Understanding the Rochester Carburetor Parts Diagram

The intricacies of vintage fuel delivery systems are a fascinating subject for enthusiasts and restorers alike. Grasping the fundamental elements that govern their functionality can greatly enhance one’s appreciation for automotive engineering. A thorough examination of these mechanisms reveals the harmony between design and performance.

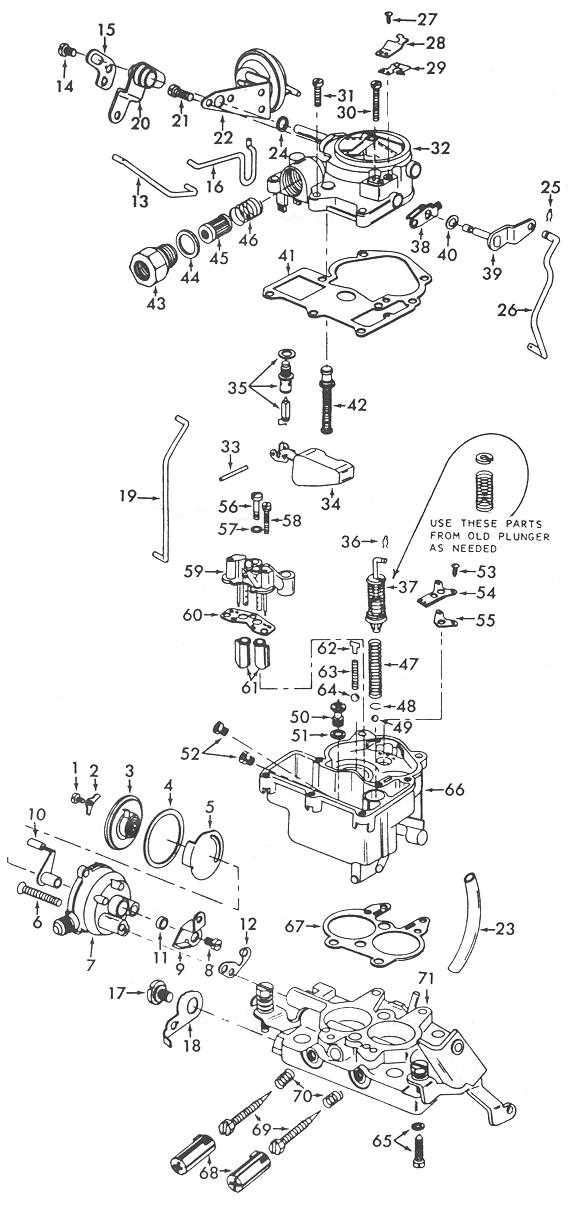

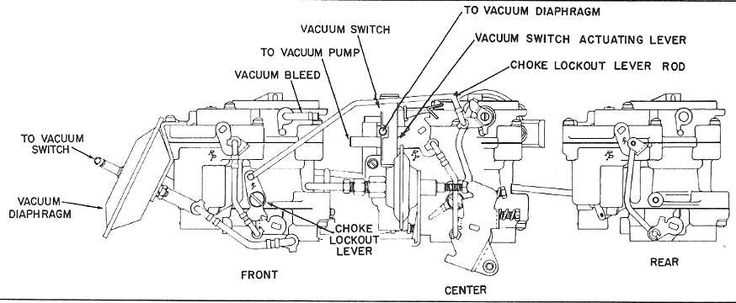

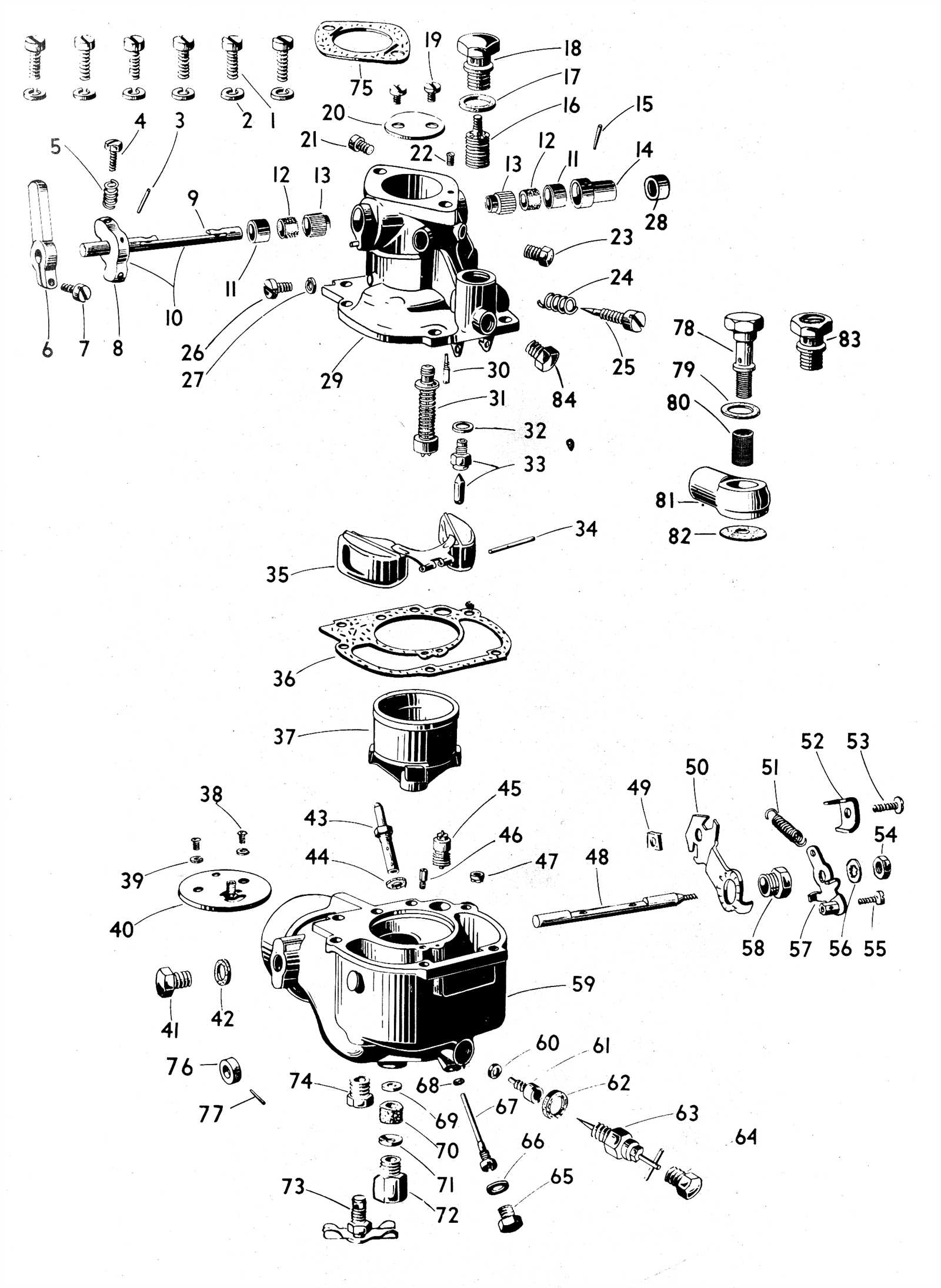

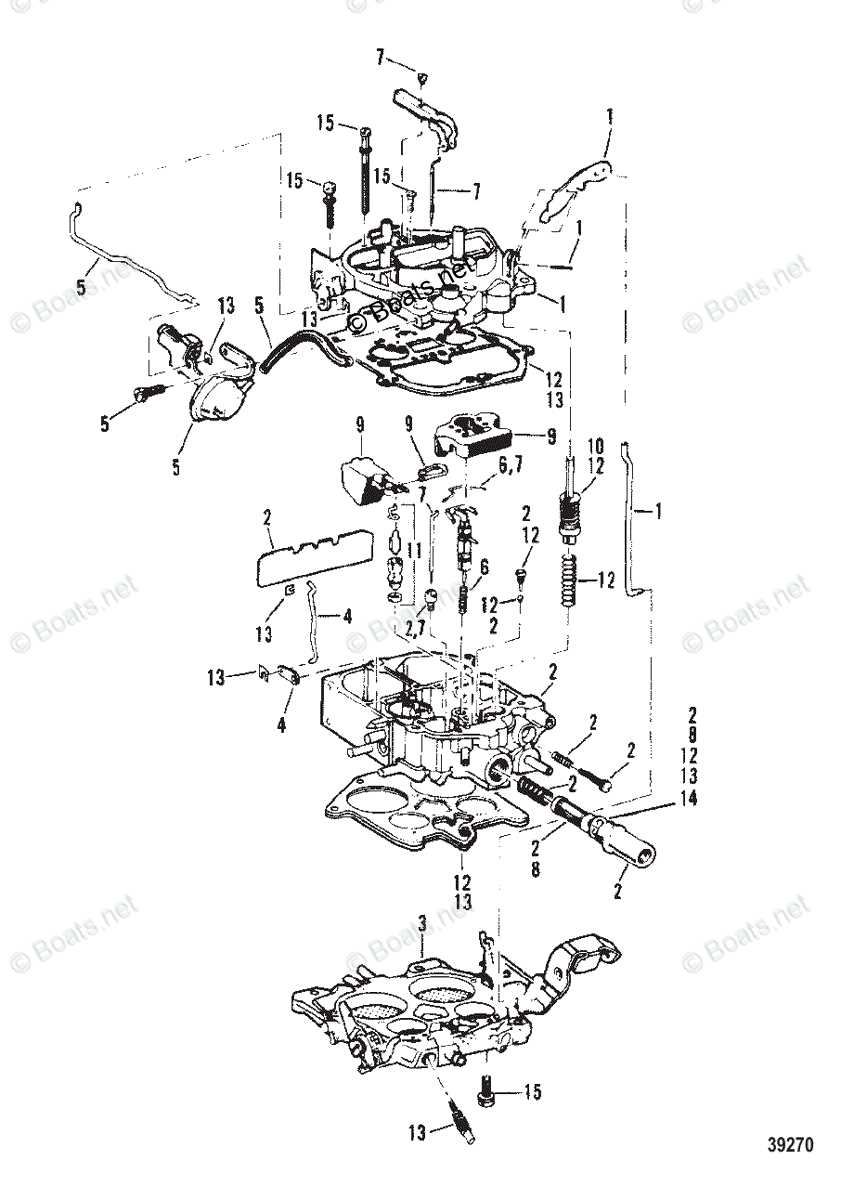

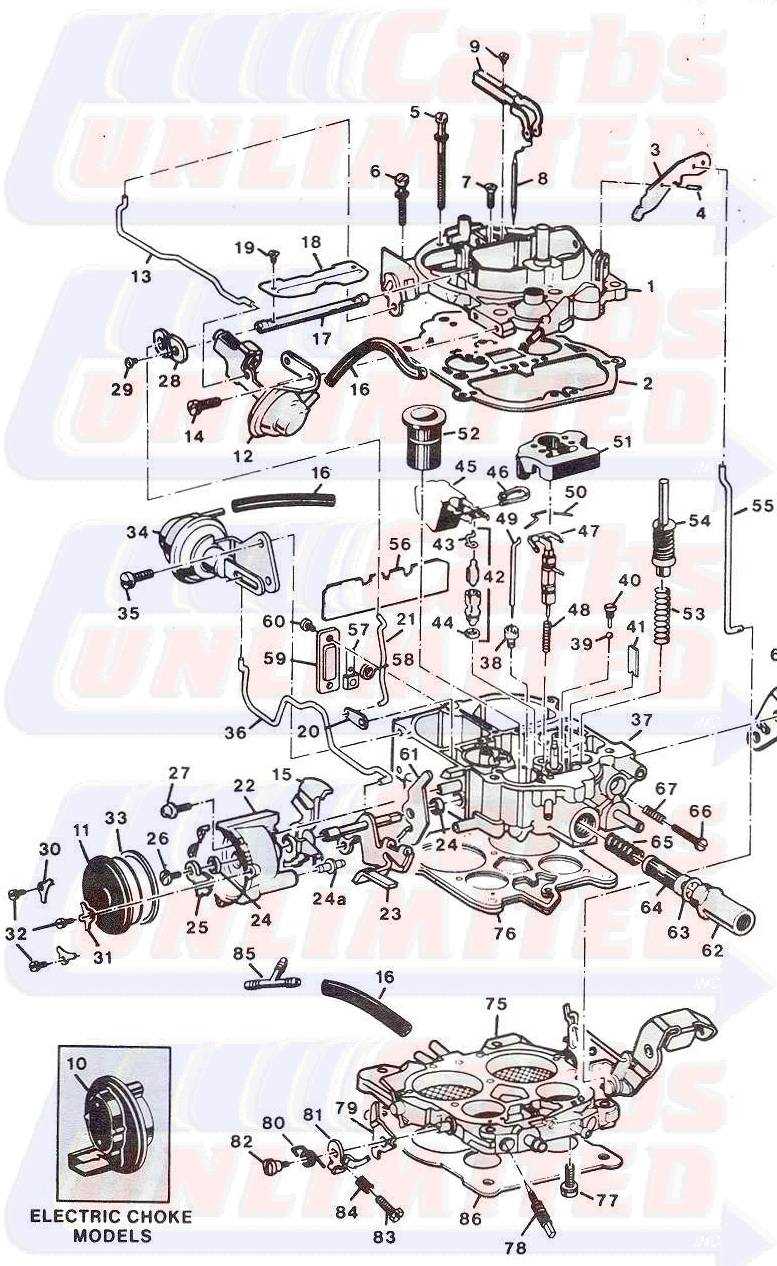

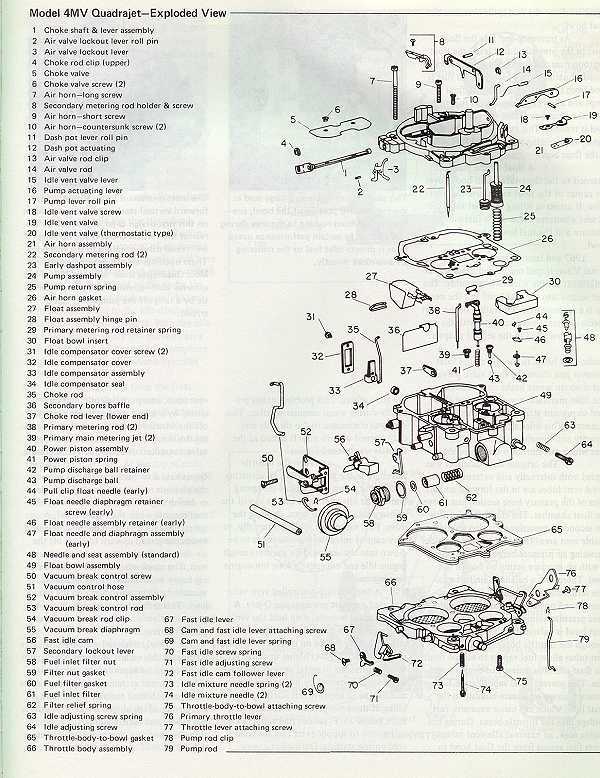

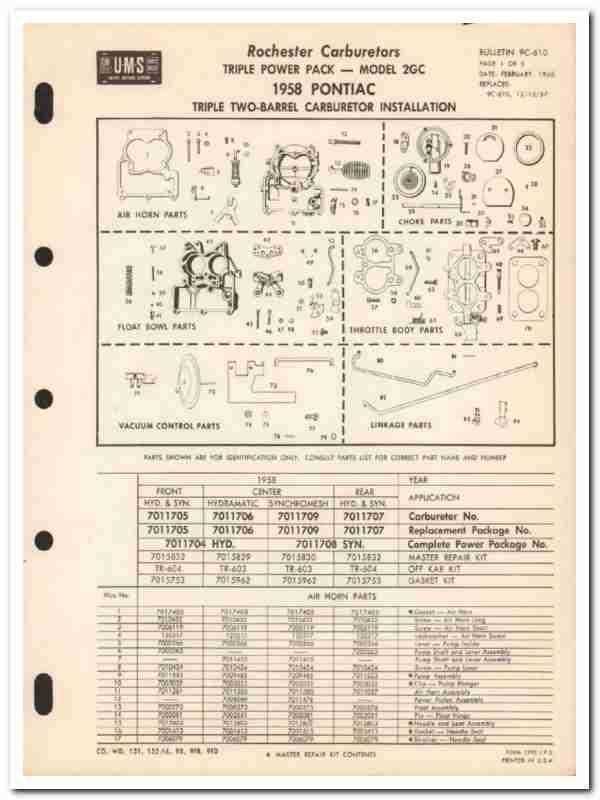

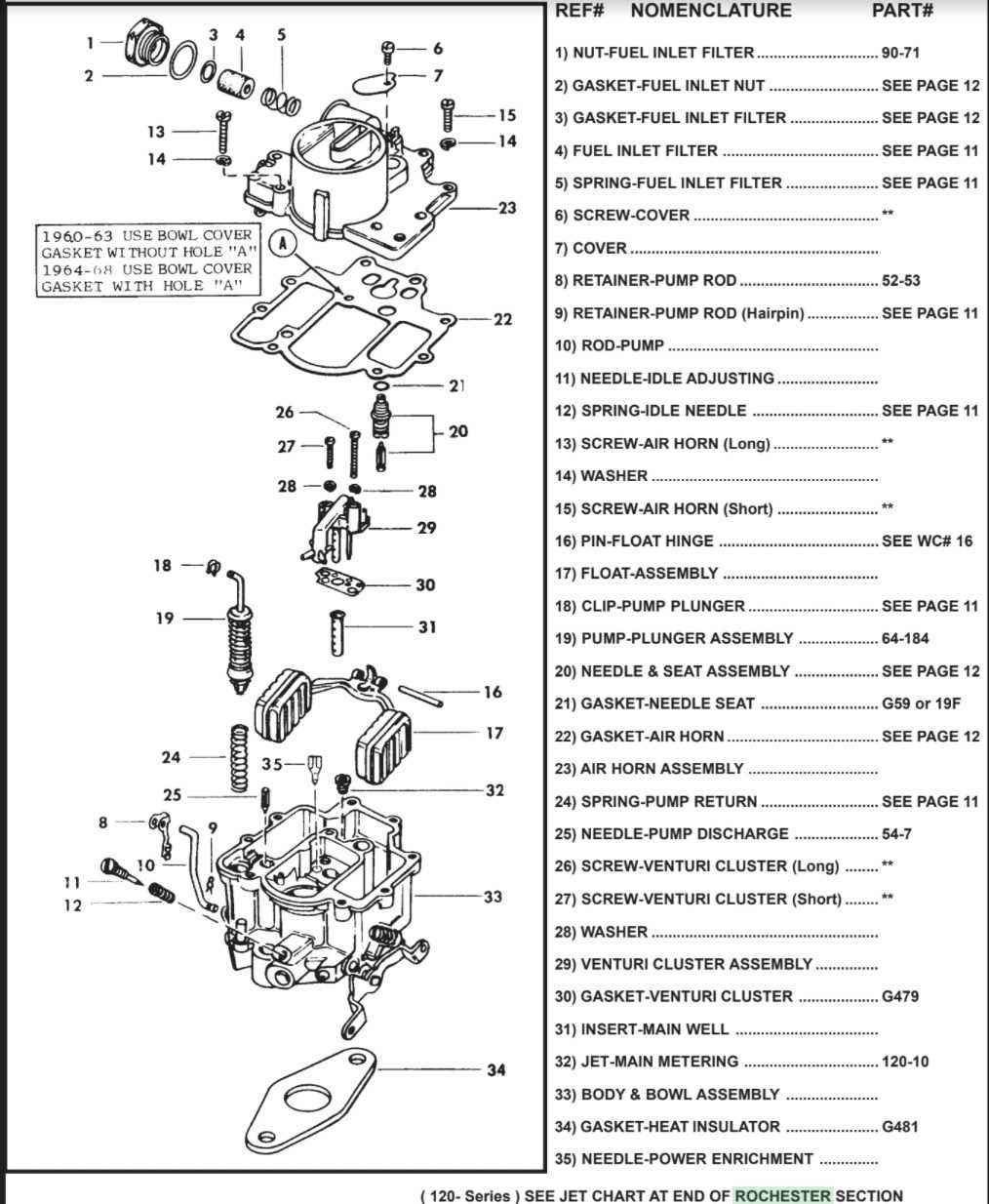

For those seeking to optimize or restore their classic vehicles, visual representations of these components can serve as invaluable resources. These illustrations provide a clear overview, aiding in identifying and troubleshooting specific issues. By breaking down the configuration, one can delve into the ultimate understanding of how each piece contributes to the system’s overall efficiency.

Furthermore, familiarity with these crucial elements not only enhances the restoration process but also empowers enthusiasts to make informed decisions regarding upgrades and repairs. Whether one is embarking on a complete rebuild or a simple maintenance task, having access to detailed visuals can be the key to success in reviving these timeless machines.

Understanding Rochester Carburetor Basics

This section delves into the fundamental concepts surrounding a particular type of fuel delivery system commonly found in various motor vehicles. By examining its components and their functions, one can gain insight into how this mechanism optimizes engine performance and fuel efficiency. A thorough understanding of its operation is essential for effective maintenance and troubleshooting.

Key Components and Their Functions

At the heart of this system lies a series of crucial elements that work together to mix air and fuel in the right proportions. The throttle controls the amount of air entering the engine, while the metering system regulates the fuel flow. Additionally, various adjustments can influence the overall performance, allowing for fine-tuning based on specific needs.

Common Issues and Maintenance Tips

Over time, certain challenges may arise, including blockages or improper adjustments that can hinder efficiency. Regular inspections and cleanings are vital for keeping the system functioning optimally. Familiarity with common symptoms, such as rough idling or poor acceleration, can help identify problems early and ensure the longevity of the engine.

Key Components of Rochester Carburetors

Understanding the essential elements of fuel mixing devices is crucial for optimizing performance and efficiency. Each component plays a significant role in ensuring smooth operation and effective fuel delivery.

| Component | Description |

|---|---|

| Throttle Body | Regulates airflow into the engine, impacting power and speed. |

| Float Chamber | Maintains a constant fuel level, ensuring consistent delivery to the engine. |

| Jets | Control the fuel flow into the air stream, crucial for the correct air-fuel mixture. |

| Needle Valve | Manages fuel entry from the tank into the float chamber. |

| Venturi | Creates a vacuum to draw fuel into the airflow, enhancing combustion. |

Function of Each Part Explained

This section delves into the essential components of a fuel delivery system, highlighting the specific roles each element plays in ensuring optimal performance. Understanding these functions is crucial for effective maintenance and troubleshooting.

- Throttle Plate: Regulates the airflow into the engine, controlling power output based on driver input.

- Float Chamber: Maintains a consistent level of fuel, ensuring a steady supply for combustion.

- Jet Assembly: Meter fuel into the airflow, facilitating the proper air-fuel mixture for efficient combustion.

- Power Valve: Enriches the fuel mixture during heavy acceleration, enhancing performance under load.

- Idle Circuit: Ensures a smooth operation at low speeds by providing a controlled amount of fuel.

- Choke Mechanism: Aids in starting the engine by enriching the mixture during cold conditions.

- Accelerator Pump: Delivers a burst of fuel when the throttle is opened suddenly, preventing hesitation.

- Venturi: Creates a vacuum effect that draws fuel into the airstream, vital for the mixing process.

By comprehensively understanding these components, enthusiasts and mechanics can effectively diagnose issues and enhance performance.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for efficient maintenance and repair. These illustrations provide a visual guide to the various elements, helping users identify and locate each piece within a larger assembly. Familiarity with these visuals can enhance troubleshooting and promote effective assembly.

Key Elements of a Schematic

- Labels: Each component is usually marked with a specific identifier, making it easier to reference parts during repairs.

- Connections: Arrows and lines often indicate how elements are connected, helping to visualize the flow and interaction between parts.

- Legend: Many diagrams include a legend that explains symbols and terms used, providing clarity and context.

Steps to Interpret the Visual

- Start by familiarizing yourself with the legend to understand the symbols.

- Identify the main assembly and locate the components that need attention.

- Follow the lines to trace how parts interact and relate to one another.

- Use the labels to cross-reference with your inventory or purchase list.

By mastering these techniques, you can confidently navigate any technical illustration, streamlining your repair or maintenance tasks.

Common Issues with Rochester Carburetors

Various challenges can arise with fuel delivery systems, impacting performance and efficiency. Understanding these common problems is essential for proper maintenance and troubleshooting.

Fuel Leaks: One of the most prevalent issues is the occurrence of fuel leaks, often due to worn gaskets or seals. This can lead to reduced efficiency and potential safety hazards.

Clogged Jets: Blockages in the fuel delivery channels can cause poor engine performance. Regular cleaning is vital to ensure optimal operation.

Inconsistent Idling: Unstable idling can result from air leaks or incorrect adjustments. Proper tuning is crucial to maintain steady performance.

Starting Difficulties: Challenges with starting may stem from insufficient fuel delivery or air-fuel mixture problems. Addressing these factors can improve reliability.

Corrosion: Over time, components can corrode, particularly in older models. Regular inspections can help identify and rectify these issues before they escalate.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your engine components requires regular attention and care. By adopting effective maintenance practices, you can significantly extend the lifespan of these vital systems and enhance their performance.

Regular Cleaning

Keep all components free from dirt and debris. Regularly cleaning surfaces helps prevent build-up that can lead to inefficiency and potential damage. Use appropriate cleaners and tools to avoid any abrasions.

Inspect and Replace Wear Items

Routine inspections are crucial. Identify and replace any worn or damaged elements promptly to prevent larger issues. Staying ahead of deterioration will safeguard overall functionality and performance.

Rochester vs. Other Carburetors

This section explores the differences between a renowned fuel mixing mechanism and its competitors, highlighting key aspects such as performance, efficiency, and design. By examining these variations, enthusiasts can make informed decisions regarding their vehicles’ fuel systems.

Performance Comparison

When it comes to performance, certain systems offer a distinct advantage in throttle response and power delivery. Many users report that one design provides smoother acceleration, while others may excel in maximizing fuel economy. The ultimate choice often depends on the specific requirements of the vehicle and driver preferences.

Design Features

Another important factor lies in the construction of these mechanisms. Some models boast advanced features, like improved airflow and enhanced adjustability, making them appealing for modifications. In contrast, traditional designs may prioritize simplicity and ease of maintenance, attracting those who prefer straightforward solutions.

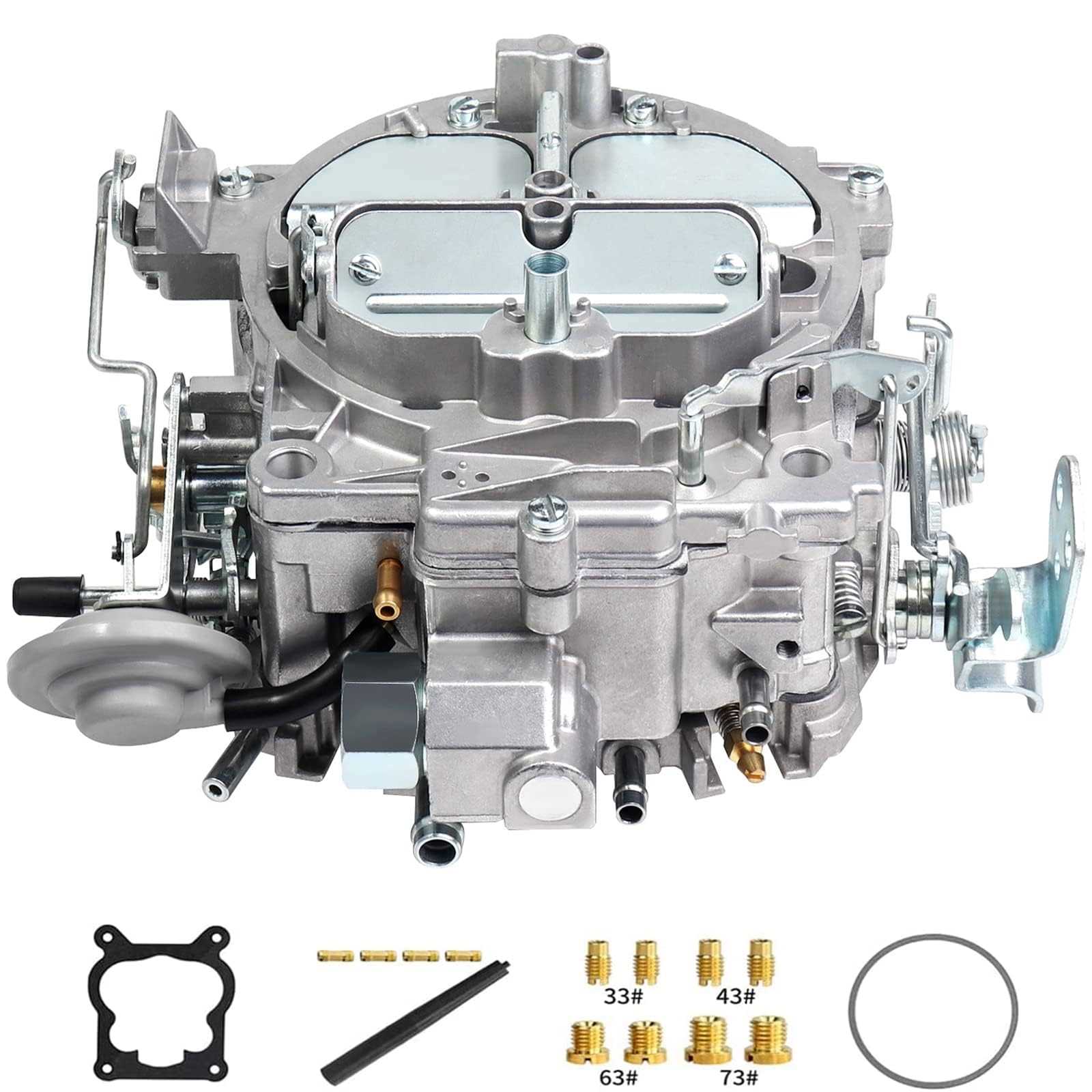

Choosing Quality Replacement Parts

When it comes to maintaining performance and reliability, selecting high-quality substitutes is crucial. Not all components are created equal, and making the right choice can significantly affect the longevity and efficiency of your machinery. This section will guide you in making informed decisions for optimal functionality.

Key Considerations

- Material Quality: Ensure that the substitutes are made from durable materials that can withstand wear and tear.

- Compatibility: Verify that the components fit seamlessly with your existing setup to avoid issues down the line.

- Reputation of the Manufacturer: Opt for well-known brands with positive reviews to ensure reliability.

- Warranty and Support: Look for options that come with a warranty and responsive customer service.

Where to Find Quality Options

- Authorized retailers often carry verified and reliable components.

- Online marketplaces with user reviews can provide insights into the quality of various options.

- Local mechanics may offer recommendations based on their experience and expertise.

Restoration Process for Classic Models

The journey of restoring vintage machinery is a rewarding endeavor that requires attention to detail and a deep appreciation for history. This process not only revives the original performance but also preserves the unique character of each model. A systematic approach ensures that every aspect is addressed, resulting in a well-functioning and aesthetically pleasing unit.

To achieve a successful restoration, consider the following steps:

- Assessment: Begin by evaluating the overall condition of the equipment. Identify areas needing repair or replacement.

- Disassembly: Carefully take apart the components, documenting each step to facilitate reassembly. Take pictures or notes to keep track of the order.

- Cleaning: Thoroughly clean each component to remove dirt, grease, and corrosion. Use appropriate solvents and tools to avoid damage.

- Repair and Replacement: Repair damaged elements and replace any worn-out pieces. Source high-quality replacements that match the original specifications.

- Reassembly: Reassemble the unit meticulously, following your documentation. Ensure each part is securely fitted and correctly positioned.

- Testing: Once reassembled, conduct a series of tests to ensure everything operates as intended. Make adjustments as necessary.

- Finishing Touches: Apply paint or other finishes to enhance appearance, ensuring it matches the historical look of the model.

By following these structured steps, enthusiasts can successfully restore their classic models, allowing them to enjoy their beauty and functionality for years to come.

Impact of Weather on Performance

Weather conditions significantly influence engine functionality and overall efficiency. Variations in temperature, humidity, and atmospheric pressure can alter the behavior of fuel delivery systems, impacting performance metrics such as acceleration and fuel consumption.

Temperature Effects

- Cold weather can lead to thicker fuel, causing difficulty in mixing with air.

- High temperatures may cause vapor lock, resulting in inconsistent fuel flow.

Humidity and Pressure Considerations

- Increased humidity can enhance combustion efficiency by aiding vaporization.

- Lower atmospheric pressure may reduce oxygen availability, affecting power output.

Upgrading Your Carburetor System

Enhancing your fuel delivery mechanism can significantly improve engine performance and efficiency. This process involves selecting the right components that align with your vehicle’s needs, ensuring optimal air-fuel mixture for combustion.

First, assess the existing setup to identify areas for improvement. Consider elements such as flow rates, responsiveness, and overall design. Upgrading to high-performance components can lead to better throttle response and increased power.

Moreover, integrating advanced technology, such as electronic controls, can provide greater precision in fuel management. This not only enhances performance but also contributes to better fuel economy.

Finally, regular maintenance of your upgraded system is essential. Cleaning and calibrating the components will ensure longevity and consistent performance, ultimately maximizing your vehicle’s capabilities.

Resources for Further Learning

Expanding your knowledge about automotive components can significantly enhance your understanding of engine performance and maintenance. Whether you are a hobbyist or a professional, accessing quality information is essential for mastering the intricacies of these systems. Below are several valuable resources that can aid in your journey of discovery.

Books and Manuals

Investing in reputable literature is a great way to gain in-depth insights. Look for specialized manuals that focus on mechanical assemblies, their functions, and troubleshooting methods. Technical handbooks often include illustrations and detailed explanations that can clarify complex concepts. Additionally, many guides cater to various skill levels, making them accessible to beginners as well as seasoned enthusiasts.

Online Courses and Forums

The internet offers a plethora of online platforms where you can engage with interactive courses and discussions. Websites like edX and Coursera provide structured learning experiences taught by industry experts. Furthermore, joining community forums allows for real-time interaction with fellow learners. Sharing experiences and tips can lead to invaluable insights and foster a supportive learning environment.