Nikki 6100 Carburetor Parts Diagram Guide

In the intricate world of internal combustion engines, the efficiency of fuel delivery is paramount. A well-optimized system ensures not only peak performance but also longevity of the engine itself. For enthusiasts and professionals alike, a clear comprehension of the individual elements that contribute to this system can significantly enhance maintenance and repair practices.

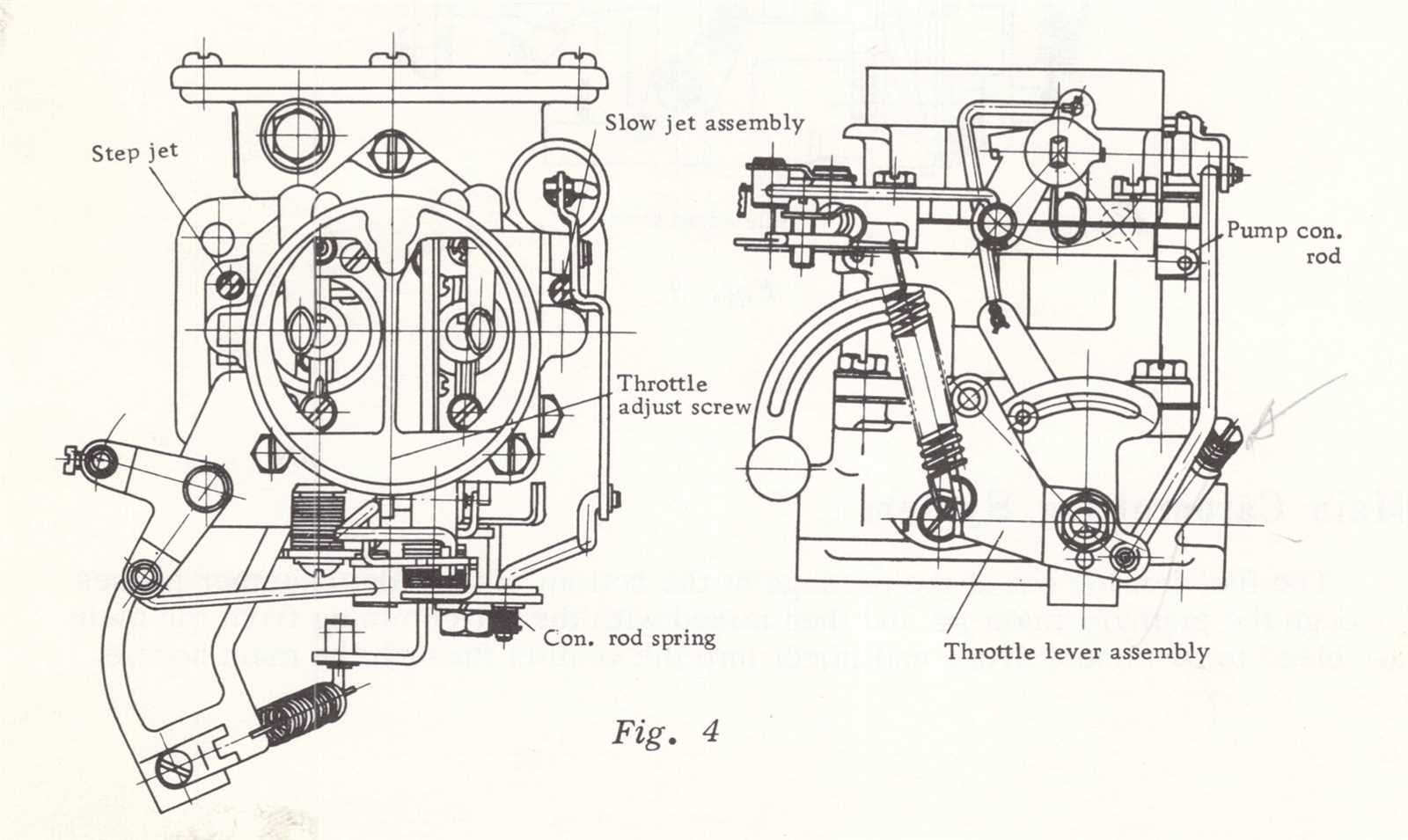

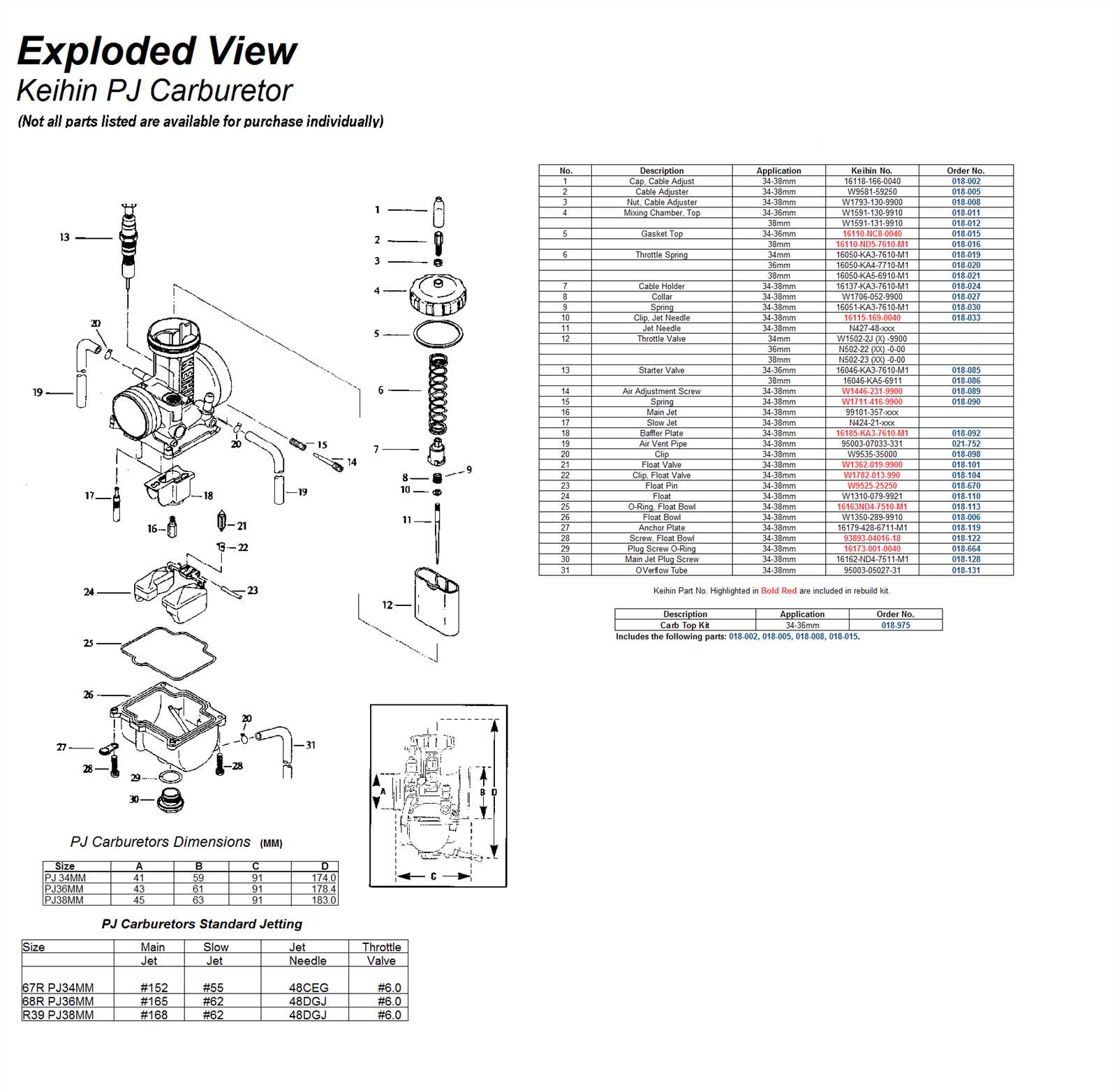

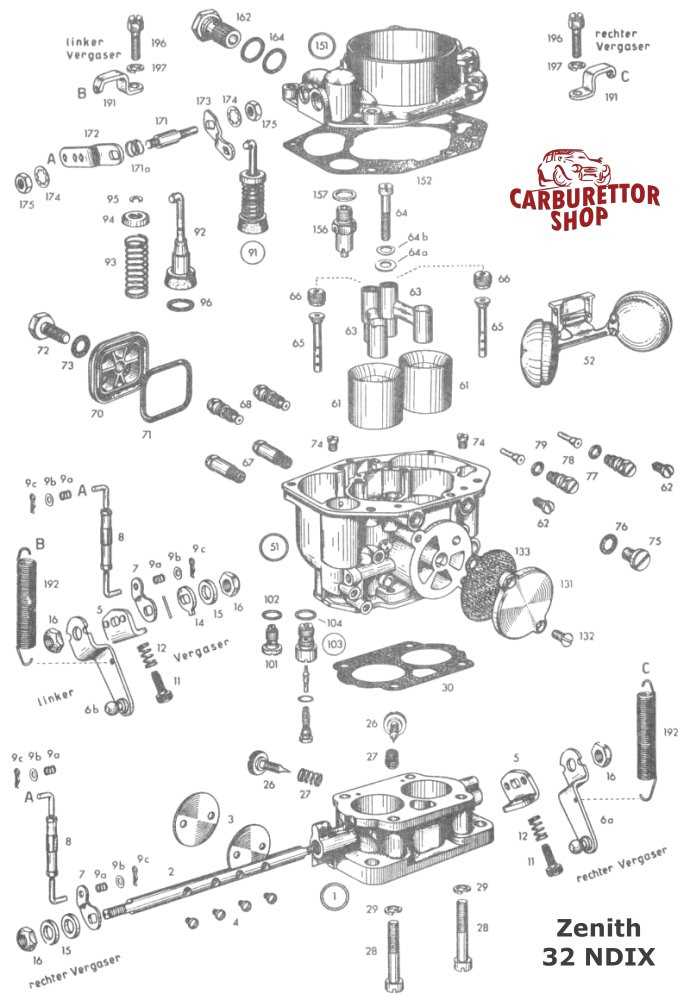

Visual aids play a crucial role in deciphering the layout and function of these components. By examining detailed illustrations, one can easily identify how each piece interacts within the broader assembly. This knowledge not only aids in troubleshooting but also empowers users to make informed decisions during upgrades or replacements.

Whether you are working on a vintage model or a modern counterpart, understanding these mechanical intricacies allows for better handling of common issues. Grasping the specific roles and arrangements of these elements can lead to improved diagnostics and more efficient repairs, ultimately resulting in a smoother operating experience.

Nikki 6100 Carburetor Overview

This section provides an in-depth look at a specific type of fuel delivery device, which plays a crucial role in engine performance. Designed for efficiency and precision, this mechanism ensures optimal fuel-air mixture, enhancing combustion and overall engine responsiveness.

Constructed with various components, this system operates seamlessly to maintain the necessary balance for smooth functionality. Each element is engineered to withstand wear and tear, contributing to durability and long-term reliability.

Key features include adjustable settings for tuning performance, allowing users to customize operation according to specific requirements. Moreover, the device’s design facilitates easy maintenance, ensuring that users can perform necessary checks and adjustments without extensive expertise.

In summary, understanding this mechanism is essential for anyone interested in maximizing engine efficiency and performance. Familiarity with its structure and operation will enable users to appreciate its role in modern machinery.

Importance of Carburetor Maintenance

Regular upkeep of fuel delivery systems is essential for optimal engine performance and longevity. Neglecting this aspect can lead to a range of issues, including reduced efficiency and increased wear and tear. Understanding the significance of routine care can help in avoiding costly repairs and ensuring smooth operation.

Enhancing Performance

Well-maintained fuel management mechanisms promote better combustion and power output. By ensuring that components are clean and functioning correctly, the engine can operate at its peak capacity. This not only enhances acceleration but also contributes to improved fuel economy, making it crucial for both performance enthusiasts and everyday users alike.

Preventing Damage

Ignoring maintenance can result in the buildup of deposits and other harmful substances, leading to blockages and malfunctions. These issues can escalate quickly, causing significant damage to the engine and related systems. Regular checks and cleaning are vital to prevent these complications, ensuring a reliable and efficient operation.

In conclusion, prioritizing the upkeep of fuel delivery systems is key to maximizing performance and extending the lifespan of the engine. Embracing a proactive approach can save time, money, and frustration in the long run.

Identifying Nikki 6100 Components

Understanding the various elements of a fuel delivery system is essential for optimal performance and maintenance. Each component plays a critical role in the overall functionality, contributing to efficient operation and fuel management. Familiarity with these individual parts helps in troubleshooting and ensuring the longevity of the entire mechanism.

Body: The main structure houses all other elements and facilitates the flow of fuel. Its design influences the performance characteristics and is often where issues may first arise.

Float Chamber: This component regulates the fuel level within the assembly, ensuring a consistent supply. Recognizing its condition can prevent flooding or starvation scenarios.

Throttle Valve: Responsible for controlling the airflow, this part significantly affects engine responsiveness. Proper adjustment is vital for achieving the desired acceleration and power output.

Jet System: The jets are crucial for determining the fuel mixture. Different sizes and configurations can significantly alter performance and fuel efficiency, making it essential to understand their specifications.

Mixture Screw: This adjustment feature fine-tunes the air-fuel ratio, impacting combustion quality. Regular checks can enhance performance and fuel economy.

By recognizing these key components, one can better navigate the complexities of maintenance and repairs, ultimately leading to improved functionality and performance of the system.

Common Issues with Nikki Carburetors

Many enthusiasts encounter various challenges with these fuel delivery systems over time. Understanding the frequent problems can help in troubleshooting and maintaining optimal performance.

Fuel Leaks: One of the most common concerns is fuel leakage, which can occur due to worn gaskets or improper sealing. This can lead to reduced efficiency and potential safety hazards.

Clogged Jets: Blockages in the fuel jets can severely affect the mixture, resulting in poor engine performance. Regular cleaning and maintenance are essential to prevent this issue.

Sticking Floats: Floats that become stuck can disrupt fuel levels, causing either flooding or insufficient fuel supply. Ensuring they move freely is crucial for proper operation.

Misadjusted Settings: Incorrect air-fuel mixture settings can lead to rough idling or stalling. Regular adjustments based on specific requirements can alleviate these symptoms.

Vapor Lock: In hot conditions, vapor lock can occur, where the fuel vaporizes before reaching the engine. This can be mitigated through proper insulation and routing of fuel lines.

Addressing these issues promptly can enhance the longevity and performance of your equipment, ensuring a smoother and more efficient operation.

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone looking to maintain or repair machinery. These visuals serve as a roadmap, guiding users through the various components and their relationships. Familiarity with these graphics enables effective troubleshooting and assembly, ensuring that each element is correctly identified and utilized.

Start by familiarizing yourself with the legend or key, which often indicates the function and identification of different components. This section can help clarify any symbols or numbers that appear throughout the illustration. Next, pay attention to the layout, as it typically represents how parts fit together, often following the order of assembly.

As you examine the image, take note of the numbering system, which usually correlates with a list of components. This list can provide detailed descriptions, part numbers, and quantities, making it easier to procure replacements if necessary. Understanding the spatial arrangement of components is also crucial, as it can reveal how different elements interact during operation.

Lastly, consider any accompanying notes or annotations that might provide additional context or troubleshooting tips. These insights can be invaluable in understanding how to effectively address issues or perform maintenance tasks. By mastering the art of reading these illustrations, you can enhance your repair skills and ensure your equipment operates smoothly.

Essential Tools for Repairing Carburetors

Proper maintenance and repair of fuel delivery systems require a specific set of instruments. Utilizing the right tools ensures efficiency and precision, leading to successful adjustments and restorations. Here is a list of essential instruments to have on hand when undertaking such tasks.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing and tightening screws in various components. |

| Socket Wrench | To access nuts and bolts that secure assembly parts. |

| Needle-Nose Pliers | For gripping and manipulating small components. |

| Cleaning Brushes | To clear debris from intricate passages and surfaces. |

| Feeler Gauges | For measuring gaps and ensuring precise settings. |

| Fuel Line Disconnect Tool | To safely detach fuel lines without damage. |

| Compression Tester | To assess engine compression and diagnose issues. |

| Vacuum Gauge | For evaluating the performance of the system under various conditions. |

Equipping yourself with these instruments can significantly enhance the effectiveness of your repairs and maintenance tasks. Each tool serves a unique purpose, contributing to the overall success of the process.

Step-by-Step Disassembly Guide

This section provides a comprehensive procedure for dismantling a specific type of fuel management device. Following these instructions carefully will ensure that each component is handled properly, minimizing the risk of damage and facilitating easier reassembly.

Preparation

Before beginning the disassembly process, gather all necessary tools and materials. Ensure your workspace is clean and well-organized to avoid losing small components. Here’s a list of essential items you will need:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing screws |

| Wrench | To loosen and remove fasteners |

| Cleaning Cloth | For wiping down components |

| Container | To store small parts securely |

Disassembly Steps

Begin by ensuring that the unit is completely cool and free from any residual fuel. Follow these steps in order:

- Remove the outer casing by unscrewing the retaining screws.

- Carefully detach the air intake assembly, noting the orientation for reassembly.

- Unscrew the main assembly and gently lift it out.

- Take apart any additional components such as gaskets and valves, placing them in your container.

- Inspect each part for wear or damage, cleaning as necessary.

Once disassembly is complete, you will have access to all internal mechanisms for maintenance or replacement. Proceed with caution and follow best practices for storage and handling to ensure longevity of the device.

Reassembly Tips for Optimal Performance

Achieving peak functionality after disassembly requires careful attention during the reassembly process. Each component plays a vital role in overall efficiency, and proper handling can significantly impact performance. Follow these guidelines to ensure a smooth and effective reconstruction.

Cleanliness is Key

Before reassembling, ensure all components are thoroughly cleaned. Residue and contaminants can hinder operation and lead to malfunctions. Use appropriate cleaning agents and tools to remove dirt, grime, and old sealants, allowing for a pristine environment where each part can function optimally.

Systematic Assembly

Approach the reassembly methodically. Start with the largest components and work your way to the smaller pieces. This order minimizes the risk of losing parts and helps maintain focus. Double-check alignment and fit as you proceed, ensuring that each item sits correctly in its designated place. Utilize diagrams or manuals if available, as these can provide valuable guidance throughout the process.

Upgrading Nikki 6100 Parts

Enhancing the performance of your fuel delivery system can lead to significant improvements in efficiency and responsiveness. By focusing on specific components, you can achieve a smoother operation and better fuel economy. This section will guide you through key upgrades that can optimize functionality and reliability.

1. Enhanced Fuel Jets: Upgrading to high-flow jets can increase the volume of fuel delivered, resulting in improved power output. Consider the specific demands of your engine when selecting the appropriate size for optimal performance.

2. Performance Needle: A custom needle can fine-tune fuel delivery at various throttle positions, leading to better acceleration and smoother transitions. This adjustment can greatly enhance the driving experience.

3. Air Filter Modifications: Replacing the standard air filter with a high-performance option allows for greater airflow, contributing to a more efficient combustion process. This change can help unleash additional horsepower.

4. Gasket and Seal Upgrades: Investing in high-quality gaskets and seals can prevent leaks and ensure proper air-fuel mixture. This can lead to a more stable operation and longer lifespan of your system.

5. Throttle Response Enhancements: Improving the throttle linkage and incorporating lighter components can enhance responsiveness, making acceleration feel more immediate and engaging.

By focusing on these strategic improvements, you can achieve a more efficient and powerful performance, ensuring that your vehicle operates at its best.

Cleaning Techniques for Carburetor Parts

Proper maintenance of internal engine components is essential for optimal performance. Regular cleaning not only ensures longevity but also enhances efficiency by preventing build-up that can lead to malfunctions. Employing effective techniques is crucial to restoring these elements to their original functionality.

1. Soaking Method: Submerging the components in a specialized cleaning solution is one of the most effective ways to remove stubborn deposits. Allow them to soak for several hours or overnight, depending on the level of grime. After soaking, rinse thoroughly with clean water to eliminate any residue from the cleaning agent.

2. Ultrasonic Cleaning: This technique utilizes high-frequency sound waves to agitate a cleaning solution, creating tiny bubbles that penetrate hard-to-reach areas. This method is particularly useful for intricate designs and can significantly reduce manual scrubbing time. Ensure that the solution used is compatible with the materials of the components.

3. Manual Scrubbing: For less contaminated elements, a soft-bristle brush and a suitable cleaner can be effective. Gently scrub to remove dirt and debris, paying close attention to corners and crevices. This technique is ideal for maintaining delicate surfaces without causing damage.

4. Compressed Air: After initial cleaning, using compressed air helps to dislodge remaining particles from crevices. This is particularly useful for ensuring that all surfaces are free of contaminants before reassembly.

5. Chemical Cleaning Agents: Selecting the right chemical solution can enhance the cleaning process. Acetone, carburetor cleaner, or specialized degreasers can effectively dissolve stubborn residues. Always follow safety precautions and manufacturer instructions when using these agents.

Incorporating these methods into your maintenance routine will ensure that engine components operate smoothly and efficiently, contributing to overall performance and reliability.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and ensure a smooth process. Proper preparation and awareness of potential hazards can significantly reduce the risk of injury and equipment damage.

Essential Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and a mask.

- Ensure the workspace is clean and well-lit to minimize tripping hazards and facilitate effective work.

- Disconnect power sources and remove any fuel before beginning repairs to avoid fire hazards.

Tool and Equipment Safety

- Use tools that are in good condition; replace or repair any damaged items.

- Follow manufacturer guidelines for using specific tools to avoid misuse.

- Store tools safely when not in use to prevent accidents.

By adhering to these precautions, you can create a safer environment that fosters efficiency and protects both you and the equipment being serviced.

Where to Find Replacement Parts

Locating suitable components for your equipment can be crucial for maintaining its performance and longevity. Fortunately, there are several reliable sources where you can find what you need.

- Online Retailers: Websites specializing in machinery and engine supplies often have a wide selection of components. Check user reviews for quality assurance.

- Local Automotive Stores: Many brick-and-mortar shops carry essential items. It’s a good idea to call ahead to confirm availability.

- Manufacturer’s Website: The official site may offer direct sales or a list of authorized dealers that can help you acquire genuine components.

- Forums and Online Communities: Engaging with enthusiasts and experts in dedicated forums can lead you to rare finds or recommendations on where to shop.

- Salvage Yards: Consider visiting local salvage yards for used components. This can be a cost-effective way to source what you need.

By exploring these avenues, you can ensure that your equipment runs smoothly and efficiently.

Expert Recommendations for Long-Term Care

Maintaining the efficiency and longevity of mechanical components requires a thoughtful approach to care and regular maintenance. By implementing a few best practices, users can ensure optimal performance and durability over time. Here are key strategies to consider for preserving these essential systems.

Regular Inspections

- Conduct routine visual checks for signs of wear and tear.

- Monitor performance closely to identify any irregularities early on.

- Keep an eye out for leaks or unusual sounds that may indicate issues.

Proper Cleaning Techniques

- Utilize appropriate cleaning agents to avoid damage to sensitive components.

- Ensure all parts are dry before reassembly to prevent corrosion.

- Implement a cleaning schedule based on usage frequency to maintain optimal function.

By following these expert recommendations, users can significantly enhance the reliability and lifespan of their equipment, minimizing the risk of unexpected failures and costly repairs.