Maintenance Tips for Coaster Brakes

Proper upkeep of your bicycle’s stopping system is essential for ensuring optimal performance and longevity. Regular attention to the components involved can enhance safety and improve overall functionality. Here are some effective strategies to maintain this mechanism.

1. Regular Inspection: Periodically check the components for wear and tear. Look for any signs of damage or corrosion that might affect performance.

2. Cleaning: Keep the system free from dirt and debris. Use a soft brush or cloth to gently clean the surfaces, ensuring that no foreign particles obstruct movement.

3. Lubrication: Apply appropriate lubricant to the moving parts to reduce friction and ensure smooth operation. Be cautious not to over-lubricate, as excess can attract dirt.

4. Adjustment: Make necessary adjustments to ensure the system engages and disengages properly. This can involve tweaking tension or alignment as required.

5. Replacement: If you notice persistent issues or excessive wear, consider replacing components to restore optimal functionality. Using high-quality replacements will improve reliability.

Implementing these strategies will help maintain the efficiency of your stopping mechanism, contributing to a safer and more enjoyable riding experience.

Coaster Brake vs. Other Brake Types

When comparing different stopping mechanisms for bicycles, it is essential to understand the unique features and functionalities each type offers. The distinct characteristics of various systems influence their performance, user experience, and maintenance requirements. By exploring these differences, one can better appreciate the strengths and weaknesses of each mechanism.

One notable difference lies in the engagement method. Some systems require the rider to squeeze levers to activate the stopping mechanism, while others allow for engagement through pedaling backward. This fundamental distinction affects how riders interact with their bicycles and can influence overall safety and ease of use.

Maintenance requirements also vary among these systems. Certain designs demand regular adjustments and more frequent servicing, while others are relatively low-maintenance, appealing to riders who prefer a hassle-free experience. Understanding the upkeep associated with each option can greatly affect long-term satisfaction and performance.

Additionally, the riding style and environment play crucial roles in determining the ideal stopping mechanism. For example, urban cyclists may prioritize responsiveness and reliability in stop-and-go traffic, while those in hilly regions might favor systems that offer better control on steep descents. Evaluating personal needs and circumstances can lead to a more informed decision when selecting a mechanism.

Repairing Coaster Brake Systems

Maintaining and fixing the stopping mechanism is crucial for ensuring a smooth and safe ride. A well-functioning system allows for better control and stability, reducing the risk of accidents. This section outlines the steps involved in the repair process, along with common issues and solutions.

Identifying Common Issues

Regular inspections can help spot issues before they become serious. Here are a few frequent problems that may arise:

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Insufficient stopping power | Poor deceleration, longer stopping distance | Check for wear on the components, adjust the tension |

| Unusual noises | Creaking or grinding sounds during use | Lubricate moving parts, inspect for debris |

| Pedal resistance | Difficulty in pedaling, stuck mechanism | Clean the internal components, replace worn-out parts |

Steps for Repair

The following procedure outlines the essential steps to repair the mechanism effectively:

1. Remove the wheel from the frame to gain access to the mechanism.

2. Inspect all components for damage and wear.

3. Clean the internal system thoroughly to remove dirt and debris.

4. Lubricate moving parts to ensure smooth operation.

5. Reassemble the mechanism and adjust as necessary for proper function.

6. Test the system to confirm that it operates effectively and safely.

Tools Required for Brake Maintenance

Maintaining the stopping mechanism of a vehicle is crucial for safety and performance. To ensure that everything functions smoothly, specific instruments are essential. Proper preparation and the right tools can significantly ease the maintenance process, enhancing both efficiency and effectiveness.

Essential Instruments

- Wrench set

- Socket set

- Screwdriver set

- Torque wrench

- Cleaning materials

Additional Equipment

- Lubricant

- Measuring calipers

- Pliers

- Work gloves

- Safety goggles

Upgrading Coaster Brake Components

Enhancing the components of a traditional stopping mechanism can significantly improve performance and reliability. By replacing older elements with modern alternatives, riders can experience smoother operation and increased durability. Upgrades often involve selecting high-quality materials that contribute to the overall efficiency of the system.

Consideration of Compatibility is essential when choosing new elements. Ensuring that the upgrades fit well with existing structures will prevent complications during installation and usage. It’s advisable to consult specifications and compatibility charts provided by manufacturers.

Improved Materials play a crucial role in the enhancement process. Opting for components made from advanced alloys or reinforced materials can lead to better resistance against wear and tear, thus extending the lifespan of the assembly. Additionally, these materials often provide improved performance under various conditions.

Installation Process should be approached with care. Proper tools and techniques are necessary for ensuring that every element is secured correctly. Following manufacturer guidelines during installation will help avoid any potential issues that could arise from improper fitting.

Regular maintenance of upgraded elements is vital for sustaining optimal performance. Periodic checks for wear and ensuring that all components are functioning as intended will help maintain the benefits gained from the enhancements.

Safety Considerations for Coaster Brakes

When it comes to the operation of bicycle stopping mechanisms, understanding the importance of safety is paramount. Proper maintenance and awareness of potential hazards can significantly enhance the overall riding experience and prevent accidents.

It is essential to regularly inspect the system for wear and tear, ensuring that all components are functioning correctly. Neglecting these checks can lead to reduced performance, posing risks to the rider and others on the road.

| Safety Tip | Description |

|---|---|

| Regular Inspections | Check the functionality of the stopping mechanism and related components before each ride. |

| Proper Lubrication | Ensure all moving parts are adequately lubricated to prevent corrosion and facilitate smooth operation. |

| Appropriate Gear | Always wear a helmet and protective gear to minimize injury in case of sudden stops. |

| Environmental Awareness | Be mindful of the riding environment, adjusting your speed accordingly on uneven surfaces or in adverse weather conditions. |

By adhering to these guidelines, riders can enjoy a safer and more reliable cycling experience, minimizing risks associated with malfunctioning stopping systems.