Understanding the Motorcycle Carburetor Parts Diagram

The intricate mechanisms that ensure optimal performance in two-wheeled vehicles are often overlooked. These systems play a crucial role in delivering the right mix of fuel and air to the engine, enhancing efficiency and power. A deeper exploration reveals the various components that work in harmony to achieve this balance.

Each element within this assembly has a specific function, contributing to the overall operation and maintenance of the vehicle. By examining the layout and relationships between these elements, enthusiasts and mechanics alike can gain valuable insights into troubleshooting and performance enhancement. Understanding these connections is essential for anyone looking to optimize their ride.

Visual aids can significantly enhance comprehension, allowing for a clearer grasp of how each section interacts with the others. By breaking down these systems into their fundamental components, one can appreciate the engineering marvel that enables the smooth operation of these machines. Whether for maintenance or modification, a thorough knowledge of these vital systems empowers riders to take control of their vehicles.

Understanding Motorcycle Carburetor Basics

Grasping the fundamentals of fuel delivery systems is essential for any enthusiast. These mechanisms play a crucial role in mixing air and fuel for optimal engine performance. A well-functioning assembly ensures efficient combustion, contributing to speed and responsiveness on the road.

Key components include those responsible for regulating airflow and liquid flow. Understanding their interactions can enhance tuning and maintenance efforts. Proper adjustments lead to improved throttle response and fuel efficiency, making the riding experience more enjoyable.

Moreover, recognizing the signs of wear or malfunction can prevent larger issues. Regular inspection of the assembly is advisable, as it can reveal critical insights into overall engine health. A knowledgeable approach allows for timely interventions, ensuring longevity and reliability.

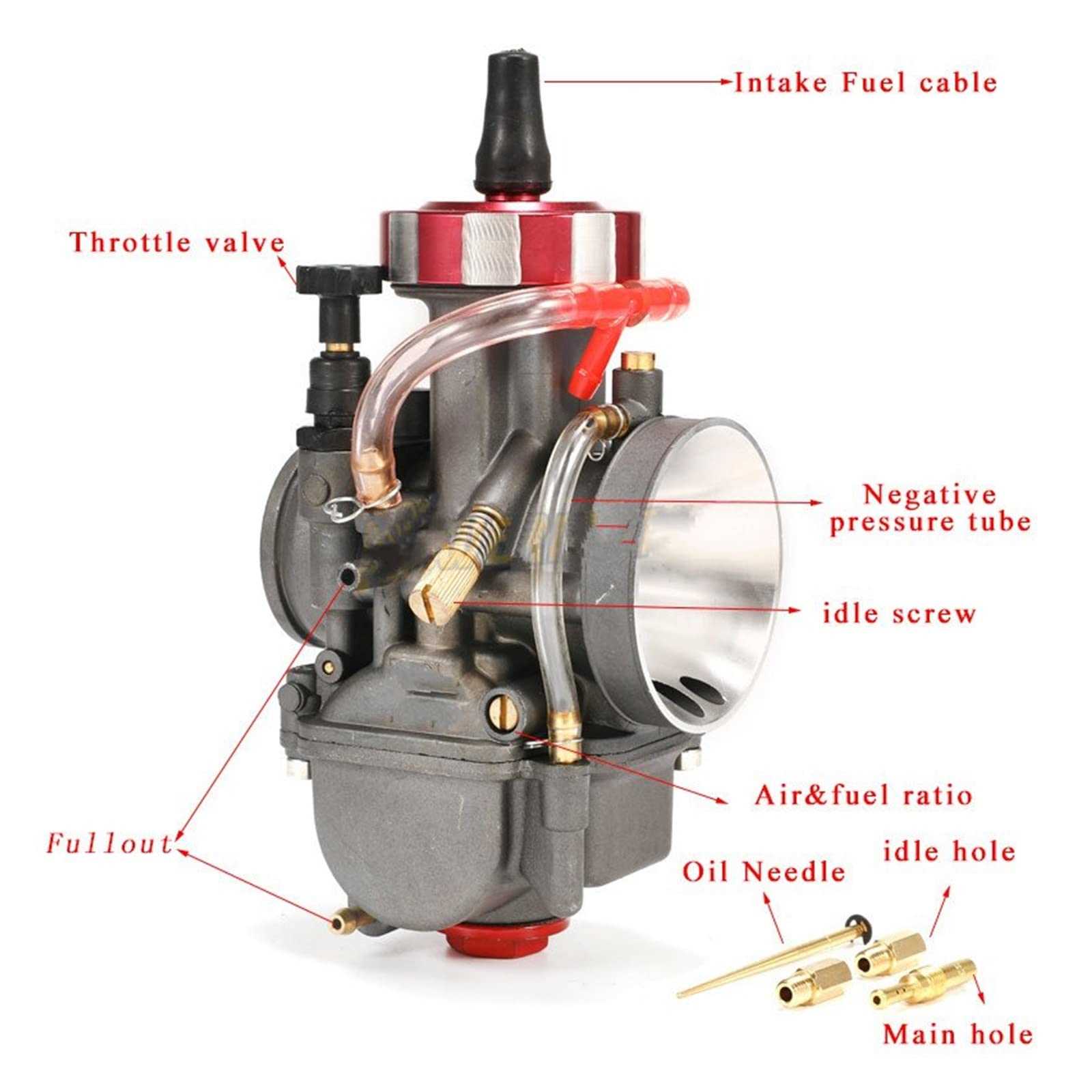

Key Components of a Carburetor

Understanding the essential elements of an air-fuel mixing device is crucial for maintaining optimal engine performance. Each component plays a significant role in ensuring efficient combustion, contributing to the overall functionality of the system. Below are the primary elements that work together to regulate the flow and mixture of fuel and air.

Essential Elements

The main components include a throttle, float chamber, jet system, and more. Each of these parts interacts to facilitate the precise delivery of fuel and air, ultimately influencing the engine’s power output and responsiveness.

Component Overview

| Component | Function |

|---|---|

| Throttle | Regulates the air-fuel mixture entering the engine based on demand. |

| Float Chamber | Maintains a consistent fuel level for reliable operation. |

| Jets | Control the amount of fuel delivered into the airflow, influencing the mixture ratio. |

| Choke | Reduces airflow during cold starts, enriching the mixture for easier ignition. |

| Venturi | Creates a vacuum to draw fuel into the airflow, aiding in proper mixing. |

How Carburetors Function in Engines

In internal combustion systems, a vital mechanism blends air and fuel to create a combustible mixture essential for engine operation. This process ensures optimal performance by regulating the flow of each component, adapting to various conditions to maintain efficiency.

The core functionality revolves around principles of airflow and pressure differentials. As air enters the system, it moves through a narrowing section, causing a drop in pressure. This drop draws in fuel from a reservoir, allowing for precise mixing before it enters the combustion chamber.

| Function | Description |

|---|---|

| Air Intake | Air is drawn into the system, creating a necessary flow for combustion. |

| Pressure Regulation | The narrowing section lowers pressure, facilitating fuel intake. |

| Fuel Mixing | Air and fuel are combined in the right proportions for combustion. |

| Atomization | Fuel is atomized into fine droplets for efficient burning. |

This mechanism is crucial for achieving the ultimate efficiency and power output in any engine, allowing for smooth operation across different speeds and loads.

Types of Carburetors for Motorcycles

When it comes to optimizing fuel-air mixtures for two-wheeled machines, various designs play a crucial role in performance and efficiency. Each design serves distinct functions, catering to different engine requirements and rider preferences.

Here are some common types:

- Constant Velocity – These systems maintain a consistent airflow, providing smoother acceleration and better performance across a range of speeds.

- Slide Valve – Utilizing a slide mechanism, this type allows for quick adjustments to the air-fuel mixture, making it popular among sport enthusiasts.

- Diaphragm – Known for their simplicity and reliability, diaphragm designs are often found in entry-level models, offering decent performance for everyday use.

- Electronic Fuel Injection – Although not a traditional design, this modern approach automates fuel delivery, ensuring optimal performance under varying conditions.

Choosing the right design is essential for enhancing the overall riding experience. Each type presents unique advantages and is suited for different applications, whether for racing, touring, or casual riding.

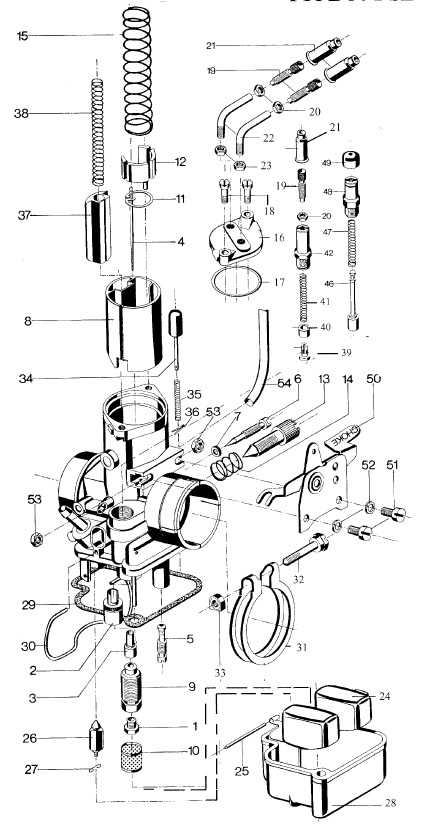

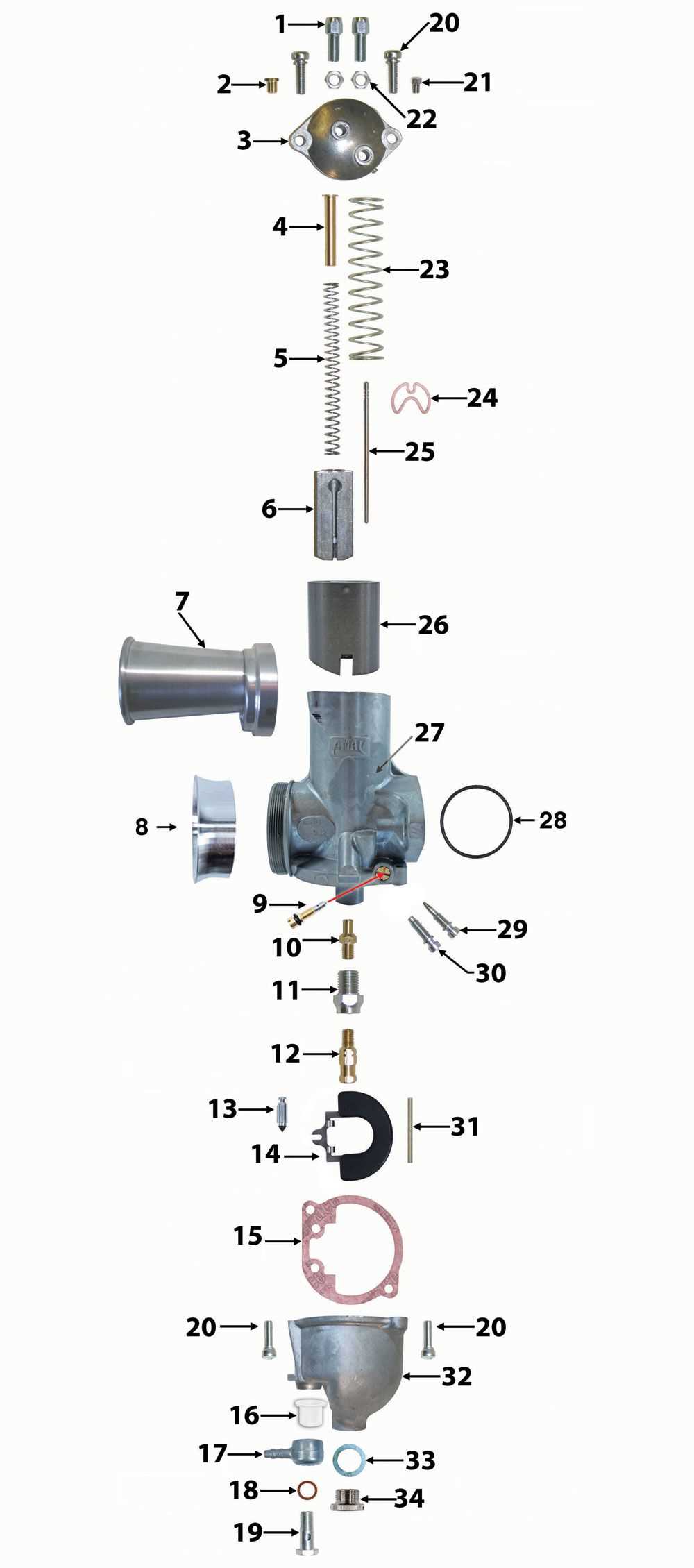

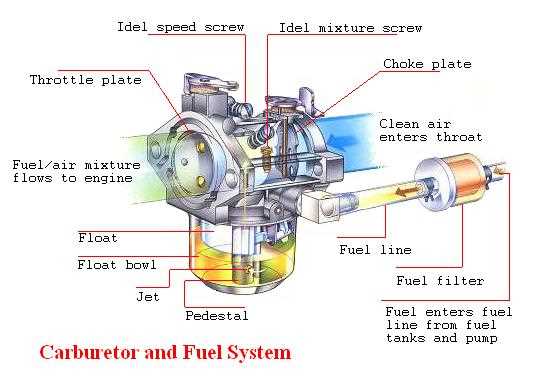

Identifying Carburetor Parts Diagram

This section focuses on understanding the essential components involved in the fuel delivery system of certain vehicles. Recognizing these elements is crucial for maintenance and troubleshooting, ensuring optimal performance and longevity.

Key Components

- Throttle Valve

- Float Chamber

- Jet Nozzle

- Choke Mechanism

Functions of Each Element

- Throttle Valve: Regulates air-fuel mixture flow.

- Float Chamber: Maintains consistent fuel levels.

- Jet Nozzle: Delivers the precise amount of fuel.

- Choke Mechanism: Aids in starting by enriching the mixture.

Fuel Delivery System Overview

The fuel delivery system is a critical component in the operation of any internal combustion engine, responsible for providing the necessary mixture of fuel and air for combustion. Its efficiency and functionality directly influence performance, emissions, and overall engine health.

Key Components

- Fuel Tank

- Fuel Pump

- Fuel Filter

- Mixing Chamber

- Throttle Valve

Operation Process

- Fuel is drawn from the storage unit.

- The pump transports it to the filtering system.

- Clean fuel enters the mixing chamber.

- The air-fuel mixture is adjusted through the throttle valve.

- The mixture is delivered to the engine for combustion.

Air-Fuel Mixture Importance

The balance between air and fuel in an internal combustion engine is crucial for optimal performance. This mixture directly influences power output, efficiency, and emissions. Achieving the right ratio ensures smooth operation and responsiveness, while deviations can lead to issues such as knocking or stalling.

An ideal blend promotes complete combustion, maximizing energy extraction from the fuel. Conversely, a rich mixture can waste fuel and create harmful pollutants, while a lean mixture may cause overheating and potential engine damage. Understanding this balance is essential for maintaining the longevity and functionality of the engine.

Common Issues with Carburetors

Understanding frequent challenges associated with fuel delivery systems is essential for maintaining optimal engine performance. These complications can arise from various factors, affecting efficiency and responsiveness. Identifying and addressing these issues can lead to smoother operation and enhanced reliability.

One prevalent issue is the buildup of deposits within the system. This can occur due to the accumulation of dirt and contaminants in the fuel, leading to restricted flow and inconsistent performance. Regular cleaning and maintenance can help mitigate this problem.

Another common challenge involves improper tuning. If the fuel-to-air mixture is not calibrated correctly, it can result in poor acceleration, stalling, or excessive fuel consumption. Regular adjustments and inspections are crucial to ensure the system operates within the correct parameters.

Additionally, wear and tear on seals and gaskets can lead to leaks, which compromise the overall efficiency of the system. Detecting these leaks early through visual inspection or testing can save time and resources in the long run.

Lastly, vapor lock can occur, especially in warmer conditions, where fuel vaporizes before reaching the combustion chamber. This can cause starting issues or engine stalling. Utilizing insulated lines and ensuring proper routing can help alleviate this concern.

Maintenance Tips for Carburetor Longevity

Proper upkeep is essential for ensuring optimal performance and extending the lifespan of your engine’s fuel management system. Regular attention to certain areas can prevent issues and maintain efficiency.

- Regular Cleaning: Clean the fuel delivery components periodically to prevent build-up and ensure smooth operation.

- Check Fuel Quality: Use high-quality fuel to reduce the risk of contaminants affecting functionality.

- Inspect Gaskets: Replace worn or damaged seals to prevent leaks and maintain proper pressure.

By following these tips, you can delve deeper into enhancing the performance and durability of your fuel management system.

Adjusting Carburetor Settings Effectively

Fine-tuning the mixture and flow of fuel and air is essential for optimal engine performance. Proper adjustments can lead to smoother operation, improved efficiency, and enhanced responsiveness. Understanding the fundamental aspects of these settings will enable you to achieve the best results and maintain your vehicle in peak condition.

Understanding the Basics

To effectively modify the mixture, you must first familiarize yourself with the components involved. Each element plays a crucial role in regulating fuel flow and ensuring the correct ratio with air. Paying close attention to the throttle response and idle speed will provide valuable insights into the current settings and where adjustments are necessary.

Step-by-Step Adjustment Process

1. Warm Up: Before making any modifications, allow the engine to reach its optimal operating temperature. This ensures accurate readings during the adjustment process.

2. Check Idle Speed: Begin by measuring the idle speed. Adjust the idle screw to achieve the recommended RPM, which can vary depending on the model.

3. Mixture Tuning: Gradually adjust the mixture screw while monitoring engine performance. Turning it clockwise usually enriches the mixture, while counterclockwise leans it out. Listen for changes in the engine’s sound and responsiveness.

4. Test Ride: After making adjustments, take the vehicle for a test ride. Observe how it accelerates and responds under different conditions. Make further tweaks as needed, keeping in mind that fine adjustments can make a significant difference.

By following these steps and being attentive to changes in performance, you can achieve a well-balanced setup that maximizes your vehicle’s potential.

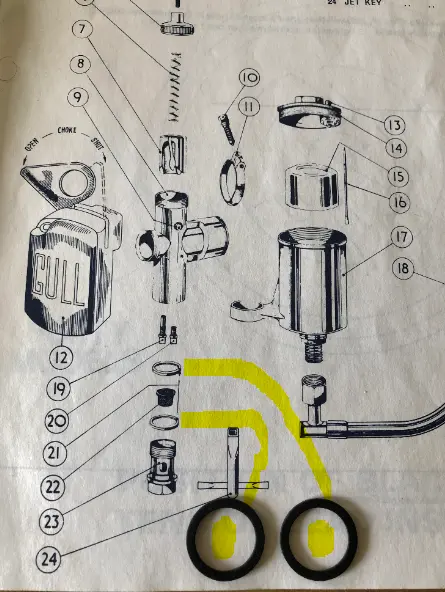

Replacing Worn Carburetor Parts

Regular maintenance is essential for optimal performance and longevity of your engine’s fuel system. Over time, certain components may wear out, leading to inefficiency and operational issues. Identifying and replacing these deteriorated elements is crucial for restoring functionality and enhancing overall performance.

Inspection is the first step in the replacement process. Carefully examine each element for signs of damage, such as cracks, corrosion, or unusual wear. Pay close attention to seals and gaskets, as they are often the first to fail and can cause leaks that disrupt the fuel delivery system.

Once you’ve identified the worn components, proceed with replacement. Ensure you use high-quality, compatible replacements to avoid future complications. Follow manufacturer guidelines during installation to maintain proper function and avoid additional issues down the line.

Finally, after replacing the necessary components, test your engine to ensure everything operates smoothly. Regular upkeep and timely replacements will significantly enhance performance and reliability.

Tools Needed for Carburetor Repair

Repairing the fuel delivery system of your two-wheeled vehicle requires a specific set of instruments to ensure efficiency and accuracy. Understanding the necessary tools will streamline the process and lead to better results.

Essential Instruments

- Socket Wrench Set

- Flat and Phillips Screwdrivers

- Needle-Nose Pliers

- Adjustable Wrench

- Torque Wrench

Additional Helpful Tools

- Clean Rags

- Fuel Line Cutters

- Vacuum Gauge

- Small Brushes for Cleaning

- Service Manual for Reference

Having the right tools at hand not only facilitates the repair but also enhances the overall experience, making it both efficient and enjoyable.

Choosing the Right Carburetor Model

Selecting the appropriate fuel delivery system is crucial for optimal performance and efficiency. Various models offer distinct features that can significantly impact the overall functionality of your vehicle. Understanding these differences is essential for making an informed decision.

Firstly, consider the engine specifications, as the right model must match the power output and design of your engine. Size and flow rate are key factors that influence performance, so ensure compatibility with your existing setup.

Additionally, think about the riding conditions you typically encounter. If you often ride in varied environments, a more versatile model may be necessary. Ease of tuning and maintenance should also play a role in your selection process, as a user-friendly option can enhance your experience.

Finally, research the available options from reputable manufacturers. Look for reviews and recommendations that highlight reliability and performance, as choosing a trusted brand can lead to long-term satisfaction.