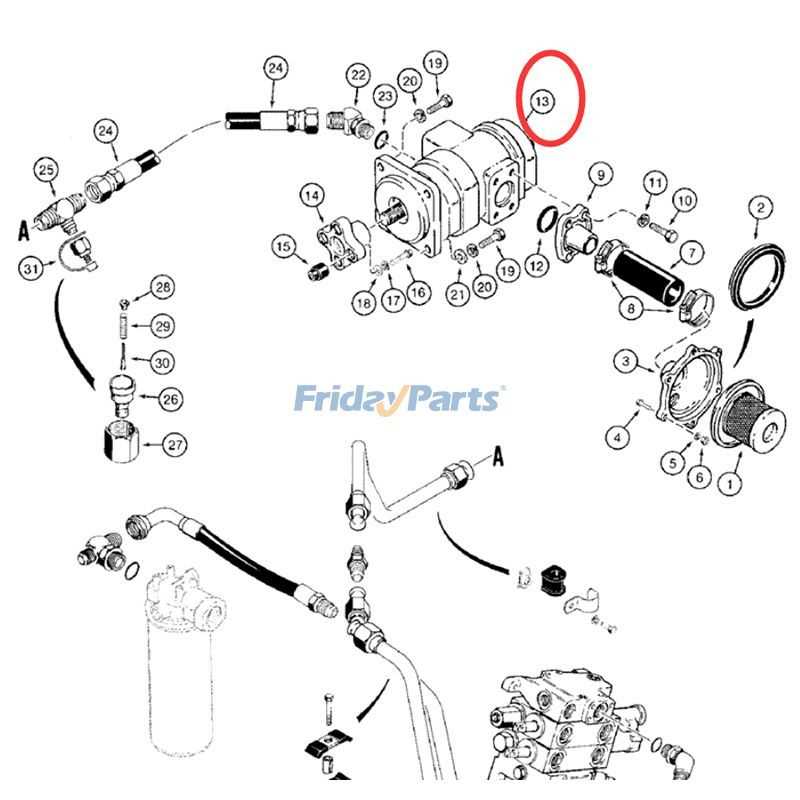

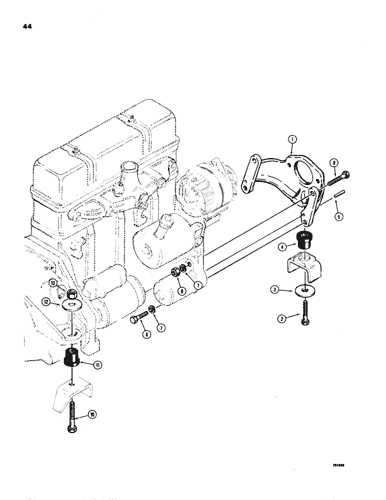

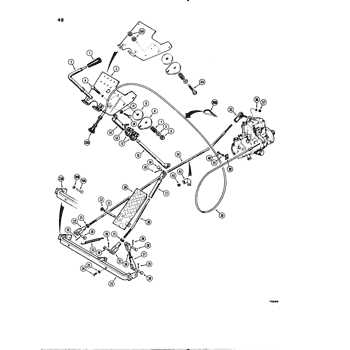

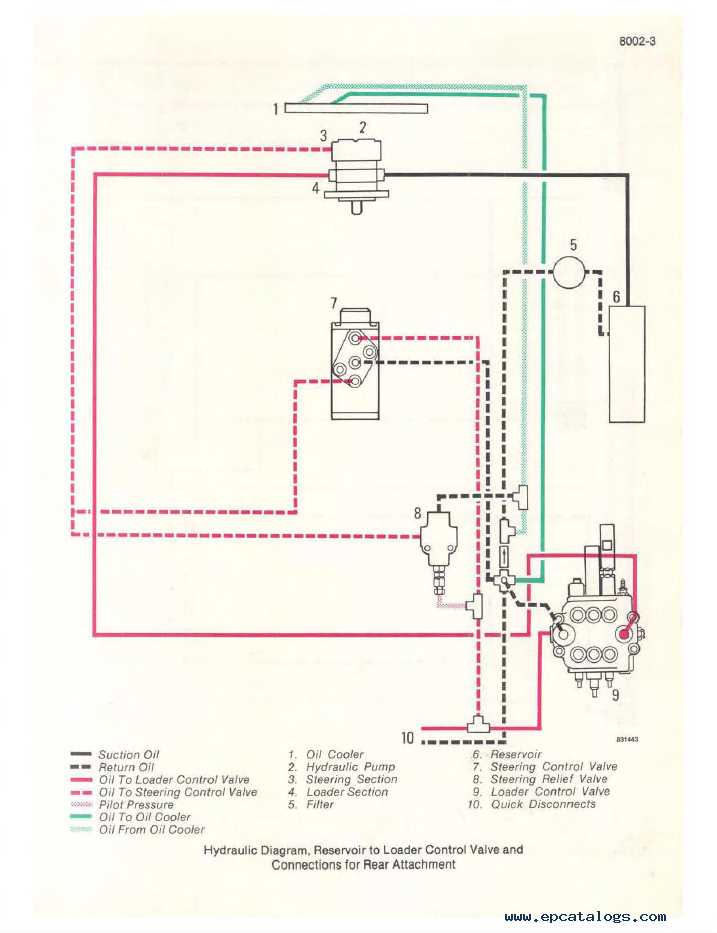

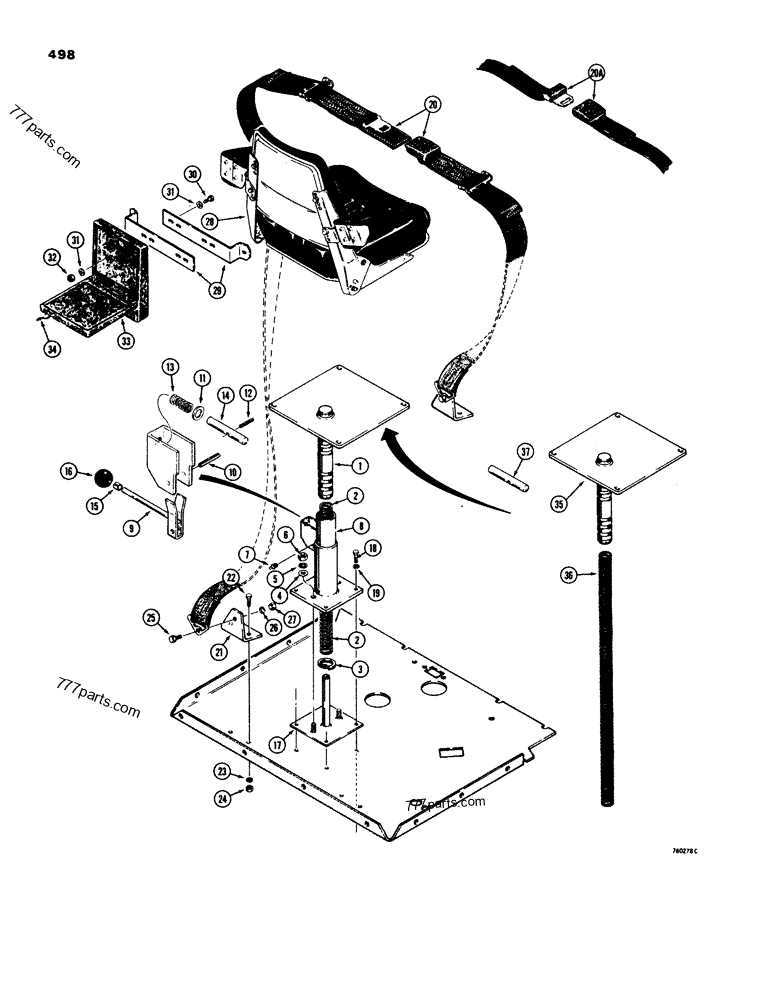

Parts Diagram for 580C Case Backhoe

Exploring the intricacies of heavy machinery is essential for operators and technicians alike. A clear visual representation of various components enhances comprehension and maintenance efforts. This section aims to provide insight into the arrangement and functionality of key elements within excavating equipment.

By examining the structure of these machines, users can identify essential mechanisms and their interconnections. Such knowledge fosters efficient troubleshooting and effective repairs, ultimately prolonging the lifespan of the equipment. Understanding these layouts not only aids in operation but also empowers users to optimize performance through informed decision-making.

Understanding the key elements of a digging machine is crucial for its efficient operation and maintenance. These vital components work together to ensure functionality and performance, allowing for a range of tasks on construction sites and other projects.

Main Structure and Framework

The framework serves as the backbone of the machine, providing stability and support for various attachments. Key elements include:

- Chassis: The base structure that supports the entire assembly.

- Stabilizers: Outriggers that enhance stability during operation.

- Boom: The arm that extends for digging and lifting tasks.

Operating Mechanisms

Various mechanisms drive the performance and control of the equipment, allowing for precise movements and adjustments. Important components consist of:

- Hydraulic System: Provides the necessary force for lifting and digging.

- Transmission: Facilitates the transfer of power from the engine to the wheels.

- Controls: The operator interface for managing movements and functions.

Importance of Parts Diagrams

Understanding the components of heavy machinery is crucial for efficient maintenance and repair. Visual representations help operators and technicians identify individual elements, ensuring accurate assessments and timely interventions.

By utilizing these illustrations, users can effectively communicate issues, enhance problem-solving strategies, and facilitate smoother operations. Below is a summary of the advantages:

| Benefits | Description |

|---|---|

| Clarity | Provides clear insights into component placement and functionality. |

| Efficiency | Speeds up the repair process by minimizing guesswork. |

| Education | Acts as a learning tool for new operators to familiarize themselves with machinery. |

| Documentation | Serves as a reference for future maintenance and troubleshooting. |

Key Features of 580C Model

This model stands out due to its impressive capabilities and robust construction. Designed for various tasks, it offers a blend of power and precision, making it an essential machine in the construction and agricultural sectors.

Performance and Power

- Equipped with a high-performance engine, providing exceptional torque and efficiency.

- Enhanced hydraulic system for superior lifting and digging capabilities.

- Advanced transmission options for seamless operation on different terrains.

Operator Comfort and Safety

- Spacious cab designed for optimal visibility and reduced fatigue during long hours of work.

- Intuitive controls for easy maneuvering and operation.

- Robust safety features to protect the operator and ensure secure working conditions.

Common Issues with Backhoe Parts

Heavy machinery often encounters various challenges that can impact its performance and efficiency. Understanding these issues is crucial for effective maintenance and repair. Several factors can lead to malfunctions, ranging from wear and tear to improper usage.

Frequent Wear: Components can deteriorate over time due to constant operation. This wear can manifest as decreased functionality or increased noise, indicating the need for inspection and replacement.

Fluid Leaks: One of the most common concerns involves leaks from hydraulic systems. These can lead to reduced pressure and efficiency, necessitating timely repairs to avoid further damage.

Electrical Failures: Electrical systems may experience shorts or failures, affecting the overall operation. Regular checks can help identify and address these issues early.

Connection Issues: Loose or damaged connections can disrupt the machine’s functionality. Ensuring that all connections are secure and in good condition is vital for optimal performance.

Operator Errors: Incorrect operation can lead to unnecessary strain on components, causing premature failures. Proper training and adherence to operational guidelines can mitigate this risk.

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repairs. These illustrations provide a detailed view of various elements and their interrelations, helping users identify what is needed for their machinery.

Identifying Key Symbols

Familiarizing yourself with the common symbols used in these visuals is crucial. Each symbol corresponds to a specific element or function, allowing for quick identification and understanding. Take note of any legends provided, as they clarify the meaning of each symbol.

Understanding Assembly Layouts

Examine the overall layout carefully. Each section typically displays a logical arrangement of components, illustrating how they fit together. Pay attention to the connections and orientations to gain insights into the assembly process, which aids in disassembly and reassembly tasks.

Identifying Spare Parts Easily

Understanding how to recognize essential components is crucial for effective maintenance. With a clear approach, anyone can navigate through the array of available items, simplifying the replacement process.

Start by familiarizing yourself with the general layout of the machinery. Visual references can greatly enhance your ability to pinpoint what you need. Utilize labeled illustrations or detailed manuals that depict each segment.

Furthermore, keeping a record of frequently used items will aid in quick identification. Establishing a systematic inventory helps streamline future repairs and minimizes downtime. Always consult trusted resources to ensure accuracy in your selections.

Maintenance Tips for 580C Backhoe

Proper upkeep is essential for ensuring optimal performance and longevity of your equipment. Regular attention to various components can prevent costly repairs and enhance operational efficiency.

Routine Checks

Establishing a schedule for routine inspections helps identify potential issues early. Focus on key areas such as fluid levels, filters, and wear components.

Lubrication Practices

Consistent lubrication of moving parts minimizes friction and wear. Ensure you are using the appropriate lubricant and follow manufacturer recommendations.

| Component | Recommended Action | Frequency |

|---|---|---|

| Hydraulic Fluid | Check and refill | Weekly |

| Filters | Inspect and replace | Monthly |

| Grease Points | Apply lubricant | Every 50 hours |

Finding Quality Replacement Parts

When it comes to maintaining heavy machinery, sourcing high-quality components is essential for optimal performance and longevity. Identifying reliable sources can significantly impact the efficiency of repairs and overall functionality.

Researching Suppliers is crucial. Look for vendors with a solid reputation and positive customer feedback. Online reviews and ratings can provide insights into the reliability of a supplier.

Comparing Options allows you to weigh the quality and price of various offerings. Sometimes, investing a bit more in durable components can save you money in the long run by reducing the frequency of replacements.

Checking Compatibility with your equipment is vital. Ensure that the selected components fit seamlessly and meet the specifications required for your machinery’s operation.

Ultimately, thorough research and careful selection can lead to a more efficient and dependable repair process, ensuring your equipment remains in top condition.

Comparing Diagrams Across Models

When examining different models, visual representations serve as essential tools for understanding the intricacies of each system. These illustrations not only highlight the unique components of each variant but also provide insights into how various elements interact. By analyzing these visuals, one can appreciate the evolution and design choices made across different iterations.

Identifying Common Features

Many systems share fundamental characteristics that can be recognized across various representations. Key components, such as hydraulic systems and structural elements, often remain consistent, allowing for easier maintenance and repair. This consistency aids operators in quickly familiarizing themselves with new machinery.

Noting Distinctions

While similarities are evident, it is equally important to identify unique aspects that may affect performance or functionality. Variations in dimensions or layout can lead to significant differences in usability. Understanding these distinctions is crucial for selecting the right model for specific tasks and ensuring optimal performance.

Safety Precautions During Repairs

When undertaking maintenance on heavy machinery, adhering to safety guidelines is crucial to prevent accidents and ensure a secure working environment. These measures not only protect the individual performing the repairs but also safeguard the equipment and surrounding personnel.

- Personal Protective Equipment (PPE): Always wear appropriate gear, including gloves, goggles, and helmets, to shield against potential hazards.

- Work Area Maintenance: Keep the workspace organized and free of clutter to reduce the risk of tripping or falling.

- Equipment Inspection: Before starting any repair, thoroughly examine the machinery to identify any pre-existing issues that could pose safety risks.

- Proper Tools Usage: Ensure that all tools are in good condition and used correctly to avoid accidents caused by equipment failure.

- Emergency Preparedness: Familiarize yourself with emergency procedures, including the location of first aid kits and emergency exits.

By following these essential precautions, individuals can effectively minimize risks associated with machinery repairs, creating a safer and more efficient working environment.

Resources for Further Assistance

For those seeking additional support and information regarding equipment maintenance and repair, numerous resources are available. These can help users gain insights and solutions tailored to their specific needs.

- Online Forums: Engage with communities of enthusiasts and professionals who share their experiences and advice.

- Manufacturer Websites: Explore official sites for detailed guides, FAQs, and customer support options.

- Repair Manuals: Consider purchasing or downloading manuals that provide step-by-step instructions for maintenance tasks.

- YouTube Tutorials: Access video content demonstrating repair techniques and tips from experts in the field.

- Local Dealers: Consult local retailers for parts, tools, and personalized advice from knowledgeable staff.

Utilizing these resources can greatly enhance understanding and efficiency in handling machinery-related tasks.

Benefits of Using Official Diagrams

Utilizing authentic visual guides can greatly enhance the efficiency and accuracy of maintenance and repair tasks. These resources provide clear representations, making it easier for users to understand the components and their relationships within machinery.

Clarity and Precision

Official visuals ensure that users have access to precise information. The clarity offered helps in avoiding common misunderstandings that can lead to errors. Key advantages include:

- Detailed depictions of components

- Accurate measurements and specifications

- Identification of parts and functions

Enhanced Troubleshooting

Having access to reliable visuals simplifies the troubleshooting process. Users can quickly locate issues and implement appropriate solutions, resulting in:

- Faster problem identification

- Reduced downtime

- Improved overall performance