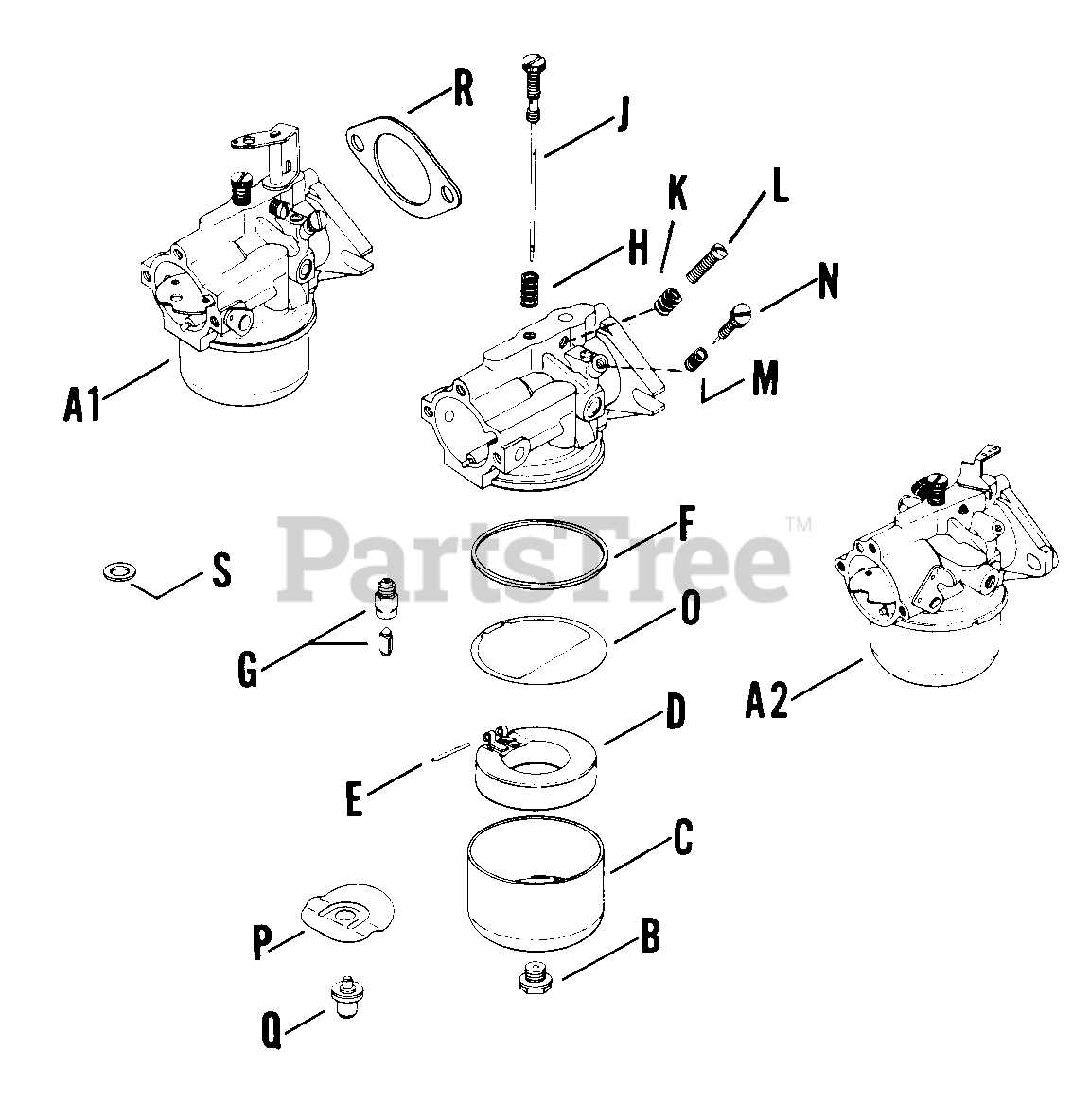

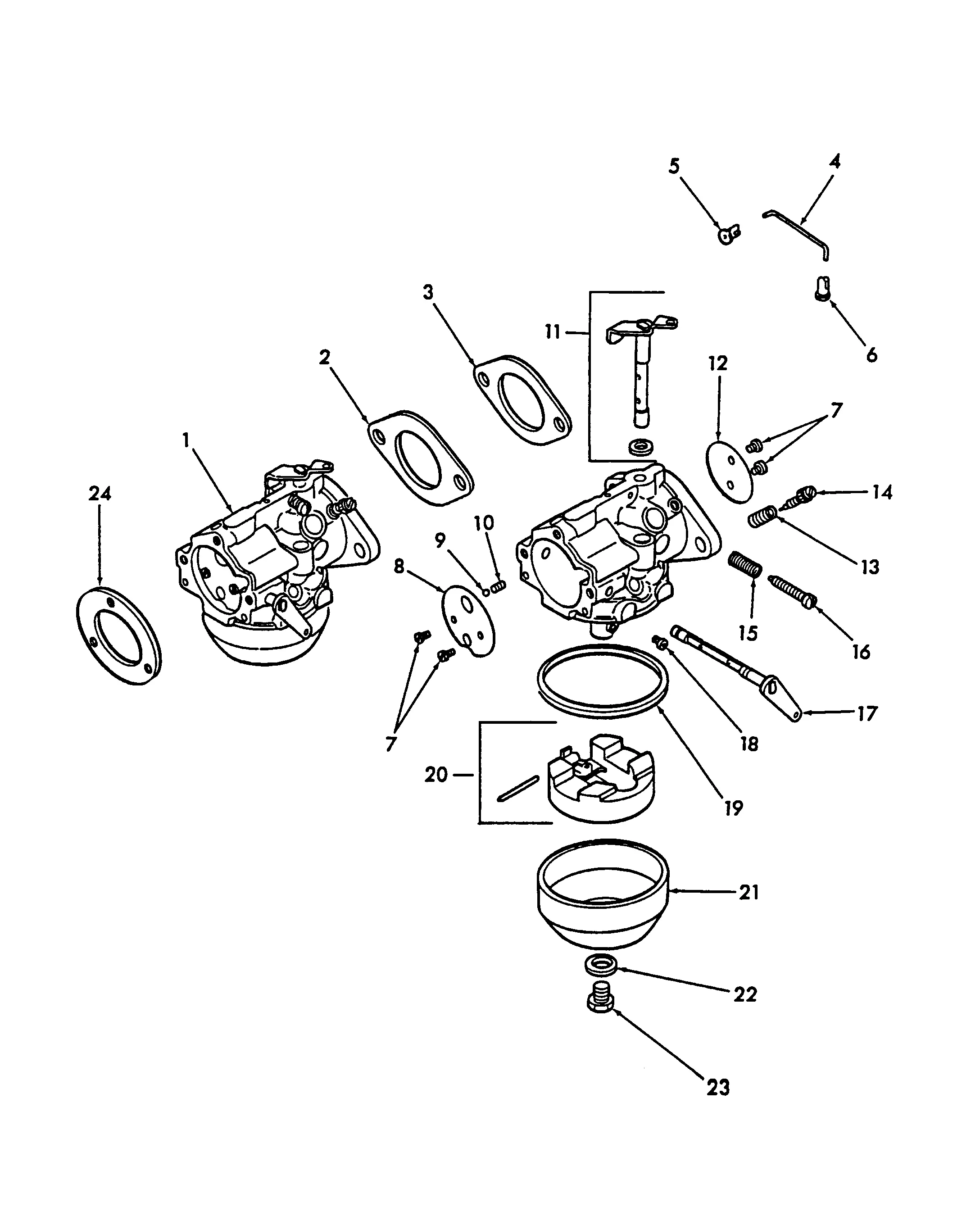

Kohler Carburetor Parts Diagram Overview

The intricate world of engine mechanisms can often seem overwhelming, yet gaining clarity on its various elements is crucial for effective maintenance and repair. This section aims to simplify the complexities surrounding essential fuel delivery systems, providing a visual guide to their functionalities and interactions.

By exploring the layout of these vital components, readers will uncover how each piece contributes to overall performance. A detailed examination can enhance understanding, ultimately leading to more informed decisions during servicing.

Whether you are a seasoned technician or a curious enthusiast, grasping these intricacies can elevate your skills. Dive in to explore the ultimate resource that demystifies the essential workings of fuel systems.

Kohler Carburetor Overview

This section provides a comprehensive insight into the essential fuel mixing device that plays a crucial role in engine performance. Understanding its components and functionality is vital for effective maintenance and troubleshooting.

The mechanism is designed to ensure the proper blend of air and fuel, allowing for optimal combustion within the engine. Familiarity with its design and operation can enhance efficiency and extend the lifespan of the machinery.

| Component | Description |

|---|---|

| Float Chamber | Regulates fuel supply to the mixing area. |

| Jet Assembly | Controls the flow of fuel into the air stream. |

| Throttle Plate | Regulates airflow and engine speed. |

| Choke Mechanism | Aids in starting the engine by enriching the fuel mixture. |

| Gaskets | Provide sealing to prevent leaks and ensure efficiency. |

Common Issues with Kohler Carburetors

Engines often face challenges that can hinder their performance, leading to frustration for users. Understanding the typical problems associated with fuel delivery systems can help in diagnosing and resolving issues efficiently. These systems are critical for optimal engine operation, and even minor faults can result in significant performance drops.

Fuel Flow Restrictions

One prevalent issue is the restriction of fuel flow, which can be caused by clogged filters or contaminated fuel. Such blockages lead to inadequate fuel reaching the engine, resulting in stalling or difficulty starting. Regular maintenance and timely replacements of filters can mitigate this problem.

Air-Fuel Mixture Imbalances

Another common concern involves imbalances in the air-fuel mixture. If the blend is too rich or too lean, it can cause poor combustion, leading to rough idling or excessive emissions. Adjustments may be necessary to restore the correct proportions, ensuring smoother operation and better efficiency.

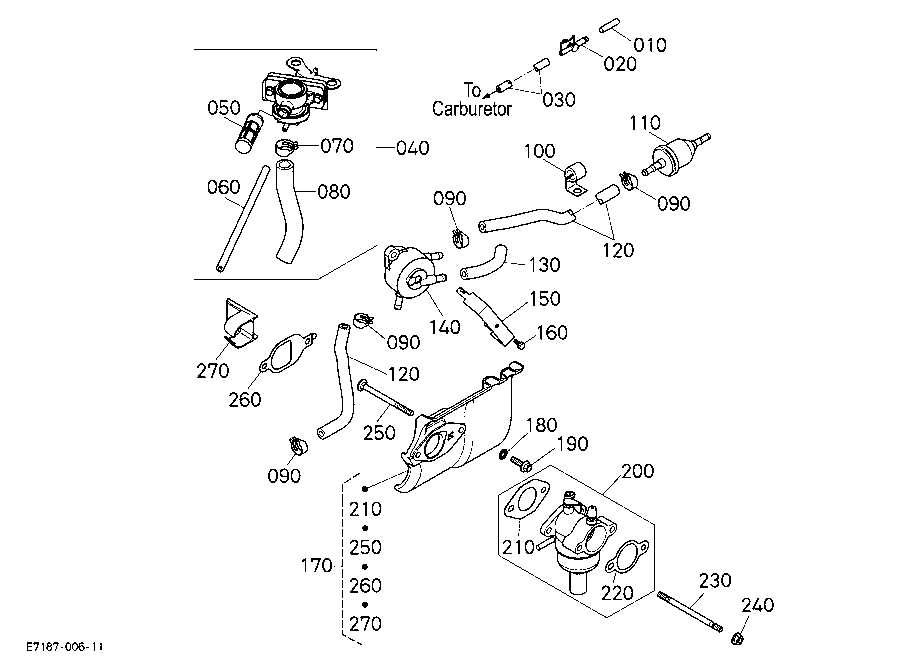

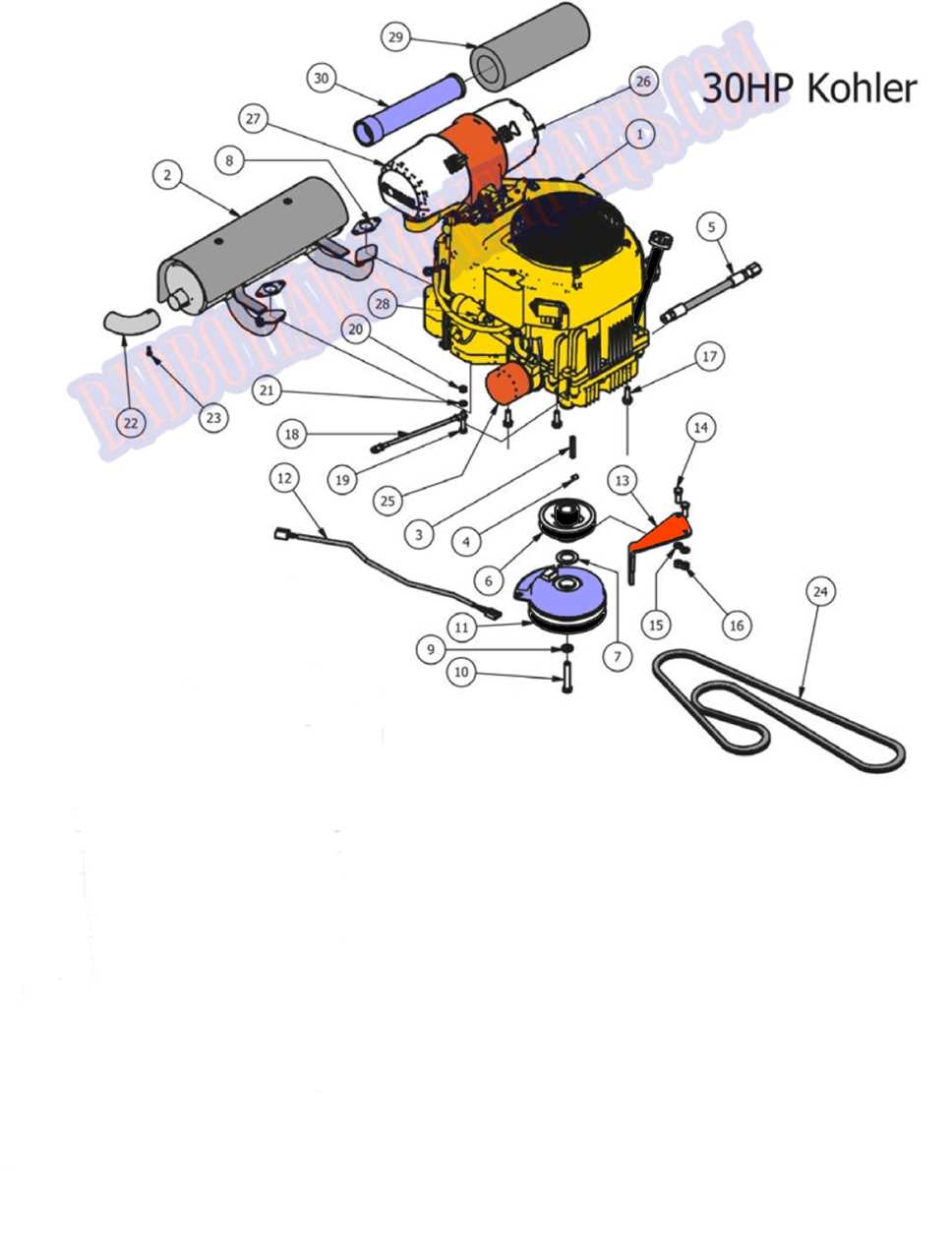

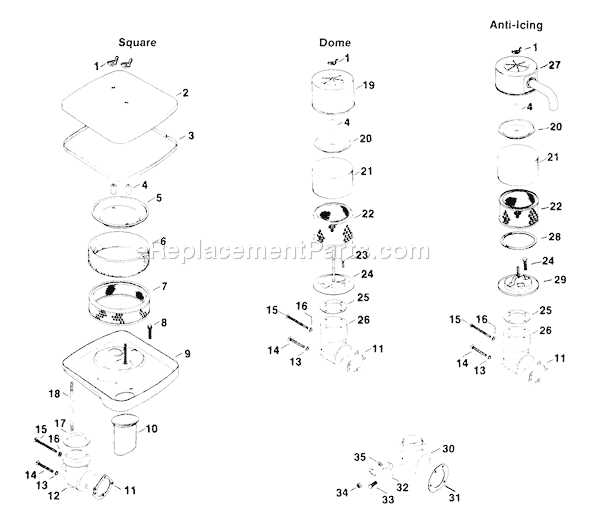

Parts Identification for Kohler Models

Understanding the components of engine systems is crucial for maintenance and repair. Each model has its unique assembly, requiring precise identification of individual elements to ensure optimal performance. By familiarizing oneself with these components, users can more effectively troubleshoot issues and conduct necessary replacements.

When examining the various sections of these engines, it’s essential to recognize key features that distinguish one model from another. These can include different shapes, sizes, and connection points that are tailored to specific functions. Proper identification aids in sourcing the correct components, enhancing overall efficiency and longevity of the equipment.

Familiarity with the arrangement and interaction of each segment contributes significantly to successful repairs. Detailed reference materials are available to assist in identifying these components accurately, ensuring that users have the right information at their fingertips. This knowledge empowers individuals to make informed decisions when it comes to service and upkeep.

How to Read Carburetor Diagrams

Understanding the layout and components of an engine’s fuel delivery system is essential for effective maintenance and troubleshooting. Familiarity with the graphical representations of these systems can significantly enhance your ability to identify and resolve issues.

Here are some key tips to effectively interpret these visuals:

- Familiarize Yourself with Common Symbols: Each component is usually represented by a specific icon. Knowing these can help you quickly locate parts.

- Follow the Flow: Most illustrations depict the flow of fuel or air. Understanding the sequence can clarify how the system operates.

- Check for Labels: Many diagrams include labels or legends that provide important information about each part’s function and connection.

- Identify Connections: Pay attention to how components are interconnected, as this can reveal potential areas for blockage or failure.

- Use a Reference Guide: Keep a reference book or online resource handy to look up any unfamiliar terms or symbols.

By honing your skills in reading these illustrations, you can make informed decisions during repairs and enhance the performance of your engine.

Maintenance Tips for Kohler Carburetors

Proper upkeep of fuel management systems is essential for optimal engine performance and longevity. Regular attention to various components ensures smooth operation and prevents common issues that can arise from neglect.

Start with routine inspections to identify signs of wear or damage. Clean the assembly periodically to remove dirt and debris that can impede functionality. Ensure all connections are secure, as loose fittings can lead to air leaks and affect efficiency.

Check the fuel filter regularly and replace it as needed to maintain clean fuel flow. Adjust settings according to the manufacturer’s specifications to ensure precise fuel delivery. Lubricate moving parts to minimize friction and extend the life of the mechanism.

Lastly, consider using high-quality fuel to reduce the buildup of harmful deposits, and always consult the manufacturer’s guidelines for specific maintenance recommendations tailored to your equipment.

Essential Tools for Carburetor Repair

Having the right instruments on hand is crucial for effectively addressing issues with fuel delivery systems. These tools not only facilitate a smooth repair process but also ensure that the components are handled correctly and efficiently.

Here’s a list of essential tools that can make the task much easier:

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are necessary for removing and tightening screws.

- Wrenches: Both adjustable and fixed wrenches are vital for loosening and tightening various fittings.

- Socket Set: A complete socket set allows for easy access to nuts and bolts in tight spaces.

- Needle-Nose Pliers: Useful for gripping small parts and reaching into confined areas.

- Cleaners and Solvents: Effective for degreasing and removing dirt from components, ensuring everything operates smoothly.

- Gaskets and Seals: Having replacements on hand can prevent leaks and ensure a proper seal.

- Compression Tester: Helps to assess the performance of the system and diagnose issues.

- Vacuum Gauge: Essential for testing vacuum pressure and identifying potential problems.

Equipping yourself with these tools can greatly enhance your ability to perform repairs, allowing for a thorough inspection and adjustment of all necessary elements involved in fuel management systems.

Aftermarket vs. Original Parts Comparison

When considering components for machinery maintenance, the choice between standard and alternative options can significantly impact performance and longevity. Each type offers unique advantages and potential drawbacks, making it essential to understand their implications for functionality and cost-effectiveness.

Quality and Performance

Standard components are typically manufactured to meet specific factory standards, ensuring compatibility and reliability. In contrast, alternative options may vary in quality, with some providing exceptional performance while others could lead to inefficiencies.

Cost Implications

Pricing is a crucial factor when selecting components. While standard options often come with a higher price tag, alternative choices can provide significant savings. However, these savings may come at the risk of reduced durability or increased maintenance requirements.

| Factor | Standard Options | Alternative Options |

|---|---|---|

| Quality | High reliability | Varied quality |

| Performance | Consistent | Inconsistent |

| Cost | Higher | Lower |

| Durability | Long-lasting | Potentially shorter |

Signs Your Carburetor Needs Attention

Understanding when your engine’s fuel delivery system requires maintenance is crucial for optimal performance. Various symptoms can indicate that something is amiss, affecting efficiency and reliability. Recognizing these signs early can prevent further complications and costly repairs.

Unusual Engine Performance

If you notice stalling, rough idling, or difficulty starting, it may suggest an underlying issue. These performance irregularities often stem from improper fuel flow or air mixture problems. Pay close attention to how the engine responds during acceleration; hesitation or sputtering can signal the need for immediate inspection.

Increased Fuel Consumption

Another telling sign is a noticeable rise in fuel usage. If your vehicle or machinery is consuming more fuel than usual, it might indicate inefficiencies in the fuel delivery mechanism. This increase not only affects your wallet but also suggests that the engine is not operating as intended. Timely evaluation can help restore balance and improve overall function.

In summary, being aware of these indicators can help you maintain your engine’s health. Regular checks and maintenance are key to ensuring longevity and performance.

Understanding Carburetor Fuel Systems

A fuel delivery system is crucial for the optimal performance of internal combustion engines. It ensures the correct mixture of fuel and air reaches the combustion chamber, facilitating efficient operation and energy generation. Understanding the components and their interactions can help troubleshoot issues and enhance engine performance.

| Component | Function |

|---|---|

| Fuel Bowl | Holds a reserve of fuel for the system. |

| Venturi | Creates a vacuum to draw fuel into the air stream. |

| Jets | Control the flow of fuel into the airstream. |

| Float | Regulates the fuel level in the bowl. |

| Throttle Valve | Controls the amount of air-fuel mixture entering the engine. |

By examining each component and its role, one can delve deeper into optimizing performance and resolving potential issues within the fuel system.

Steps for Proper Carburetor Installation

Ensuring the correct setup of the fuel delivery system is crucial for optimal engine performance. Following a systematic approach can help achieve a seamless installation, minimizing potential issues and enhancing functionality.

Preparation and Inspection

Begin by gathering all necessary tools and components. Carefully inspect each element for wear or damage, as this can affect overall performance. Make sure to clean all surfaces to ensure a proper seal and prevent debris from entering the system.

Installation Procedure

Start by aligning the assembly with the designated mounting points. Tighten the fasteners in a crisscross pattern to ensure even pressure. It’s essential to adhere to the manufacturer’s specifications regarding torque settings. After securing, double-check all connections, including fuel lines and gaskets, to confirm everything is properly seated.