Comprehensive Guide to Case 580 Super N Parts Diagram

When it comes to the intricate world of heavy equipment, grasping the various elements that make up these powerful machines is essential. Each component plays a critical role in ensuring optimal performance, efficiency, and longevity. Familiarity with the layout and interaction of these parts can significantly enhance maintenance efforts and operational knowledge.

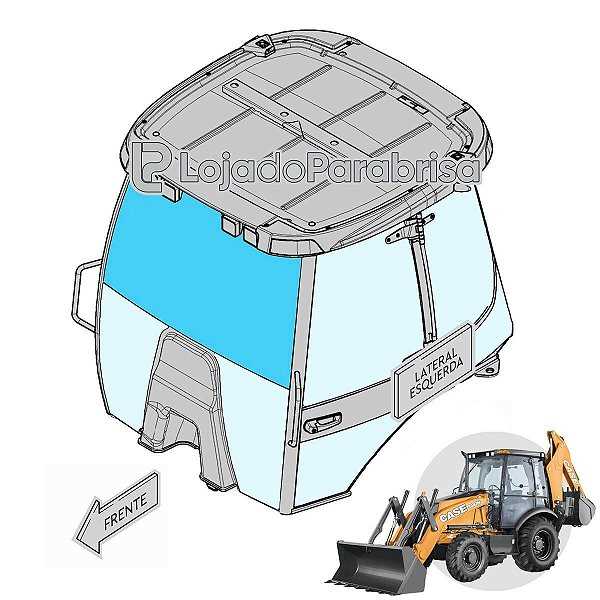

Visual representations of machinery can serve as invaluable tools for technicians and operators alike. They provide a clear overview, allowing individuals to identify specific sections and understand how each part contributes to the overall functionality. Whether for troubleshooting, repairs, or upgrades, having access to a detailed visual guide simplifies complex tasks.

Furthermore, a thorough comprehension of the machinery’s structure aids in recognizing potential issues before they escalate. By familiarizing oneself with the arrangement and relationship of various elements, operators can proactively manage equipment health and reduce downtime. This proactive approach not only extends the lifespan of the machinery but also ensures safety on the job site.

Understanding Case 580 Super N Parts

In the world of heavy machinery, a comprehensive grasp of the components that make up a machine is essential for optimal performance and maintenance. Each element plays a crucial role in ensuring the equipment operates efficiently, contributing to its overall functionality and longevity. This section delves into the significance of knowing these individual elements and how they work in harmony to achieve desired results.

The Importance of Component Knowledge

Being familiar with the various components enhances the ability to troubleshoot issues and perform repairs effectively. Understanding how each section interacts with others allows operators and technicians to make informed decisions regarding maintenance and upgrades. Knowledge of the mechanical intricacies can lead to improved performance and reduced downtime.

Common Components and Their Functions

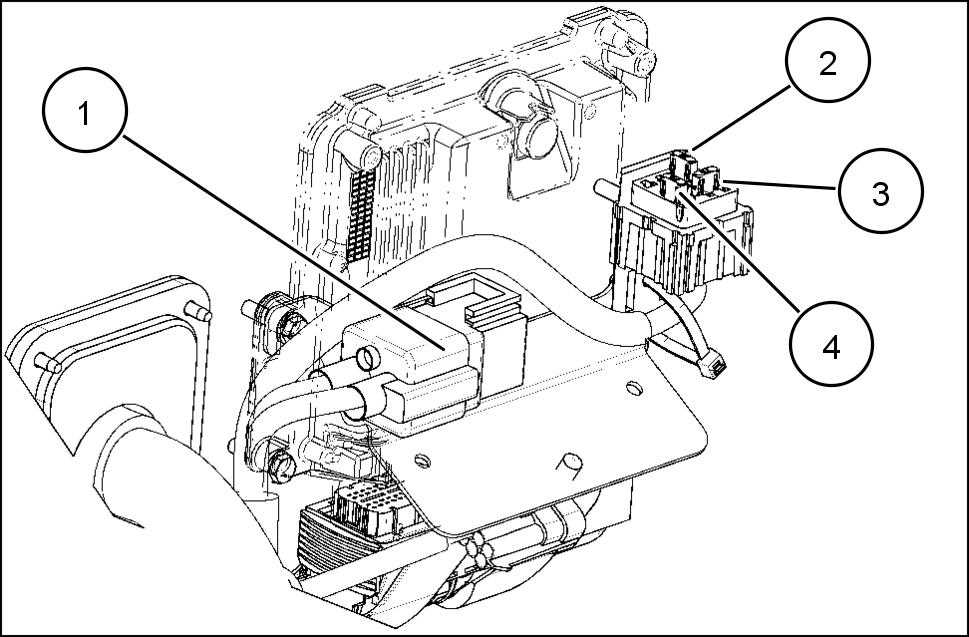

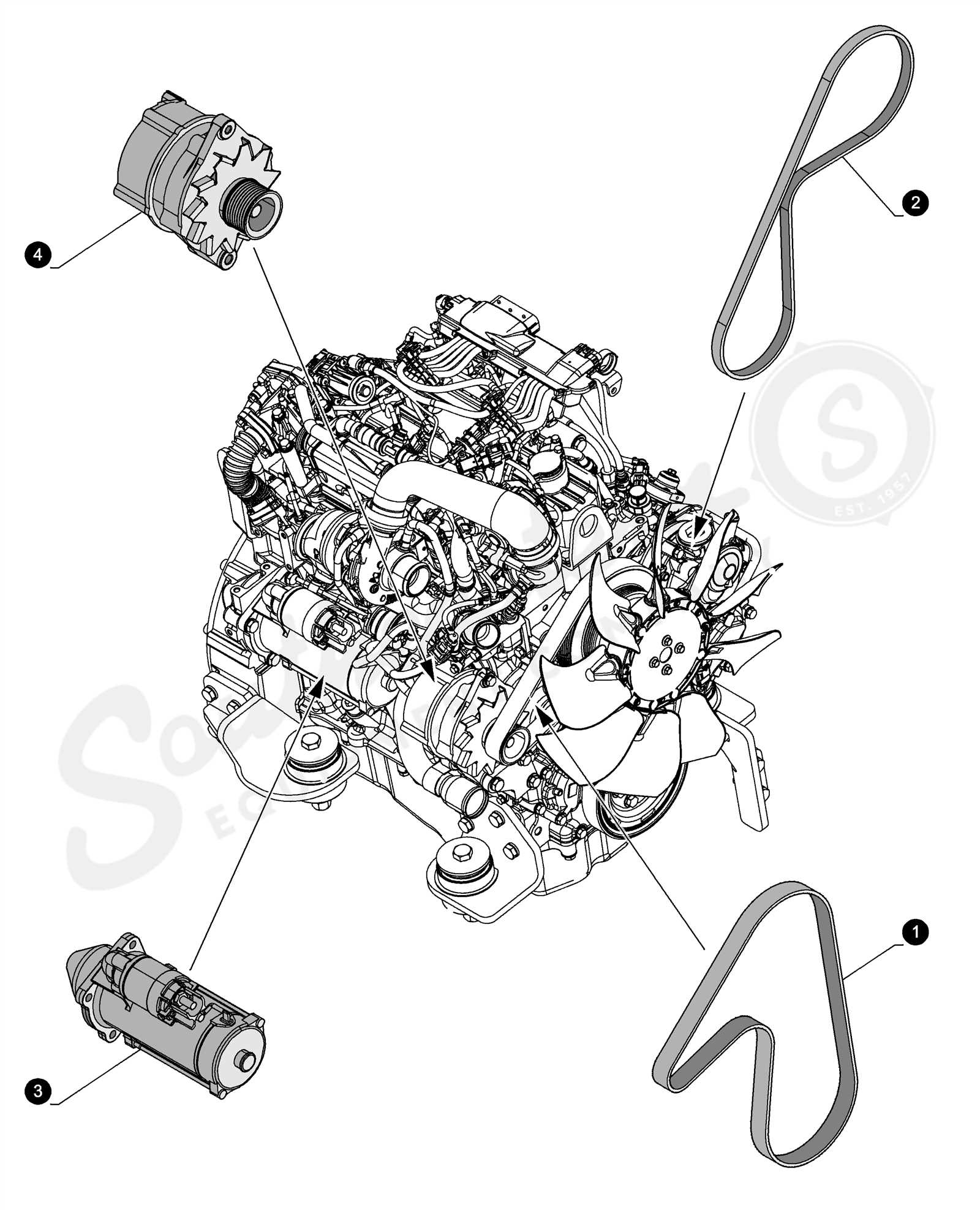

Among the vital elements are the engine, hydraulic systems, and transmission. The engine serves as the powerhouse, generating the necessary energy for operation. The hydraulic system facilitates movement and power transmission, while the transmission controls the speed and torque delivered to various attachments. Familiarity with these parts ensures effective handling of the machinery and maximizes productivity.

Overview of the Case 580 Super N

This section provides a comprehensive examination of a popular piece of machinery widely utilized in construction and landscaping. Known for its robustness and versatility, this model is favored by professionals for various applications, including digging, lifting, and loading tasks. Its design incorporates advanced engineering, ensuring reliability and efficiency in demanding environments.

Key Features: The machinery boasts a powerful engine that delivers impressive performance while maintaining fuel efficiency. Its user-friendly controls enhance operator comfort and precision, making it an ideal choice for both experienced operators and newcomers alike.

Durability and Maintenance: Built with high-quality materials, this model is engineered to withstand harsh working conditions. Regular maintenance is straightforward, allowing for prolonged use and reduced downtime. Accessing essential components for servicing is simplified, ensuring that operators can keep the equipment in optimal condition.

In summary, this machine exemplifies a perfect blend of power, versatility, and ease of use, making it a valuable asset in any fleet. Its reputation in the industry is a testament to its performance and reliability, setting a standard for others to follow.

Key Components of the Machine

Understanding the essential elements of this construction equipment is crucial for optimal performance and maintenance. Each component plays a vital role in the overall functionality, contributing to efficiency and durability.

Major Functional Parts

- Engine: The heart of the machine, providing the necessary power for operation.

- Hydraulic System: Facilitates movement and control of various attachments through fluid pressure.

- Transmission: Transmits power from the engine to the wheels, enabling mobility.

- Frame: The structure that supports all other components, ensuring stability and strength.

Operational Attachments

- Loader: Used for lifting and moving materials.

- Backhoe: Designed for digging and excavation tasks.

- Bucket: An attachment for scooping and carrying loose materials.

- Forks: Ideal for handling pallets and heavy loads.

Each of these components is integral to the overall operation, and understanding their roles can enhance both productivity and safety during use.

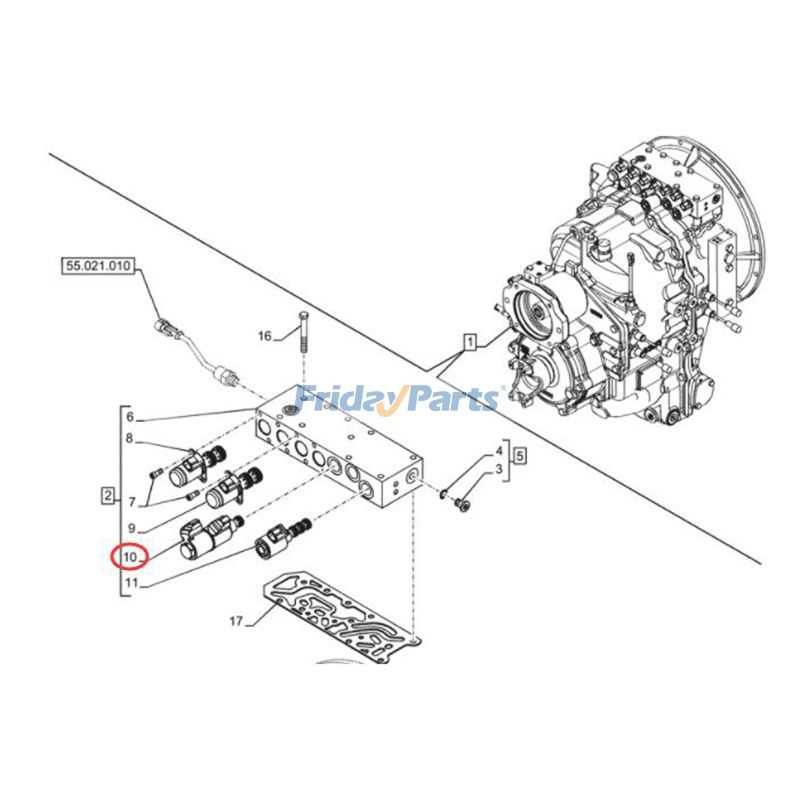

Importance of Parts Diagrams

Understanding the intricate components of machinery is essential for effective maintenance and repair. Visual representations serve as invaluable tools, offering clarity and guidance for both professionals and enthusiasts. They help to identify individual elements, making it easier to pinpoint issues and streamline the repair process.

Enhanced Clarity

Detailed illustrations allow users to visualize complex assemblies, simplifying the task of locating and recognizing each component. This clarity is particularly beneficial during troubleshooting, enabling quick identification of worn or damaged elements. Moreover, clear representations contribute to better communication among team members, ensuring everyone is on the same page regarding repairs and replacements.

Facilitating Efficient Repairs

By utilizing these visual aids, technicians can efficiently navigate the intricacies of equipment. When a breakdown occurs, having a reference at hand minimizes downtime and maximizes productivity. Understanding the arrangement of components not only aids in quick repairs but also enhances preventive maintenance practices, ultimately extending the lifespan of the machinery.

In summary, visual guides are essential tools that enhance understanding, facilitate efficient repairs, and promote effective maintenance practices. Their role in the repair process cannot be overstated, as they provide the clarity needed to keep machinery running smoothly.

How to Read a Parts Diagram

Understanding an illustration of components is essential for effective maintenance and repair tasks. These visual representations serve as guides, helping users identify various elements, their functions, and how they fit together within a larger assembly.

To effectively interpret such a representation, consider the following steps:

- Familiarize Yourself with the Legend:

- Look for a legend that explains symbols or abbreviations.

- Note any color codes used to differentiate components.

- Identify Major Sections:

- Break down the illustration into its main segments.

- Understand how these sections relate to the overall function.

- Locate Specific Components:

- Use the numbering system to find individual items quickly.

- Cross-reference with any accompanying parts list for details.

- Analyze Connections:

- Observe how components interact and connect with each other.

- Identify any fasteners or attachments that may be needed.

- Take Notes:

- Jot down any parts that need replacement or inspection.

- Document any observations regarding assembly order or installation techniques.

By following these guidelines, users can navigate through any representation of components with confidence, ensuring accurate repairs and effective maintenance strategies.

Common Issues and Solutions

In the realm of heavy machinery, understanding typical challenges and their remedies is essential for efficient operation. Operators often encounter various mechanical or functional problems that can hinder productivity. Identifying these issues promptly can lead to effective solutions and minimize downtime.

Frequent Challenges

- Poor Performance: Machines may not operate at expected efficiency due to wear and tear.

- Hydraulic Failures: Leaks or pressure drops can cause significant operational setbacks.

- Electrical Malfunctions: Issues with wiring or components can lead to operational failures.

- Starting Difficulties: Problems with ignition or fuel supply can prevent the engine from starting.

Recommended Solutions

- Regular Maintenance: Conduct routine inspections and replace worn components to ensure optimal performance.

- Hydraulic System Checks: Regularly inspect hoses and connections for leaks; replace damaged parts as needed.

- Electrical System Diagnostics: Utilize diagnostic tools to identify and fix wiring issues promptly.

- Fuel System Inspection: Ensure the fuel supply is adequate and clean to prevent starting problems.

Where to Find Replacement Parts

Locating suitable components for machinery maintenance can often be a challenging task. Understanding where to seek reliable suppliers is crucial for ensuring optimal performance and longevity of your equipment. Various avenues exist for sourcing these essential items, each offering distinct advantages.

One of the most effective methods is to explore authorized dealers, who typically provide genuine components tailored specifically for your model. Additionally, online marketplaces have emerged as convenient platforms, offering a wide range of alternatives at competitive prices. It’s also beneficial to tap into forums and community groups, where fellow enthusiasts share insights and recommendations about reputable sources. Lastly, local repair shops can be invaluable resources, often possessing both new and refurbished options for critical elements.

Maintenance Tips for Longevity

Regular upkeep is crucial for ensuring the extended life and optimal performance of heavy machinery. Implementing a consistent maintenance routine not only enhances functionality but also minimizes the likelihood of unexpected failures. By focusing on key areas, operators can achieve a smoother operation and reduced downtime.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Fluid Checks and Changes | Every 100 hours | Prevents overheating and wear |

| Filter Replacements | Every 200 hours | Improves system efficiency |

| Visual Inspections | Weekly | Identifies potential issues early |

| Tire and Track Condition | Monthly | Ensures proper traction and stability |

| Greasing Moving Parts | Every 50 hours | Reduces friction and extends component life |

By adhering to these guidelines, operators can foster a reliable and efficient machine, thereby enhancing productivity and reducing long-term costs.

Comparison with Other Models

When examining different machinery, it’s crucial to assess their unique features and specifications to understand how they stack up against each other. This section delves into the distinctions and similarities of a specific model in relation to its competitors, highlighting aspects such as performance, functionality, and user experience.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 85 HP | 90 HP | 80 HP |

| Operating Weight | 8,000 lbs | 8,500 lbs | 7,500 lbs |

| Digging Depth | 12 ft | 11 ft | 13 ft |

| Loader Capacity | 2,500 lbs | 2,700 lbs | 2,300 lbs |

| Fuel Efficiency | 25 MPG | 22 MPG | 24 MPG |

Each model exhibits distinct characteristics that cater to varying needs, making it essential for operators to consider these differences when selecting the most suitable option for their tasks. Factors such as engine output and operational weight play a significant role in determining overall effectiveness in diverse work environments.

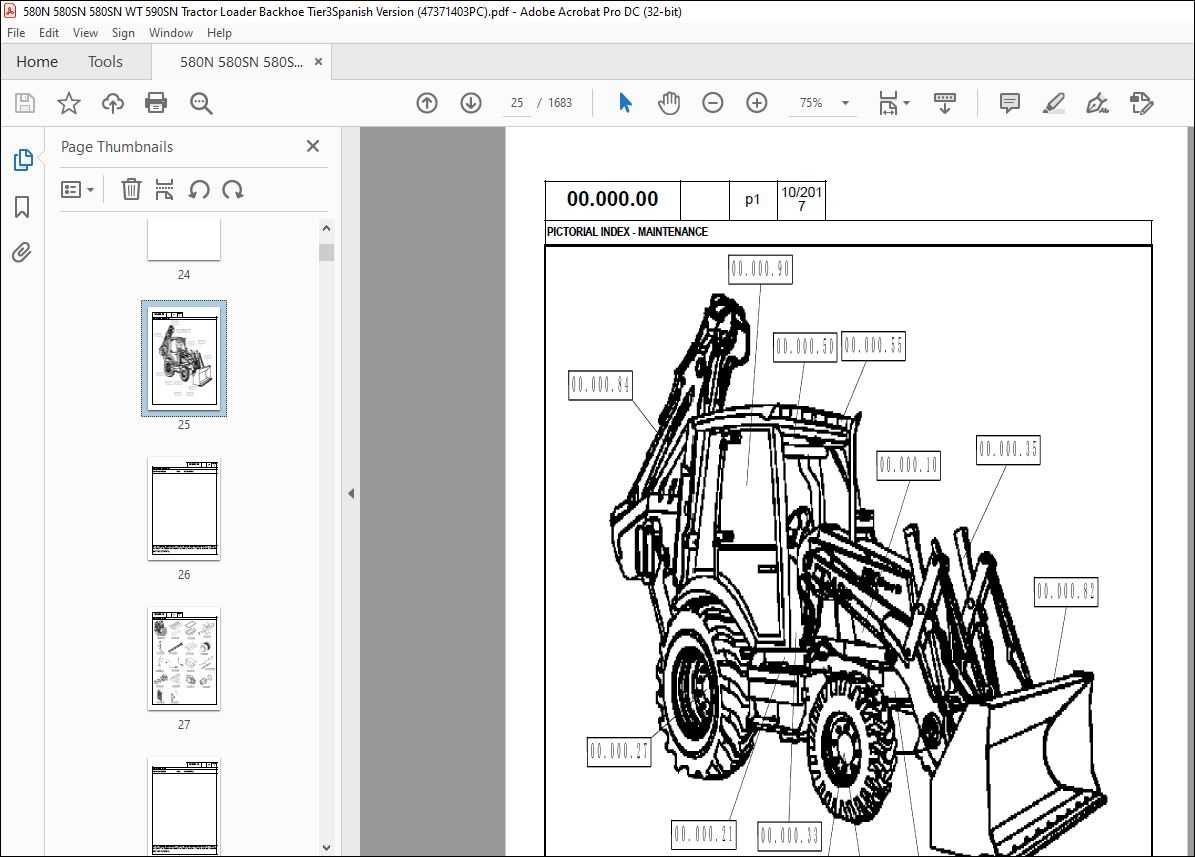

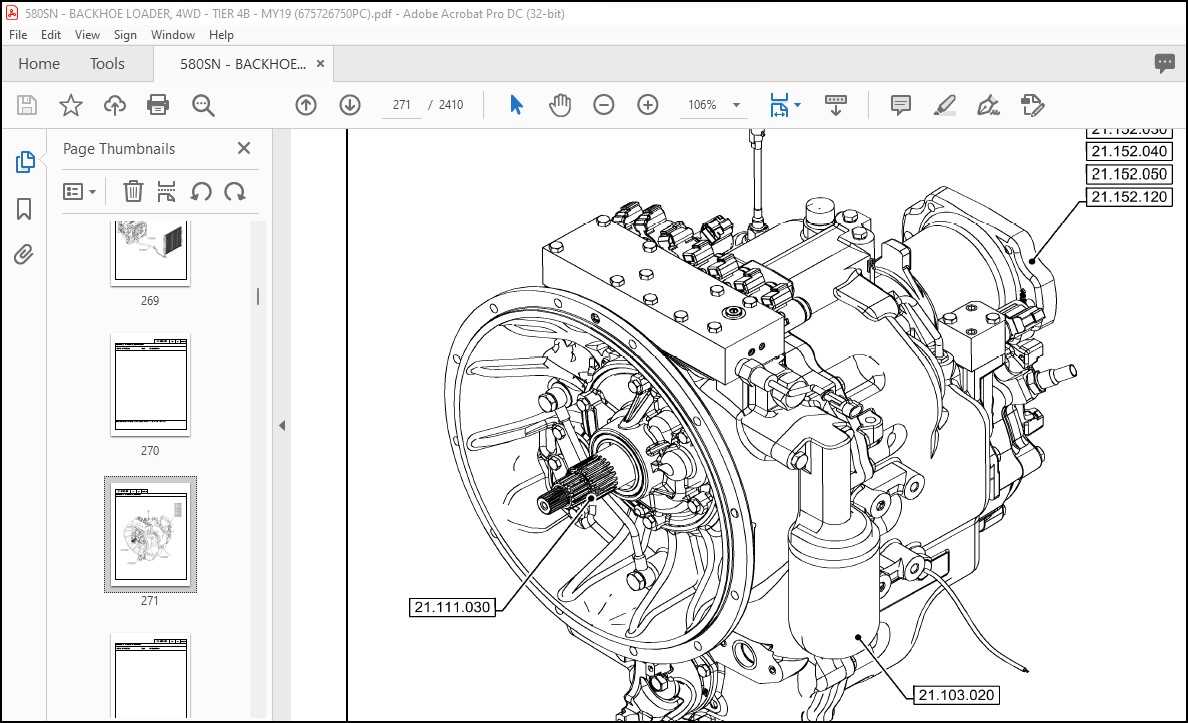

Resources for Repair Manuals

Accessing accurate and detailed documentation is crucial for anyone involved in machinery maintenance. These manuals provide essential insights into the assembly, disassembly, and troubleshooting of equipment. Whether you’re a seasoned technician or a novice, having the right resources at your disposal can greatly enhance your repair efforts.

Where to Find Manuals

- Manufacturer Websites: Many original equipment manufacturers offer downloadable manuals directly on their websites. This is often the most reliable source for the latest versions.

- Online Retailers: Websites like eBay or Amazon may list new or used manuals, sometimes at affordable prices.

- Specialized Forums: Online communities and forums dedicated to machinery often have members who share or sell copies of repair manuals.

- Library Resources: Local libraries or technical colleges may have physical or digital collections of repair manuals available for public access.

Types of Documentation Available

- Service Manuals: Comprehensive guides that cover repair and maintenance procedures.

- Owner’s Manuals: Basic guides providing operational instructions and maintenance tips.

- Technical Bulletins: Updates and advisories that offer specific instructions on common issues and fixes.

- Parts Catalogs: Listings that provide part numbers and descriptions for ordering replacements.

Frequently Asked Questions

This section addresses common inquiries related to equipment components and their arrangements. Here, we aim to provide clear and concise answers to help users better understand the subject matter and facilitate maintenance or repairs.

What should I do if I can’t find a specific component?

If you’re having trouble locating a certain part, consider checking various suppliers online or consulting the manufacturer’s resources. Additionally, forums and communities dedicated to machinery can often provide valuable insights and alternative sourcing options.

How often should I perform maintenance on my equipment?

Regular maintenance is essential for optimal performance. It’s recommended to follow the guidelines provided in the user manual, which typically outline maintenance intervals based on usage. Keeping an eye on wear and tear will also help you determine the best schedule for your needs.

Contacting Support for Assistance

Reaching out for help when encountering issues with machinery is essential for maintaining efficiency and productivity. Whether you’re facing a technical challenge or need clarification on operation, effective communication with support teams can lead to swift resolutions. Understanding how to navigate this process is crucial for minimizing downtime.

Preparing Your Inquiry

Before contacting support, gather all relevant information regarding your situation. Include specific details such as model numbers, symptoms of the problem, and any troubleshooting steps you’ve already taken. This information allows the support team to assist you more efficiently and provides context for your issue.

Using Available Channels

Utilize the various contact methods provided, such as phone, email, or online chat. Each option offers distinct advantages; for instance, phone calls allow for real-time dialogue, while emails can be useful for detailed explanations. Always ensure to be clear and concise in your communication, which enhances the likelihood of a prompt and accurate response.

Remember that support teams are there to help you, and maintaining a courteous demeanor can facilitate better interactions. Be patient as they work through your inquiry, and don’t hesitate to ask follow-up questions if necessary.