Understanding the Shimano Disc Brake Parts Diagram

The intricacies of modern braking systems are essential for optimal performance and safety in cycling. A comprehensive grasp of each element involved can greatly enhance your maintenance skills and overall riding experience. This section aims to shed light on the various components that work harmoniously within these hydraulic mechanisms.

To achieve peak efficiency, it’s crucial to recognize how each segment interacts with others. A clear visual representation of these components not only aids in understanding their functions but also serves as a valuable tool for troubleshooting issues. By exploring this detailed overview, you will be equipped with the knowledge to tackle any challenges that may arise.

In addition, familiarizing yourself with these mechanical elements empowers you to make informed decisions regarding upgrades and replacements. Whether you are a seasoned enthusiast or a beginner, delving into the world of these sophisticated systems will ultimately enrich your cycling journey.

Understanding Shimano Disc Brakes

The realm of modern cycling involves sophisticated mechanisms that enhance safety and performance. Among these innovations, certain components play crucial roles in ensuring efficient stopping power and rider control. Grasping the fundamentals of these systems is essential for both enthusiasts and casual riders alike.

Key Components of the System

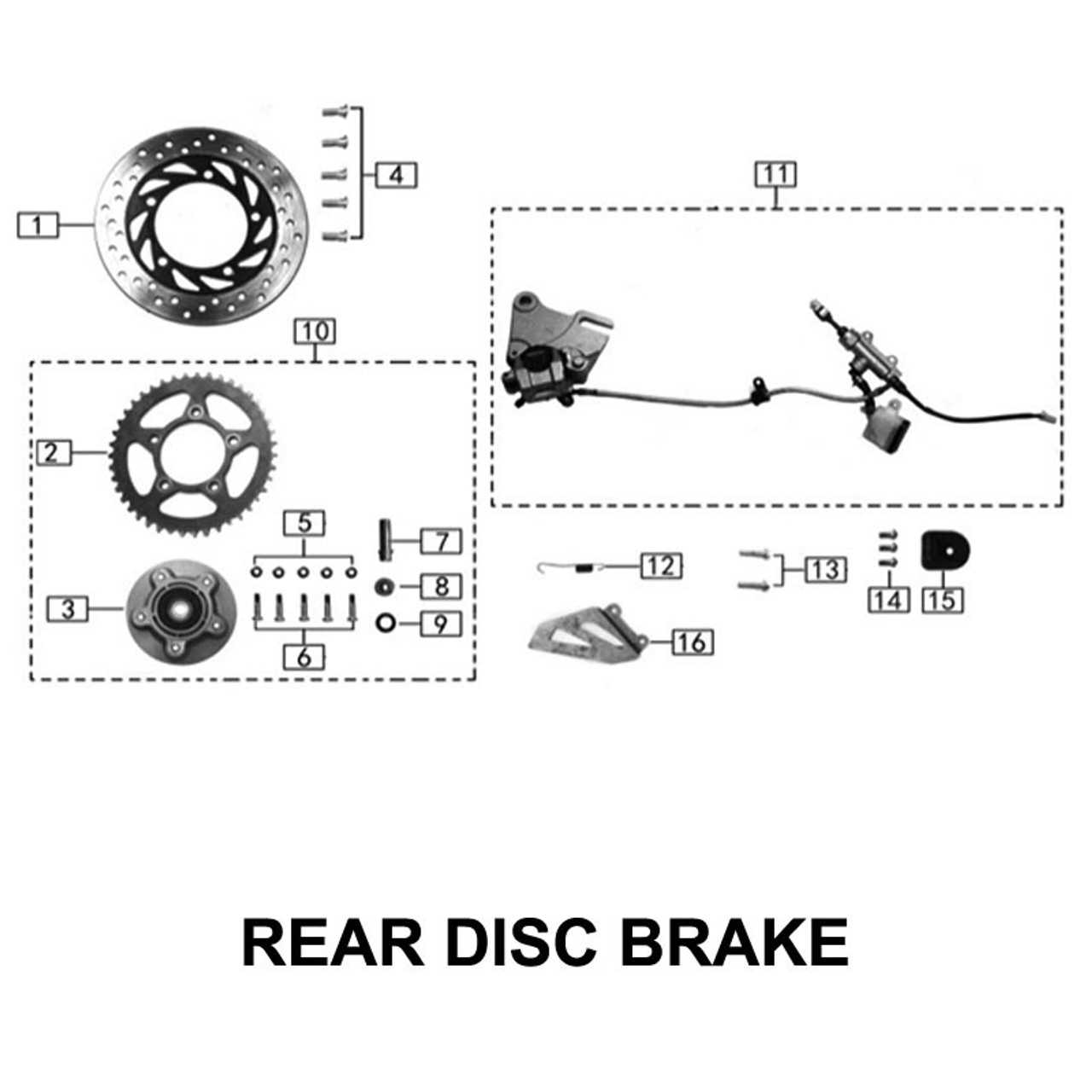

- Calipers: These units house the mechanism that applies force to the pads, generating the necessary friction.

- Pads: Typically made from various materials, these elements directly contact the rotor to slow down the wheel.

- Rotors: Attached to the wheel, they provide a surface for the pads to grip and are vital for heat dissipation.

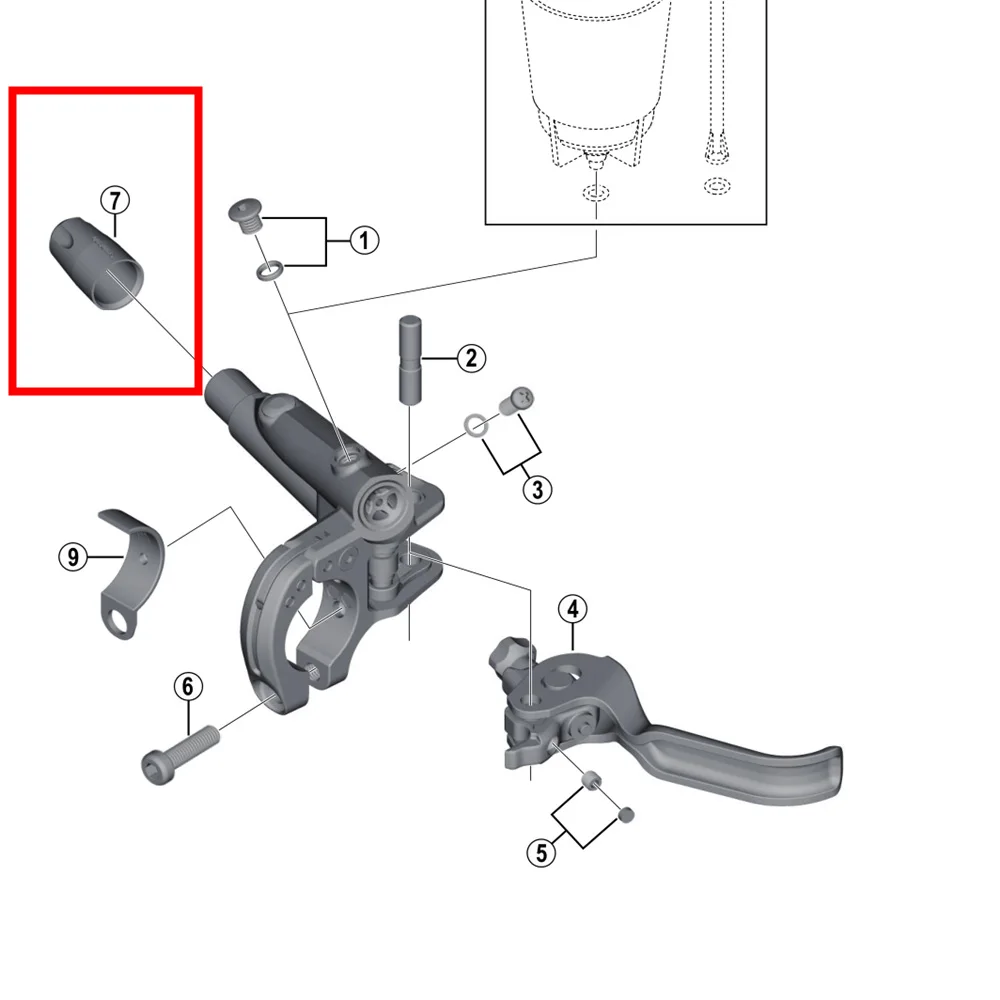

- Levers: Located on the handlebars, these controls allow the rider to engage the stopping mechanism with ease.

Maintenance Tips

- Regularly check pad wear and replace them when necessary.

- Ensure the rotors are true and free from debris.

- Inspect the hydraulic system for leaks or air bubbles.

- Clean all components to maintain optimal performance.

By familiarizing oneself with these essential elements and adhering to maintenance practices, riders can ensure a safe and enjoyable cycling experience.

Components of Shimano Brake Systems

The intricacies of modern stopping systems involve a range of elements that work in harmony to ensure optimal performance and safety. Understanding these components is essential for maintenance and upgrades, allowing for a seamless riding experience.

| Component | Description |

|---|---|

| Caliper | Responsible for gripping the rotor to create friction and reduce speed. |

| Rotor | The circular metal disc that interacts with the caliper to enable effective stopping power. |

| Pads | Friction material that presses against the rotor, facilitating the braking process. |

| Levers | Actuated by the rider’s hand, these elements control the caliper’s engagement. |

| Hydraulic Lines | Convey hydraulic fluid to transfer force from the lever to the caliper. |

How to Read a Brake Diagram

Understanding the layout of a braking system is essential for proper maintenance and troubleshooting. A schematic representation provides valuable insights into the components and their interconnections, helping you identify issues and carry out effective repairs.

Begin by familiarizing yourself with the symbols and labels used in the representation. Each element typically corresponds to a specific component, such as calipers, rotors, or levers. Pay attention to the orientation and arrangement, as this indicates how the parts interact with each other during operation.

Next, follow the flow of the system. Look for arrows or lines that demonstrate movement or force application. This can help you understand the sequence of actions, such as how pressure is transferred from one part to another when the mechanism is engaged.

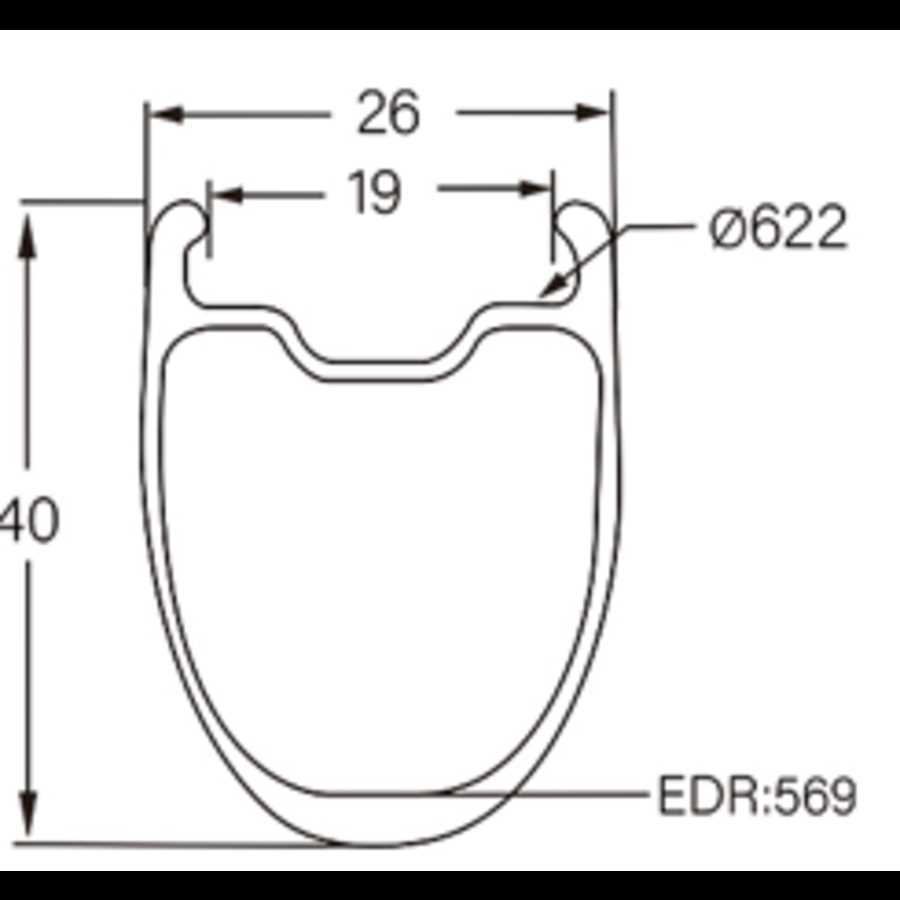

Additionally, note any specifications or measurements provided. These details can be crucial for ensuring compatibility and proper fitment when replacing or adjusting components. Understanding these figures can prevent potential issues during installation or maintenance.

Finally, cross-reference the schematic with a physical inspection of your system. This hands-on approach allows you to verify the accuracy of the representation and gain a deeper understanding of the assembly. By effectively interpreting these visual aids, you can enhance your ability to work on braking systems efficiently and confidently.

Common Shimano Brake Models Explained

Understanding the various models of braking systems is essential for cyclists seeking optimal performance. Each model offers unique features tailored for different riding styles and conditions. Below, we delve into some of the most popular configurations, highlighting their key attributes and ideal applications.

| Model | Type | Key Features | Best For |

|---|---|---|---|

| SLX | Hydraulic | Excellent modulation, lightweight, reliable performance | Trail riding and aggressive terrain |

| XT | Hydraulic | Superior stopping power, enhanced heat management, user-friendly maintenance | All-mountain and cross-country racing |

| Deore | Mechanical | Durable design, easy adjustment, cost-effective | Casual riding and entry-level mountain biking |

| XTR | Hydraulic | Top-tier performance, ultra-lightweight, optimized for speed | Professional racing and high-performance setups |

| Alivio | Mechanical | Reliable stopping power, straightforward installation, versatile | Recreational biking and urban commuting |

Functions of Each Brake Part

Understanding the various components involved in the stopping mechanism is crucial for maintaining performance and safety. Each element serves a specific role in ensuring effective deceleration and control during operation. Below, we delve into the essential functions of these components.

Main Components and Their Roles

- Caliper: This unit houses the pads and is responsible for applying pressure to them, generating the necessary friction to slow down the wheel.

- Pads: These are the friction materials that press against the rotor, creating the force needed to reduce speed.

- Rotor: The disc that the pads grip; it converts kinetic energy into heat through friction, allowing the vehicle to slow down.

- Master Cylinder: This component converts the force from the lever into hydraulic pressure, enabling the caliper to engage the pads.

- Fluid Lines: These tubes carry the hydraulic fluid from the master cylinder to the caliper, facilitating the pressure transfer needed for operation.

Additional Elements

- Brake Lever: The part that the operator engages, initiating the process that leads to deceleration.

- Brake Fluid: The hydraulic fluid that transfers force from the master cylinder to the caliper, essential for effective functioning.

- Mounting Hardware: These components secure the various parts together, ensuring stability and alignment during use.

- Heat Sinks: Some systems include additional components to dissipate heat, helping to maintain performance under heavy use.

Each of these elements works in concert, allowing for smooth and reliable stopping. Understanding their functions can greatly enhance maintenance practices and overall performance.

Maintenance Tips for Disc Brakes

Regular upkeep of your stopping system is essential for optimal performance and safety. By following a few simple guidelines, you can ensure that all components function smoothly and effectively, enhancing your riding experience.

Here are some essential practices to maintain your braking mechanism:

| Tip | Description |

|---|---|

| Inspect Regularly | Check for wear and tear on all components, ensuring that nothing is loose or damaged. |

| Clean Components | Use appropriate cleaning solutions to remove dirt and debris from the surfaces, which can affect performance. |

| Check Alignment | Ensure that all elements are correctly aligned for maximum efficiency and effectiveness. |

| Monitor Fluid Levels | Keep an eye on the hydraulic fluid levels, topping up as necessary to maintain proper pressure. |

| Replace Worn Items | Be proactive in replacing any parts that show significant wear to avoid potential failure. |

By implementing these strategies, you can extend the lifespan of your stopping system and ensure a safer ride every time you hit the road.

Troubleshooting Brake Issues

When faced with problems related to your stopping system, understanding the underlying causes is essential for effective resolution. Identifying symptoms accurately can lead to quicker fixes and improved performance.

Common Symptoms

- No response when engaged

- Unusual noise during operation

- Vibration or wobbling

- Fluid leaks around the mechanism

Diagnostic Steps

- Inspect for visible wear or damage.

- Check fluid levels and consistency.

- Ensure all components are securely fastened.

- Test the system under various conditions to replicate issues.

Upgrading Shimano Brake Components

Enhancing your cycling experience often involves refreshing your stopping system. Upgrading key components can significantly improve performance, safety, and responsiveness. This section delves into the various options available for those looking to elevate their setup.

When considering enhancements, focus on the following elements:

- Calipers: Upgrading to a higher-grade caliper can provide improved modulation and stopping power.

- Pads: Choosing advanced friction materials can lead to better grip and longevity.

- Rotors: Larger or more efficient rotors can improve heat dissipation and overall braking performance.

- Fluid: Using high-quality hydraulic fluid can enhance responsiveness and reduce fade.

It’s essential to evaluate compatibility with your existing system before making any changes. Researching the best combinations can lead to optimal results and an improved riding experience.

Installation can be straightforward, but it’s advisable to consult manufacturer guidelines or seek professional assistance to ensure everything functions smoothly. Regular maintenance of upgraded components will also prolong their life and maintain performance.

In summary, strategic upgrades can transform your stopping system, making your rides safer and more enjoyable. Consider the specific needs of your riding style and conditions to select the best enhancements.

Compatibility of Parts and Models

Understanding the relationships between various components and their respective models is essential for ensuring optimal performance and safety. This section delves into how different elements interact, highlighting the importance of compatibility in the selection and maintenance process.

Components are designed with specific tolerances and specifications that dictate their interaction with other elements. Each model may have unique requirements that must be met for seamless functionality. It is crucial to verify that selected components align with the designated system to prevent issues during operation.

Additionally, interchangeability among various models can provide flexibility, but it also necessitates a careful examination of compatibility. Using components from different lines may yield satisfactory results, yet it may also introduce risks if the specifications do not match precisely. Always consult the manufacturer’s guidelines to ensure that the chosen items are suitable for the intended application.

Ultimately, a thorough understanding of compatibility will aid in achieving the best performance and longevity from your setup. Being informed and meticulous in your selections can prevent unnecessary complications and enhance overall experience.

Installation Guide for Disc Brakes

This section provides a comprehensive overview of the essential steps to properly install braking components on your bicycle, ensuring optimal performance and safety. A careful approach will enhance your riding experience by maximizing control and reliability.

Tools and Materials Needed

Before beginning, gather the following tools and materials:

| Tool/Material | Purpose |

|---|---|

| Torque Wrench | To ensure correct tightening of components |

| Hex Wrenches | For securing various fittings |

| Clean Cloth | To wipe components during installation |

| Brake Fluid | For hydraulic systems |

Step-by-Step Installation

Follow these steps for an effective setup:

1. Begin by removing the wheel and cleaning the mounting area. 2. Position the assembly onto the frame and align the mounting holes. 3. Secure components using the appropriate tools, ensuring they are tight but not over-torqued. 4. If applicable, fill the hydraulic system with fluid and bleed it to remove air. 5. Finally, reattach the wheel and check alignment before testing the system.

Benefits of Using Shimano Brakes

Utilizing high-quality stopping mechanisms offers numerous advantages for cycling enthusiasts. These systems provide reliable performance, ensuring safety and control during various riding conditions. With an emphasis on precision engineering, they enhance the overall experience and contribute to greater confidence on the road or trail.

One of the standout features is their exceptional modulation, allowing riders to adjust stopping power seamlessly. This responsiveness can be crucial in challenging environments, where quick decision-making is essential. Furthermore, the durability of these systems means they can withstand intense use, making them a long-term investment for avid cyclists.

Maintenance is also simplified with this technology, which leads to reduced downtime and increased enjoyment on rides. Overall, incorporating these advanced mechanisms not only improves performance but also elevates the joy of cycling, providing peace of mind during every journey.

Comparing Shimano with Other Brands

In the realm of cycling components, different manufacturers offer unique technologies and features that can significantly affect performance and user experience. This section explores the distinctions between one prominent brand and its competitors, emphasizing design philosophy, performance, and user satisfaction.

Performance and Reliability

When evaluating various offerings, reliability and performance under different conditions are crucial factors. Each brand adopts distinct engineering approaches that influence how their components respond to various terrains and riding styles.

Cost-Effectiveness

Another vital aspect to consider is the cost-to-performance ratio. While some brands provide high-end solutions with advanced features, others focus on budget-friendly options that still maintain decent quality.

| Feature | Brand A | Brand B | Brand C |

|---|---|---|---|

| Reliability | High | Medium | Variable |

| Performance | Exceptional | Good | Adequate |

| Price Range | Mid-High | Low-Mid | High |