Cub Cadet XT1 LT42 Parts Diagram Explained

When maintaining a lawn care machine, comprehending its intricate components is essential for ensuring optimal performance and longevity. A thorough exploration of these elements enables owners to tackle repairs and upgrades with confidence, ultimately enhancing their mowing experience.

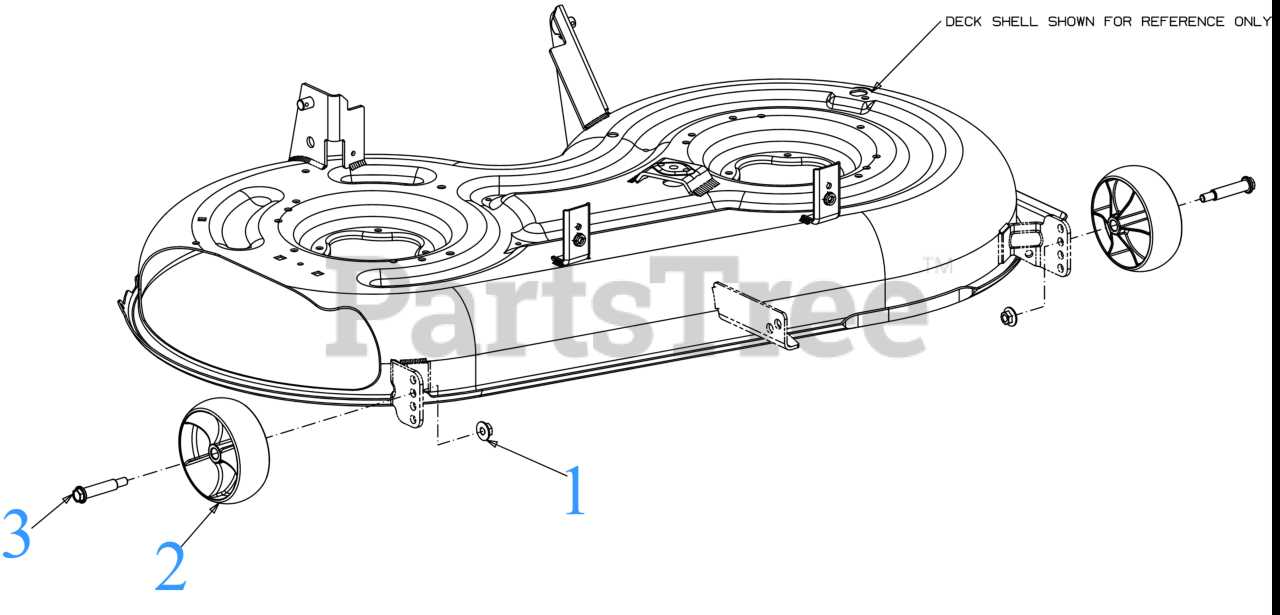

Each segment of the machinery plays a critical role in its functionality. By examining a visual representation of these components, users can easily identify specific parts, facilitating efficient troubleshooting and maintenance. This knowledge not only saves time but also empowers operators to keep their equipment in prime condition.

Additionally, understanding the layout and interconnections of these parts can lead to improved handling and operation. As users delve into the various sections of their machine, they will discover the ultimate benefits of being informed, paving the way for a smoother and more effective mowing routine.

Overview of the Lawn Tractor

This section provides a comprehensive look at a popular lawn maintenance machine designed for efficiency and ease of use. The model is well-regarded for its robust features and user-friendly operation, making it a preferred choice for homeowners.

- Engine Performance: Equipped with a powerful engine, it delivers reliable performance for various mowing tasks.

- Cutting Deck: The wide cutting deck allows for efficient mowing, reducing the time needed to cover large areas.

- Comfort Features: Designed with user comfort in mind, it includes ergonomic seating and easy-to-reach controls.

- Durability: Built with high-quality materials, this machine ensures longevity and resilience in tough conditions.

Overall, this lawn tractor combines functionality with ease of maintenance, making it an ultimate asset for yard care enthusiasts.

Key Features of XT1 LT42

This section explores the essential attributes that define this lawn maintenance equipment, emphasizing its performance and usability for various tasks.

- Powerful Engine: Equipped with a robust motor for efficient cutting and handling of tough terrains.

- Advanced Cutting Deck: Features a well-designed mowing deck that ensures a precise and clean cut.

- Ergonomic Design: Engineered for user comfort, making long hours of operation less tiring.

- Easy Maneuverability: The compact structure allows for seamless navigation around obstacles.

- Versatile Attachments: Compatible with various add-ons to enhance functionality throughout the year.

These characteristics contribute to the overall efficiency and reliability of the equipment, making it an ultimate choice for lawn care enthusiasts.

Importance of Parts Diagrams

Understanding the intricate components of any machine is crucial for efficient maintenance and repair. Visual representations of these elements serve as invaluable resources for both novices and experienced users, allowing for quick identification and troubleshooting. When an individual can easily locate and comprehend the various sections of a device, the process of assembly and disassembly becomes significantly more manageable.

Clarity is one of the primary advantages of such illustrations. They eliminate ambiguity, providing a clear roadmap that guides users through complex mechanical systems. This precision not only enhances user confidence but also minimizes the risk of errors during repairs.

Furthermore, these visual aids facilitate effective communication among team members. When everyone is on the same page regarding the specific components, discussions become more productive, leading to quicker resolutions and improved outcomes. By using these detailed visuals, maintenance teams can coordinate their efforts more efficiently, ensuring that no aspect of the repair process is overlooked.

In addition, having access to comprehensive visuals can significantly reduce downtime. When individuals can quickly identify the necessary parts for a repair, they can expedite the process and minimize disruption. This efficiency is particularly beneficial in professional settings, where time is often of the essence.

Ultimately, the role of such illustrations extends beyond mere convenience; they are essential tools that enhance understanding, foster collaboration, and promote swift action in maintaining and repairing machinery.

Common Parts for XT1 LT42

Understanding the essential components of a popular lawn mower model is crucial for effective maintenance and repairs. Each unit comprises various key elements that ensure optimal performance and longevity. Familiarity with these components can simplify troubleshooting and enhance user experience.

One vital element is the engine, which provides the necessary power for operation. Additionally, the cutting deck plays a significant role in achieving a precise cut, while the transmission system facilitates smooth movement across various terrains. Moreover, wheels and tires contribute to stability and maneuverability, making them important for overall functionality.

Regular inspection of belts and blades is also essential, as they directly impact efficiency and cutting quality. Finally, accessories like filters and battery systems can improve reliability and prolong the lifespan of the machine. Knowing these critical components allows users to delve deeper into maintenance practices and achieve ultimate performance.

How to Read Parts Diagrams

Understanding schematics is essential for effective maintenance and repair of machinery. These illustrations serve as a visual guide, providing insights into the components and their interconnections. Learning to interpret these visuals can significantly enhance your troubleshooting skills and facilitate efficient repairs.

Key Elements to Identify

When examining a schematic, several key features are important:

- Labels: Each component is typically marked with a specific identifier, helping you locate parts quickly.

- Numbers: Often, numerical codes correspond to parts lists, making it easier to find replacements.

- Connections: Lines or arrows indicate how components relate to each other, illustrating their functionality within the system.

Steps for Effective Interpretation

- Start by familiarizing yourself with the layout and symbols used in the illustration.

- Identify the main components and their labels.

- Trace the connections to understand how each part interacts.

- Refer to any accompanying documentation for additional context.

By mastering these skills, you can approach repairs with confidence, ensuring that your machinery operates smoothly and efficiently.

Finding Replacement Parts Online

Locating suitable components for your equipment can be a straightforward process if you know where to look. Online resources provide a vast selection, making it easier to find what you need without extensive searching in physical stores. Understanding how to navigate these platforms will enhance your experience and ensure you get the right items quickly.

Utilizing Manufacturer Websites

Official manufacturer sites often have dedicated sections for identifying and ordering necessary components. By entering the model number or specifications, you can efficiently access a comprehensive catalog of compatible items. This method ensures authenticity and reliability in your purchases.

Exploring Third-Party Retailers

Various online retailers offer a wide range of aftermarket options. Many platforms allow you to filter by specifications, price, and user reviews. This can lead to discovering cost-effective alternatives that suit your needs without compromising quality.

Maintenance Tips for XT1 LT42

Regular upkeep is essential for ensuring the longevity and efficiency of your mower. Proper care not only enhances performance but also prevents costly repairs. Implementing a routine maintenance schedule can greatly improve your machine’s reliability.

Routine Inspection

Conduct frequent checks on the mower’s components, such as blades and belts. Look for signs of wear and tear, and replace any damaged parts promptly. This proactive approach helps maintain optimal functionality.

Cleaning and Lubrication

Keep the equipment clean by removing grass clippings and debris after each use. Regularly lubricate moving parts to minimize friction and enhance performance. This attention to detail can lead to smoother operation and extended lifespan.

Tools Needed for Repairs

When it comes to performing maintenance and fixing machinery, having the right instruments is essential for achieving effective results. A well-equipped workspace not only streamlines the process but also enhances safety and efficiency.

Basic Hand Tools: Essential items such as wrenches, screwdrivers, and pliers form the backbone of any repair kit. These allow for easy access to various components.

Power Tools: Drills and impact wrenches can significantly reduce the time spent on repairs. Their use can be especially beneficial when dealing with stubborn or rusted parts.

Measuring Instruments: Precision tools like calipers and tape measures ensure that components fit correctly and function optimally, preventing future issues.

Safety Gear: Don’t overlook the importance of protective equipment. Gloves, goggles, and ear protection help safeguard against potential hazards during repairs.

Having these tools at your disposal will ultimately make the repair process smoother and more effective, allowing you to delve deeper into any issues that arise.

Identifying Wear and Tear

Understanding the signs of degradation is crucial for maintaining the efficiency and longevity of your machinery. Regular inspections can help spot issues early, preventing costly repairs and ensuring optimal performance.

Common Signs to Look For

During your assessments, focus on these typical indicators of wear:

| Indicator | Description |

|---|---|

| Fraying | Visible damage on belts and cables, indicating potential failure. |

| Corrosion | Rust or oxidation on metal components, compromising structural integrity. |

| Cracking | Small fissures on plastic or rubber parts, suggesting they may break under stress. |

| Excessive Vibration | Unusual movement during operation, often a sign of misalignment or loose parts. |

Importance of Timely Intervention

Addressing these issues promptly can prevent further damage and ensure the equipment runs smoothly. Regular maintenance checks and proactive replacements are key to longevity.

Ordering Genuine Cub Cadet Parts

Acquiring authentic components for your lawn equipment ensures optimal performance and longevity. By choosing original pieces, you maintain the integrity of your machine and benefit from reliable quality.

Benefits of Genuine Components

- Enhanced durability and reliability

- Precision engineering for perfect fit

- Longer lifespan of your equipment

How to Order Authentic Components

- Visit the official website or authorized dealer.

- Utilize the model number for accurate identification.

- Confirm availability and place your order.

- Track shipping and ensure correct delivery.

Aftermarket Parts: Pros and Cons

Exploring alternative components can present both advantages and disadvantages for equipment maintenance and upgrades. Users often seek these options to enhance performance or reduce costs, yet they should carefully weigh the potential impacts on reliability and compatibility.

Advantages

One of the primary benefits of opting for alternative components is cost savings. These items can often be priced more competitively than original equipment, making repairs more affordable. Additionally, aftermarket options may provide enhanced features or improved performance, catering to specific user needs.

Disadvantages

On the downside, alternative components might not always meet the same quality standards as original equipment. This can lead to issues such as reduced lifespan or compatibility problems. Furthermore, using these alternatives may void warranties, creating potential financial risks for users.

| Aspect | Aftermarket | Original |

|---|---|---|

| Cost | Lower | Higher |

| Quality | Variable | Consistent |

| Performance | Potentially Enhanced | Standardized |

| Warranty Impact | Possible Voiding | Protected |

Assembly Instructions for Key Components

This section provides essential guidelines for putting together critical elements of your equipment. A thorough understanding of each component’s role will ensure a smooth assembly process and enhance overall performance.

Preparation Steps

Before starting, gather all necessary tools and components. Ensure your workspace is clean and organized to facilitate efficient assembly. Reviewing the manual beforehand can provide clarity on the sequence of assembly and specific requirements for each part.

Assembly Process

Begin with the main chassis, ensuring it is level and stable. Next, attach the engine by aligning it with the designated mounts. Secure each connection tightly, utilizing the appropriate fasteners. Finally, double-check all components for alignment and stability before proceeding to the next stage.

Resources for XT1 LT42 Owners

Maintaining your mower can significantly enhance its longevity and performance. For owners seeking assistance, a variety of resources are available to ensure optimal care and understanding of their equipment.

Online Communities

- Forums: Join dedicated forums where enthusiasts and experts share advice, troubleshooting tips, and modifications.

- Social Media Groups: Engage with fellow owners on platforms like Facebook or Reddit to exchange experiences and solutions.

- YouTube Channels: Follow channels that provide tutorials on maintenance, repairs, and upgrades specific to your model.

Official Resources

- User Manuals: Refer to the manufacturer’s official user manual for comprehensive information on operation and maintenance.

- Customer Support: Utilize customer service for inquiries about service locations and product specifications.

- Authorized Dealers: Find nearby dealers who can offer genuine replacement items and expert advice.