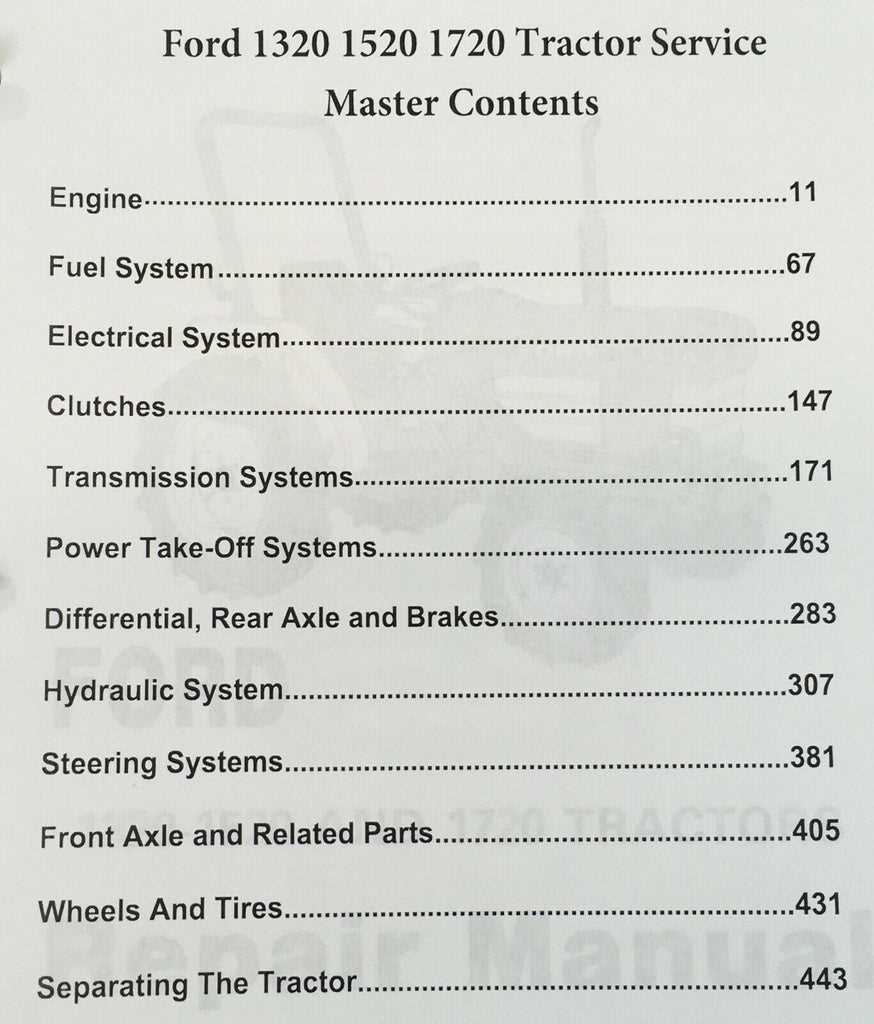

Cub Cadet 1320 Parts Diagram Overview

When maintaining or repairing outdoor machinery, having a clear understanding of how each component fits together is essential. Knowing the individual parts and their functions can greatly simplify troubleshooting or upgrading equipment. This knowledge ensures that any task, whether it’s maintenance or repair, is carried out efficiently and safely.

Breakdown of key elements in the mechanical structure of your equipment allows for easier identification of any faulty components that need replacing. With a comprehensive reference, it becomes possible to assess whether a part requires attention or is still in working condition. In addition, understanding the mechanical layout can help you avoid unnecessary disassembly.

Whether you are a seasoned professional or a hobbyist working on your yard tools, having access to a well-organized resource of machine components ensures that your tasks run smoothly. It saves time and minimizes the risk of errors during assembly, ensuring that everything works as intended once reassembled.

Understanding the Layout of the Lawn Equipment

When working with this particular model, it’s crucial to have a clear understanding of its overall structure. Each component is strategically placed to ensure optimal performance and ease of maintenance. Familiarizing yourself with how the machine is organized will help you in both routine upkeep and troubleshooting potential issues. Whether you are replacing a worn-out part or trying to improve efficiency, knowing the layout is the first step toward successful operation.

Key Sections of the Equipment

- Engine Area: The heart of the machinery where power is generated.

- Transmission: Manages the transfer of power to the wheels, providing movement.

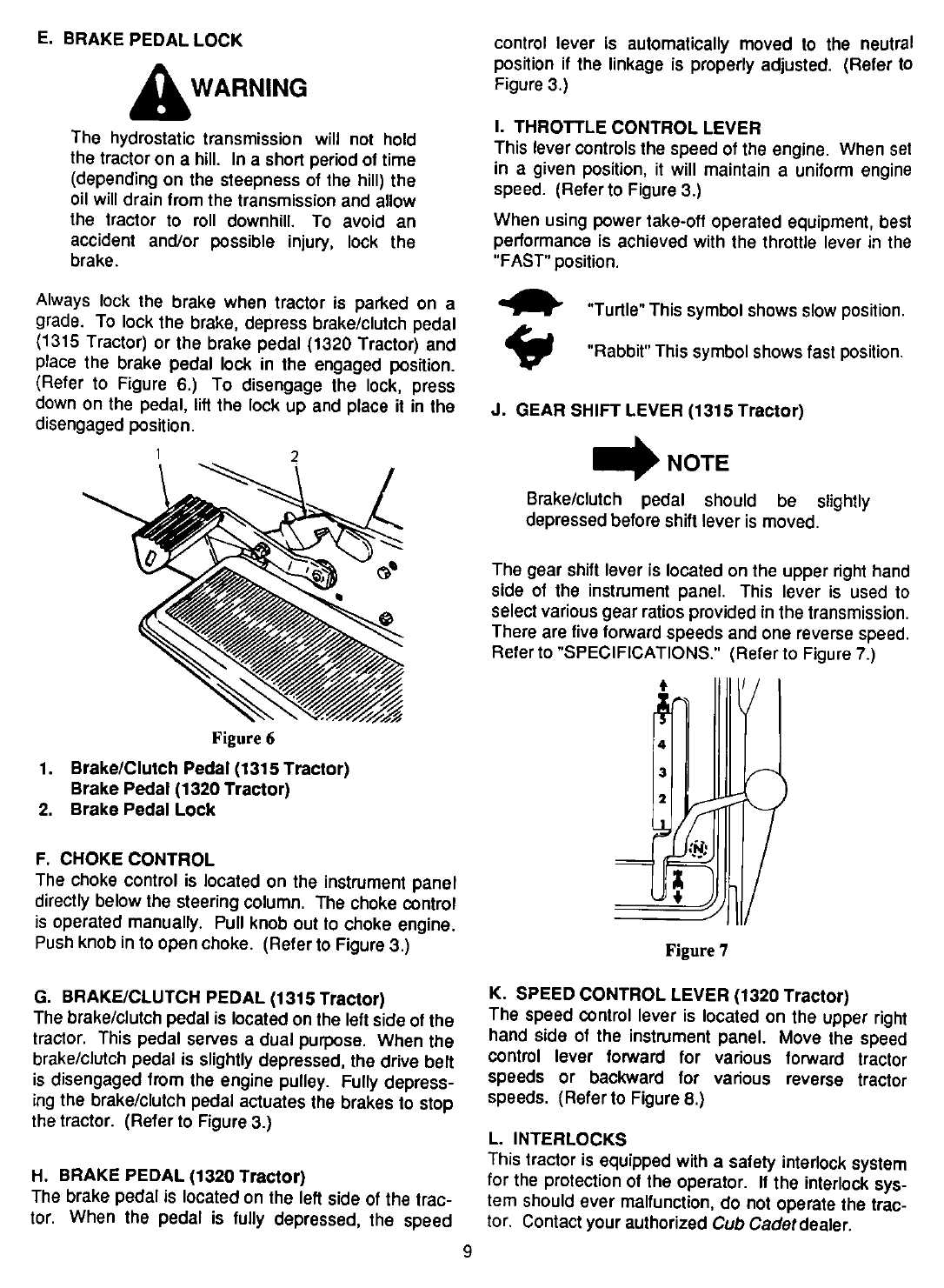

- Control Mechanism: The operator’s interface for managing speed, direction, and functionality.

- Chassis: The base structure that supports and stabilizes the equipment.

Components and Their Placement

- Fuel System: Located near the engine, responsible for providing power.

- Electrical System: Includes wiring and batteries that control the ignition and lighting.

- Wheels and Tires: Positioned for balance and movement, critical for stability during operation.

Understanding these key areas will allow you to better navigate maintenance tasks, reduce downtime, and enhance the performance of your machine over time.

Key Components of the Mower System

The mower system is comprised of several vital elements that work in unison to deliver efficient cutting performance. Each part plays an essential role in ensuring smooth operation and long-lasting durability. Understanding these core components is crucial for maintaining and optimizing the system’s functionality.

Engine: The heart of the mower, responsible for powering all moving parts. It provides the necessary energy for the blades to rotate and the wheels to move.

Cutting Blades: These are the primary components that perform the cutting action. They are designed to rotate at high speeds, ensuring even and precise grass cutting.

Transmission: The transmission enables the mower to move forward or backward. It transfers the engine’s power to the wheels, allowing the user to maneuver the machine effectively.

Deck: The deck houses the blades and ensures proper grass cutting height and alignment. It also protects other vital parts from debris and damage during operation.

Wheels: The wheels support the mower’s movement, ensuring stability and smooth navigation across different terrains.

Controls: These allow the operator to adjust speed, direction, and cutting height. Proper control settings ensure optimal performance and safety.

Each of these key components plays a critical role in the mower’s overall functionality and efficiency. Regular maintenance and understanding their purpose can help keep the system in peak working condition.

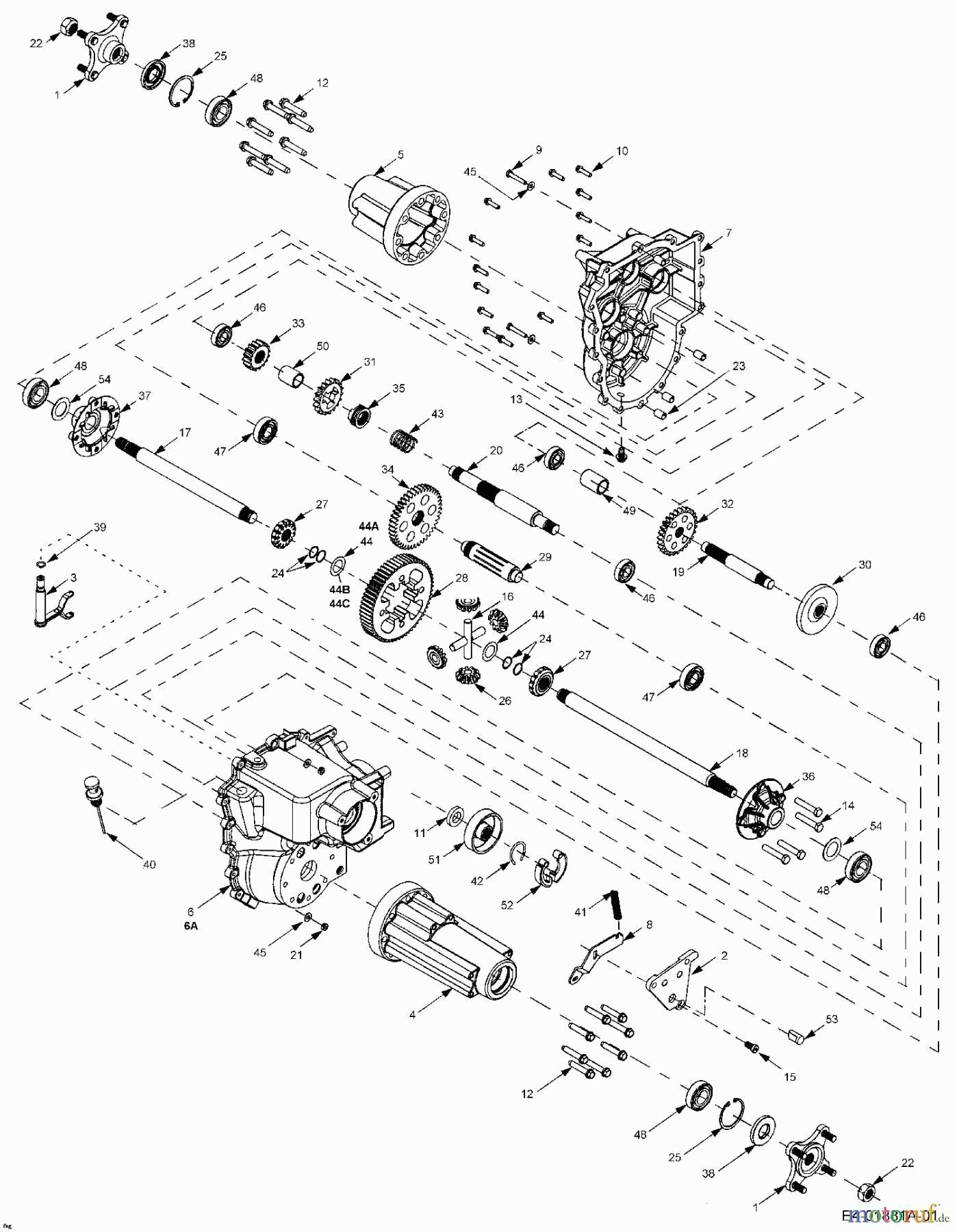

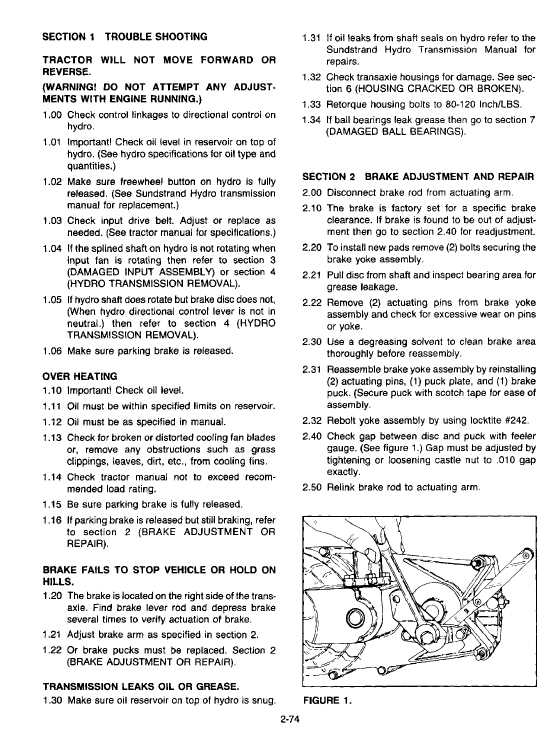

Exploring the Transmission and Drive Parts

Understanding the key components responsible for movement and power transfer in machinery is essential for maintaining optimal performance. These elements are crucial for ensuring smooth operation and efficient energy conversion from the engine to the wheels or other functional systems. By examining these elements closely, we can gain insights into the mechanical interactions that drive the system forward.

Transmission Mechanism Overview

The transmission is a complex system that manages the flow of power from the engine to other parts. It ensures that the right amount of force is applied at the appropriate time. Various gears and linkages work together to control speed and torque, adapting to different working conditions. Some critical elements include:

- Gears: Vital for adjusting speed and power transmission.

- Clutch: Connects and disconnects the engine from the drive system.

- Drive Belts: Transfers rotational motion from one component to another.

Drive System Components

The drive system converts power into motion, ensuring that it reaches the wheels or other operational mechanisms. This system includes:

- Axles: Responsible for distributing power to the wheels.

- Chain Drives: Transmit power in certain configurations, often used for heavy-duty applications.

- Bearings: Help reduce friction and support moving parts for smoother operation.

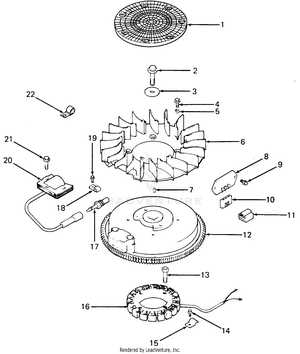

Breakdown of Electrical System Components

Understanding the electrical setup of a machine is essential for its efficient operation. The various components work together to ensure the proper functioning of different systems, from ignition to powering accessories. Each part plays a critical role in maintaining smooth performance, and having a detailed look at each one can help in diagnostics and maintenance.

- Battery: The heart of the electrical system, providing power for starting the engine and operating various electrical accessories.

- Starter Motor: Responsible for turning the engine over, initiating the combustion process to start the machine.

- Ignition Switch: A critical component that controls the power flow to the ignition system, allowing the engine to be turned on and off.

- Fuses: Protect the electrical circuits by breaking the connection when there is an overload, preventing damage to sensitive components.

- Wiring Harness: A collection of wires and connectors that route power and signals to various parts of the machine.

- Regulator/Rectifier: Ensures that the voltage supplied by the alternator is consistent and within the proper range for the system.

- Alternator: Generates electricity to charge the battery and power electrical components when the engine is running.

Each of these elements plays a specific role, and understanding their interactions can help troubleshoot issues or plan effective maintenance routines. Regular checks on these components can prolong the life of the machine and ensure reliability during operation.

Identifying the Cutting Deck Assembly

When it comes to lawn maintenance equipment, the cutting deck is a crucial component that determines the efficiency and quality of your lawn’s appearance. This section will help you identify the various parts that make up the cutting mechanism, ensuring proper maintenance and repair.

| Part | Description |

|---|---|

| Deck Housing | The main structure that holds all the cutting components together. |

| Blades | Sharp, rotating parts responsible for trimming the grass. |

| Spindle | Rotates the blades and is attached to the deck housing. |

| Pulley | Transmits power from the engine to the spindle, driving the blades. |

| Idler Pulley | Helps in maintaining tension on the drive belt to ensure smooth operation. |

| Drive Belt | The component that transfers power from the engine to the cutting deck. |

| Guards | Protect the user from debris and ensure safety during operation. |

Hydraulic Parts and Functionality Explained

Hydraulic systems are essential components that ensure the smooth operation of machinery by utilizing pressurized fluid to transfer energy. These systems are composed of various elements that work together to enable efficient movement and power transmission. Understanding the key components and how they interact can help in maintaining and troubleshooting the equipment effectively.

Key Components of a Hydraulic System

- Hydraulic Pump – Converts mechanical energy into hydraulic energy by pressurizing the fluid.

- Hydraulic Cylinders – The devices responsible for transforming hydraulic pressure into linear motion.

- Valves – Control the flow and direction of the fluid, ensuring proper functionality of the system.

- Hydraulic Hoses – Flexible tubes that carry pressurized fluid to various parts of the system.

- Filter – Ensures that the hydraulic fluid remains clean, preventing contamination that can damage the system.

How the System Functions

In a hydraulic system, the fluid is pressurized by a pump and directed through various components. The fluid travels through valves, hoses, and cylinders, providing the necessary force to move different mechanical parts. Valves regulate the fluid’s direction and flow rate, while the cylinders perform the actual movement. This process allows the equipment to operate with increased efficiency and power.

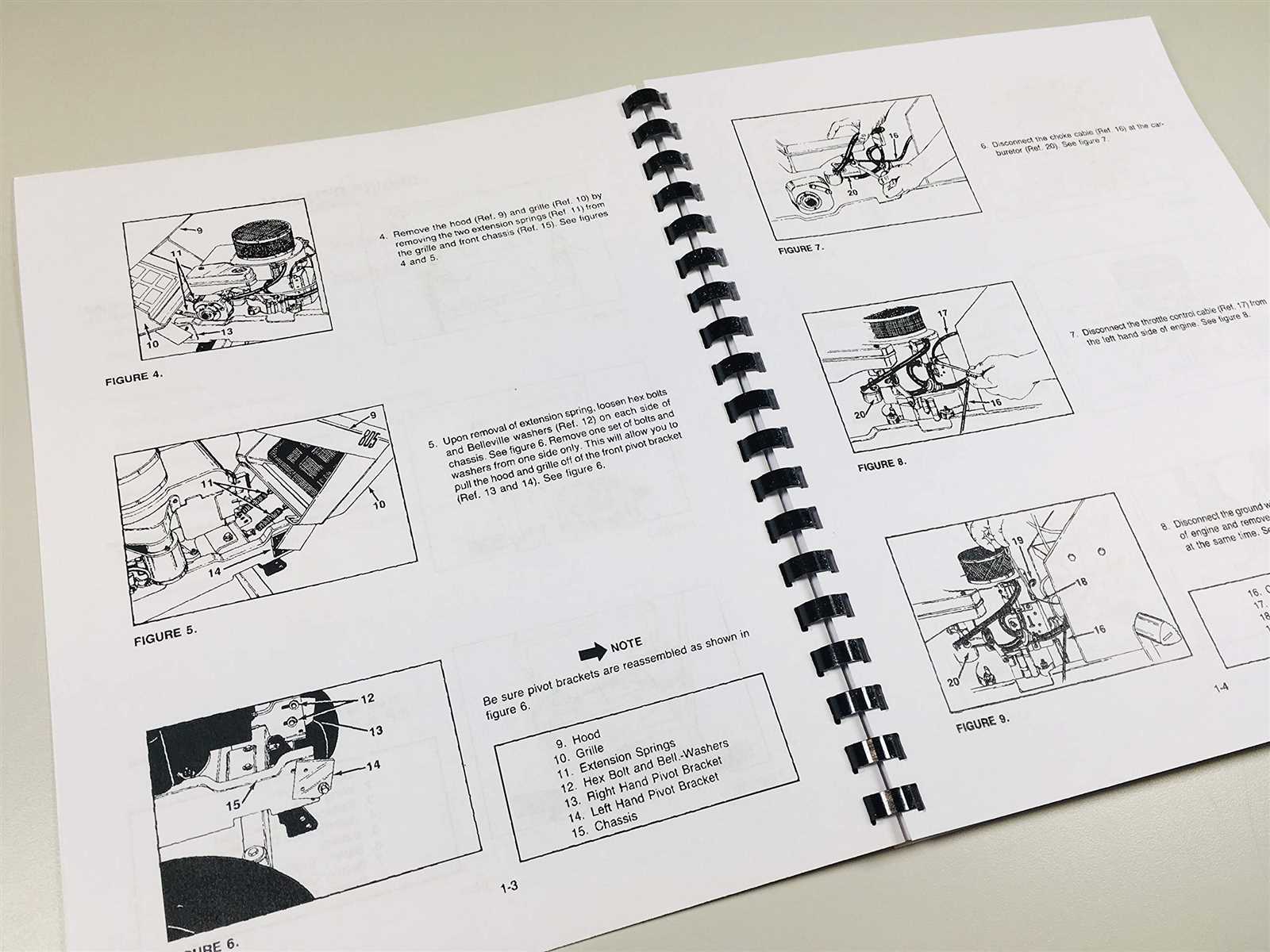

How to Maintain the Engine Parts

Regular maintenance of engine components is essential to ensure long-lasting performance and smooth operation. Proper care not only enhances efficiency but also prevents unexpected breakdowns. By adhering to simple maintenance practices, you can keep your engine running optimally and avoid costly repairs.

Clean the Air Filter

The air filter is crucial for maintaining clean airflow to the engine. Over time, dust and debris accumulate in the filter, restricting airflow and reducing engine efficiency. Regularly inspect the filter and clean or replace it when necessary to maintain proper air circulation.

Check and Replace Spark Plugs

Spark plugs play a vital role in ignition, ensuring that the fuel combusts effectively. Worn or dirty spark plugs can cause misfires or decreased engine power. Inspect the spark plugs periodically and replace them if you notice any signs of wear, corrosion, or fouling.

Replacing and Repairing Wheels and Axles

Maintaining the integrity of wheels and axles is essential for smooth operation and safe usage of your equipment. Over time, wear and tear can lead to various issues such as misalignment, uneven wear, or complete failure. Regular inspection and timely repairs ensure that your machine operates efficiently and extends its lifespan.

Before starting any repair or replacement, make sure you have the proper tools and parts on hand. It’s important to assess the condition of both the wheels and the axles to determine whether they need repairing or replacing entirely.

- Inspect the wheels for cracks, flat spots, or deep wear. Ensure they spin freely without any wobbling.

- Check the axles for any bending or corrosion. Worn-out axles can cause misalignment of the wheels, affecting stability.

- If the wheels or axles are damaged, gather the appropriate replacement components before disassembling the machine.

Once you’ve assessed the damage, proceed with the repair or replacement process:

- Lift the equipment securely and remove the wheels by loosening the bolts or pins that hold them in place.

- If the axle is damaged, you may need to remove the axle housing by unscrewing or detaching it from the main structure.

- Install the new wheel or axle by reversing the removal process, ensuring everything is aligned and securely fastened.

After completing the installation, test the equipment to ensure proper functionality and smooth operation. Regular maintenance and timely replacements will help keep your machine in optimal working condition for years to come.

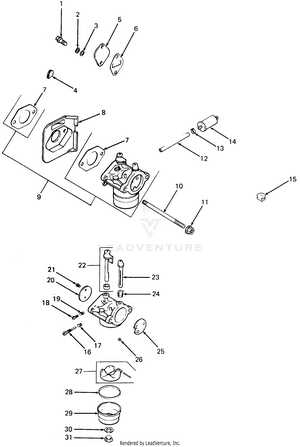

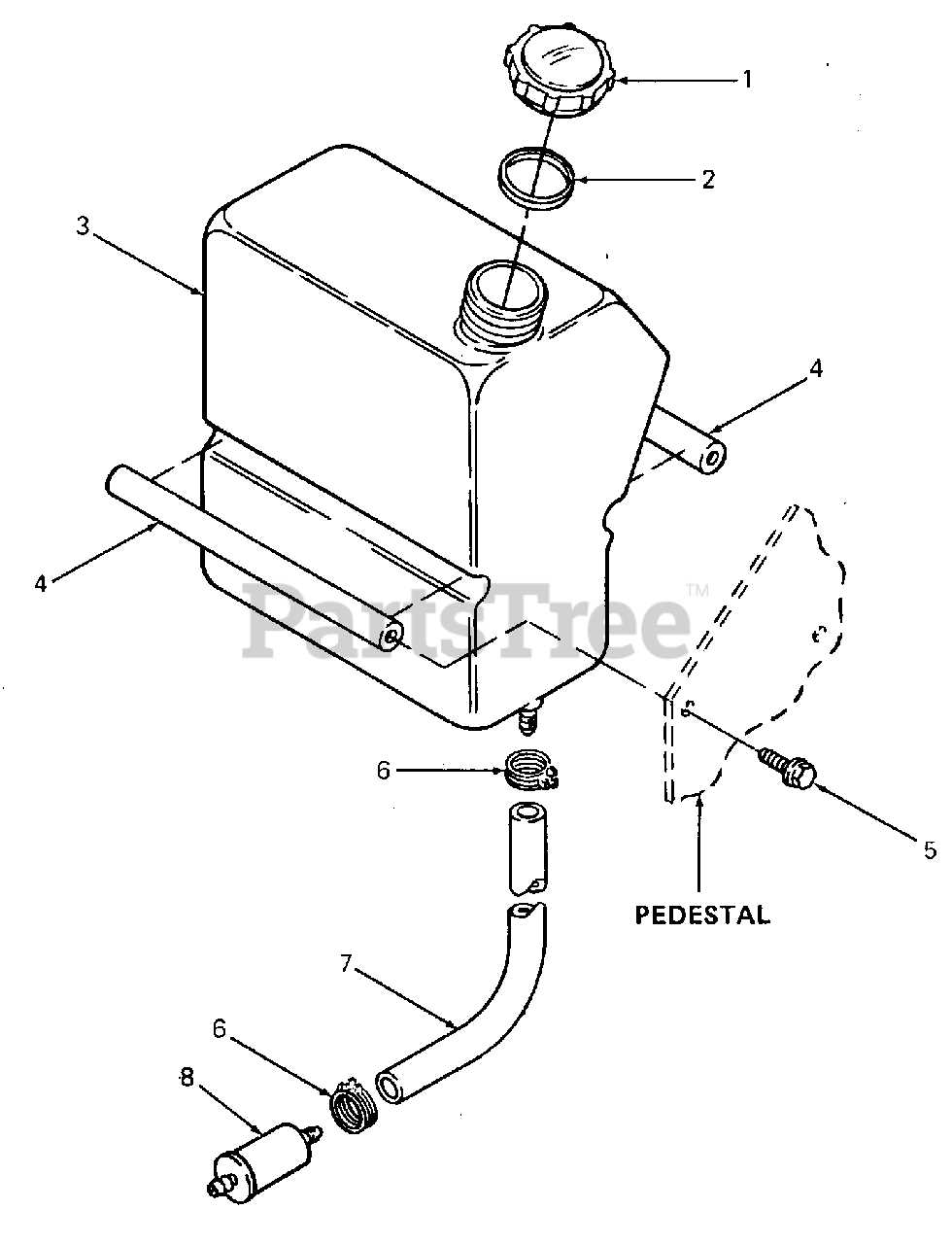

Common Issues with the Fuel System

The fuel system is a critical component for the smooth operation of any small engine. When it encounters problems, it can lead to reduced performance or even complete failure to start. Several factors can cause these issues, and addressing them early can help prevent further damage and ensure the longevity of the machine.

Clogged Fuel Filter is one of the most frequent problems. Over time, debris and contaminants can accumulate in the fuel filter, restricting fuel flow to the engine. This results in poor engine performance and can cause the engine to stall.

Fuel Line Leaks are another common issue. The fuel lines are subject to wear and tear due to exposure to heat and fuel. Cracks or holes in the fuel lines can lead to fuel leakage, which not only wastes fuel but also poses a safety hazard.

Carburetor Issues can also affect fuel delivery. A dirty or malfunctioning carburetor can cause improper fuel mixture, leading to poor combustion. This can result in the engine running roughly or failing to start altogether.

Tools Required for Efficient Disassembly

When performing maintenance or repair work, having the right tools is crucial for a smooth and effective process. The correct tools not only make disassembly easier but also ensure that components are not damaged. Investing in a well-organized toolkit can save time and effort, allowing you to get the job done efficiently.

Essential Hand Tools

Basic hand tools are indispensable when it comes to removing fasteners or handling smaller parts. These tools include wrenches, screwdrivers, and pliers, all of which are necessary to work with various connections and attachments.

| Tool | Purpose |

|---|---|

| Socket Wrench | Used for loosening bolts and nuts of varying sizes. |

| Flathead Screwdriver | Ideal for prying and separating components with minimal damage. |

| Pliers | Useful for gripping, bending, and pulling small parts. |

Specialized Tools

For more complex tasks, specialized tools may be required to reach tight spaces or handle unique fasteners. These tools help in disassembling components that are otherwise difficult to access with standard hand tools.

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures precise tightening of bolts to prevent over or under-tightening. |

| Breaker Bar | Provides extra leverage for loosening tightly secured parts. |