Cub Cadet ZT2 60 Parts Diagram Overview

For enthusiasts and professionals alike, maintaining and repairing lawn care equipment can be a rewarding yet challenging task. Having a clear visual representation of each component is essential for efficient troubleshooting and replacement. This section delves into the intricate assembly of a specific model, ensuring you have all the necessary information at your fingertips.

By familiarizing yourself with the various elements involved, you can enhance your overall experience with your mower. A comprehensive overview aids in identifying parts that require attention, ultimately leading to improved performance and longevity. Moreover, recognizing the relationships between different components empowers you to tackle maintenance with confidence.

Whether you’re a seasoned technician or a first-time owner, understanding the structure of your machine is crucial. This guide will provide insights that simplify the complexities of your equipment, ensuring you’re well-equipped to manage any issues that may arise.

Understanding Cub Cadet ZT2 60

This section explores the intricacies of a high-performance mowing machine designed for efficiency and durability. Gaining insight into its components and functionality enhances user experience and maintenance strategies.

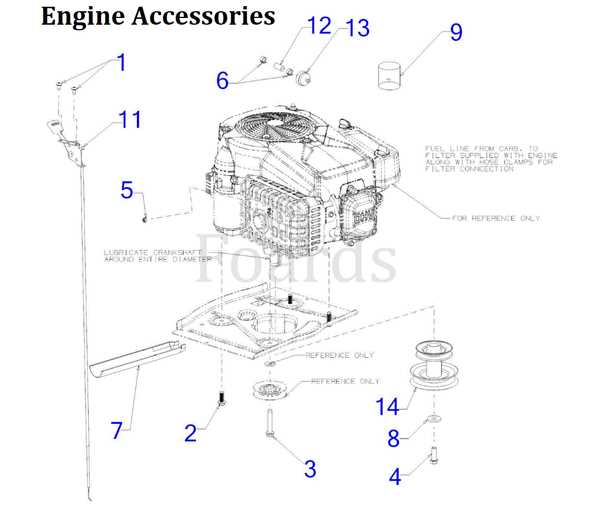

- Engine Specifications: Knowing the power source is crucial for optimal performance.

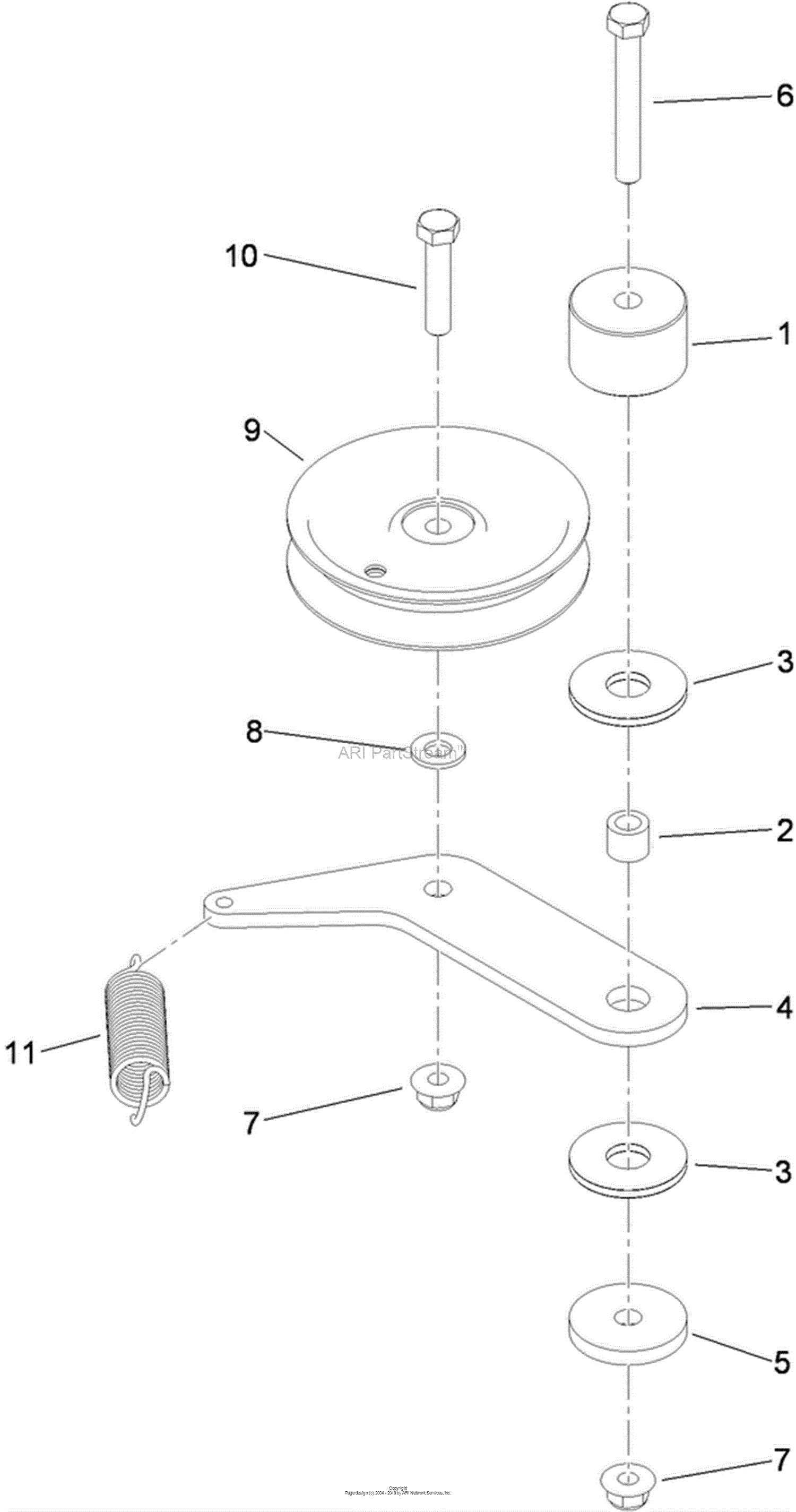

- Cutting Mechanism: Understanding how the blades interact ensures effective mowing.

- Transmission System: Familiarity with gear settings can improve maneuverability.

- Safety Features: Recognizing built-in safeguards protects users during operation.

Exploring these elements provides a comprehensive understanding of how to maximize the machine’s capabilities and longevity.

Overview of ZT2 60 Features

This section provides an insight into the remarkable attributes of a cutting-edge mowing machine designed for efficiency and comfort. With a blend of innovative technology and user-friendly design, it caters to both residential and commercial needs.

Performance and Efficiency

The powerful engine ensures optimal performance, allowing for swift mowing across diverse terrains. Coupled with a robust transmission, it offers smooth operation and excellent maneuverability, making large areas manageable.

User Comfort and Control

Designed with the operator in mind, this machine features an ergonomic seat and intuitive controls. Adjustable settings provide a personalized experience, enhancing productivity and reducing fatigue during extended use.

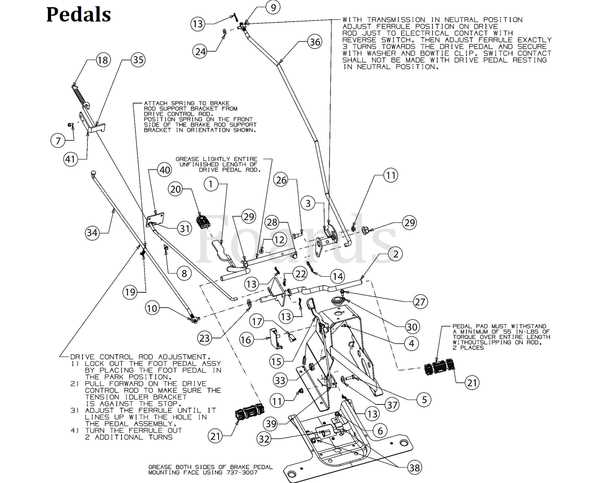

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. These illustrations facilitate easier identification and maintenance, ensuring that users can efficiently manage their equipment.

Enhanced Understanding

Comprehending intricate systems becomes simpler through detailed visuals. Users can:

- Quickly locate specific elements

- Understand the interconnections between various parts

- Identify potential issues before they escalate

Streamlined Maintenance

Effective upkeep is vital for longevity. Using visual aids allows for:

- More accurate replacements

- Reduced downtime during repairs

- Informed decision-making on service needs

Common Issues with ZT2 60 Parts

When it comes to maintaining outdoor machinery, certain challenges can arise that may hinder performance. Identifying and addressing these common complications is crucial for ensuring longevity and efficiency.

- Wear and Tear: Over time, components may degrade, leading to reduced functionality.

- Misalignment: Parts can become misaligned, resulting in operational inefficiencies.

- Clogging: Debris buildup can obstruct movement, affecting overall performance.

- Fluid Leaks: Seal failures may cause essential fluids to leak, compromising the system.

- Electrical Issues: Wiring problems can lead to power failures or erratic behavior.

Regular inspection and timely replacements can help mitigate these issues, ensuring optimal operation and reliability.

How to Use Parts Diagrams Effectively

Understanding the layout and components of machinery is essential for maintenance and repair tasks. Visual representations of these elements can greatly enhance your ability to identify, source, and replace various components. Utilizing these illustrations correctly will streamline your repair process and minimize downtime.

Getting Familiar with Visual Aids

Before diving into repairs, take time to familiarize yourself with the illustrations. This will help you grasp the relationships between different components. Here are some tips:

- Study the overall layout to understand how each part interacts with others.

- Look for annotations that provide additional context or specifications.

- Use a magnifying tool if necessary to read small labels clearly.

Using Visual Representations in Repairs

When tackling a repair, these representations can serve as a valuable reference. Follow these steps to maximize their effectiveness:

- Identify the specific component you need to work on.

- Refer to the illustration to locate the exact position of that component.

- Check for any related parts that may require attention or replacement.

- Gather the necessary tools and new components based on the information provided.

- Document any findings or observations for future reference.

By integrating these visual resources into your maintenance routine, you can ensure a more organized and efficient repair process.

Identifying Key Components in Diagrams

Understanding the essential elements depicted in schematics is crucial for effective maintenance and repair tasks. Recognizing these components enables users to troubleshoot issues efficiently and ensures that the machinery operates at optimal performance levels. This section focuses on the identification of critical parts within technical illustrations.

Each visual representation typically includes various components, such as motors, blades, and frames. Familiarity with these elements is vital for anyone looking to work on or modify equipment. The following table outlines common features and their descriptions to aid in identification.

| Component | Description |

|---|---|

| Motor | Drives the primary functions of the machinery. |

| Blades | Used for cutting or trimming, varying in size and shape. |

| Chassis | The framework that supports all other components. |

| Control Panel | Interface for operating and adjusting the equipment. |

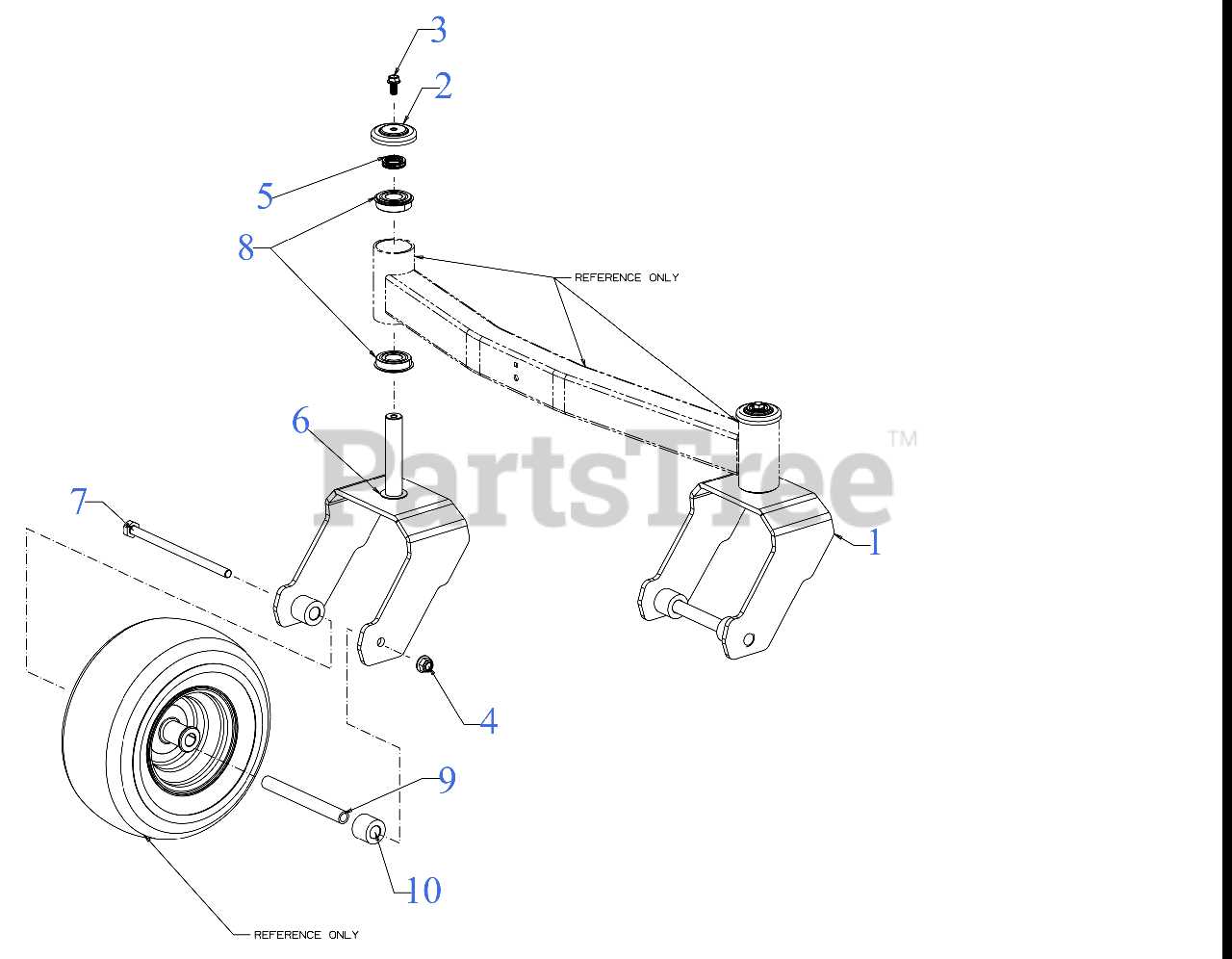

| Wheels | Facilitate mobility and maneuverability of the device. |

By mastering the identification of these key components, users can enhance their understanding of the equipment’s functionality and ensure that maintenance is performed accurately.

Maintenance Tips for ZT2 60

Regular upkeep is essential for ensuring optimal performance and longevity of your mowing machine. By adhering to a consistent maintenance schedule, you can prevent potential issues and enhance the overall efficiency of your equipment.

Check the Blades: It’s crucial to inspect and sharpen the blades regularly. Dull blades can lead to uneven cuts and increased strain on the engine. Aim to sharpen them at least once per season or more frequently if you mow in tough conditions.

Oil Changes: Changing the oil is vital for the engine’s health. Follow the manufacturer’s recommendations for oil type and change intervals. A clean engine operates more efficiently and lasts longer.

Air Filter Maintenance: Keep an eye on the air filter, as a clogged filter can restrict airflow and hinder performance. Clean or replace it as necessary to ensure optimal engine function.

Tire Pressure: Maintaining proper tire pressure is important for traction and stability. Regularly check the pressure and inflate to the recommended levels to ensure a smooth mowing experience.

Battery Care: For models equipped with batteries, regular inspection and cleaning of terminals can prevent starting issues. Ensure that the battery is charged and free from corrosion to maintain reliable operation.

Fuel Quality: Always use high-quality fuel and consider adding a fuel stabilizer, especially if the machine will be idle for an extended period. This can prevent fuel-related issues and ensure smooth operation when you are ready to mow again.

By following these essential maintenance tips, you can keep your mowing machine in top condition, ensuring it serves you well for years to come.

Where to Find Replacement Parts

When maintaining outdoor equipment, sourcing components is crucial for optimal performance. Various resources are available to help you find the necessary items to keep your machinery running smoothly.

- Authorized Dealers: Visit local distributors for authentic items and expert guidance.

- Online Retailers: Explore e-commerce platforms specializing in machinery accessories.

- Manufacturer’s Website: Check the official site for direct purchases and updated catalogs.

- Aftermarket Suppliers: Research third-party vendors for cost-effective alternatives.

- Local Repair Shops: Consult with professionals who may offer parts or services.

Each of these options provides a way to delve into finding what you need while ensuring quality and reliability in your equipment maintenance.

Benefits of OEM vs. Aftermarket Parts

When it comes to maintaining machinery, the choice between original equipment manufacturer (OEM) components and alternative aftermarket options is crucial. Each type has its own set of advantages that can impact performance, reliability, and long-term costs.

Choosing OEM components ensures compatibility and quality, while aftermarket options often provide cost savings and variety. Here are some key benefits of each:

Benefits of OEM Components

- Quality Assurance: Designed specifically for the equipment, ensuring high performance and durability.

- Perfect Fit: Original components guarantee compatibility with existing machinery, reducing the risk of issues.

- Manufacturer Support: OEM parts typically come with warranties and access to customer service for support.

- Resale Value: Using original components can help maintain the equipment’s value over time.

Benefits of Aftermarket Options

- Cost-Effective: Often available at a lower price point, allowing for significant savings.

- Variety: A wider range of options and features that may not be available through the manufacturer.

- Upgrades: Aftermarket parts can provide enhancements and improved performance characteristics.

- Accessibility: Generally easier to find and purchase from various suppliers.

In summary, the decision between OEM and aftermarket components hinges on individual needs and priorities. Evaluating factors like quality, cost, and specific use cases can guide the best choice for maintaining equipment efficiency and longevity.

Step-by-Step Repair Process

This section provides a comprehensive guide to effectively troubleshooting and fixing mechanical issues. Following a systematic approach ensures that every component is carefully inspected, allowing for a thorough resolution of problems. Each step is designed to enhance understanding and facilitate a smooth repair experience.

Begin by gathering all necessary tools and materials. Having everything at hand will streamline the process and minimize interruptions. Next, consult the manufacturer’s manual for specific instructions related to your model. This will provide insights into the construction and functions of various components.

Next, visually inspect the equipment for any obvious signs of damage or wear. Pay close attention to moving parts, belts, and connections. If something seems amiss, take note of it before proceeding to disassemble relevant sections for a more detailed examination.

Once disassembled, clean each component thoroughly. Removing dirt and debris will prevent future issues and allow for better visibility when inspecting for damage. After cleaning, systematically assess each part for wear or defects, making notes of any that need replacement.

Replace any faulty components with high-quality alternatives. When reassembling, ensure that all parts are securely fastened and correctly aligned. Follow the reverse order of disassembly, and take your time to avoid mistakes.

Finally, conduct a test run to confirm that the repairs were successful. Monitor performance closely during this phase, as it will help identify any lingering issues. If everything operates smoothly, your repair process is complete, leading to optimal functionality.

Resources for Further Assistance

When it comes to maintaining and repairing outdoor power equipment, having access to reliable resources is crucial. Whether you are seeking technical support, replacement components, or troubleshooting guides, various platforms can provide the assistance you need to ensure your machine operates smoothly.

Online Forums and Communities

Engaging with online communities can be incredibly beneficial. Many enthusiasts and experts share their knowledge, tips, and experiences. These forums often cover a wide range of topics, from basic maintenance to advanced repairs.

Manufacturer Websites and Support

Visiting the official website of the manufacturer is another excellent way to find accurate and detailed information. Most manufacturers offer manuals, FAQs, and direct customer support options to assist users in resolving any issues.

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Community-driven platforms for advice and support. | Visit Forum |

| Official Website | Access to manuals, FAQs, and customer service. | Visit Site |

| Local Dealers | Authorized dealers can provide expert advice and parts. | Find a Dealer |