Understanding the Keihin CVK Carburetor Parts Diagram

In the realm of internal combustion engines, the efficient functioning of fuel delivery systems is crucial for optimal performance. A comprehensive grasp of the various components that contribute to this process can enhance maintenance and troubleshooting efforts. By exploring the intricacies involved, enthusiasts and mechanics alike can gain valuable insights.

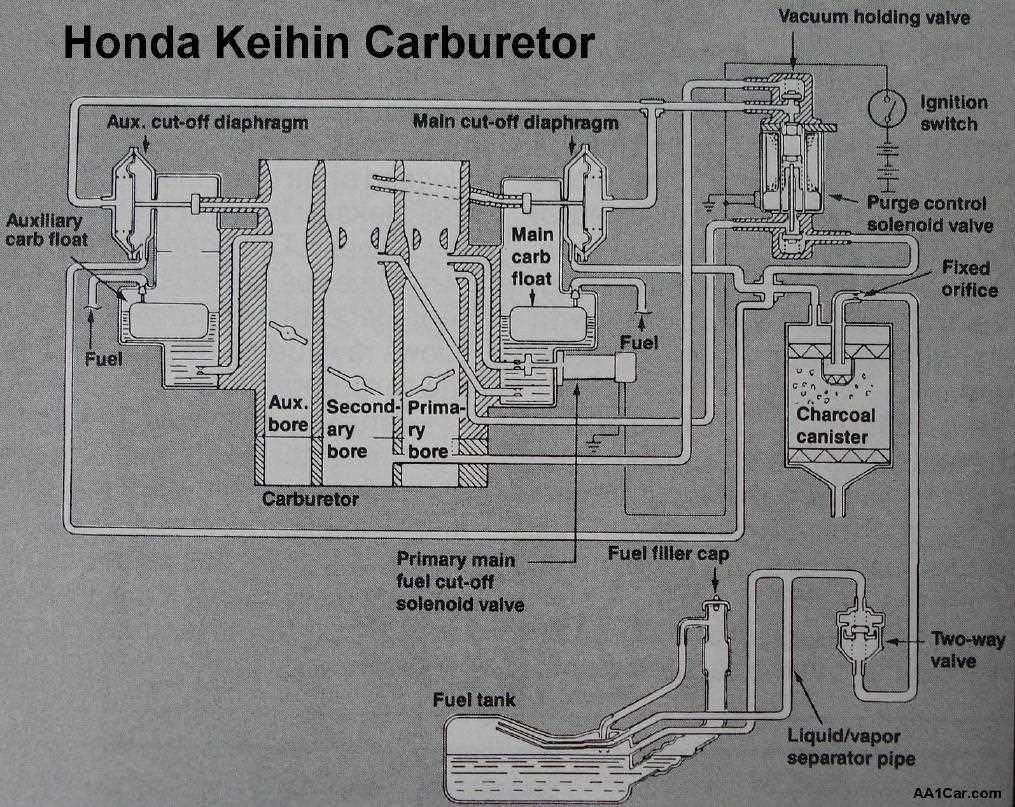

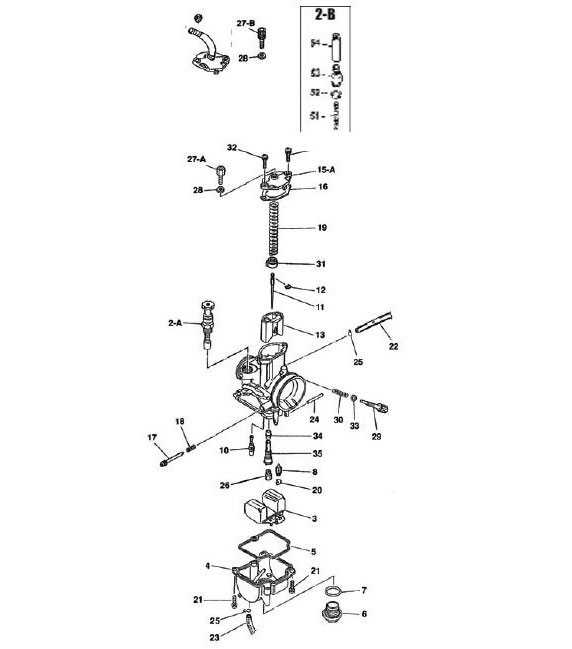

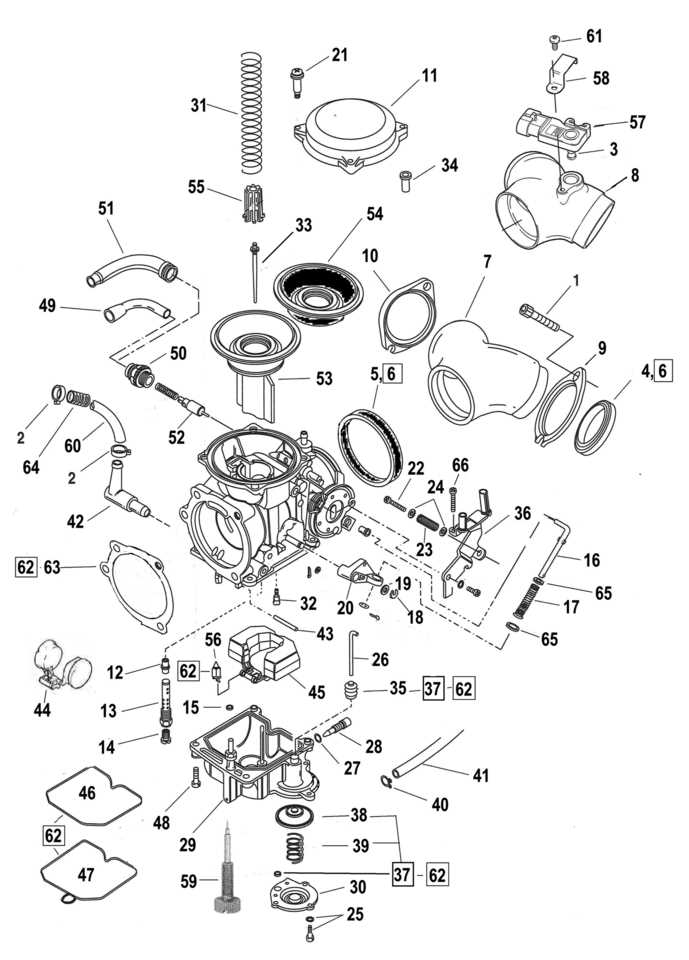

Visual representations play an essential role in simplifying complex mechanical structures. They serve as invaluable tools for both learning and reference, allowing individuals to identify and understand the various elements that work in harmony to ensure proper fuel flow. Delving into these illustrations can uncover the ultimate relationship between each component.

By breaking down these systems into their fundamental parts, users can appreciate the engineering behind each piece and its function. This knowledge not only aids in repairs but also fosters a deeper appreciation for the technology that powers our vehicles. Whether you’re a seasoned professional or a curious novice, understanding these elements is key to mastering the art of engine care.

Understanding the Keihin CVK Carburetor

This section aims to provide an in-depth look at a specific fuel delivery mechanism widely used in various vehicles. It highlights the essential components and their functions, focusing on how they work together to ensure optimal performance and efficiency. Recognizing the significance of each element is crucial for anyone interested in enhancing their knowledge of engine management systems.

Core Components

Central to this mechanism are the fundamental units that facilitate the mixing of air and fuel. These include the throttle body, float chamber, and jet assembly. Each component plays a vital role in regulating the flow of mixtures, ultimately influencing the engine’s operation and responsiveness.

Functionality Insights

Understanding how these elements interact allows for a greater appreciation of the overall system. The process of atomization and mixture formation is critical, as it directly affects combustion efficiency. Regular maintenance and precise adjustments can lead to improved performance and longevity of the entire mechanism.

Key Components of the CVK Design

The design of this fuel delivery system features several critical elements that work together to ensure optimal performance and efficiency. Understanding these components is essential for anyone looking to enhance their vehicle’s functionality or troubleshoot issues.

One of the primary elements is the throttle mechanism, which regulates the airflow into the system, allowing for precise control over engine power. Accompanying this is a float chamber, which maintains a steady supply of fuel, ensuring consistent operation under various conditions.

The jet assembly plays a vital role in mixing fuel and air, with calibrated openings that enable the right proportions for different engine demands. Additionally, an adjustable needle helps fine-tune the mixture, accommodating various operating scenarios and improving overall efficiency.

A choke is also integrated into the design, aiding in cold starts by enriching the fuel mixture. Lastly, a housing unit encases these components, providing structural integrity and protection from external elements.

How the CVK Carburetor Works

This essential device plays a pivotal role in mixing fuel and air, ensuring optimal combustion within the engine. It operates through a finely-tuned system that regulates the flow of these two vital components, contributing to efficient performance and responsiveness.

Understanding the Mechanism

The mechanism relies on a venture effect, where air passing through a narrowed section creates a drop in pressure, drawing fuel from a reservoir. This harmonious interaction is crucial for achieving the right air-fuel mixture, ultimately affecting engine output and efficiency.

Importance of Precision

Precision in this assembly is vital; even minor adjustments can lead to significant differences in performance. The ultimate goal is to maintain a stable and responsive system that adapts to varying operating conditions, ensuring reliable power delivery.

Identifying Common CVK Parts

Understanding the essential components of an engine management system can significantly enhance performance and maintenance. This section will explore the typical elements found within such systems, aiding in identification and troubleshooting.

| Component Name | Function |

|---|---|

| Throttle Valve | Regulates airflow into the engine, controlling speed and power output. |

| Float Chamber | Maintains a constant fuel level, ensuring consistent delivery to the engine. |

| Jet Needle | Adjusts the fuel-air mixture, impacting acceleration and efficiency. |

| Main Jet | Determines the amount of fuel supplied at higher speeds, affecting overall performance. |

| Choke | Enriches the fuel mixture during cold starts for easier ignition. |

| Air Filter | Prevents contaminants from entering the system, protecting internal components. |

Maintenance Tips for CVK Carbs

Proper upkeep of your fuel delivery system is crucial for optimal engine performance. Regular attention can prevent issues such as poor fuel efficiency, rough idling, and difficult starts. This section provides essential guidelines to help you maintain these vital components effectively.

Regular Cleaning

Cleaning is one of the most important aspects of maintenance. Over time, deposits and debris can accumulate, affecting performance. It is advisable to periodically disassemble the system and clean all accessible parts using a suitable solvent. Pay special attention to the jets and passages, as even minor blockages can lead to significant problems.

Check Seals and Gaskets

Inspecting seals and gaskets is essential for maintaining air and fuel integrity. Worn or damaged components can lead to leaks, which may cause erratic operation. Replace any compromised seals promptly to ensure a tight fit and proper function. Regular inspections can help you catch these issues before they escalate.

Common Issues and Troubleshooting

This section addresses frequent problems that users encounter with fuel delivery systems and offers guidance on how to resolve them effectively. Understanding these issues can enhance performance and reliability.

Performance Drops

A notable decrease in efficiency often indicates an underlying issue. Check for clogs in fuel passages or incorrect settings that may hinder optimal flow. Ensuring that all components are clean and properly adjusted is crucial for maintaining peak performance.

Difficulty Starting

If the engine struggles to start, it may be due to improper fuel mixture or air leaks. Inspect gaskets and seals for any damage and adjust the fuel-air ratio as necessary. Regular maintenance can prevent these issues and ensure smooth operation.

Upgrading Your CVK Carburetor

Enhancing your fuel delivery system can lead to significant improvements in performance and efficiency. By focusing on specific components, you can optimize the overall function, leading to a smoother ride and better throttle response. Understanding the anatomy of your system will enable you to make informed decisions about upgrades.

| Component | Benefits of Upgrading |

|---|---|

| Jetting | Improves fuel flow and tuning for better power delivery. |

| Slide Assembly | Enhances throttle response and reduces lag during acceleration. |

| Needle Valve | Provides precise fuel metering for optimal performance across RPM ranges. |

| Air Filter | Increases airflow, allowing for more efficient combustion. |

By carefully selecting and upgrading these elements, you can significantly enhance your engine’s performance and overall driving experience.

Tools Needed for CVK Repairs

When undertaking maintenance or repair tasks on your fuel management system, having the right tools at hand is crucial for efficiency and effectiveness. A well-equipped toolkit not only simplifies the process but also ensures that each component can be handled with care, minimizing the risk of damage.

| Tool | Description |

|---|---|

| Screwdriver Set | A variety of sizes and types are essential for removing and securing fasteners. |

| Wrench Set | Various sizes to fit nuts and bolts, ensuring a secure grip for adjustments. |

| Cleaning Kit | Specialized brushes and solvents to remove deposits and debris. |

| Calibration Tool | For precise adjustments, ensuring optimal performance of the system. |

| Protective Gear | Gloves and goggles to ensure safety during the repair process. |

Differences Between CVK and Other Carbs

This section explores the unique characteristics that set one type of fuel delivery system apart from its counterparts. Understanding these distinctions can enhance performance and adaptability in various applications.

Operational Mechanisms

Different systems utilize various mechanisms for fuel delivery, impacting responsiveness and efficiency. The key operational aspects vary widely between types.

Design Features

Each design offers unique advantages, which can influence installation and maintenance. Notable differences include the arrangement of components and materials used.

| Feature | Type A | Type B | Type C |

|---|---|---|---|

| Response Time | Fast | Moderate | Slow |

| Maintenance | Easy | Moderate | Difficult |

| Fuel Efficiency | High | Medium | Variable |

Performance Benefits of CVK Carbs

Enhancing engine efficiency and responsiveness can significantly elevate the overall driving experience. The unique design and functionality of these fuel delivery systems contribute to improved throttle response, smoother operation, and better fuel economy, making them a popular choice among enthusiasts.

Improved Throttle Response

One of the key advantages lies in the immediate reaction to throttle inputs. This responsiveness allows for precise control over acceleration, enhancing the rider’s connection to the machine. As a result, riders experience a more dynamic and engaging ride.

Enhanced Fuel Efficiency

Another notable benefit is the potential for better fuel consumption. By optimizing the air-fuel mixture, these systems can lead to increased mileage without sacrificing performance. This efficiency not only saves money but also reduces environmental impact.

Where to Find Replacement Parts

Locating components for your engine’s fuel delivery system can seem daunting, but there are various reliable avenues to explore. Whether you’re in need of a specific element or a complete overhaul, knowing where to search is key to a successful repair.

Online Retailers offer a vast selection of components, often at competitive prices. Websites dedicated to motorcycle or small engine maintenance frequently stock both OEM and aftermarket options. Reading customer reviews can guide you toward high-quality choices.

Local Mechanics and repair shops are another excellent resource. Many establishments maintain a supply of essential components and can provide valuable insights on which parts are best suited for your model. Building a rapport with a trusted mechanic can also lead to helpful recommendations.

Specialty Stores that focus on engine maintenance may carry the specific items you need. These shops often have knowledgeable staff who can assist in identifying the correct components and may even offer installation services.

Forums and Online Communities can be invaluable for finding rare items. Engaging with fellow enthusiasts can lead to discovering sellers or even individuals willing to part with their extra inventory. Sharing your needs on these platforms often results in useful leads.

By exploring these options, you can ensure that your engine performs optimally with the right components in place.