Cub Cadet SC 500 EZ Parts Breakdown and Diagram

Maintaining and servicing outdoor machinery requires a solid understanding of the inner workings of each unit. Familiarity with the various elements that make up these machines is essential for ensuring smooth operation and durability. In this section, we will provide an overview of how the different elements work together to maintain the functionality of the equipment.

The focus will be on understanding the layout and how individual pieces interact. Whether you’re performing routine maintenance or addressing specific issues, a clear grasp of each part’s role is crucial for achieving efficient results.

Understanding the overall structure of the machine allows users to troubleshoot problems more effectively and make informed decisions about repairs and replacements. Additionally, knowing how each piece contributes to the equipment’s performance ensures that it continues to function as intended over time.

Overview of Cub Cadet SC 500 EZ

The machine in question is a robust and efficient tool designed to simplify lawn care tasks. It offers a combination of advanced features and user-friendly controls, ensuring that even challenging terrains can be maintained with ease. The device is ideal for homeowners seeking both convenience and performance in their yard maintenance routines.

Main Features

- Reliable power source that ensures consistent operation.

- Ergonomic design to reduce user fatigue during extended use.

- Adjustable settings for personalized control over mowing tasks.

Advantages of the Model

- Easy to maneuver, making it suitable for various lawn types.

- Durable build quality for long-term reliability.

- Low maintenance requirements due to its efficient design.

Main Components of the Mower

The structure of the mower is designed to ensure efficient grass cutting and ease of use. Its essential parts work together to provide smooth performance and optimal control during operation. Each element plays a crucial role in ensuring that the mower runs effectively on various types of terrain.

- Engine: Powers the machine, allowing it to tackle different lawn sizes and conditions with consistent strength.

- Blade System: The cutting mechanism that trims the grass evenly, ensuring a clean and precise finish.

- Wheels: Provide stability and maneuverability, helping the mower move smoothly across uneven ground.

- Handlebar: Offers the user control over the direction and speed of the mower, making operation comfortable and easy.

- Grass Bag: Collects clippings as the mower moves, reducing the need for frequent cleanup and maintaining a tidy lawn.

- Deck: Protects the blades and engine while also determining the width of the cutting path.

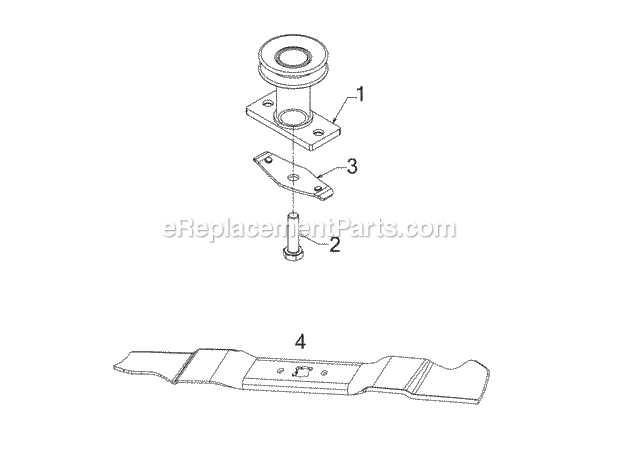

Understanding the Cutting Deck Structure

The cutting deck plays a critical role in ensuring effective lawn mowing. Its structure consists of various components that work together to deliver clean and even cuts across different terrains. Understanding how these elements function helps in maintaining efficiency and prolonging the lifespan of the equipment.

Main Components and Their Functionality

The deck comprises several essential parts that each serve a distinct purpose. Blades are the most prominent feature, responsible for slicing through grass with precision. Underneath, a mechanism supports the rotation of these blades, allowing smooth movement even on uneven ground. The chassis, which holds everything in place, is designed for stability during operation.

Adjustability and Maintenance Considerations

A key feature of the cutting deck is its adjustability. Operators can modify the height settings, enabling the mower to handle various grass lengths. Regular maintenance is vital to ensure optimal performance. Cleaning the undercarriage, sharpening the blades, and checking for wear on key parts are crucial to keep the equipment functioning effectively.

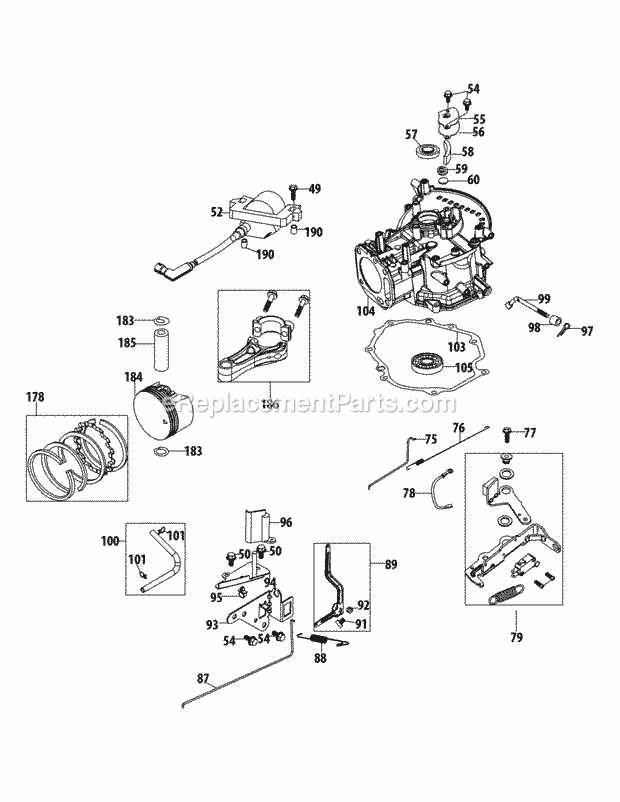

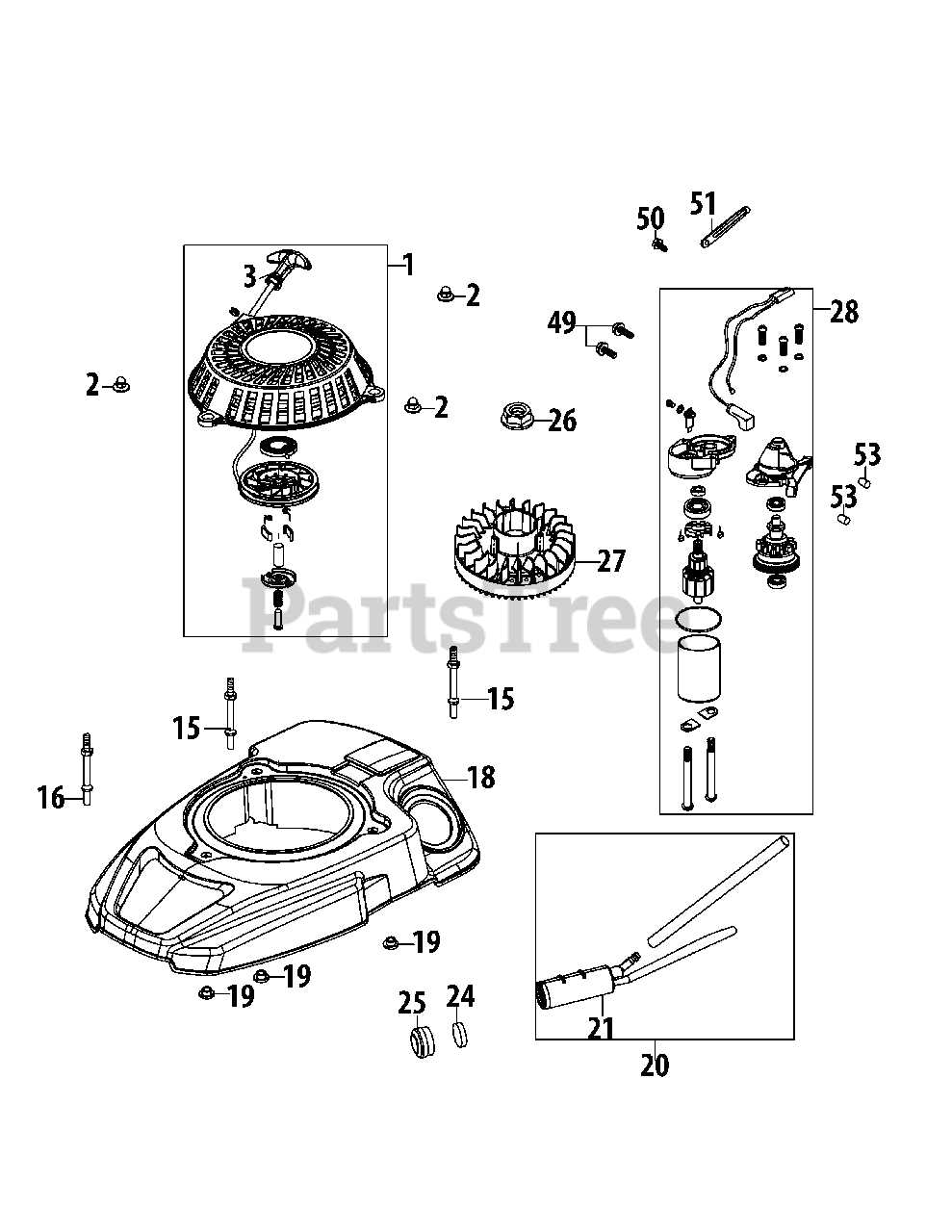

Engine and Power System Breakdown

The power unit and propulsion system represent the core of any lawn maintenance equipment, responsible for delivering consistent performance. By focusing on the internal mechanics, one can better understand how different components work together to generate force and maintain operational efficiency. This breakdown provides insights into the key elements involved in generating and transferring power to the wheels and cutting system.

Engine Structure: At the heart of the system lies the engine, a crucial component designed to convert fuel into mechanical energy. With multiple interconnected parts working in harmony, the engine ensures smooth operation and reliability. Regular maintenance is essential for optimal functioning.

Transmission and Drive System: The transmission ensures that the power generated by the engine is efficiently transferred to the wheels. It controls the speed and torque, allowing for smooth and controlled movement across varying terrains. The drive system, through a series of belts and gears, further assists in transferring energy to the wheels, ensuring efficient propulsion.

Key Considerations: Ensuring the engine and power system are well-maintained is vital for long-term performance. Regular checks, timely part replacements, and proper lubrication help in keeping the equipment running smoothly and efficiently.

Wheels and Traction System Explained

The wheels and traction system are essential for ensuring smooth and efficient movement across various terrains. This section will explore the functionality behind the wheels and the traction mechanism, offering a clear understanding of how these components work together to provide stability and control.

Wheel Design

The design of the wheels plays a critical role in maintaining balance and enabling ease of maneuverability. Typically, the wheels are crafted to handle different surfaces, providing durability and comfort while navigating both flat and uneven areas.

- Durable materials are used to ensure longevity

- Grooved patterns enhance grip and minimize slippage

- Lightweight construction allows for easier control

Traction System

The traction system is engineered to provide superior control, particularly on slopes and uneven terrain. This mechanism allows the operator to maintain steady motion, even when faced with challenging conditions. It ensures that the wheels maintain contact with the ground, preventing loss of traction.

- Self-propelling mechanism to reduce manual effort

- Adjustable settings for varied speed and terrain types

- Enhanced grip for optimal performance on inclines

Blade Assembly and Maintenance Guide

This section provides essential information regarding the assembly and upkeep of the cutting mechanism of your lawn care equipment. Proper management of this component is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also contributes to the safety of the operator.

To ensure the cutting mechanism operates effectively, it is important to follow specific procedures during assembly and routine maintenance. Below is a detailed overview of the key steps involved in this process:

| Step | Description |

|---|---|

| 1 | Ensure that the equipment is powered off and disconnected from any power source before beginning assembly. |

| 2 | Gather all necessary tools and components required for the installation of the cutting element. |

| 3 | Carefully attach the cutting blade to the spindle, ensuring that it is securely fastened to prevent any movement during operation. |

| 4 | Check the blade alignment to ensure it is positioned correctly for even cutting. |

| 5 | After assembly, conduct a visual inspection and test the equipment to confirm proper functionality. |

| 6 | Regularly inspect the blade for signs of wear or damage and sharpen or replace as needed to maintain cutting efficiency. |

Handlebar Design and Adjustments

The configuration and adaptability of handlebars play a crucial role in the overall functionality and user comfort of lawn maintenance equipment. Properly designed handlebars ensure ease of maneuverability and can significantly affect the operator’s efficiency during use. The ability to adjust the height and angle of the handlebars allows for a customized fit, catering to various user preferences and enhancing the overall experience.

Ergonomics and Comfort

Thoughtful ergonomic design minimizes strain on the user’s body during operation. Handlebars that offer a comfortable grip and appropriate positioning enable extended use without discomfort. It is important to regularly evaluate the setup to maintain optimal comfort levels, as fatigue can impair performance and lead to less effective mowing.

Adjustment Mechanisms

Most modern machines incorporate intuitive adjustment mechanisms for the handlebars, allowing users to easily modify their height and angle. These features are essential for achieving a personalized fit, accommodating different user heights and preferences. Regular maintenance of these mechanisms ensures their reliability and smooth operation, contributing to a seamless mowing experience.

Throttle and Speed Control Parts

This section delves into the components responsible for regulating engine speed and throttle response in small engines. Understanding these elements is crucial for effective operation and maintenance, ensuring optimal performance during use.

Key Components

- Throttle Lever: The primary mechanism used to control the amount of air and fuel entering the engine.

- Governor: A device that automatically adjusts the engine speed based on load conditions, maintaining stability during operation.

- Linkage: A system of rods and cables connecting the throttle lever to the engine, facilitating smooth control.

- Carburetor: A vital part that mixes air and fuel for combustion, influenced directly by the throttle position.

Maintenance Tips

- Regularly inspect the throttle lever for wear and ensure it moves freely.

- Check the governor settings to ensure proper engine speed control.

- Lubricate the linkage components to prevent stiffness and ensure responsive operation.

- Keep the carburetor clean to maintain efficient air-fuel mixture and throttle response.

Bagging System and Related Components

The bagging mechanism plays a crucial role in efficiently collecting and disposing of grass clippings and debris during lawn maintenance. This system is designed to enhance the overall performance of the mower, ensuring that the lawn remains tidy and well-groomed. Understanding the various elements that constitute this assembly can greatly aid in maintenance and optimization.

| Component | Description | Function |

|---|---|---|

| Bag | A sturdy container made of breathable material. | Collects clippings and prevents them from scattering. |

| Hopper | The structure that holds the bag in place. | Directs the grass clippings into the bag efficiently. |

| Chassis Attachment | Framework that connects the bagging system to the mower. | Ensures stability and secure positioning of the system. |

| Intake Vent | An opening that allows clippings to flow into the bag. | Facilitates smooth airflow and efficient collection. |

Regular inspection and proper care of these components can significantly enhance the efficiency of the collection system, leading to a more effective lawn maintenance experience.

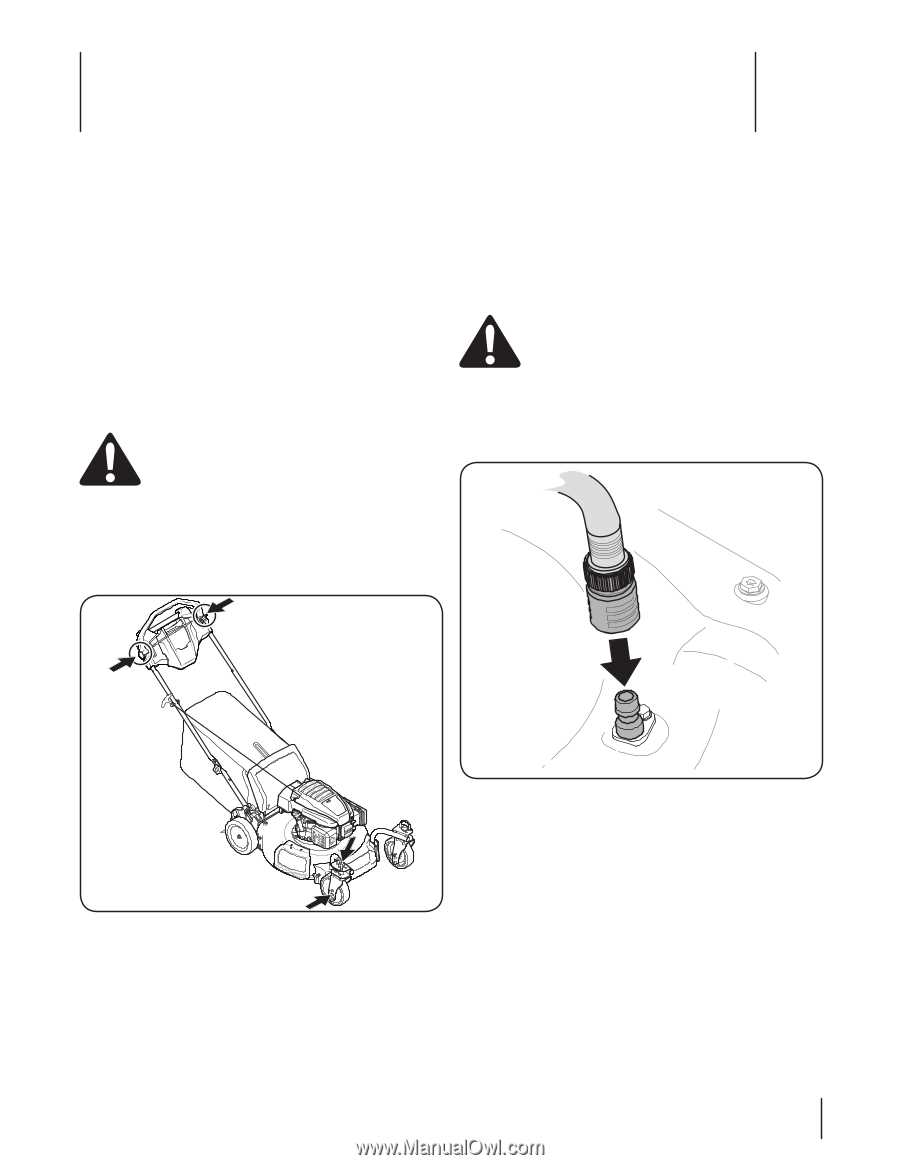

Safety Features and Mechanisms

The significance of safety features in modern outdoor power equipment cannot be overstated. These mechanisms are designed to protect users from potential hazards while ensuring efficient operation. Various components work in harmony to enhance safety, making equipment usage more secure and reliable.

Emergency Shut-off Systems

Emergency shut-off systems serve as critical safety elements in outdoor machinery. These systems allow for immediate cessation of operation in case of an unexpected situation, reducing the risk of accidents. Users can activate these mechanisms quickly, ensuring that any hazardous conditions are promptly addressed.

Protective Guards and Shields

Protective guards and shields are essential features that prevent accidental contact with moving parts. These barriers are strategically placed to shield users from potential injuries while enabling visibility of the operational area. The incorporation of such protective elements significantly enhances user confidence and safety during operation.

| Feature | Description |

|---|---|

| Emergency Shut-off | Instantly halts operation to mitigate hazards. |

| Protective Guards | Prevents contact with dangerous components. |

| Safety Interlocks | Ensures equipment cannot operate when improperly configured. |

| Operator Presence Control | Requires user engagement for continued operation. |

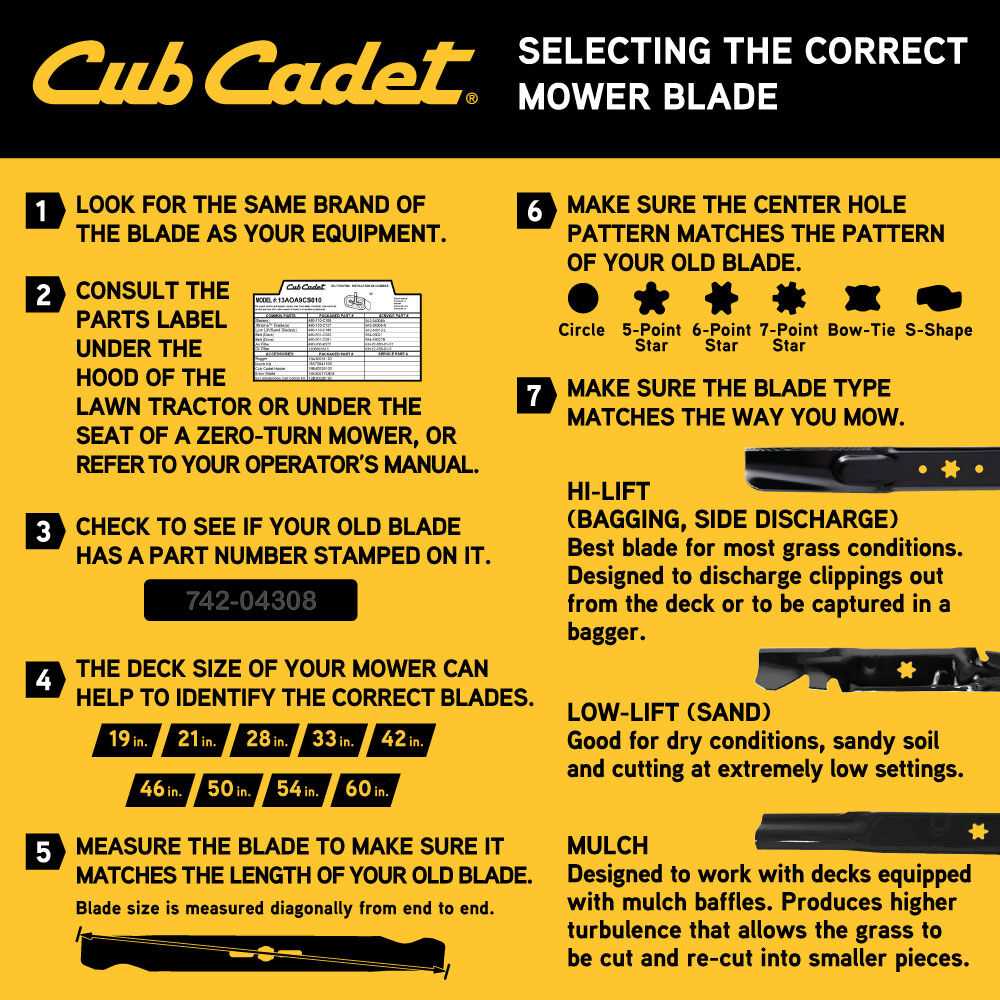

Replacement Parts and Compatibility Tips

When maintaining outdoor equipment, ensuring the right components are utilized is crucial for optimal performance. Understanding the various options available for substitution can enhance the longevity and efficiency of your machine. Below are some essential considerations for selecting the appropriate components and ensuring compatibility.

Key Considerations for Component Selection

- Verify the specifications of your equipment to ensure the selected components match the required dimensions and performance characteristics.

- Consult the manufacturer’s guidelines or manuals for recommendations on suitable replacements to avoid performance issues.

- Evaluate user reviews and feedback on alternative components to gauge reliability and effectiveness.

Compatibility Guidance

- Cross-reference model numbers with compatible replacements to ensure proper fit.

- Utilize parts from reputable brands that have a proven track record in the market.

- Consider aftermarket options, but always confirm their reliability before making a purchase.

By adhering to these guidelines, you can make informed decisions that enhance the functionality and durability of your equipment.