Understanding the Components of a Brake Caliper Diagram

The intricacies of vehicle stopping systems are vital for safe operation and performance. Each element within this assembly plays a crucial role, contributing to the overall efficiency and effectiveness of halting motion. Grasping the functionality of these components can enhance both knowledge and maintenance practices.

Exploring the individual elements reveals how they interact harmoniously to ensure reliable performance. From the housing to the inner mechanisms, each aspect is designed with precision, aiming for optimal responsiveness. Understanding these features is the ultimate step toward improving vehicle safety.

By delving into the specifics of these essential parts, one can appreciate the engineering marvel behind modern stopping systems. Whether for routine inspections or deeper repairs, familiarity with each element enhances the driver’s experience and ensures longevity of the vehicle.

Understanding Brake Calipers

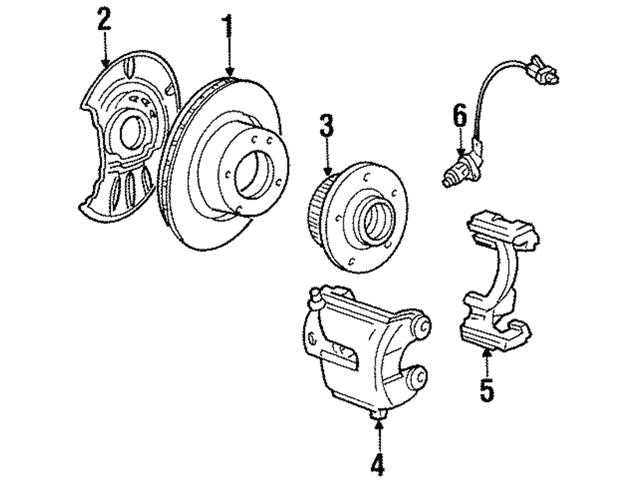

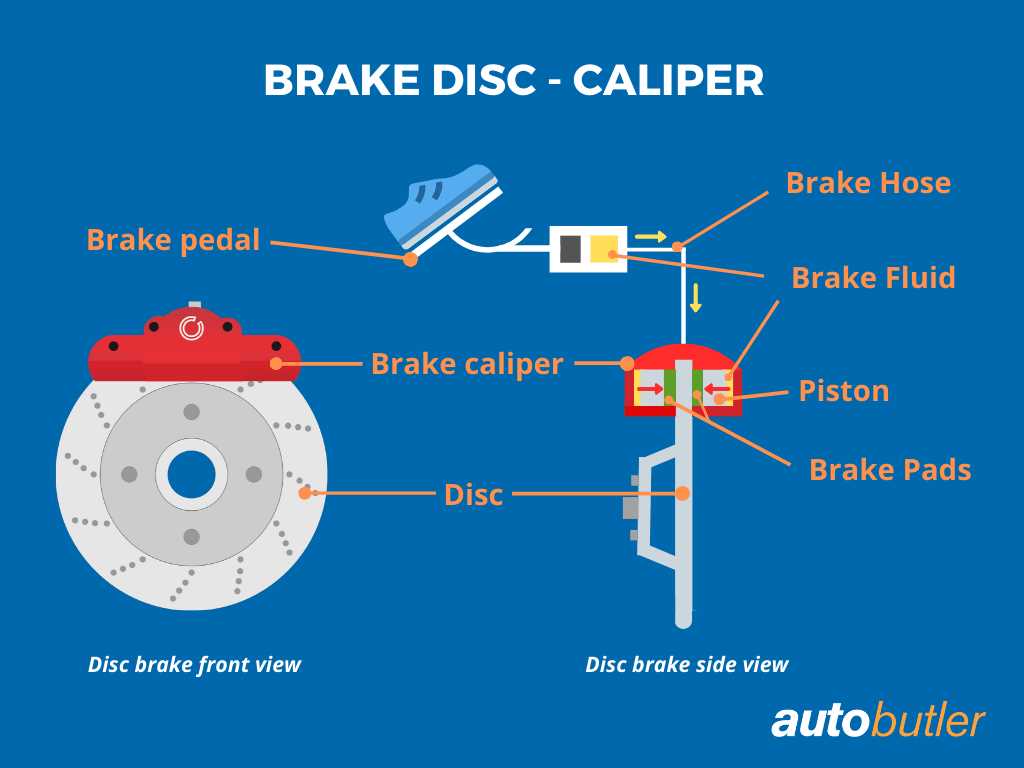

In the realm of automotive systems, the mechanism responsible for slowing down or stopping a vehicle plays a critical role in ensuring safety and control. This device utilizes friction to achieve its function, transforming kinetic energy into heat through its various components. A deeper understanding of this essential element reveals its intricate design and operation, which are vital for effective performance.

Key Components

- Housing: The outer shell that encases the inner mechanisms.

- Piston: A movable piece that generates force when hydraulic fluid is applied.

- Friction Material: The material that makes contact with the rotating surface to create the necessary resistance.

- Hydraulic System: A system that transfers force from the pedal to the movable component.

Functionality Overview

The operation begins when the driver applies pressure to the pedal, which sends fluid through the hydraulic system. This fluid activates the movable element, pushing it against the friction material. As the two surfaces engage, the vehicle slows down due to the generated heat and friction. Understanding this process is essential for recognizing the significance of maintenance and timely replacements.

- Regular inspection can prevent performance issues.

- Worn friction material can lead to diminished stopping power.

- Hydraulic leaks can compromise the entire system.

By grasping the fundamental aspects of this crucial automotive component, one can appreciate its importance in vehicle safety and efficiency.

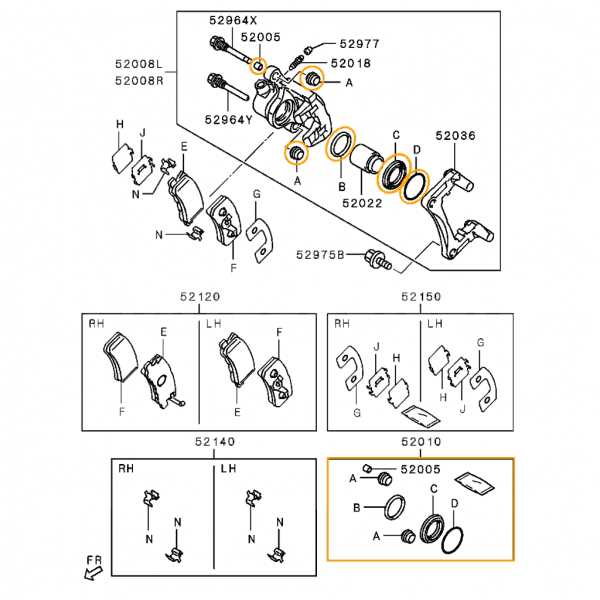

Key Components of Brake Calipers

The effective functioning of a stopping mechanism relies on several critical elements that work together seamlessly. Understanding these essential components is vital for comprehending how the entire system operates during a vehicle’s deceleration.

Main Elements

- Housing: This outer structure encases the internal components and provides support and protection.

- Piston: A crucial part that applies pressure to the friction material, initiating the stopping action.

- Friction Material: The material that generates the necessary grip on the rotating surface to slow down the vehicle.

- Seal: Ensures that hydraulic fluid remains contained and prevents contamination.

- Fluid Passageways: Channels through which hydraulic fluid moves to create pressure, facilitating the function of the piston.

Supportive Features

- Mounting Bracket: Connects the assembly to the vehicle’s structure, providing stability.

- Guide Pins: Allow for smooth movement and alignment during operation, ensuring even pressure distribution.

- Bleeder Valve: A small valve that allows for the removal of air bubbles from the hydraulic system, enhancing performance.

Each of these elements plays a significant role in ensuring that the deceleration system functions efficiently and reliably. A well-maintained assembly is essential for vehicle safety and performance.

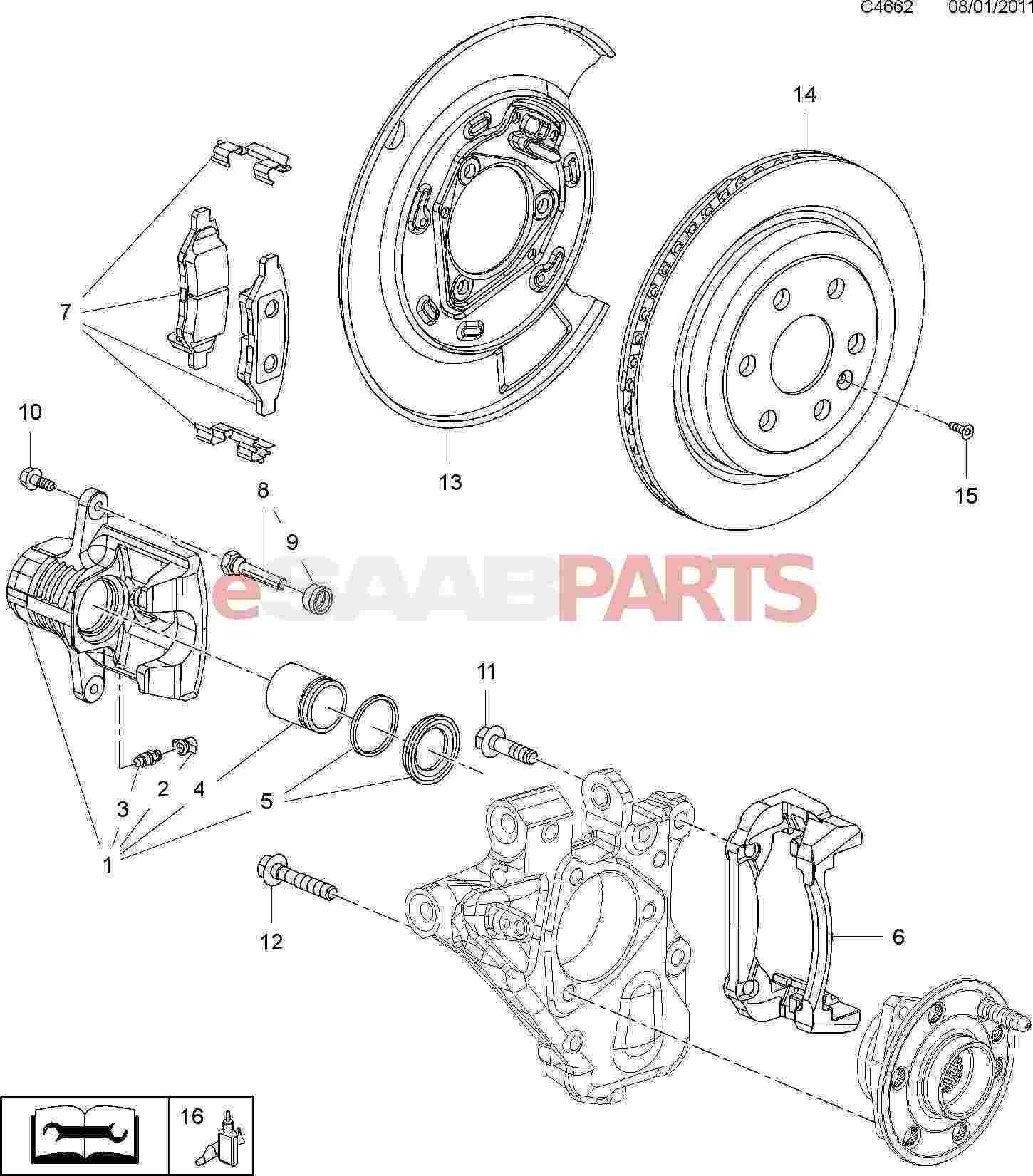

Functionality of Brake Caliper Parts

This section explores the crucial elements that contribute to the effective operation of a stopping mechanism in vehicles. Each component plays a significant role in ensuring safety and performance during deceleration.

Housing serves as the protective shell, providing structural integrity while facilitating the attachment of other elements. Pistons are vital for exerting force on the friction material, generating the necessary pressure for effective engagement. The slider pins ensure smooth movement, allowing the mechanism to respond quickly to driver inputs.

Additionally, the seals prevent fluid leaks, maintaining optimal hydraulic pressure for efficient operation. Lastly, the brake pads create friction against the rotor, ultimately enabling the vehicle to slow down or stop. Understanding these functionalities highlights their importance in overall driving safety.

Types of Brake Calipers Explained

The various mechanisms used in modern stopping systems can be categorized based on their design and function. Each variant serves a specific purpose and offers distinct advantages, contributing to overall performance and efficiency. Understanding these classifications can enhance knowledge about vehicle safety and maintenance.

Single-Piston Units are among the most common types found in smaller vehicles. They utilize a single piston to apply force, making them lightweight and cost-effective. However, their performance may be limited under heavy loads or high-stress conditions.

Multi-Piston Variants are designed for high-performance applications. By incorporating multiple pistons, these systems provide improved clamping force and more even pressure distribution across the friction surface. This results in better stopping power and reduced wear.

Fixed Designs offer another innovative solution, where the clamping mechanism remains stationary while the friction components move. This design enhances consistency in braking performance and is often favored in racing environments due to its reliability.

Sliding Systems feature a mechanism that allows the assembly to move slightly during operation, ensuring even pressure is applied. While they may not deliver the same level of performance as fixed designs, they are widely used in everyday vehicles for their balance of efficiency and cost.

In summary, each type of stopping mechanism plays a crucial role in vehicle dynamics, contributing to safety and performance in varying driving conditions. Understanding these distinctions aids in making informed decisions regarding maintenance and upgrades.

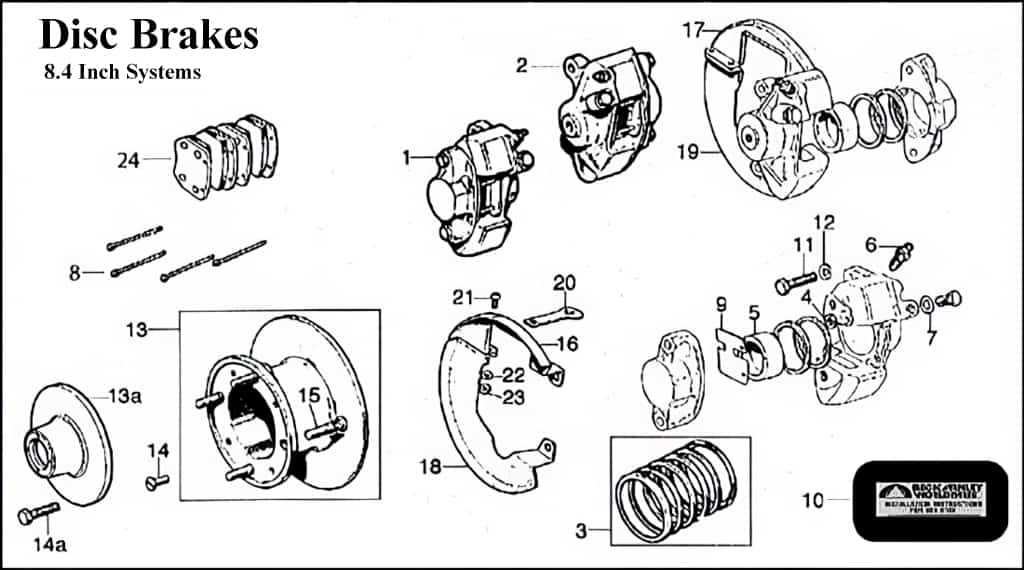

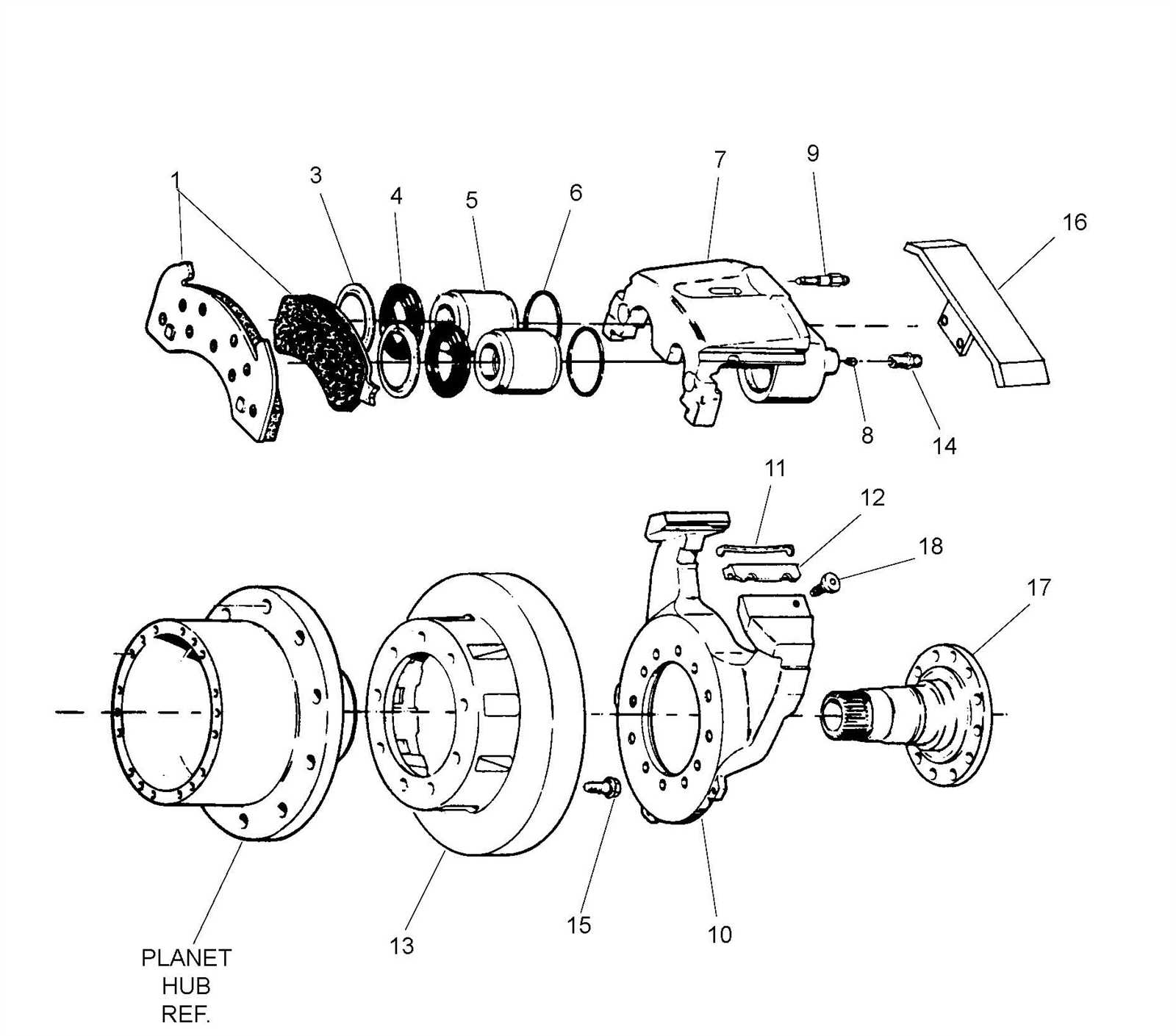

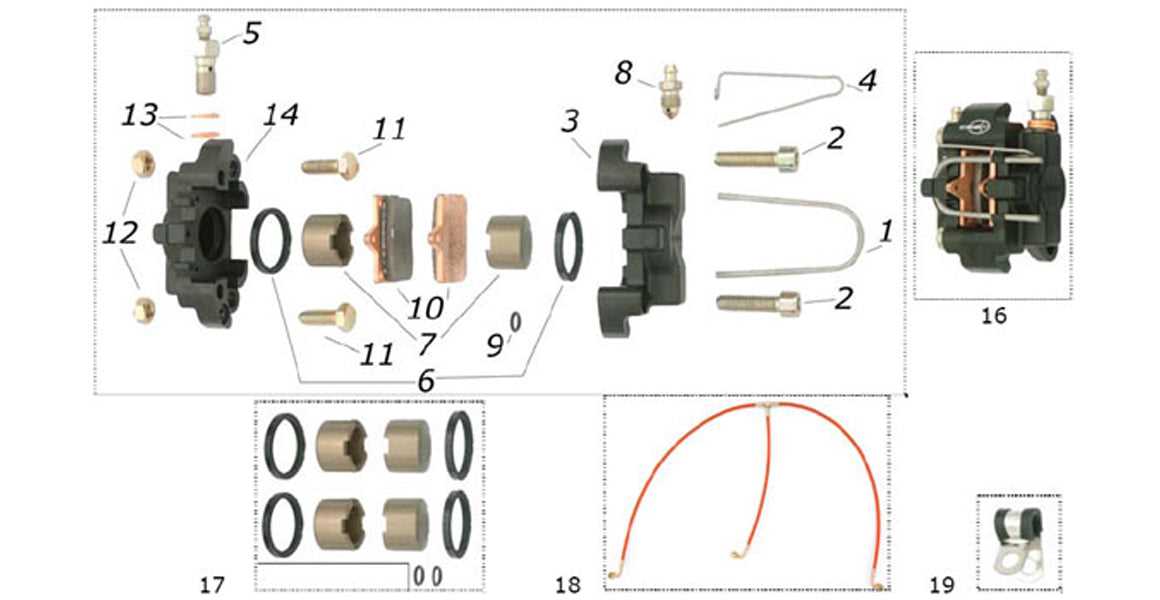

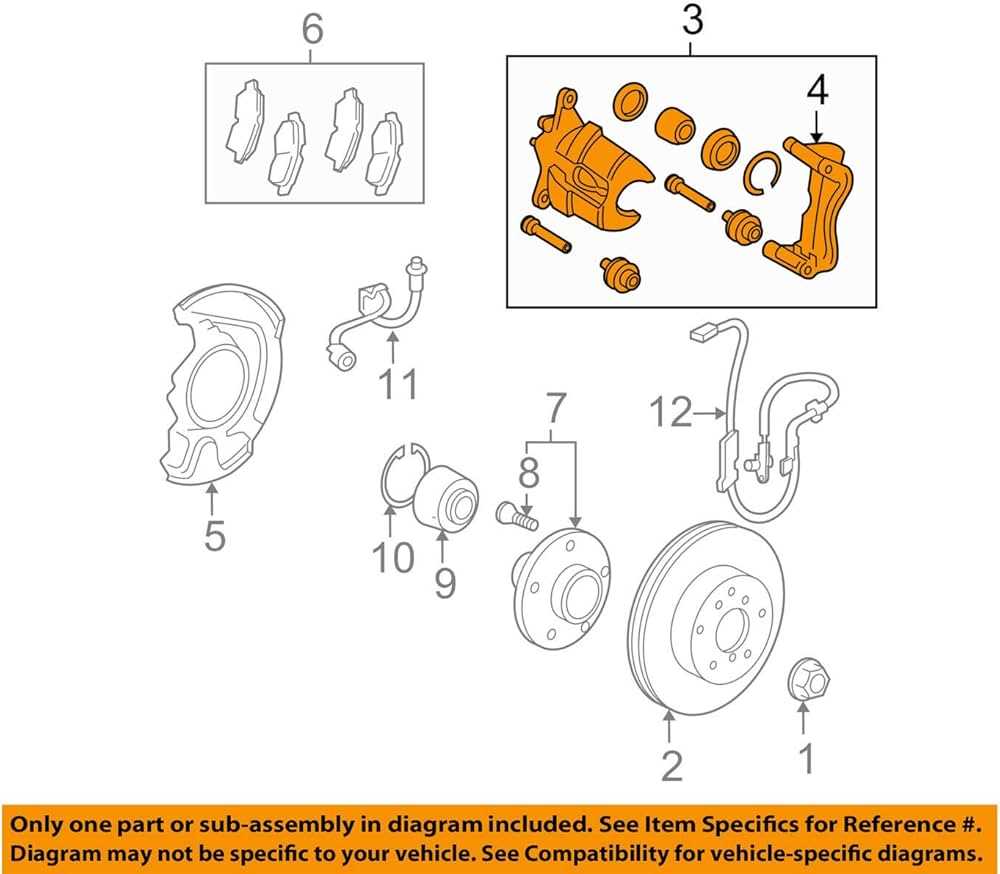

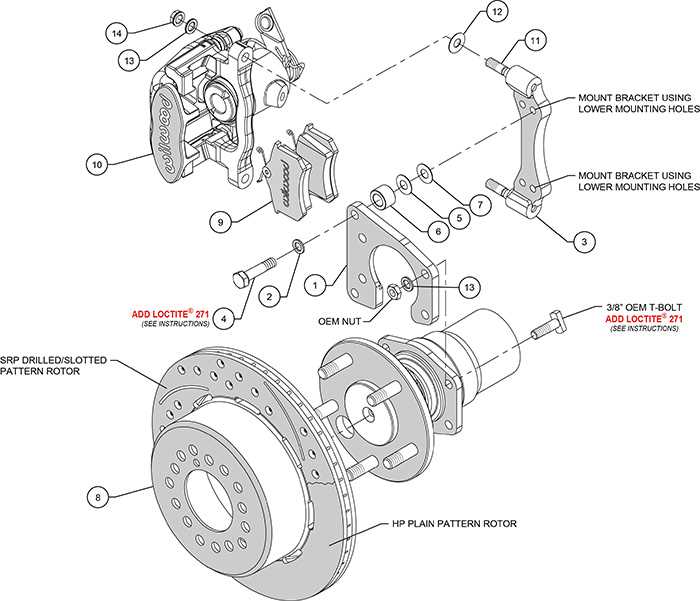

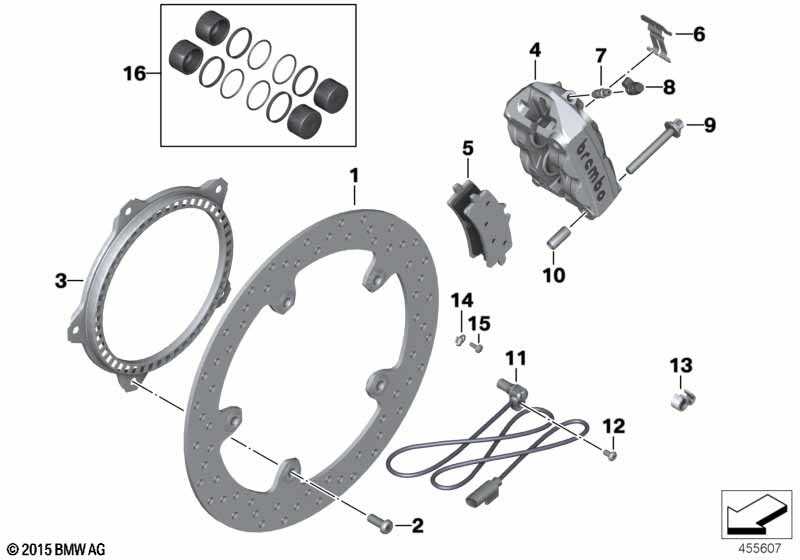

Diagram Overview of Brake Calipers

This section presents a comprehensive visual representation of a critical component in automotive systems. It highlights the intricate design and functionality of the unit, emphasizing its role in ensuring vehicle safety and performance. Understanding the structure helps in grasping how this mechanism operates under various conditions.

Key Elements of the Structure

The illustration showcases several essential elements that contribute to the overall efficiency of the assembly. Each component works in harmony to facilitate the necessary friction required for deceleration. The layout offers insight into the engineering precision involved in its design.

Functionality and Interaction

By examining the visual representation, one can appreciate how the different components interact during operation. This synergy is vital for achieving optimal stopping power and response. The detailed view allows for a deeper understanding of the mechanical processes at play within the system.

Common Issues with Brake Calipers

Understanding the common challenges that can arise with these essential components is crucial for maintaining optimal vehicle performance. Various factors can lead to malfunctions, affecting both safety and driving experience.

1. Leaking Fluid

One of the most prevalent problems is the leakage of hydraulic fluid. This issue often stems from worn seals or damaged components, which can significantly diminish stopping power. Regular inspections can help identify these leaks early, preventing further damage and ensuring safe operation.

2. Sticking Mechanism

A sticking mechanism can result from corrosion or debris buildup. When the components fail to move freely, it can cause uneven wear on the associated parts, leading to decreased effectiveness. Timely maintenance and cleaning can mitigate this issue, ensuring that everything operates smoothly.

In conclusion, addressing these common challenges promptly can enhance safety and extend the lifespan of the system.

Maintenance Tips for Brake Calipers

Ensuring the optimal performance of your vehicle’s stopping system is crucial for safety and longevity. Regular upkeep can help prevent issues such as uneven wear or decreased effectiveness, ultimately enhancing your driving experience. Here are some essential tips to keep everything functioning smoothly.

| Tip | Description |

|---|---|

| Inspect Regularly | Check for leaks, cracks, or corrosion at least once a month. Early detection can save you from more extensive repairs. |

| Clean Components | Use a gentle cleaner to remove dust and debris from surrounding areas. This prevents contaminants from causing wear over time. |

| Check Fluid Levels | Ensure hydraulic fluid is at the recommended level. Low fluid can lead to poor performance and potential failure. |

| Lubricate Moving Parts | Apply appropriate grease to sliding surfaces. Proper lubrication reduces friction and wear, extending lifespan. |

| Monitor Brake Pads | Inspect wear on pads during routine checks. Replace them as needed to maintain effective stopping power. |

By following these maintenance practices, you can enhance the reliability and performance of your vehicle’s stopping system, ensuring safer journeys for you and your passengers.

How Calipers Affect Vehicle Performance

The effectiveness of a vehicle’s stopping mechanism is crucial for overall performance and safety. The components responsible for engaging the wheels play a significant role in how well a vehicle can slow down or come to a complete stop. Their design and functionality directly influence handling, responsiveness, and stability during various driving conditions.

Impact on Handling

Components that manage friction against the wheels contribute to the vehicle’s handling characteristics. When these elements are designed for optimal performance, they enhance the driver’s ability to control the vehicle, especially in challenging environments. A well-engineered system ensures that the car remains stable during sudden stops, allowing for precise maneuvering.

Heat Dissipation and Performance Consistency

Effective heat management is essential for maintaining consistent performance during prolonged use. High temperatures can lead to decreased effectiveness, known as fade. A well-constructed stopping mechanism disperses heat efficiently, ensuring that the vehicle retains its stopping power under demanding conditions. This reliability is vital for both everyday driving and high-performance scenarios.

In conclusion, the design and functionality of these essential components are integral to the overall driving experience, directly affecting safety, responsiveness, and performance consistency.

Differences Between Fixed and Floating Calipers

Understanding the distinctions between two types of clamping systems is essential for optimizing performance and efficiency in automotive applications. Each design has its unique features and advantages, influencing how they interact with friction components during operation.

Fixed systems are characterized by their stationary nature. They feature a rigid structure that remains in one position while exerting force evenly across the friction material. This design often results in enhanced stability and consistent performance, particularly under heavy loads.

On the other hand, floating systems allow for movement. They utilize a sliding mechanism that enables the assembly to shift slightly in response to pressure. This flexibility can lead to improved adaptability and may provide a more uniform wear pattern on the friction material, enhancing longevity.

In summary, the choice between fixed and floating configurations can significantly impact overall functionality. Evaluating factors such as application, load conditions, and maintenance will guide users toward the most suitable option for their needs.

Brake Caliper Materials and Their Benefits

In the realm of automotive engineering, the choice of materials significantly influences performance, durability, and efficiency. Various substances are utilized in the construction of critical components, each offering unique advantages that enhance overall functionality.

| Material | Benefits |

|---|---|

| Aluminum | Lightweight, excellent heat dissipation, and corrosion resistance. |

| Cast Iron | High strength, durability, and superior thermal stability under heavy loads. |

| Composite Materials | Reduced weight, increased stiffness, and enhanced resistance to thermal expansion. |

| Stainless Steel | Corrosion resistance, strength, and longevity, making it suitable for harsh environments. |

Each material brings distinct benefits, allowing engineers to tailor components for specific performance requirements and driving conditions. The right selection ultimately contributes to improved safety and efficiency in vehicle operation.

Installation Process for Brake Calipers

Properly setting up this crucial component is essential for the optimal functioning of a vehicle’s stopping mechanism. A systematic approach ensures safety and performance, making it vital to follow the correct procedure during the installation phase.

Preparation Steps

Before beginning the installation, gather all necessary tools and materials. Ensure the workspace is clean and organized to facilitate a smooth process. Here are the initial steps to consider:

| Step | Action |

|---|---|

| 1 | Gather tools: wrenches, sockets, and a torque wrench. |

| 2 | Lift the vehicle securely using jack stands. |

| 3 | Remove the wheel to access the assembly. |

Installation Procedure

Once the preparation is complete, proceed with the installation following these steps:

| Step | Action |

|---|---|

| 1 | Align the new component with the mounting bracket. |

| 2 | Secure it in place using the appropriate fasteners. |

| 3 | Torque the bolts to manufacturer specifications. |

| 4 | Reinstall the wheel and lower the vehicle. |

By adhering to these steps, you ensure the efficient operation of your vehicle’s stopping system, promoting safety on the road.

Upgrading Brake Calipers: What to Know

Enhancing your vehicle’s stopping system can significantly improve safety and performance. When considering upgrades, it’s essential to understand how these modifications affect overall functionality, responsiveness, and driving experience. Investing in quality components can lead to better handling and increased confidence on the road.

Benefits of Upgrading

Upgrading to high-performance alternatives can offer numerous advantages. Improved heat dissipation is one such benefit, allowing for consistent performance even under intense conditions. Additionally, lighter materials can enhance agility, leading to quicker stops and enhanced control. These enhancements are particularly noticeable during high-speed driving or competitive environments.

Considerations Before Upgrading

Before making any modifications, it’s crucial to assess compatibility with your vehicle’s existing system. Consulting with professionals or researching specific models can help ensure that new components integrate seamlessly. Furthermore, consider the potential impact on maintenance and the overall cost of the upgrade. Balancing performance with practicality will lead to a more satisfying upgrade experience.