Cub Cadet Parts Diagram Overview and Guide

In the world of outdoor machinery, the intricate design and functionality of various elements play a crucial role in ensuring optimal performance. Each component is meticulously crafted, serving a specific purpose within the overall system. By gaining insight into these mechanisms, users can enhance maintenance practices and extend the lifespan of their machines.

Exploring the relationships between individual parts reveals the complexity of the machinery and highlights the importance of proper care. Familiarity with these connections enables users to troubleshoot issues effectively and implement timely solutions. This knowledge ultimately empowers owners to take charge of their equipment’s longevity and reliability.

Moreover, understanding the layout and interaction of components provides a solid foundation for those looking to make informed upgrades or repairs. As we delve into the specifics, the ultimate goal is to equip readers with the information needed to navigate the intricacies of their machines confidently.

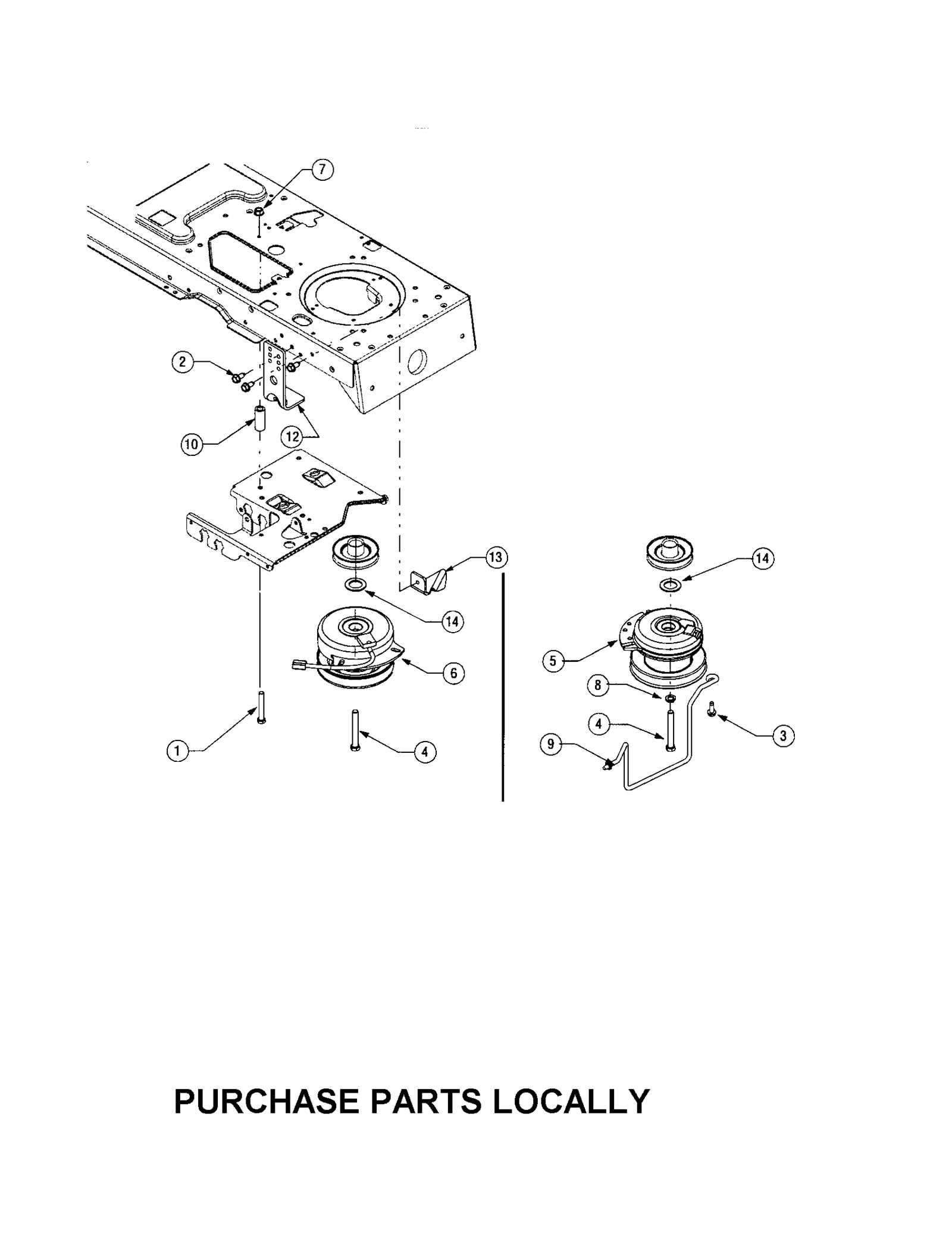

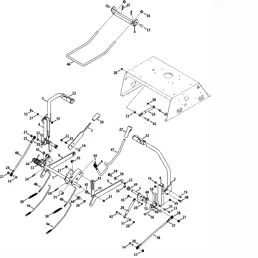

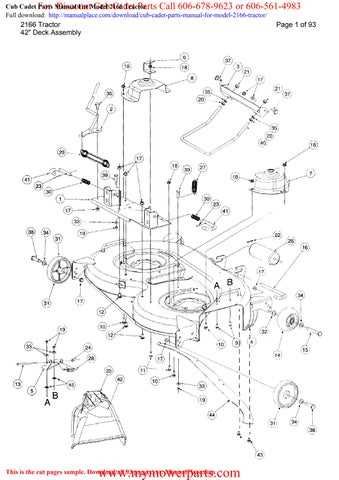

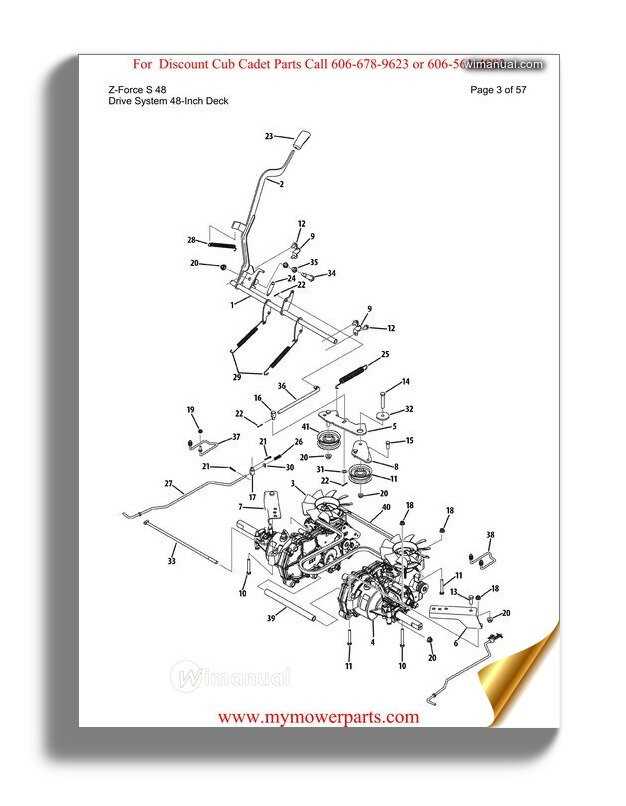

Overview of Component Schematics

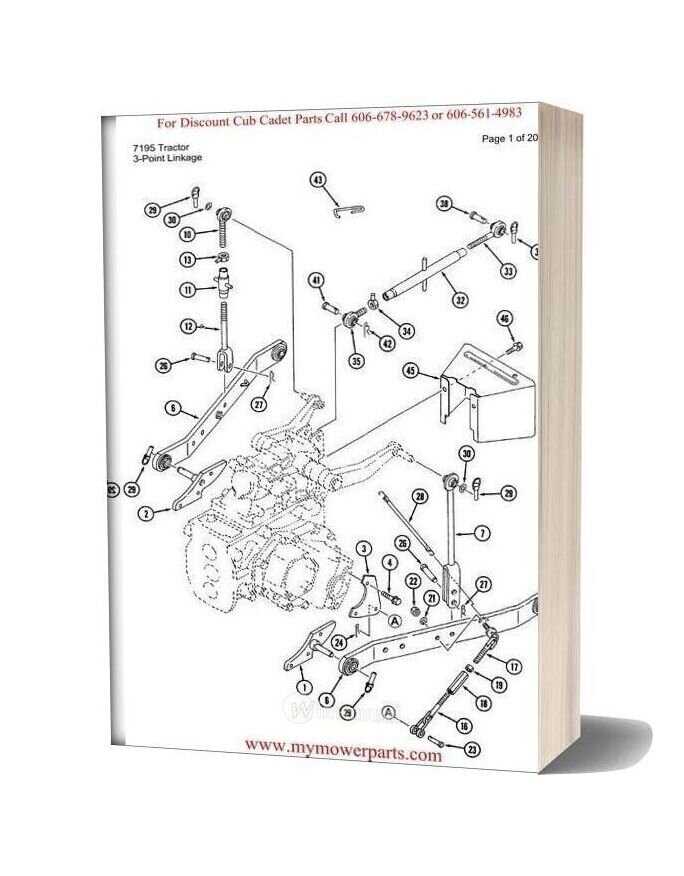

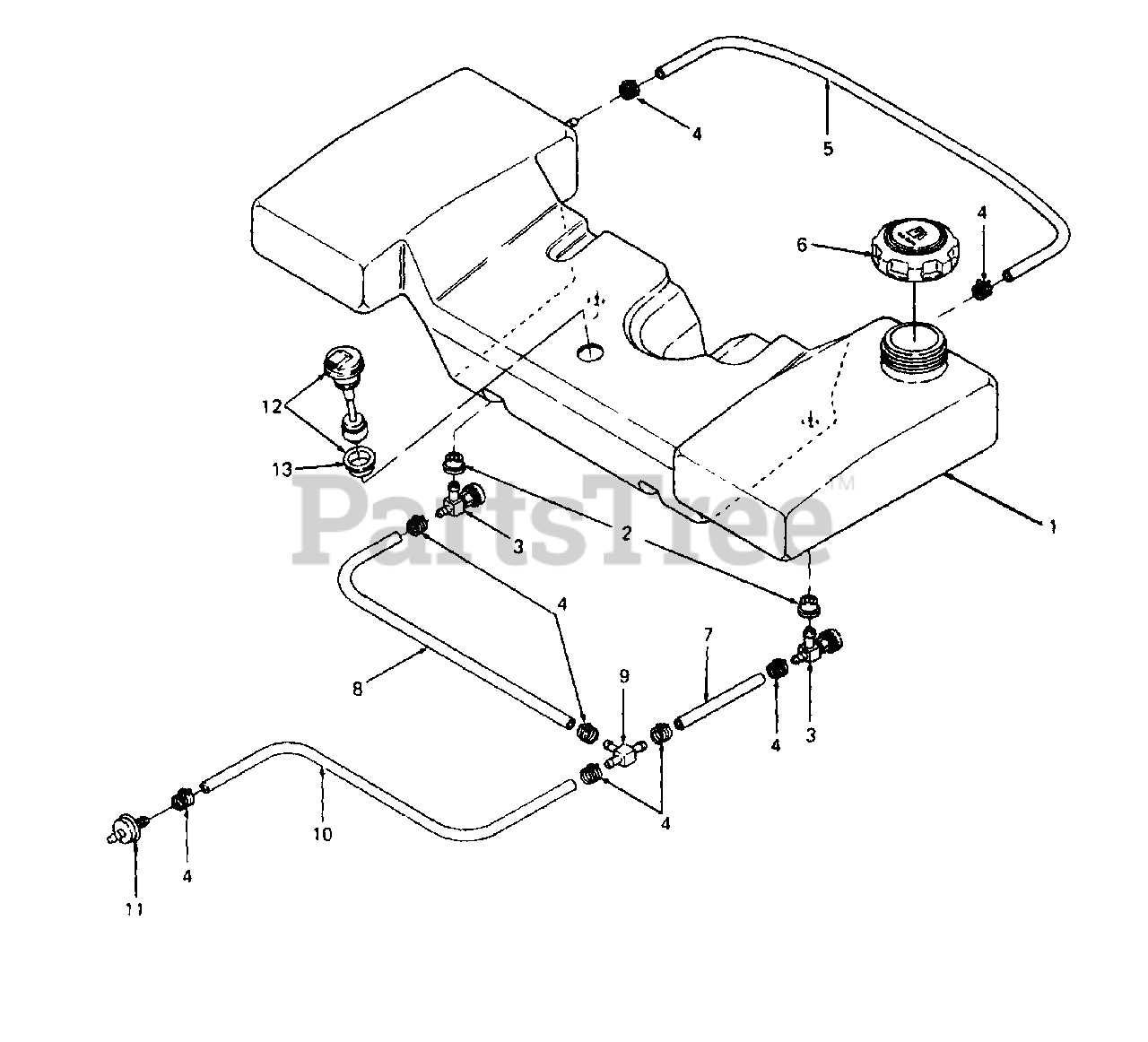

This section provides a comprehensive look at the visual representations used to identify and understand the various elements of outdoor equipment. These schematics are essential for both novice users and seasoned technicians, as they facilitate the identification of individual components and their interrelations within the machinery.

Understanding these illustrations not only aids in the maintenance and repair processes but also enhances the user’s ability to effectively operate their equipment. With clear depictions, users can quickly locate specific items and comprehend their functions, ensuring efficient troubleshooting and replacements.

Moreover, having access to detailed layouts significantly reduces the time spent on repairs, allowing for a more streamlined approach to equipment management. Familiarity with these visual guides empowers users to tackle issues confidently, ensuring the longevity and performance of their machines.

Understanding Cub Cadet Models

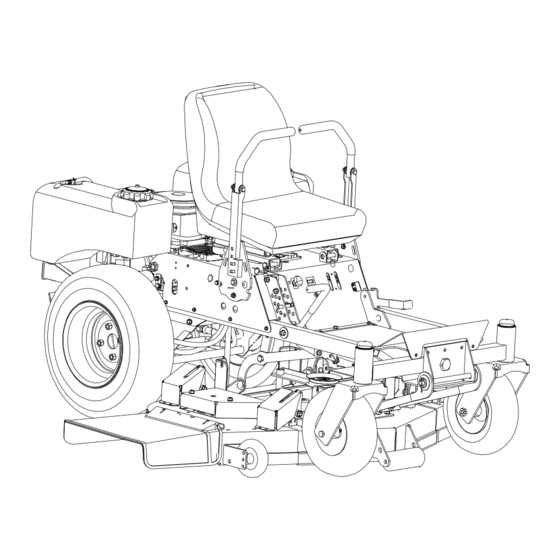

When exploring the world of lawn care and maintenance machinery, it’s essential to familiarize oneself with the various models available. Each variant is designed to meet specific needs, whether for residential or commercial purposes. Grasping the distinctions among these machines can significantly enhance user experience and efficiency.

These machines come in several configurations, each catering to different functionalities and terrains. Here are key aspects to consider:

- Engine Types: Different models feature various engine specifications that impact power and efficiency.

- Size and Weight: The dimensions and mass of a machine affect its maneuverability and storage options.

- Transmission Systems: Options range from manual to automatic, influencing ease of use and control.

- Attachments: Many variants offer compatibility with additional tools, enhancing versatility for various tasks.

- Maintenance Requirements: Understanding the upkeep needed can prolong the lifespan and performance of the equipment.

Identifying the right model for your specific needs ensures optimal performance and satisfaction in maintaining your outdoor spaces. By knowing what features to look for, you can make an informed decision that will meet your requirements effectively.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as invaluable tools, offering clarity and insight into the intricate assembly of various systems. They allow users to quickly identify specific elements, ensuring that the right parts are addressed during servicing.

Efficiency in Repairs is significantly enhanced when one has access to accurate visual guides. These illustrations streamline the repair process by minimizing the time spent searching for components. When users can easily see how elements fit together, it reduces the likelihood of errors and facilitates a smoother workflow.

Enhancing User Knowledge is another key benefit. Familiarity with the structure of equipment empowers users to better understand functionality and performance. This knowledge not only aids in troubleshooting but also fosters confidence when working with the machinery, ultimately leading to more successful outcomes.

Furthermore, having a reliable reference promotes preventive maintenance. By regularly consulting these visual guides, users can identify wear and tear on specific parts before they lead to significant issues. This proactive approach can extend the lifespan of equipment and reduce overall costs.

In summary, visual representations are essential for anyone involved in the upkeep of machinery. They enhance efficiency, boost knowledge, and support preventive practices, making them an indispensable resource for both professionals and enthusiasts alike.

How to Read Diagrams Effectively

Understanding visual representations can significantly enhance your ability to troubleshoot and repair equipment. Mastering the interpretation of these illustrations allows you to quickly locate components, understand their relationships, and follow instructions more accurately.

Key Elements to Focus On

- Symbols: Familiarize yourself with common icons and their meanings. Each symbol represents a specific part or function, aiding in quick identification.

- Labels: Pay close attention to any text annotations. These often provide essential information about dimensions, specifications, or assembly sequences.

- Connections: Analyze how various elements are interconnected. Understanding these relationships can clarify assembly or disassembly processes.

Steps for Effective Interpretation

- Start with the Legend: Review the key that explains symbols and notations. This is crucial for accurate understanding.

- Identify the Main Components: Look for major elements that play a role in the overall functionality.

- Follow the Flow: Trace the sequence of actions or connections as indicated. This will help you grasp the operational process.

- Refer Back as Needed: Don’t hesitate to revisit sections of the illustration if you encounter confusion. Repetition can reinforce understanding.

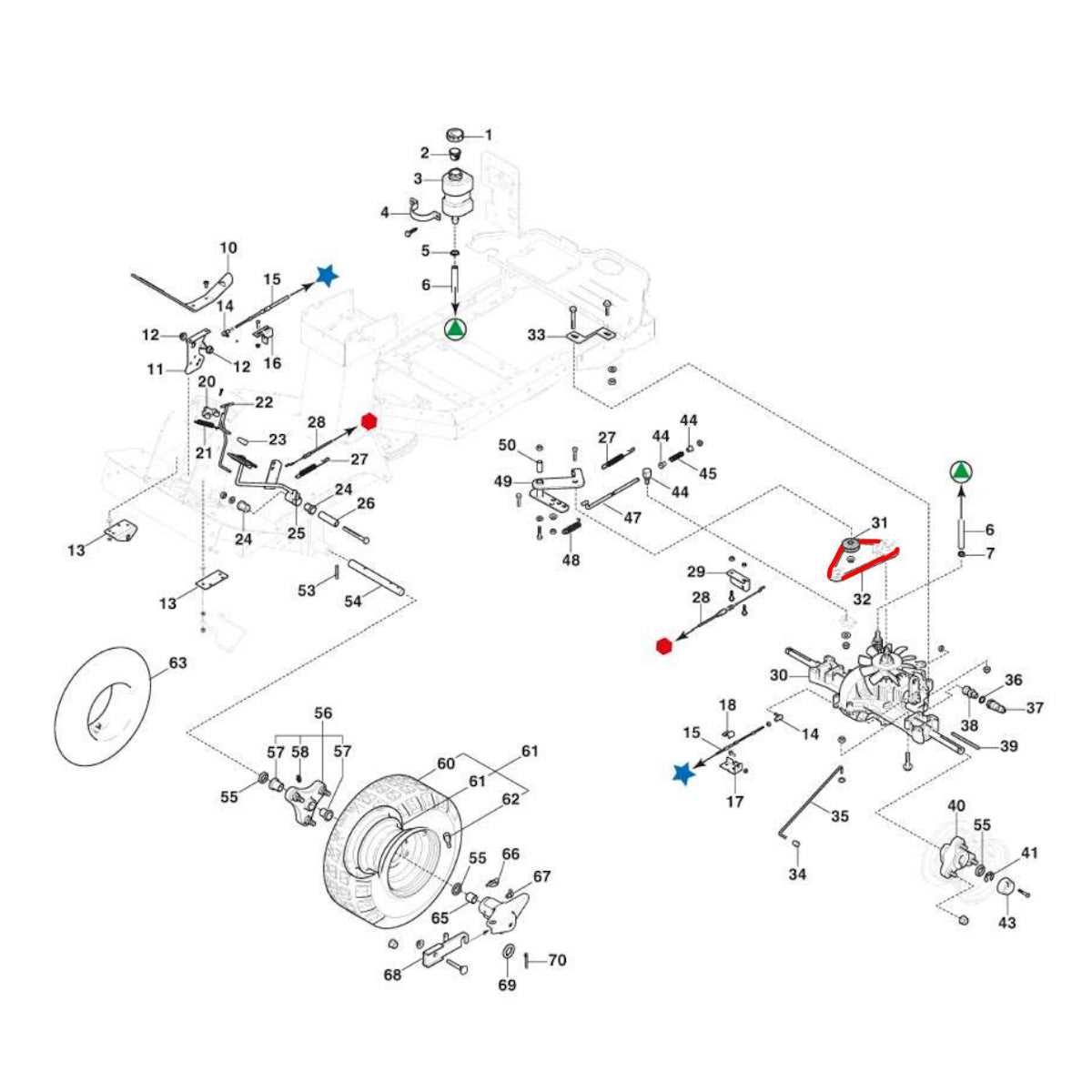

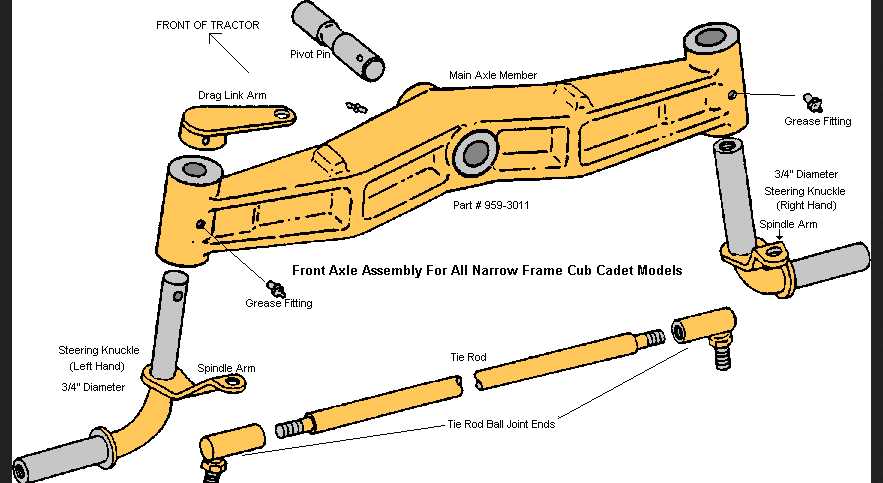

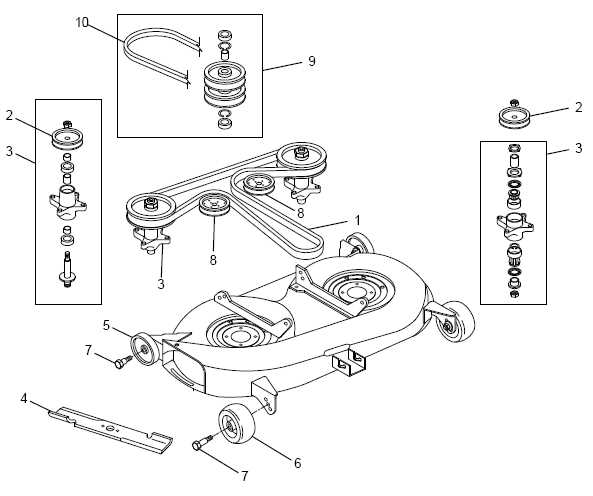

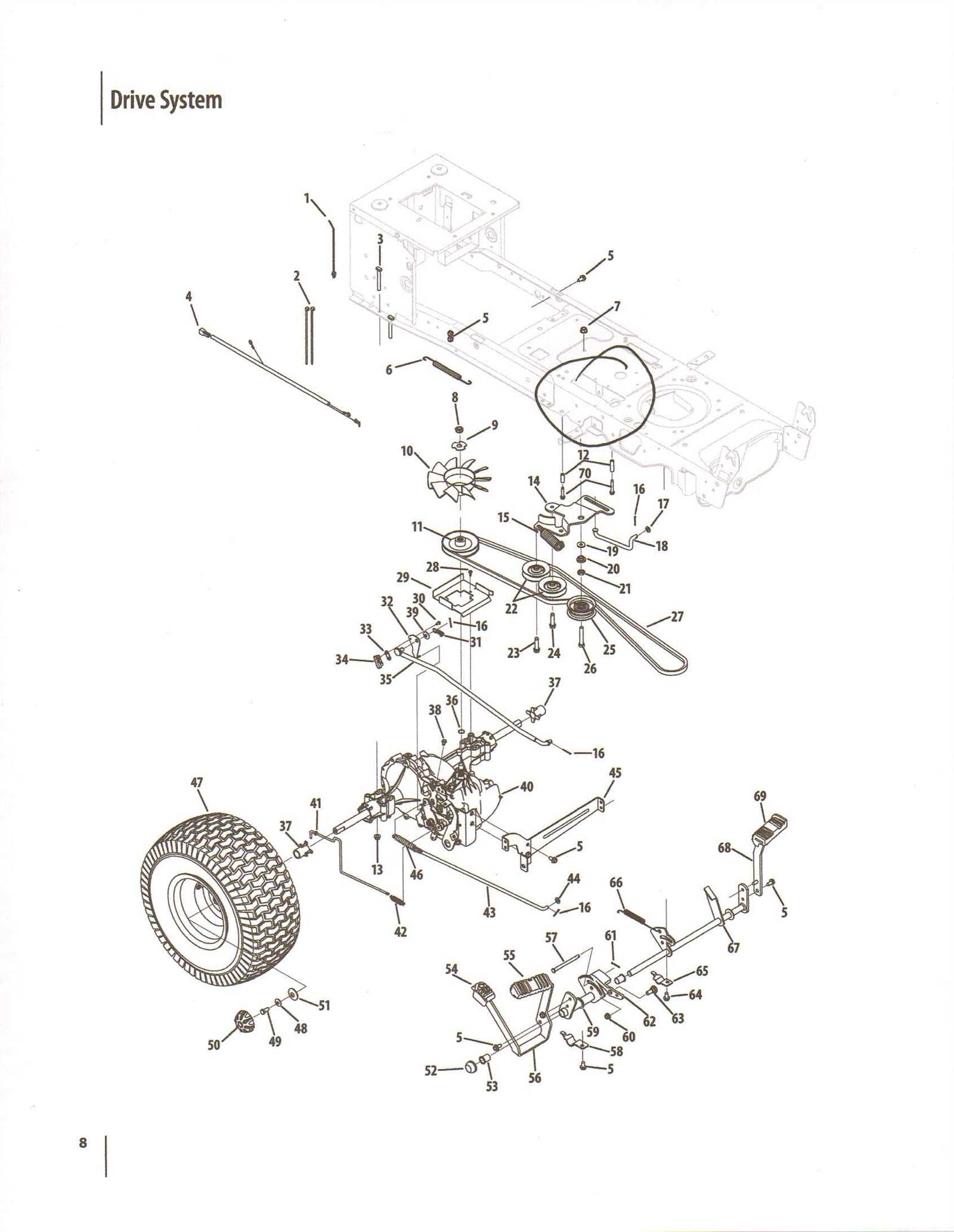

Common Parts in Cub Cadet Machines

In any machinery, specific components play vital roles in ensuring optimal performance and longevity. Understanding these elements is essential for effective maintenance and troubleshooting. This section highlights the key elements commonly found in various models, emphasizing their functions and significance.

The engine is the powerhouse, converting fuel into mechanical energy. A reliable ignition system ensures efficient starting and operation. The transmission, often overlooked, allows for smooth speed adjustments and power delivery to the wheels.

Another critical element is the cutting mechanism, which varies in design depending on the type of machine. The deck is crucial for achieving a clean and even cut, while blades require regular inspection for wear and sharpness. Wheels and tires contribute to maneuverability and stability on different terrains.

Electrical components, such as the battery and wiring harness, are essential for powering lights and starting systems. Filters, including air and fuel, maintain engine efficiency by ensuring clean operation. Understanding these components enhances your ability to care for and optimize your machine’s performance.

Where to Find Diagrams Online

Locating visual representations for machinery components is essential for maintenance and repairs. Fortunately, there are numerous resources available online that provide detailed illustrations and schematics. These resources can aid users in identifying specific parts and understanding assembly configurations.

Online Resources

Several websites cater to those seeking visual aids for their equipment. Some of the most reliable platforms include manufacturer websites, dedicated parts retailers, and community forums. Each of these sources offers unique advantages in terms of accessibility and comprehensiveness.

| Resource Type | Description |

|---|---|

| Manufacturer Websites | Official sites often have extensive libraries of diagrams for their products, ensuring accuracy and up-to-date information. |

| Parts Retailers | Online shops typically provide visuals along with parts listings, making it easier to find what you need for repairs. |

| Community Forums | Forums can be a treasure trove of shared knowledge, where users often post diagrams and troubleshooting tips. |

Tips for Effective Searching

When searching for these resources, consider using specific keywords related to your equipment model. Additionally, utilizing advanced search options on search engines can yield more precise results. Bookmarking helpful sites can also streamline future searches, ensuring that you have quick access to necessary materials.

DIY Repairs Using Diagrams

Repairing machinery can be daunting, but visual guides simplify the process significantly. By utilizing detailed illustrations, enthusiasts can confidently tackle maintenance tasks, enhancing their understanding and skills. These resources break down complex systems into manageable components, making DIY projects more approachable.

Understanding the Components

Familiarizing yourself with each element is crucial for successful repairs. Visual references help identify parts, allowing you to pinpoint issues quickly. This knowledge empowers you to make informed decisions, ensuring that replacements are accurate and effective.

Step-by-Step Guidance

Following illustrated instructions provides clarity during repairs. Each step is laid out systematically, reducing the risk of mistakes. With clear visuals, even novice repairers can achieve professional results, transforming the ultimate repair experience into a rewarding endeavor.

Ordering Replacement Parts Made Easy

Finding the right components for your outdoor equipment doesn’t have to be a daunting task. Streamlined processes and clear resources can simplify the journey, allowing you to quickly identify and procure what you need. This section will guide you through effective strategies for securing the necessary items without hassle.

Utilizing Online Resources

Many websites offer comprehensive catalogs and user-friendly interfaces that enable you to search by model or specifications. Take advantage of these tools to pinpoint exactly what you require, ensuring compatibility and quality.

Consulting Professionals

When in doubt, reaching out to knowledgeable professionals can save you time and effort. They can provide insights on what to order, helping you make informed decisions that lead to successful repairs and maintenance.

Identifying Parts by Model Number

Understanding how to recognize components through their specific identification codes is essential for efficient maintenance and repairs. Each model is associated with a unique number that serves as a key to accessing detailed information about its individual elements. This process simplifies the task of sourcing replacements and ensures compatibility with existing equipment.

Benefits of Model Number Identification

Utilizing model numbers enhances the accuracy of identifying necessary components. Efficiency is greatly improved, as users can quickly locate the correct items without the risk of purchasing incompatible or incorrect alternatives. Moreover, it aids in the availability of documentation, such as manuals and specifications, which can further guide maintenance efforts.

Steps to Find the Right Model Number

To determine the appropriate identification code, begin by examining the equipment for labels or tags that typically display this information. These are often located in accessible areas, ensuring users can easily reference them. Once obtained, enter the number into a search engine or consult the manufacturer’s resources to retrieve a comprehensive overview of available components.

Benefits of Using Original Parts

Utilizing genuine components for maintenance and repairs ensures optimal performance and longevity of your machinery. These authentic elements are designed specifically to fit and function seamlessly within the system, offering numerous advantages that aftermarket alternatives may not provide.

Quality Assurance: Original components are manufactured to strict standards, ensuring reliability and durability. This leads to reduced wear and tear over time, ultimately saving you from frequent replacements.

Enhanced Performance: When you use original elements, you can be confident that your equipment will operate at peak efficiency. These components are engineered to work harmoniously with other parts, minimizing the risk of malfunction.

Warranty Protection: Many manufacturers offer warranties that cover equipment using genuine parts. This protection can save you significant costs in the long run and provides peace of mind knowing your investment is safeguarded.

Improved Safety: Using original components contributes to the overall safety of your machinery. They undergo rigorous testing to ensure they meet safety regulations, reducing the likelihood of accidents caused by faulty or incompatible parts.

Resale Value: Keeping your equipment in top condition with genuine components can enhance its resale value. Buyers often prefer well-maintained machines with authentic parts, as they indicate reliability and quality.

In summary, opting for original components is a smart choice that leads to enhanced performance, safety, and long-term savings, ensuring your machinery remains dependable for years to come.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of outdoor equipment requires regular upkeep and attention. Adopting a consistent maintenance routine can prevent costly repairs and extend the lifespan of your machinery. Below are essential tips to help you keep your equipment in top condition.

Routine Inspections

Regular checks are vital to identify any wear and tear before they escalate into significant issues. Consider the following:

- Inspect belts and hoses for signs of fraying or cracking.

- Check fluid levels, including oil, fuel, and coolant.

- Examine filters and replace them as needed to ensure optimal performance.

Seasonal Maintenance Tasks

Seasonal upkeep is crucial to prepare your equipment for varying conditions. Follow these guidelines:

- Before winter storage, clean the exterior and remove any debris.

- In spring, inspect the battery and charging system for reliability.

- Sharpen blades and ensure all moving parts are lubricated.

By implementing these practices, you can significantly enhance the longevity and performance of your machinery.

Resources for Additional Support

Finding reliable information and assistance can significantly enhance your maintenance experience. Several avenues are available to help you navigate your equipment needs and ensure optimal performance.

- Manufacturer’s Website: Official platforms often provide manuals, guides, and troubleshooting tips.

- User Forums: Engaging with communities can yield practical advice from fellow users facing similar challenges.

- Local Dealerships: Authorized retailers can offer personalized support and access to genuine components.

- Online Tutorials: Video resources can visually guide you through repairs and upkeep processes.

- Customer Support: Reaching out directly to the manufacturer can clarify any specific queries you may have.

Utilizing these resources can empower you to tackle your equipment effectively and maintain its longevity.