Understanding the Honda GX240 Carburetor Parts Diagram

For those looking to enhance the performance and efficiency of their small engines, a thorough comprehension of the fuel delivery mechanisms is essential. These systems play a pivotal role in ensuring optimal combustion and, consequently, effective power generation. Familiarity with the components involved allows for informed maintenance and troubleshooting.

Exploring the intricate assembly of these mechanisms reveals the significance of each element in achieving precise fuel management. From controlling the air-fuel mixture to regulating flow, every piece is crucial for the engine’s overall functionality. An in-depth look at the structure not only aids in repairs but also fosters a greater appreciation for mechanical design.

Whether you are a seasoned technician or a novice enthusiast, understanding these components will empower you to address issues more effectively. This knowledge is key to optimizing performance, prolonging the lifespan of the equipment, and enhancing user experience.

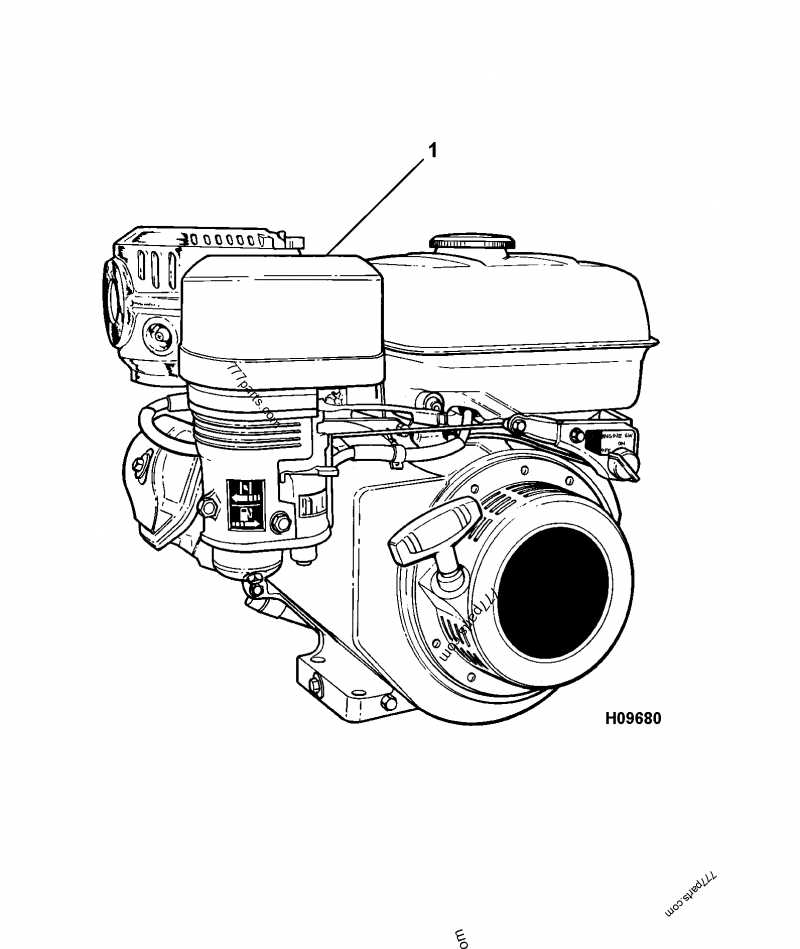

Understanding the GX240 Engine

The engine in question is a robust and versatile power unit commonly utilized in various applications. Renowned for its reliability and efficiency, this model is designed to meet the demands of both professional and recreational use. Its engineering excellence ensures optimal performance, making it a favored choice among users who require dependable machinery.

Key Features and Benefits

This power unit boasts several features that enhance its functionality. With a compact design, it is easily integrated into different setups. The air intake system is designed to maximize airflow, contributing to improved combustion and energy output. Additionally, the unit is equipped with a user-friendly interface, simplifying operation and maintenance tasks.

Applications and Usage

Due to its versatility, this engine is employed in various fields, including landscaping, construction, and recreational activities. Users appreciate its ability to power equipment such as generators, pumps, and tillers. The unit’s durability ensures it can withstand challenging conditions, making it an ideal choice for both everyday and heavy-duty tasks.

Importance of Carburetor in Engines

The component responsible for mixing air and fuel is vital for the efficient operation of internal combustion engines. It ensures that the correct ratio of these two elements reaches the combustion chamber, facilitating optimal performance and energy output.

Functionality is key; the device regulates the flow of fuel, adapting to varying conditions such as throttle position and engine load. This adaptability is crucial for maintaining engine efficiency and responsiveness. When the mixture is well-balanced, the engine operates smoothly, producing the desired power while minimizing emissions.

Moreover, maintenance of this essential component is paramount. Regular checks and cleanings can prevent issues such as clogging, which can lead to poor performance or even engine failure. Understanding its role helps users appreciate the complexity of engine dynamics and the importance of proper upkeep.

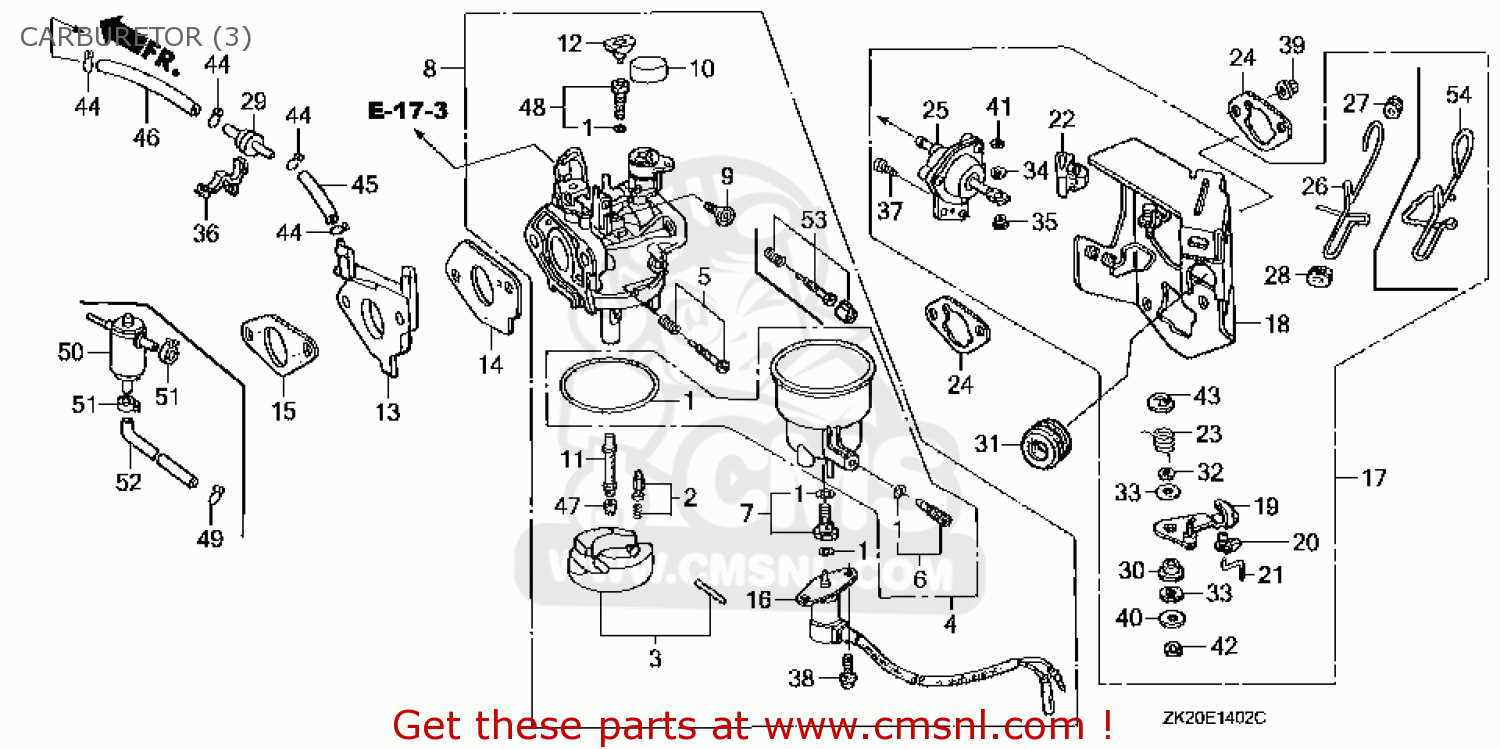

Overview of GX240 Carburetor Design

The design of the fuel mixing component for small engines plays a crucial role in optimizing performance and efficiency. This assembly is engineered to blend air and fuel in precise ratios, ensuring smooth operation under various conditions. Understanding its structure and functionality provides insights into how it influences overall engine performance.

This assembly typically consists of several key elements that work together seamlessly. The main components include a throttle valve, fuel inlet, and a venturi that creates the necessary suction to draw fuel into the airflow. Each part has a specific function that contributes to the overall efficacy of the engine’s operation.

| Component | Function |

|---|---|

| Throttle Valve | Regulates airflow, controlling engine speed |

| Fuel Inlet | Allows fuel to enter the mixing chamber |

| Venturi | Creates a vacuum to draw fuel into the air stream |

| Float Chamber | Maintains a consistent fuel level for optimal performance |

Each component is meticulously designed to ensure reliability and efficiency. Proper maintenance and understanding of these elements can lead to enhanced performance and longevity of the entire engine system.

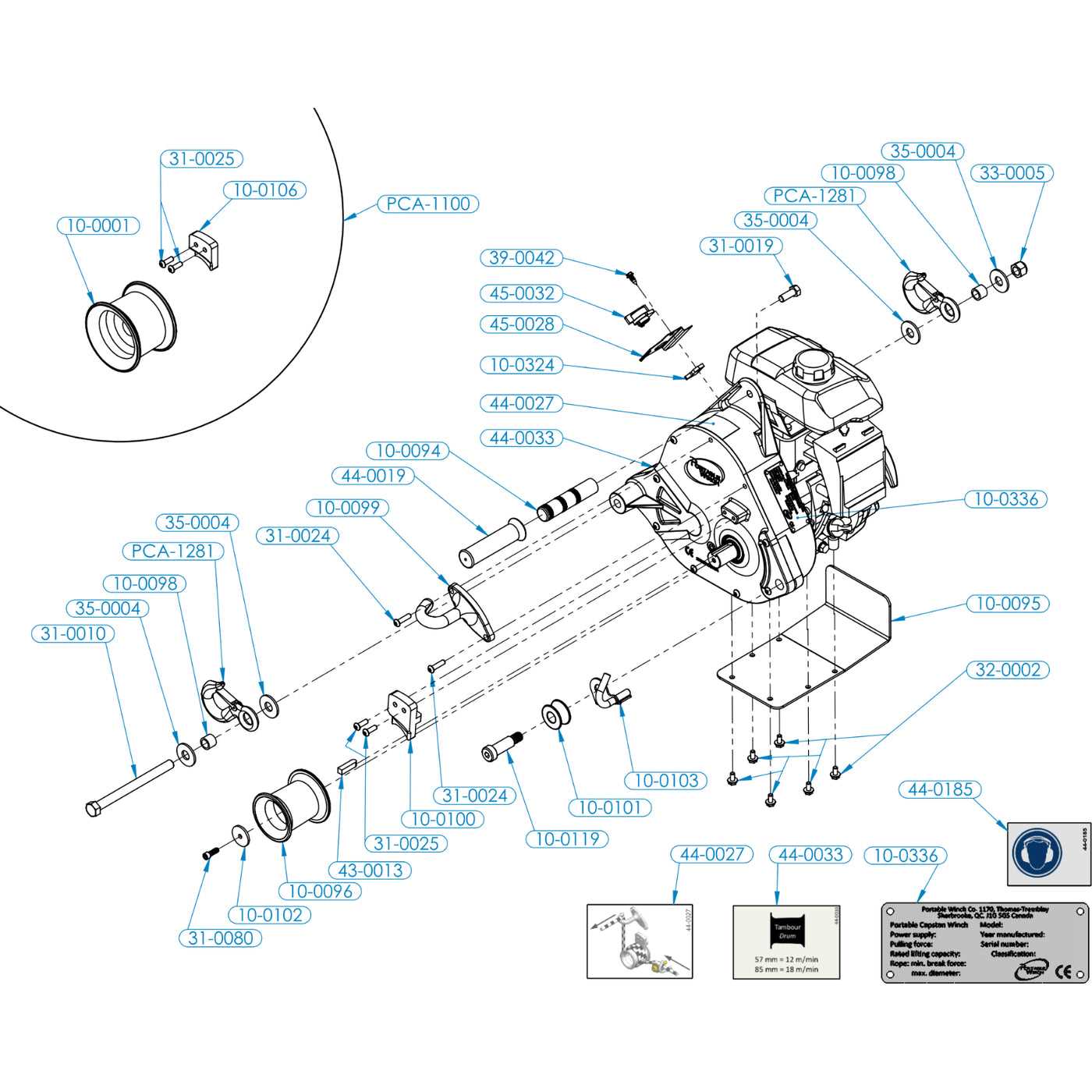

Main Components of the Carburetor

Understanding the essential elements of a fuel-air mixing device is crucial for effective maintenance and performance optimization. Each component plays a vital role in the overall functionality, ensuring proper fuel delivery and air regulation for efficient combustion.

- Float Chamber: This section holds a reservoir of fuel, regulating the amount that flows into the mixing chamber.

- Needle Valve: Operated by the float, this valve controls fuel entry into the chamber, preventing overflow.

- Venturi Tube: A constricted passage that accelerates air, creating a vacuum that draws in fuel for mixing.

- Throttle Plate: This adjustable plate modulates airflow, influencing engine speed and power output.

- Choke Valve: A device that restricts airflow during startup to enrich the fuel mixture for easier ignition.

- Mixture Screw: A tuning mechanism that allows for fine adjustments of the fuel-air ratio, enhancing performance.

Each of these elements works in concert to ensure optimal engine function. Regular inspection and understanding of these components can lead to improved efficiency and longevity of the device.

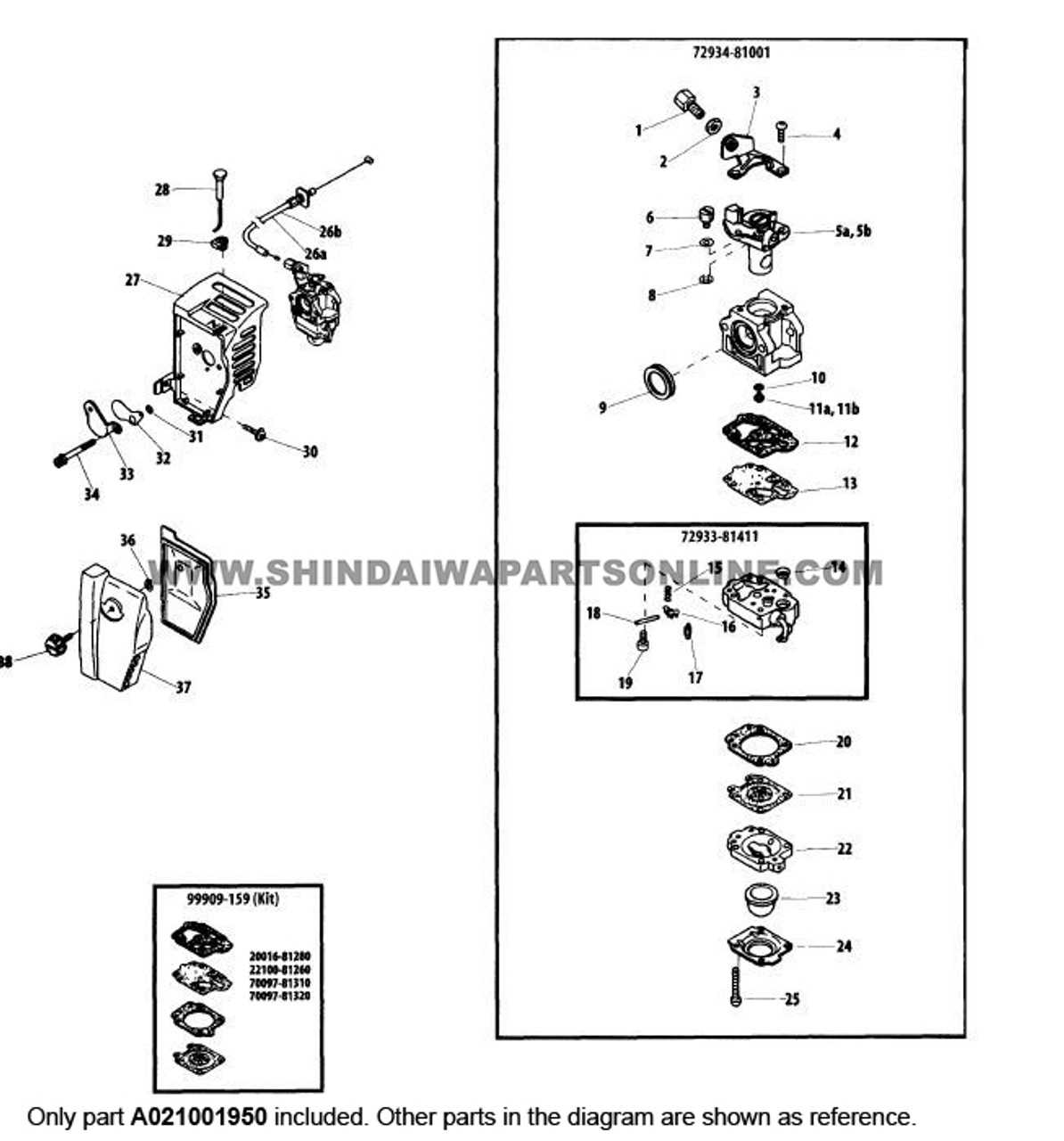

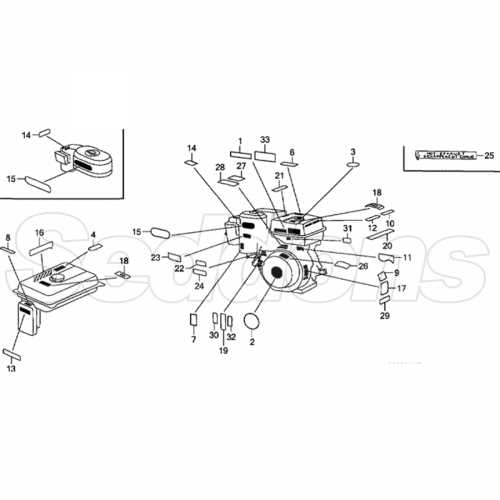

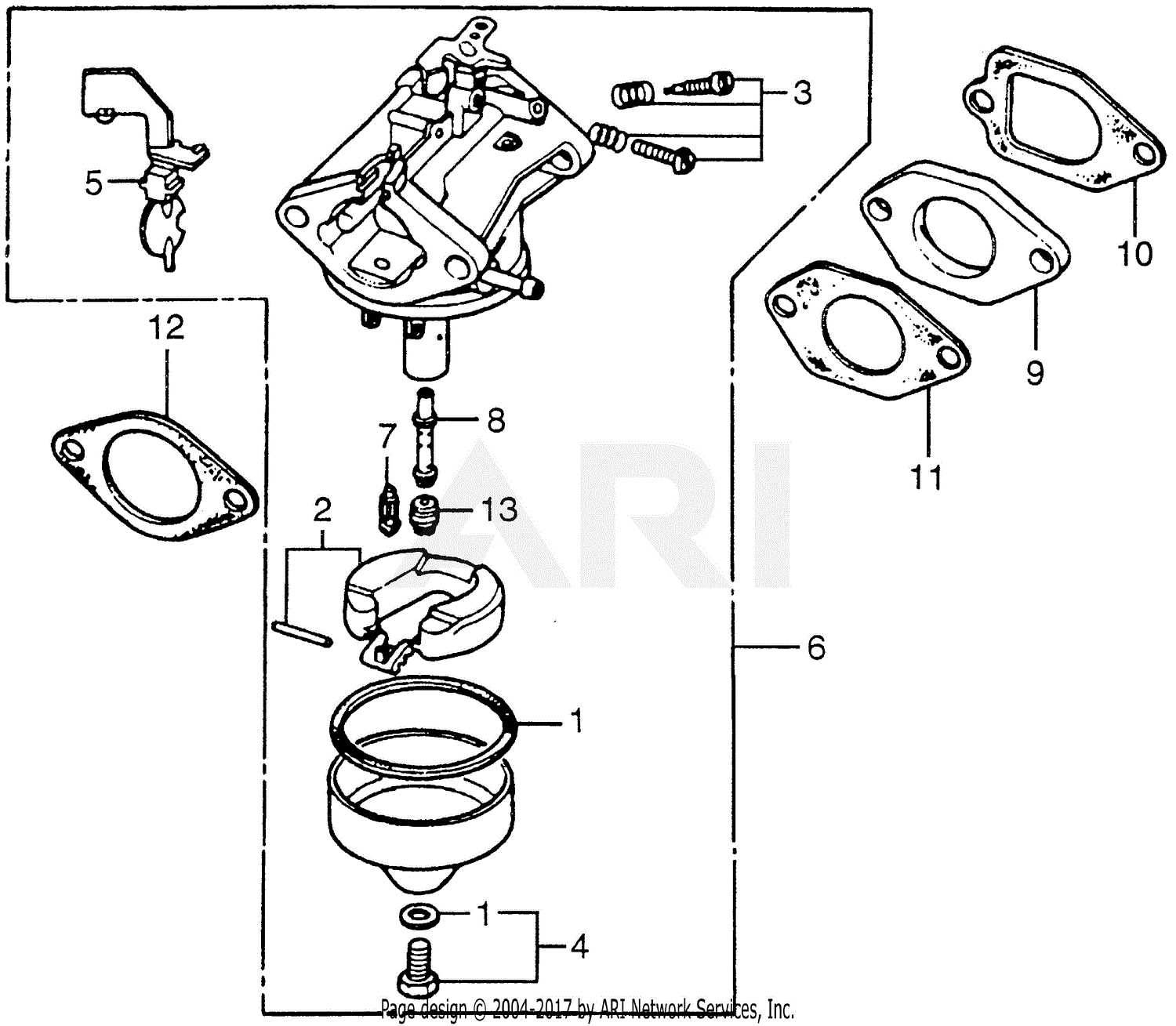

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repairs. These visual aids simplify the identification of components and their relationships, enabling users to grasp assembly and disassembly processes with ease.

When approaching these illustrations, consider the following steps:

- Familiarize Yourself with the Layout: Begin by observing how the components are organized. Typically, items are grouped by functionality or location.

- Identify Symbols and Labels: Look for any annotations that explain what each part represents. Familiar symbols can indicate sizes, quantities, or specific types of components.

- Trace Connections: Follow lines or arrows to understand how different elements interact with each other. This will clarify assembly sequences and help prevent mistakes during reassembly.

- Check for Exploded Views: If available, these detailed representations show parts separated to illustrate how they fit together, offering a clearer perspective on assembly order.

By practicing these techniques, you will enhance your ability to interpret visual representations and execute tasks more confidently.

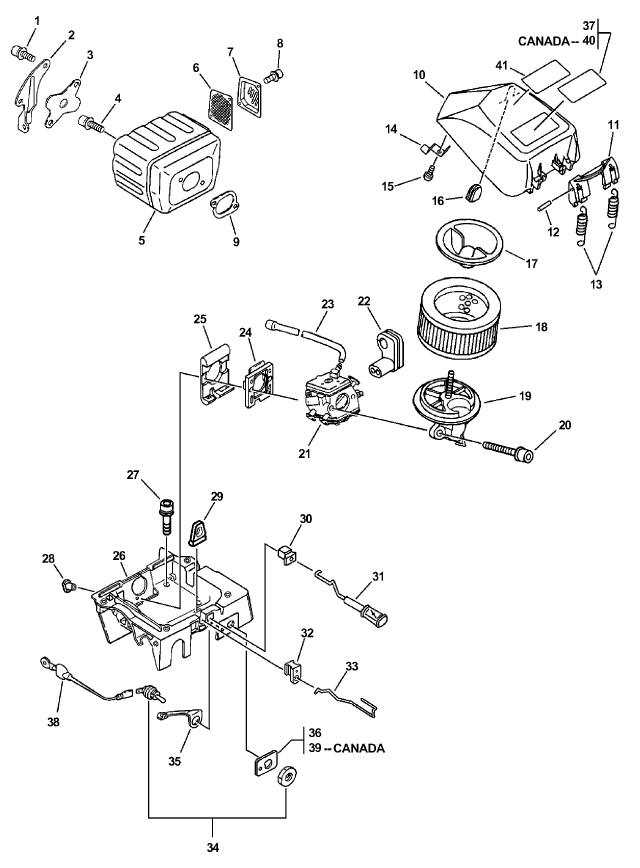

Common Issues with GX240 Carburetors

Engines equipped with small fuel delivery systems often encounter a variety of challenges that can affect performance and efficiency. Understanding these common problems is essential for maintaining optimal functionality. This section highlights typical issues that can arise, along with their potential causes and solutions.

Fuel Blockages

One of the most prevalent issues is the accumulation of debris and sediment within the fuel pathways. Clogged jets or filters can restrict the flow of fuel, leading to poor engine performance or stalling. Regular maintenance, including cleaning or replacing filters, can mitigate this problem and ensure smooth operation.

Air Leaks

Another frequent concern involves unwanted air entering the system, which can disrupt the fuel-to-air ratio. Faulty gaskets or improperly seated connections are common culprits. Identifying and repairing these leaks is crucial for restoring the correct mixture and achieving optimal engine efficiency.

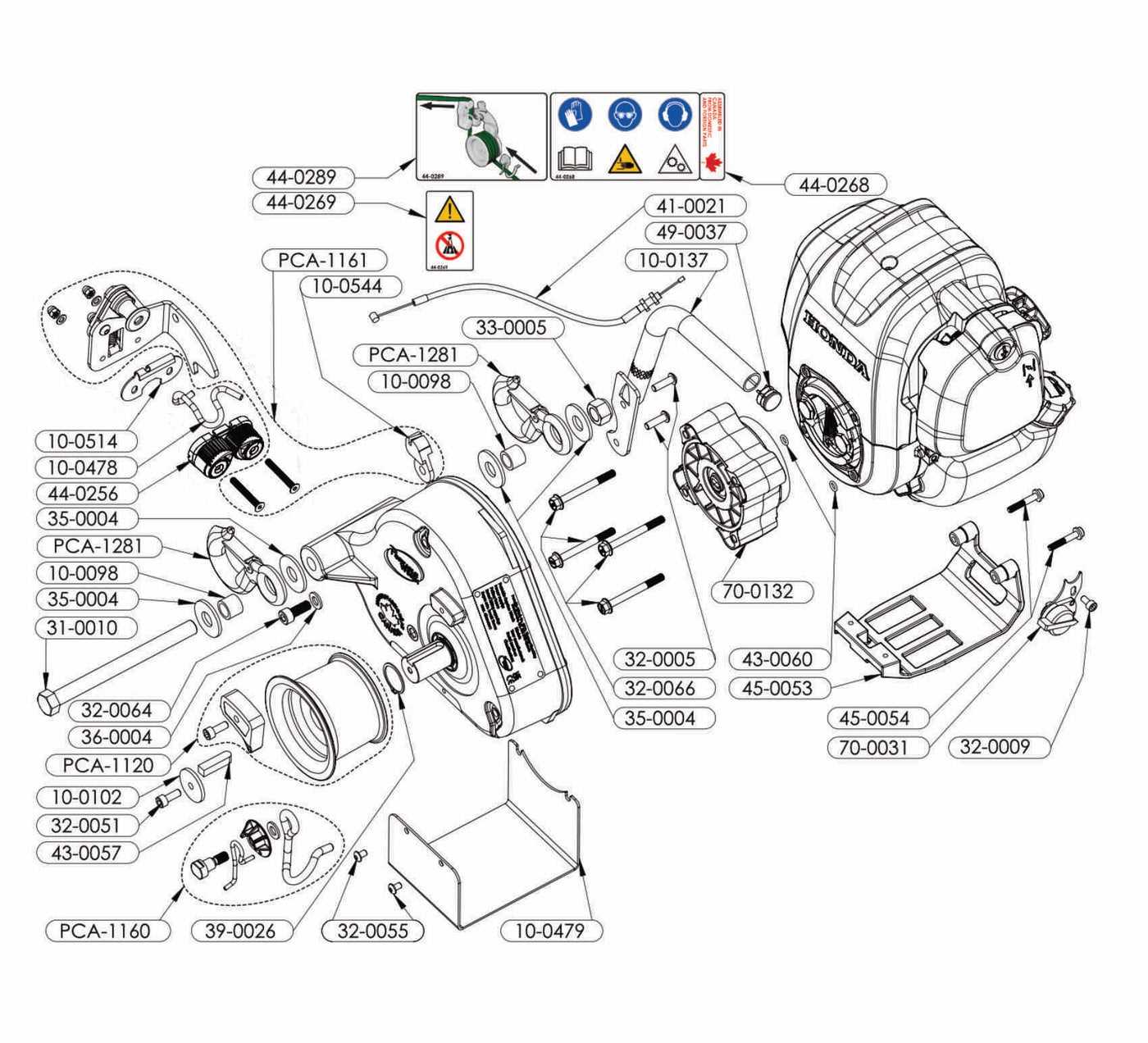

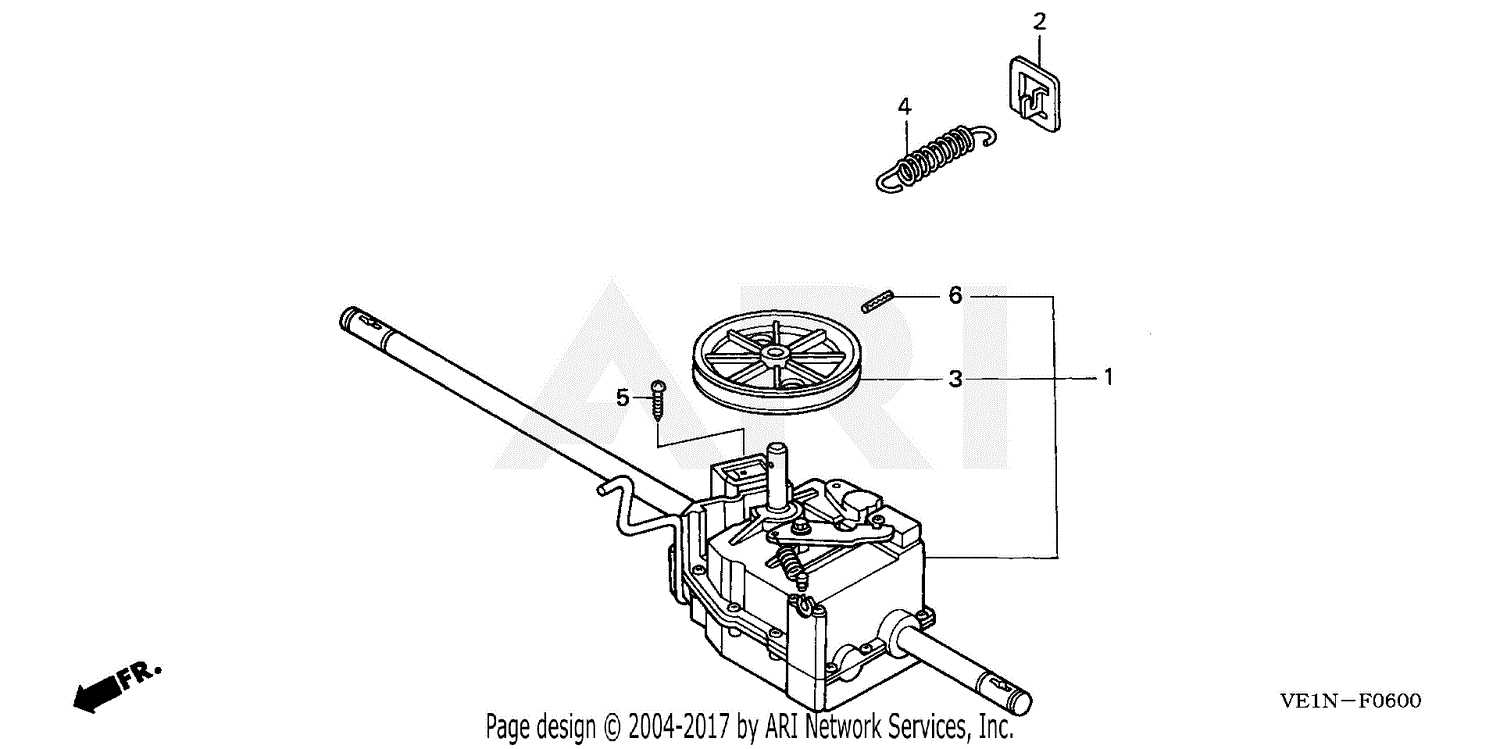

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to carefully dismantling the assembly for maintenance or repair. Following these steps will ensure that each component is handled properly, minimizing the risk of damage and facilitating reassembly.

Preparation

- Gather necessary tools: screwdriver, pliers, and cleaning materials.

- Ensure a clean workspace to avoid losing small components.

- Wear safety gloves to protect your hands during the process.

Disassembly Steps

- Start by disconnecting any fuel lines and electrical connections to ensure safety.

- Remove the outer casing or cover by unscrewing any screws or bolts.

- Carefully take out the first internal component, noting its position and orientation.

- Continue removing components sequentially, keeping them organized.

- Inspect each part for wear and tear as you disassemble.

- Once all components are removed, clean each part thoroughly for the next steps.

After completing the disassembly, review all components before proceeding with maintenance or replacement. Proper handling during this stage is crucial for successful reassembly and optimal performance.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring optimal performance and extending the lifespan of your equipment. By following a few key practices, you can keep your machinery running smoothly and efficiently for years to come.

Routine Inspection

- Check for leaks and wear on components regularly.

- Inspect all connections to ensure they are secure.

- Look for any signs of corrosion or damage.

Cleaning Procedures

- Remove debris and dirt from exterior surfaces to prevent build-up.

- Use appropriate solvents to clean internal components without causing damage.

- Ensure air intake and exhaust pathways are clear for optimal airflow.

By implementing these maintenance strategies, you can significantly enhance the durability and reliability of your equipment, avoiding costly repairs and downtime.

Finding Quality Replacement Parts

When it comes to maintaining small engines, ensuring the availability of high-quality components is essential for optimal performance and longevity. Finding suitable replacements can be a daunting task, but with the right approach, it becomes manageable.

Here are some strategies to consider when searching for reliable components:

- Research Reputable Suppliers: Look for established vendors with positive reviews and a track record of quality.

- Check Compatibility: Ensure that the replacements are compatible with your specific engine model to avoid performance issues.

- Look for OEM Options: Original Equipment Manufacturer items often guarantee better fit and durability.

- Compare Prices: Shop around to find competitive pricing, but beware of deals that seem too good to be true.

Additionally, engaging with online communities can provide valuable insights and recommendations:

- Join Forums: Participate in discussions where enthusiasts share experiences and advice.

- Follow Social Media Groups: Connect with groups dedicated to small engine maintenance for tips on sourcing components.

- Utilize Review Sites: Read customer feedback on different suppliers to gauge their reliability.

By implementing these strategies, you can effectively locate high-quality replacements that will enhance your engine’s performance and extend its lifespan.

Upgrading Your Carburetor Performance

Enhancing the efficiency of your fuel delivery system can lead to significant improvements in engine performance. By optimizing airflow and fuel mixture, you can achieve better acceleration, improved fuel economy, and smoother operation. This section will explore various modifications and components that can elevate your system’s functionality.

Several key upgrades can make a noticeable difference. Whether you are looking to replace certain components or adjust existing settings, the following table outlines popular enhancements that can be considered for optimal performance.

| Upgrade Component | Description | Benefits |

|---|---|---|

| High-Performance Jet | Replaces standard jets for increased fuel flow. | Improves throttle response and power output. |

| Upgraded Air Filter | Provides better airflow compared to factory filters. | Enhances combustion efficiency and engine breathing. |

| Adjustable Mixture Screw | Allows for fine-tuning of the air-fuel mixture. | Optimizes performance under varying conditions. |

| Performance Float | Improves fuel delivery stability. | Reduces the risk of flooding and enhances reliability. |

| Manifold Upgrade | Replaces the stock manifold with a high-flow option. | Increases overall airflow into the engine. |

Implementing these modifications can lead to a more responsive and powerful engine, allowing for a better overall experience. Assess your current setup and consider which enhancements align with your performance goals.