Understanding the Press Brake Parts Diagram for Efficient Operation

The intricate machinery used in metal shaping is essential for various industrial applications. Understanding the configuration and functionality of each element is vital for optimal performance and maintenance. This knowledge not only enhances efficiency but also ensures safety during operation.

Key components play a significant role in the overall effectiveness of these machines. Each section contributes uniquely to the bending process, impacting both precision and durability. Gaining insight into how these elements interact can lead to improved productivity and reduced downtime.

By exploring the layout and functions of these crucial elements, one can delve into the ultimate mechanics that drive successful metal forming. This exploration serves as a foundation for both operators and engineers, facilitating informed decisions in both usage and repairs.

Understanding Press Brake Components

In the realm of metal forming, various elements come together to achieve precise bending and shaping of materials. Each component plays a crucial role, ensuring efficiency and accuracy in the fabrication process. Gaining insight into these individual elements allows for better maintenance and enhanced performance of the entire system.

Key Elements and Their Functions

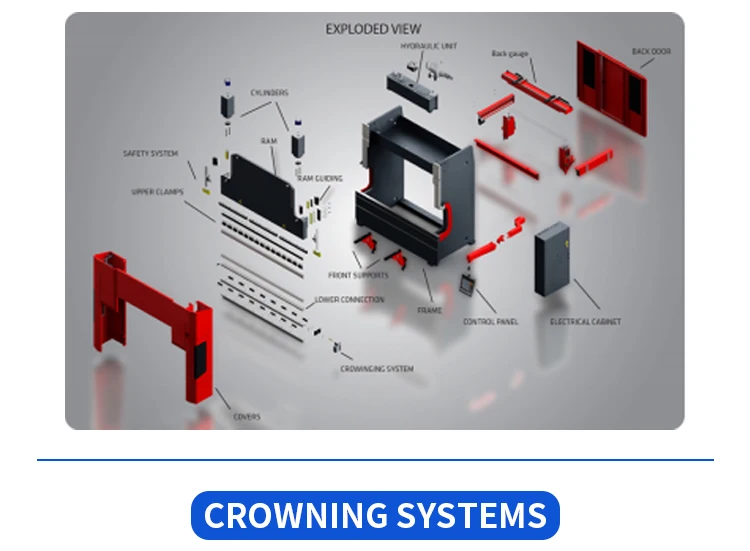

Essential components include the frame, which provides structural integrity, and the tooling, responsible for creating the desired shapes. Hydraulic systems often power these machines, allowing for controlled movements and adjustments. Understanding how these parts interact can lead to optimized usage and longevity.

Importance of Proper Maintenance

Regular upkeep of each element is vital for smooth operation. Identifying wear and tear can prevent significant breakdowns, ensuring that the machine performs at its ultimate capacity. Knowledge of these components equips operators with the tools needed for effective troubleshooting and repair.

Importance of Accurate Diagrams

Precise illustrations are essential in any technical field, serving as critical tools for understanding complex systems. They provide clarity and facilitate effective communication among professionals, ensuring that everyone is on the same page. The quality of these visuals can significantly impact the efficiency and safety of operations.

When dealing with intricate machinery, accurate representations allow for easy identification of components, reducing the risk of errors during assembly or maintenance. These visuals also aid in training new personnel, equipping them with the knowledge necessary to navigate intricate designs confidently.

Moreover, clear illustrations enhance troubleshooting processes by pinpointing potential issues quickly. This can lead to faster repairs and less downtime, ultimately contributing to improved productivity and operational success. In essence, the role of detailed visuals cannot be overstated; they are indispensable for fostering a deeper understanding and ensuring the smooth functioning of technical equipment.

Key Parts of Press Brakes Explained

This section provides an overview of essential components involved in the bending process, highlighting their functions and significance in achieving precision and efficiency. Understanding these elements is crucial for optimizing operations and enhancing the overall performance of the machinery.

Essential Mechanisms

Actuators play a pivotal role in converting energy into movement, enabling the bending mechanism to function effectively. Additionally, clamps secure the material in place, ensuring accuracy during the shaping process.

Control Systems

Modern machinery often incorporates digital interfaces that enhance user interaction and monitoring. These systems allow for precise adjustments and real-time feedback, streamlining operations and improving safety.

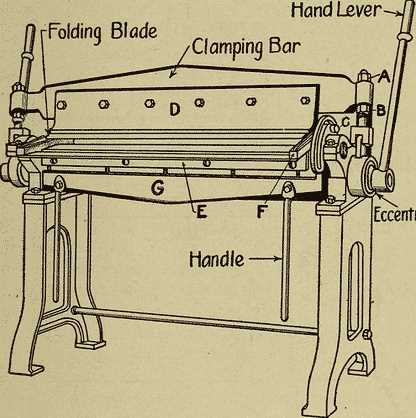

Functionality of the Bending Tool

The bending tool plays a crucial role in shaping materials through controlled deformation. Its primary purpose is to apply force to a workpiece, enabling it to take on desired angles and curves with precision. This capability is essential in various manufacturing processes, ensuring both accuracy and efficiency.

Mechanism of Operation

The tool operates by exerting pressure on the material, which causes it to yield and bend according to specified dimensions. This mechanism relies on a combination of hydraulic or mechanical systems that facilitate the movement and positioning of the tool, allowing for varied applications.

Importance in Manufacturing

Utilizing such a tool enhances production quality and reduces material waste. By achieving the ultimate bend with minimal effort, manufacturers can streamline processes, ultimately improving productivity and product integrity.

Common Types of Press Brake Systems

In the realm of metal forming technology, various systems are designed to achieve precise bending and shaping of materials. Each system possesses unique features tailored to specific applications and operational requirements.

- Hydraulic Systems:

These systems utilize hydraulic fluid to generate force, allowing for significant flexibility and power. They are often favored for their ability to handle thick materials and complex bends.

- Mechanical Systems:

Employing a flywheel mechanism, these systems are known for their speed and efficiency. They are particularly effective for high-volume production, providing consistent and rapid performance.

- Pneumatic Systems:

Utilizing compressed air, pneumatic systems are lightweight and easy to operate. They are best suited for lighter applications, where speed is more critical than sheer power.

- Electric Systems:

These advanced systems rely on electric motors for operation, offering enhanced energy efficiency and precise control. They are increasingly popular in modern manufacturing environments.

- Hybrid Systems:

Combining elements from both hydraulic and electric technologies, hybrid systems provide a balance of power and efficiency. They are designed to meet the demands of diverse applications.

Choosing the right system is crucial for optimizing productivity and ensuring the quality of the final product. Each type has its own advantages and is suitable for various industrial needs.

Maintaining Press Brake Efficiency

Ensuring optimal functionality of machinery is crucial for enhancing productivity and minimizing downtime. Regular attention to maintenance practices can significantly impact performance and lifespan, leading to more efficient operations. Identifying key areas for upkeep is essential for achieving the best results.

Regular Inspections: Conducting frequent evaluations of equipment can help detect wear and tear early. Look for signs of damage or misalignment that could hinder operation.

Lubrication: Proper lubrication of moving components is vital. Using the right type of lubricant reduces friction, preventing unnecessary wear and ensuring smooth operation.

Calibration: Periodic calibration is essential to maintain accuracy. Regular adjustments help achieve precise results and prevent errors during the manufacturing process.

Training Personnel: Investing in staff training enhances understanding of machinery operation and maintenance. Well-informed operators can identify issues early, ensuring continuous efficiency.

In conclusion, focusing on maintenance strategies not only boosts productivity but also extends the operational life of the equipment, making it a crucial aspect of successful manufacturing.

Identifying Wear and Tear in Parts

Understanding the signs of degradation in mechanical components is crucial for maintaining optimal functionality. Regular monitoring can prevent unexpected failures and extend the lifespan of equipment. Various indicators can signal that certain elements are experiencing wear, and recognizing these early can lead to timely interventions.

Common Signs of Degradation

Components may exhibit several symptoms as they begin to wear down. Observing these indicators can help in assessing their condition effectively.

| Indicator | Description |

|---|---|

| Cracks | Visible fractures that may compromise structural integrity. |

| Deformation | Altered shapes that affect alignment and function. |

| Excessive Noise | Unusual sounds during operation indicating friction or misalignment. |

| Corrosion | Rust or oxidation that weakens components over time. |

Monitoring and Maintenance

Regular inspections and maintenance routines are essential for identifying wear and tear. Implementing a proactive approach allows for the replacement or repair of affected components before they lead to larger issues, ensuring consistent performance and safety.

Upgrading Press Brake Components

Enhancing the key elements of your forming machinery can significantly improve performance and efficiency. This process involves assessing existing functionalities and implementing modern solutions that align with current technological advancements. The goal is to ensure that the equipment operates at its highest potential while meeting the demands of evolving production standards.

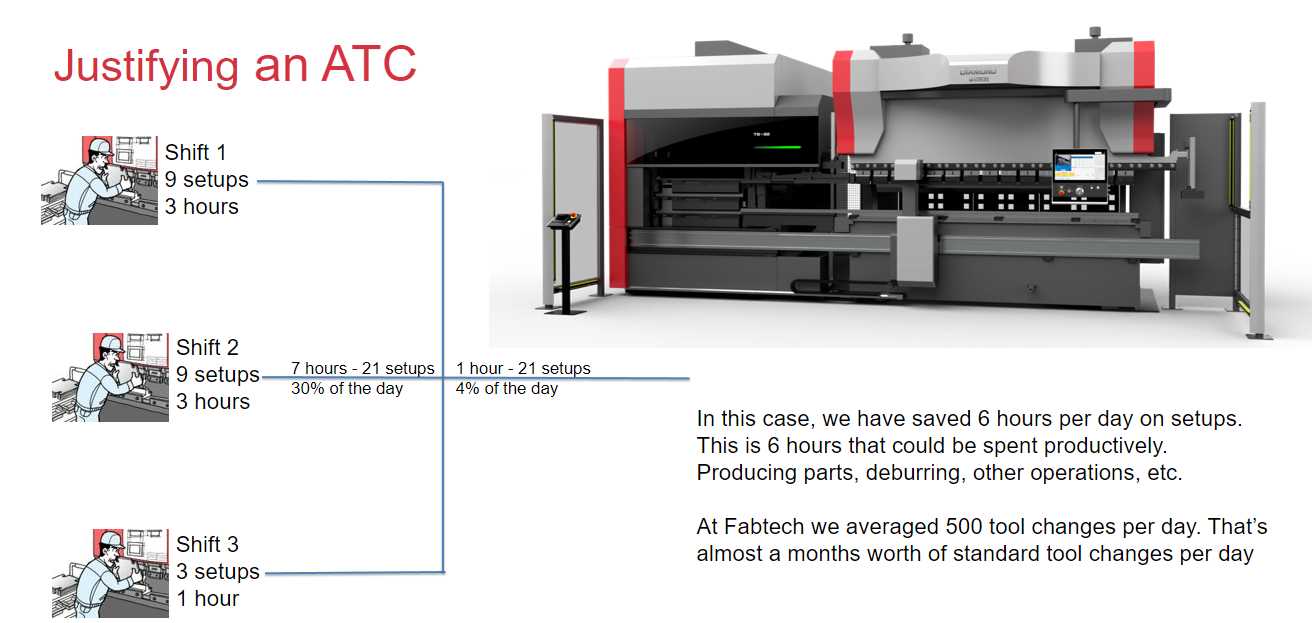

Key considerations when upgrading include evaluating the control systems, ensuring precision and responsiveness, and exploring advanced features such as automation and real-time monitoring. Investing in high-quality components can lead to reduced maintenance costs and longer lifespan for your machinery.

Additionally, upgrading to energy-efficient solutions can not only lower operational costs but also contribute to sustainability goals. Emphasizing user-friendly interfaces ensures that operators can easily adapt to the upgraded systems, enhancing overall productivity.

Safety Features in Press Brake Design

In modern machinery design, ensuring operator safety is paramount. Innovative safety mechanisms are integrated to minimize risks and enhance the overall working environment. These features not only protect users but also improve the efficiency of operations.

Emergency Stop Buttons: Placing these buttons within easy reach allows for immediate cessation of operations during unforeseen circumstances, ensuring swift action can be taken to avert accidents.

Light Curtains: These invisible beams of light detect the presence of individuals in hazardous areas, automatically halting operations if an obstruction is detected, thereby providing a crucial safety barrier.

Two-Hand Controls: Requiring the simultaneous use of both hands to initiate operations prevents unintentional activation, keeping hands and limbs safely away from moving components.

Safety Guards: Physical barriers are installed to shield users from moving parts and potential pinch points, significantly reducing the likelihood of injury during operation.

By implementing these and other advanced safety features, designers aim to create a secure working environment, ultimately promoting safer practices in industrial settings.

Integrating Technology in Press Brakes

The integration of advanced technology in manufacturing machinery has transformed operational efficiency and precision. By harnessing cutting-edge innovations, industries can achieve remarkable enhancements in productivity and quality.

Modern systems now incorporate various technological elements, including:

- Automated control systems for real-time adjustments

- Advanced sensors for enhanced monitoring and safety

- Software solutions for precise programming and simulation

These advancements not only streamline workflows but also facilitate:

- Increased accuracy in fabrication

- Reduction in operational downtime

- Improved energy efficiency

As industries continue to delve into technological integration, the ultimate goal remains the optimization of processes and the enhancement of overall product quality.

Best Practices for Press Brake Operation

Ensuring optimal performance and safety during metal forming operations requires adherence to a set of best practices. These guidelines not only enhance the efficiency of the machinery but also minimize the risk of accidents and defects in the final products. Proper training and awareness of operational techniques are essential for achieving the best results.

1. Operator Training: Comprehensive training for operators is crucial. Understanding the machinery’s capabilities and limitations helps in making informed decisions, which can significantly impact the quality of work.

2. Regular Maintenance: Scheduled maintenance is key to prolonging the lifespan of the equipment. Regular checks for wear and tear, lubrication of moving parts, and calibration of settings ensure that the machinery operates smoothly and safely.

3. Material Preparation: Properly preparing materials before beginning any task can greatly affect outcomes. Ensuring that materials are clean, free of defects, and appropriately sized minimizes errors and enhances precision.

4. Safety Protocols: Adhering to established safety protocols is non-negotiable. Utilizing personal protective equipment and ensuring that safety guards are in place can prevent accidents and injuries.

5. Tool Selection: Choosing the right tools for specific applications is vital. Using appropriate dies and tooling for the material and thickness being processed can improve accuracy and reduce waste.

6. Consistent Monitoring: Continuously monitoring the operation can help in detecting issues early. Keeping an eye on the process allows for adjustments that can enhance quality and prevent defects.

7. Documentation: Keeping detailed records of operations, maintenance, and any incidents can provide valuable insights for future processes. Documentation helps in identifying trends and areas for improvement.

By following these best practices, operators can significantly enhance productivity, maintain safety standards, and ensure the high quality of the finished products.