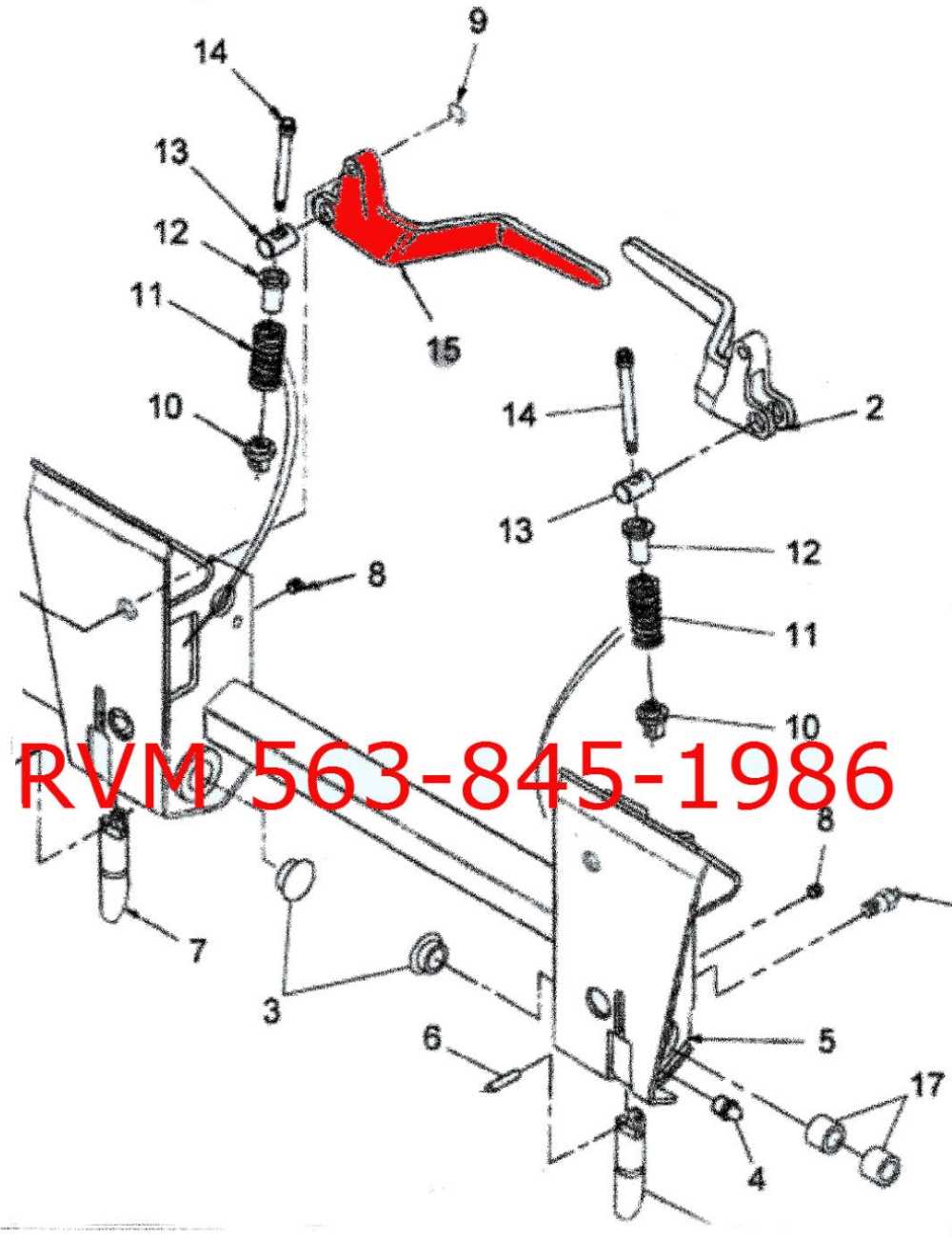

Comprehensive Guide to Case 40XT Parts Diagram

When working with complex machinery, having a clear visual representation of individual elements is essential for effective maintenance and troubleshooting. These visual guides help users grasp the intricate relationships and functions of various segments within a system.

Focusing on the specifics of a particular model can reveal critical insights into its operational efficiency. Each component plays a vital role, and understanding their arrangement and interconnections can ultimately enhance performance and longevity.

By exploring detailed illustrations, users can delve deeper into the machinery’s design, enabling better-informed decisions regarding repairs and upgrades. Mastering the layout of these essential elements is crucial for anyone involved in the operation and upkeep of heavy equipment.

Understanding the 40xt Parts Diagram

Gaining insight into machinery components is essential for effective maintenance and operation. Familiarity with the intricate layout of elements enables users to troubleshoot issues and perform necessary repairs with confidence.

This section highlights key aspects that aid in comprehending the layout of components:

- Identification: Recognizing individual elements is the first step in mastering the overall structure.

- Functionality: Understanding how each part contributes to the system’s performance enhances operational knowledge.

- Relationships: Analyzing how components interact helps in diagnosing potential problems.

For effective utilization, consider the following steps:

- Start with a thorough review of the layout.

- Note the placement and function of each component.

- Consult reference materials for additional insights.

By delving into these elements, users can ensure their machinery operates smoothly and efficiently, leading to prolonged lifespan and reliability.

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective communication in various fields, particularly in technical and engineering contexts. Detailed illustrations serve as vital tools for understanding complex systems, allowing users to grasp intricate relationships between components. Without accurate visuals, the risk of misinterpretation increases, potentially leading to costly mistakes and inefficiencies.

These representations not only facilitate better comprehension but also enhance collaboration among team members. When everyone is on the same page, the likelihood of successful project completion increases significantly. Additionally, precise visuals contribute to improved training and onboarding processes, as new employees can quickly familiarize themselves with the components and their functions.

| Benefits | Description |

|---|---|

| Clarity | Helps in understanding complex relationships between elements. |

| Collaboration | Ensures that all team members share a common understanding. |

| Efficiency | Reduces the chances of errors and misunderstandings. |

| Training | Assists in onboarding new personnel effectively. |

In summary, the accuracy of visual representations cannot be overstated. They are foundational elements that support clarity, collaboration, and efficiency in any technical endeavor.

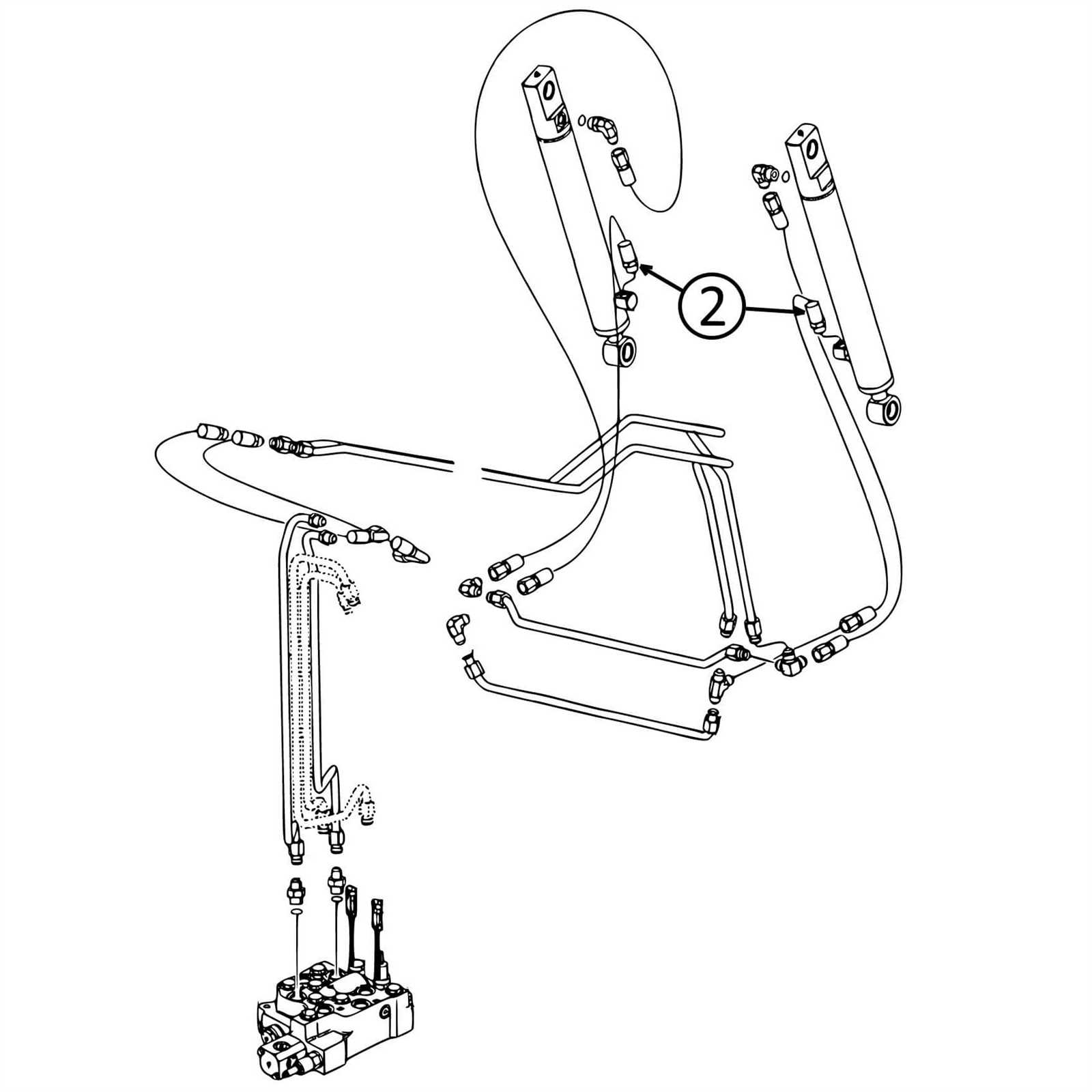

Key Components of the 40xt

Understanding the essential elements of this machinery is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance and durability, making familiarity with their functions and interrelationships important for operators and technicians alike.

Main Functional Parts

- Engine: The powerhouse of the unit, responsible for providing the necessary energy for operation.

- Transmission: Facilitates the transfer of power from the engine to the wheels, allowing for smooth movement.

- Hydraulic System: Enables various attachments and implements to operate efficiently by providing necessary fluid power.

- Chassis: The structural framework that supports all components and ensures stability during operation.

Control Mechanisms

- Operator Cabin: Designed for comfort and control, housing all necessary instruments for monitoring performance.

- Steering System: Provides precise maneuverability, ensuring effective navigation in various terrains.

- Brake System: Crucial for safety, allowing the operator to halt movement quickly and reliably.

How to Read the Diagram

Understanding a schematic representation can enhance your ability to identify components and their interconnections effectively. Familiarity with symbols and notations used is essential for accurate interpretation and troubleshooting.

| Symbol | Description |

|---|---|

| ● | Indicates a crucial element within the assembly. |

| — | Represents a connection or pathway between items. |

| △ | Denotes a variable or adjustable feature. |

| ⚙ | Symbol for mechanical parts or moving elements. |

By recognizing these symbols and their meanings, you’ll be able to navigate the visual layout more efficiently, leading to a clearer understanding of the overall assembly.

Common Issues with 40xt Parts

When dealing with machinery components, various challenges can arise that affect performance and longevity. Understanding these potential pitfalls can help in maintaining optimal operation and preventing costly repairs. Identifying common faults early on is essential for efficient management.

Wear and Tear: Over time, frequent usage can lead to degradation of materials, resulting in diminished functionality. Regular inspections can help identify signs of fatigue and prevent unexpected breakdowns.

Improper Installation: Incorrect assembly can lead to misalignment and operational inefficiencies. Ensuring that all components are correctly fitted according to specifications is crucial for optimal performance.

Contamination: Dust, dirt, and other foreign substances can infiltrate mechanisms, causing blockages and reducing efficiency. Keeping components clean and well-maintained is vital to ensure smooth operation.

Lubrication Issues: Inadequate lubrication can lead to increased friction, resulting in overheating and potential failure. Regularly checking and replenishing lubricants is essential for the longevity of the machinery.

Compatibility Problems: Using non-compatible or substandard components can lead to performance issues. It is important to ensure that all elements are designed to work harmoniously together.

By addressing these frequent concerns, operators can significantly enhance the reliability and efficiency of their equipment, ensuring a longer operational life and reduced maintenance costs.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of machinery. By following a structured maintenance routine, operators can significantly extend the lifespan of their equipment while minimizing downtime and costly repairs.

- Regular Inspections: Conduct routine checks to identify any signs of wear or damage. Early detection can prevent more serious issues.

- Lubrication: Keep moving parts well-lubricated to reduce friction and wear. Use the recommended lubricants as specified by the manufacturer.

- Cleaning: Maintain cleanliness by removing debris and contaminants. A clean machine operates more efficiently and has a longer life span.

- Component Replacement: Replace worn or damaged components promptly to prevent further damage and ensure smooth operation.

- Calibration: Regularly calibrate the equipment to maintain accuracy and performance. Proper alignment of parts is crucial for effective functioning.

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule and practices provided in the user manual.

Implementing these strategies will not only enhance the efficiency of your machinery but also contribute to its overall longevity, saving time and resources in the long run.

Tools Needed for Repairs

To effectively address maintenance and repair tasks, having the right instruments is crucial. The appropriate equipment not only streamlines the process but also enhances safety and precision. This section outlines essential tools that will facilitate efficient repairs, ensuring that you are well-prepared for any challenges that may arise.

Essential Instruments

When engaging in repair work, a variety of tools are necessary to tackle different aspects of the job. Below is a list of fundamental instruments that should be part of any repair toolkit:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For fastening and loosening screws of various sizes. |

| Wrench Set | To tighten or loosen nuts and bolts securely. |

| Pliers | For gripping, bending, and cutting wires or small parts. |

| Hammer | Used for driving nails or breaking apart components. |

| Utility Knife | Ideal for cutting materials with precision. |

Additional Supplies

In addition to the core tools, several supplementary items can greatly assist in repair tasks:

| Supply | Function |

|---|---|

| Measuring Tape | For accurate measurements of components and spaces. |

| Safety Gear | Includes gloves and goggles to protect against injuries. |

| Flashlight | Provides illumination in dimly lit areas. |

| Toolbox | For organizing and transporting all your tools easily. |

Where to Find Original Parts

Locating authentic components for machinery can significantly enhance performance and longevity. Ensuring that replacements are genuine is crucial for maintaining optimal function and reliability.

Authorized Dealers: Start by consulting with licensed distributors who specialize in your equipment. They typically offer verified items and can provide valuable assistance.

Manufacturer’s Website: Visit the official site of the equipment maker. They often have sections dedicated to sourcing original components, complete with part numbers and specifications.

Online Marketplaces: Reputable online platforms can be useful, but always verify the seller’s credibility to avoid counterfeit options. Look for listings that confirm authenticity.

Local Repair Shops: Established repair services often have connections with suppliers of genuine replacements. Engaging with these professionals may yield recommendations for sourcing.

Investing time in finding original components will ultimately lead to better performance and a longer lifespan for your machinery.

Upgrading Components for Performance

Enhancing the efficiency of your setup can significantly boost its overall capabilities. By focusing on key elements that influence speed and reliability, users can achieve remarkable improvements.

Consider the following areas for potential enhancement:

- Cooling Systems: Invest in advanced cooling solutions to maintain optimal temperatures during intensive tasks.

- Power Supply: Upgrade to a higher-rated unit to ensure stable and consistent energy delivery.

- Storage Devices: Opt for faster SSDs to reduce loading times and improve data transfer rates.

- Memory Modules: Increase RAM capacity or switch to higher frequency modules for better multitasking capabilities.

By strategically upgrading these components, users can delve deeper into performance optimization, ensuring that their system meets the ultimate demands of modern applications.

Comparing 40xt with Similar Models

This section explores the distinctions and similarities among various models in the same category, highlighting key features and performance aspects that set them apart.

When assessing comparable machines, several factors come into play:

- Performance: Evaluating engine power and efficiency.

- Design: Comparing structural robustness and ergonomic features.

- Functionality: Analyzing versatility in different applications.

- Cost-effectiveness: Reviewing initial investment versus operational costs.

Among these models, the following points stand out:

- Engine specifications significantly impact overall productivity.

- Weight and size influence maneuverability in various environments.

- Available attachments can enhance functionality for specific tasks.

Ultimately, understanding these comparisons aids potential buyers in making informed decisions tailored to their needs.

Online Resources for Diagram Access

In the digital age, finding detailed visuals and schematics for machinery has become increasingly accessible. A variety of platforms offer valuable insights into the assembly and components of equipment, catering to both professionals and enthusiasts. This section explores reliable online sources that provide such essential information.

Key Websites

- Example Resource 1 – A comprehensive repository of technical schematics.

- Example Resource 2 – User-friendly platform for accessing and sharing technical drawings.

- Example Resource 3 – Community-driven site featuring a wide range of visuals and guides.

Forums and Community Groups

- Join discussion boards where users share their experiences and resources.

- Participate in social media groups focused on technical support and information sharing.

- Utilize platforms like Reddit to seek specific advice and resources from knowledgeable members.

User Experiences and Recommendations

This section aims to share insights and suggestions from individuals who have engaged with the equipment, highlighting practical advice and firsthand accounts that can enhance user experience.

Many users have emphasized the importance of understanding the components for optimal performance. Here are some key takeaways:

- Regular maintenance is crucial for longevity. Users recommend creating a routine check-up schedule.

- Familiarity with the setup can save time during installation. Detailed manuals are highly valued for clarity.

- Using high-quality replacement components can significantly improve efficiency.

Based on collective experiences, the following recommendations stand out:

- Always refer to reliable sources for troubleshooting guides to avoid unnecessary complications.

- Join online forums or communities to share experiences and seek advice from fellow users.

- Document any modifications or upgrades to keep track of changes and their impacts.

By following these insights and suggestions, users can enhance their interaction with the equipment and ensure a smoother operation overall.