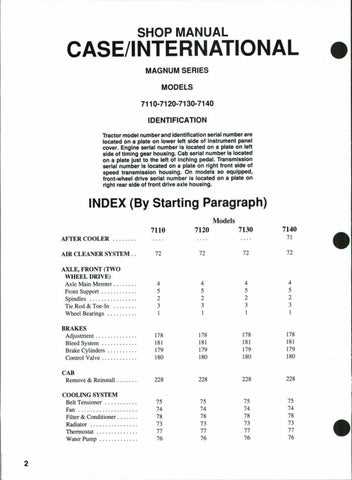

Comprehensive Guide to Case IH 7120 Parts Diagram

In the world of agricultural machinery, a comprehensive grasp of the various elements that comprise modern equipment is crucial for optimal performance and longevity. Each component plays a vital role, ensuring that the machinery operates efficiently and effectively in the field. As technology advances, so does the complexity of these systems, making knowledge about their structure and function more important than ever.

When it comes to maintenance and repairs, having access to a detailed overview of the assembly is indispensable. This information not only aids in identifying the right elements but also facilitates troubleshooting, helping operators to quickly resolve issues that may arise during operation. Understanding the arrangement and interaction of these components can lead to improved operational efficiency and reduced downtime.

By exploring the intricate layouts of these essential systems, users can enhance their familiarity with the machinery, ultimately leading to better care and performance. This article delves into the specifics of component organization, offering insights that empower users to maintain and repair their equipment effectively.

Understanding the Case IH 7120

Exploring the intricacies of modern agricultural machinery reveals a world of engineering excellence and operational efficiency. Each model is designed to enhance productivity, ensuring farmers can tackle their tasks with precision. This particular machine exemplifies the balance between power and user-friendly features, making it a staple in contemporary farming practices.

Key Features and Specifications

This model is renowned for its robust performance capabilities, powered by an advanced engine designed to handle demanding tasks. Its intuitive controls and ergonomic design contribute to a seamless user experience, allowing operators to focus on their work without unnecessary distractions. Additionally, the incorporation of innovative technologies optimizes fuel efficiency, enabling sustainable agricultural practices.

Maintenance and Care

Overview of Case IH Tractors

These agricultural machines are renowned for their innovative technology and exceptional performance, catering to a diverse range of farming needs. With a commitment to quality and efficiency, these vehicles have become a staple in the industry, helping farmers optimize their productivity and manage their operations more effectively.

Key Features

The latest models are equipped with advanced features that enhance usability and reliability. From powerful engines to sophisticated monitoring systems, these machines are designed to tackle various tasks, from plowing to harvesting. Additionally, ergonomic designs ensure operator comfort, allowing for long hours of work without fatigue.

Innovative Technology

Recent advancements include precision farming technologies that allow for data-driven decision-making. Integration with GPS systems and automated controls enables greater accuracy and efficiency, significantly improving crop yields. As agriculture evolves, these machines continue to adapt, ensuring farmers stay ahead in a competitive market.

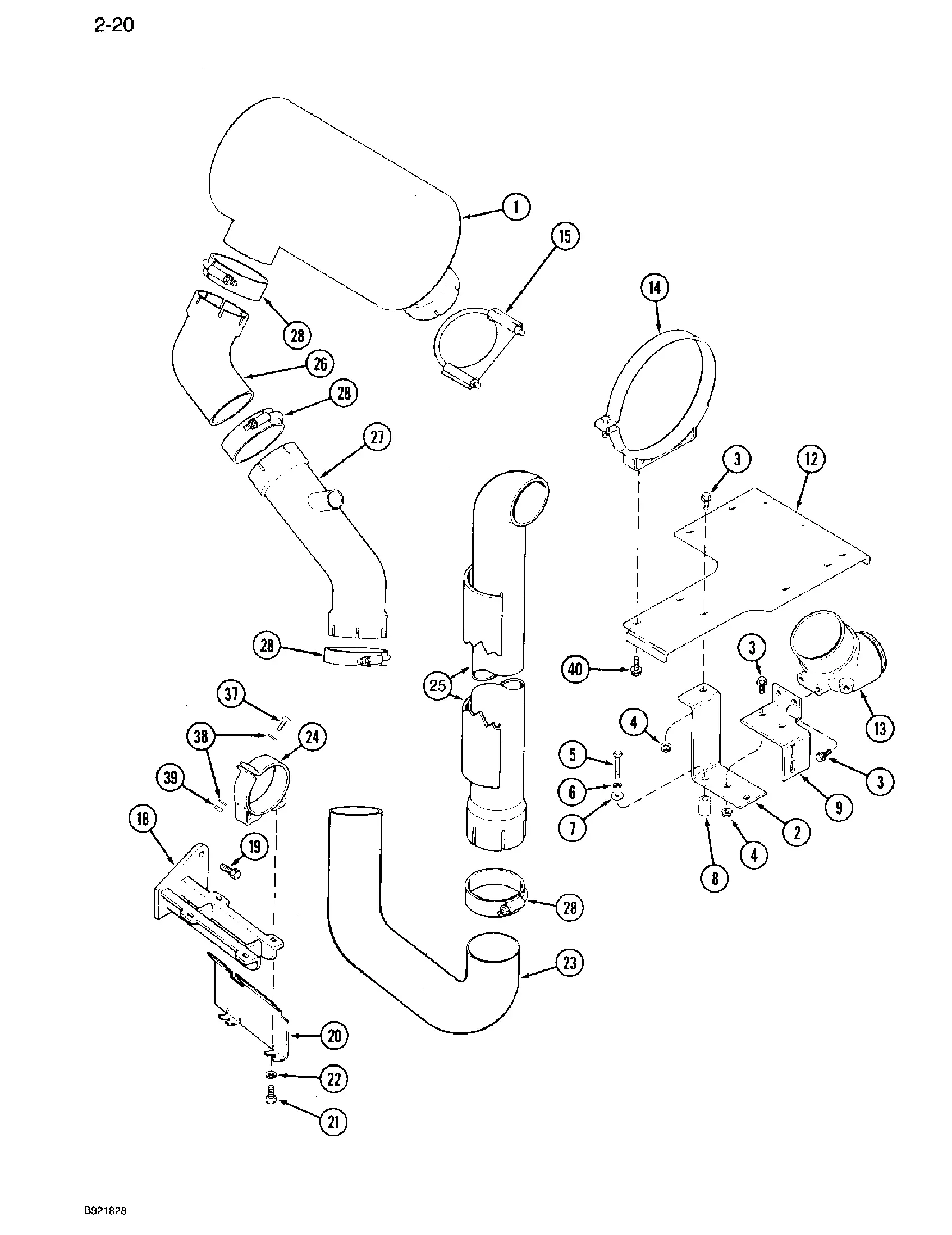

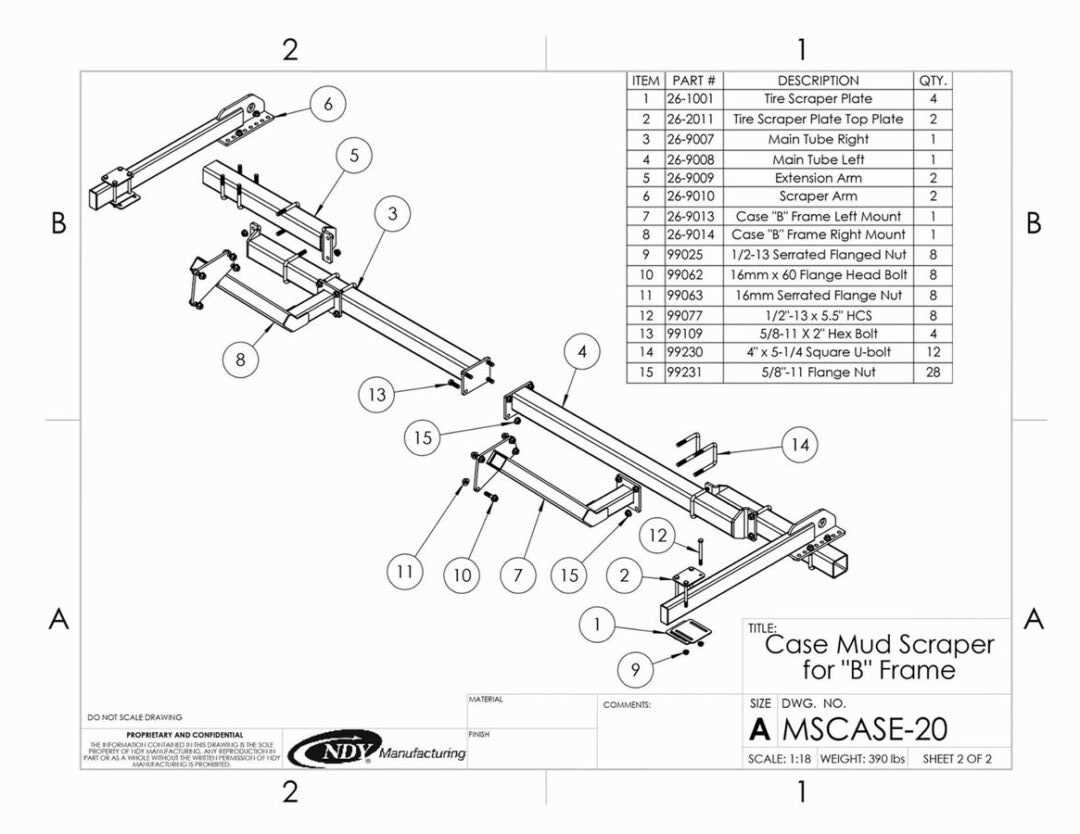

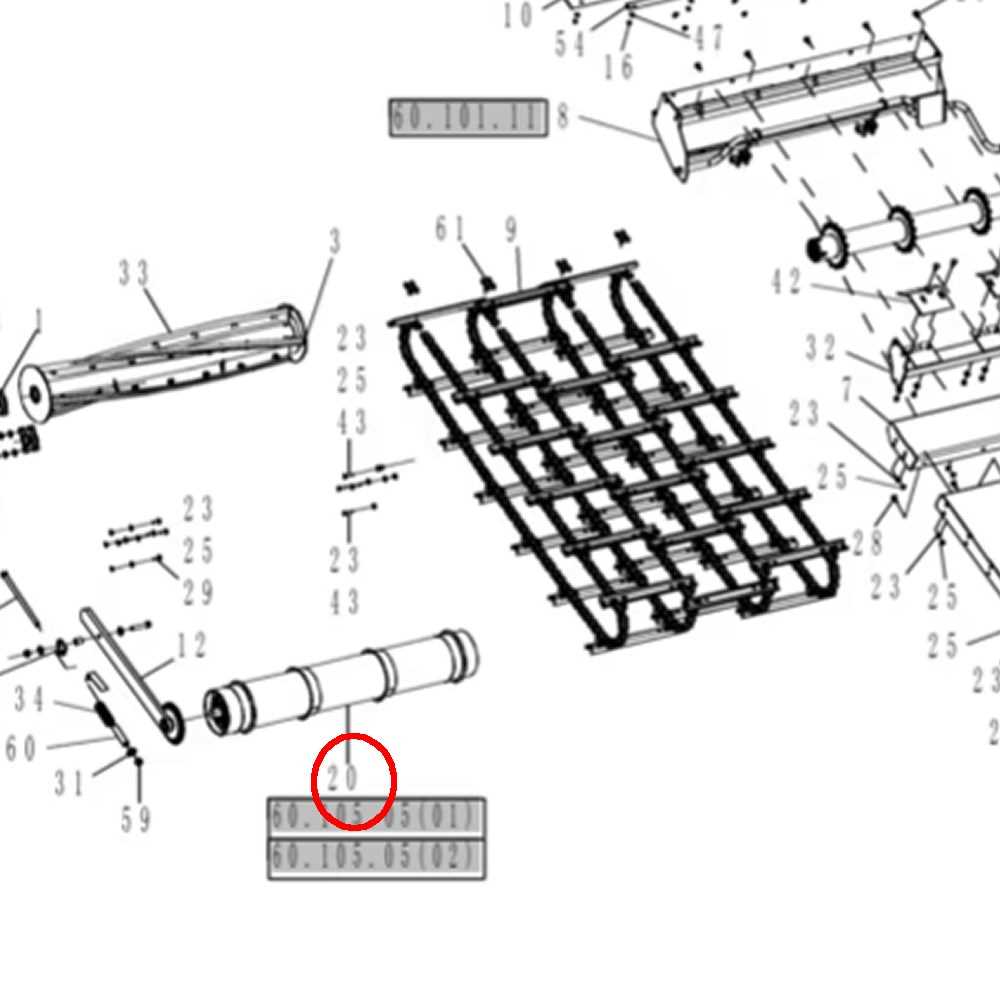

Importance of Parts Diagrams

Understanding the assembly of machinery is crucial for effective maintenance and repairs. Visual representations of components play a vital role in simplifying the identification and organization of various elements within complex systems. By breaking down the structure into easily interpretable segments, these illustrations enhance clarity and facilitate informed decision-making.

Having a visual reference allows technicians to quickly locate specific elements, reducing the time spent searching for parts. This efficiency not only expedites repairs but also minimizes downtime, which is essential for operational effectiveness.

Furthermore, these visuals serve as a valuable educational tool for both seasoned professionals and novices. They provide insight into the relationships between different components, fostering a deeper understanding of the machinery’s functionality.

| Benefits | Description |

|---|---|

| Enhanced Efficiency | Reduces time spent on identifying components. |

| Improved Understanding | Facilitates learning about component relationships. |

| Minimized Downtime | Speeds up repair processes for better productivity. |

| Accurate Repairs | Ensures the correct parts are replaced or serviced. |

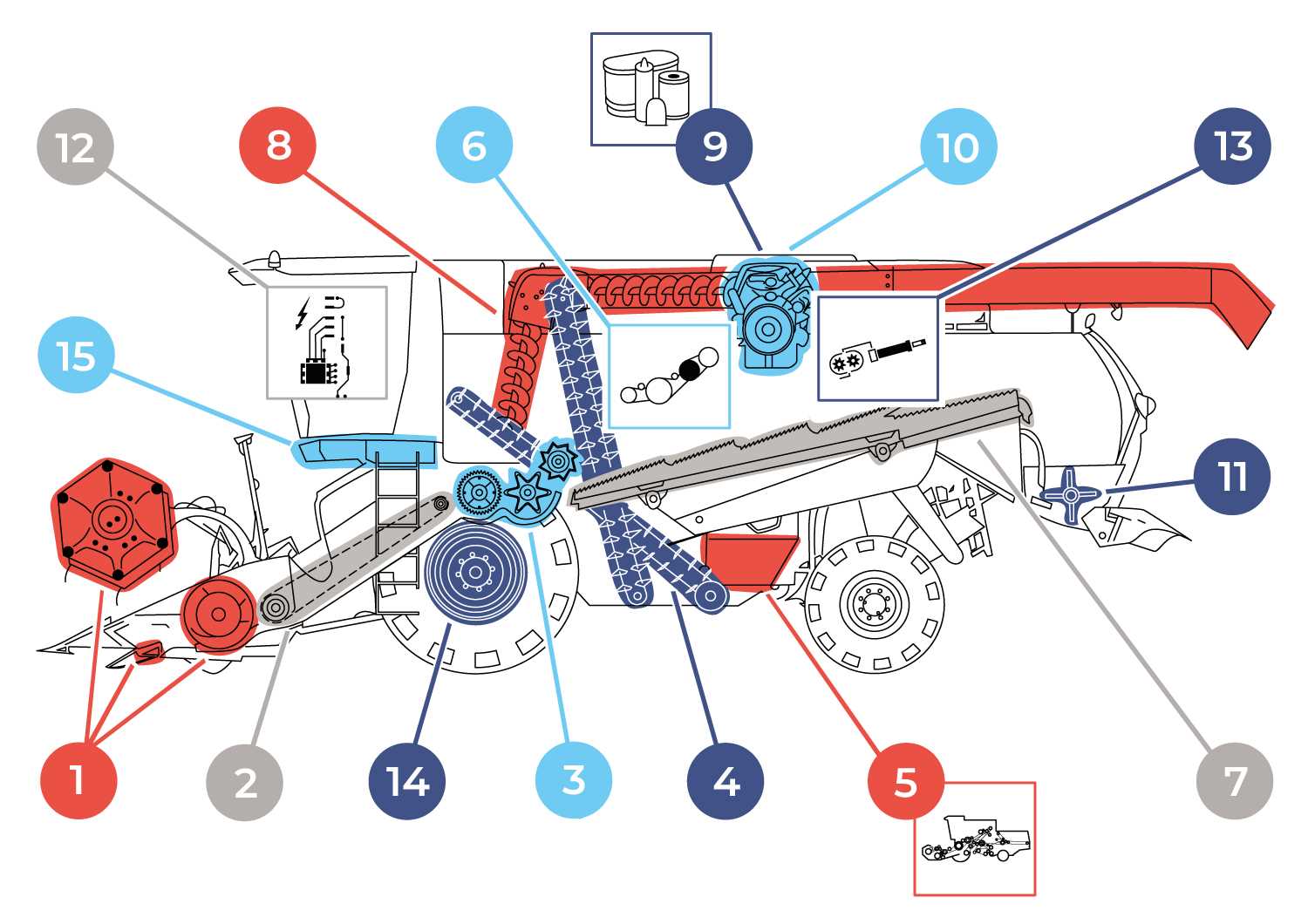

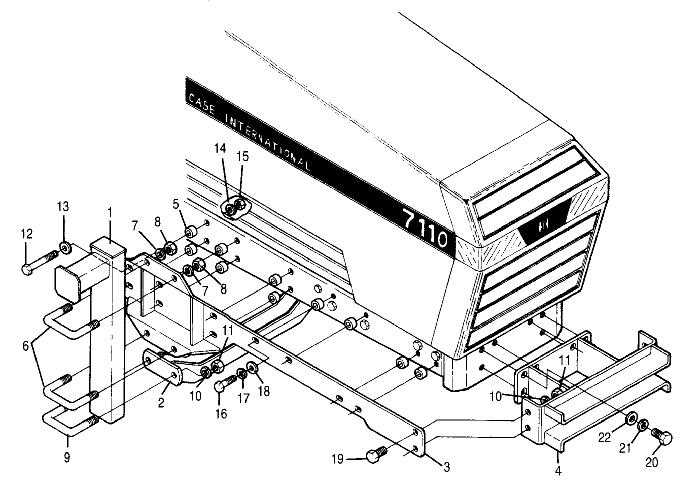

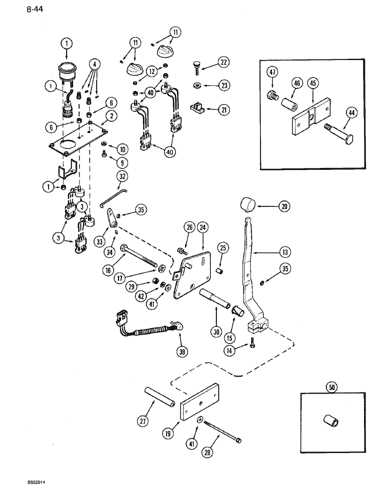

Key Components of the 7120 Model

The robust machinery is designed with several crucial elements that enhance its functionality and efficiency in agricultural operations. Understanding these components is essential for optimal maintenance and operation.

- Engine: The powerhouse of the equipment, providing the necessary torque and horsepower for various tasks.

- Transmission: This system ensures smooth power transfer, allowing for seamless speed adjustments during operation.

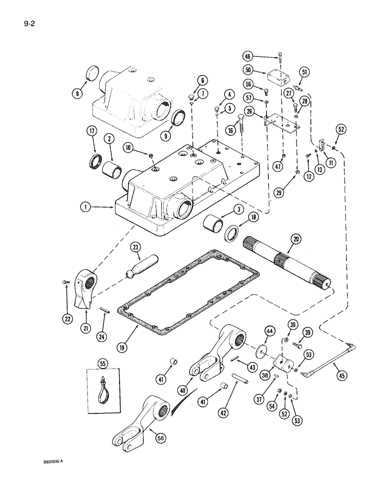

- Hydraulic System: Vital for controlling attachments and implements, it offers precise handling and responsiveness.

- Chassis: The framework that supports the entire machine, contributing to its stability and durability on uneven terrain.

- Cab: The operator’s space, equipped with controls and technology for enhanced comfort and visibility.

- Wheels and Tracks: These components are essential for mobility, ensuring traction and stability in diverse field conditions.

Each element works in harmony to maximize performance, making this machinery an invaluable asset in modern farming practices.

How to Access the Parts Diagram

Understanding the intricacies of machinery often requires a visual reference that details the various components involved. Accessing this visual resource can greatly enhance your knowledge of the equipment and aid in maintenance or repairs. The following sections will guide you through the steps to obtain this essential reference material.

Online Resources

Numerous websites provide access to detailed schematics. Start by visiting the official manufacturer’s site, which typically offers a repository of manuals and illustrations. You can also explore third-party platforms that specialize in agricultural machinery. Using the search function, input the model number or type of equipment to locate the relevant resources.

Local Dealerships

If online searches yield limited results, consider reaching out to local dealers. These establishments often have access to exclusive materials and can provide you with printed versions or digital files. Additionally, the staff may offer valuable insights and assistance regarding the equipment in question.

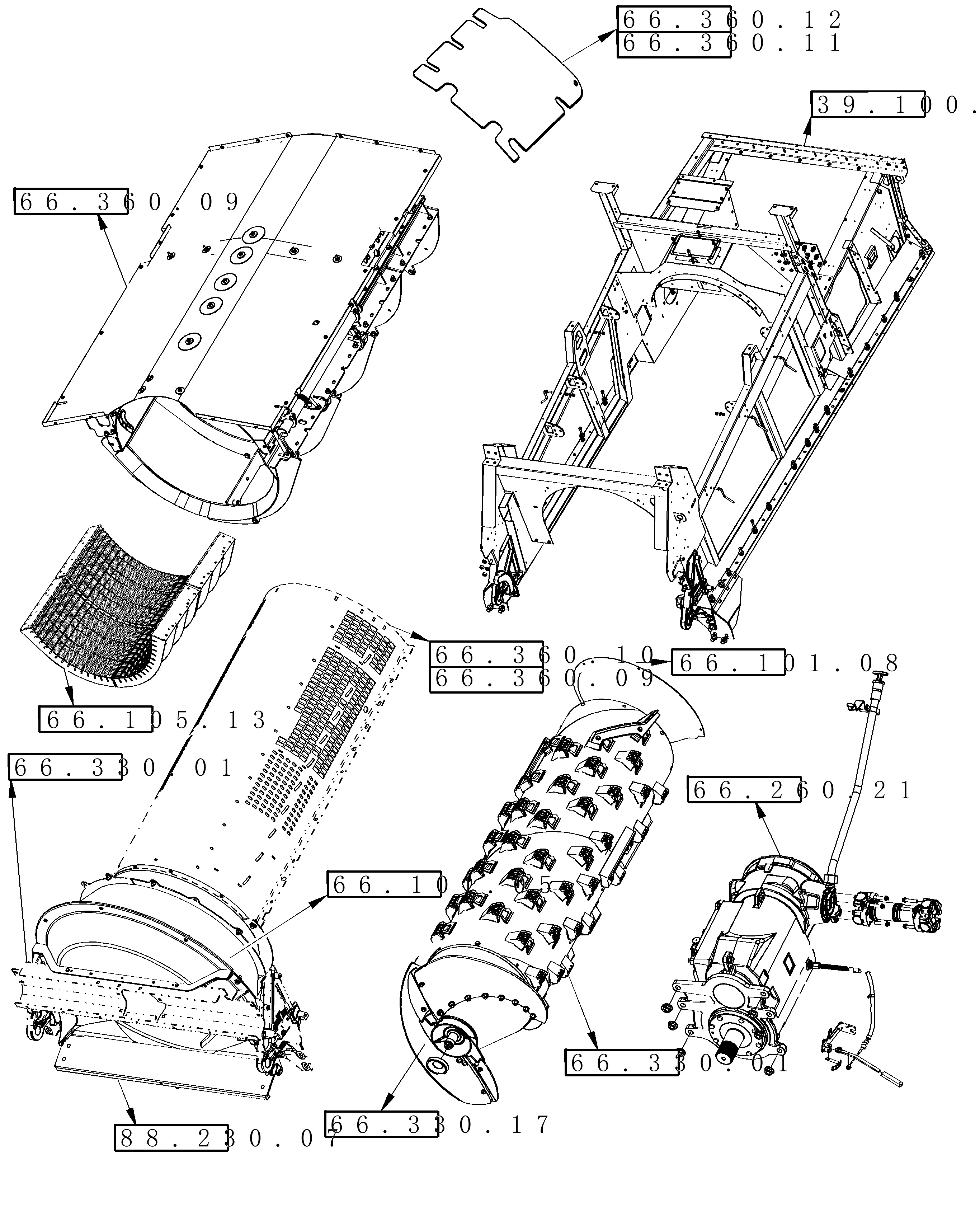

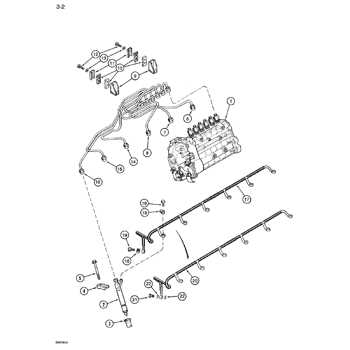

Identifying Major Assemblies

Understanding the core components of agricultural machinery is essential for effective maintenance and operation. Recognizing the key assemblies not only aids in troubleshooting but also facilitates informed decisions regarding repairs and replacements. This section outlines the primary groupings of parts commonly found in these machines, enhancing overall comprehension of their structure and function.

Main Groupings

- Engine Assembly

- Transmission System

- Hydraulic Mechanism

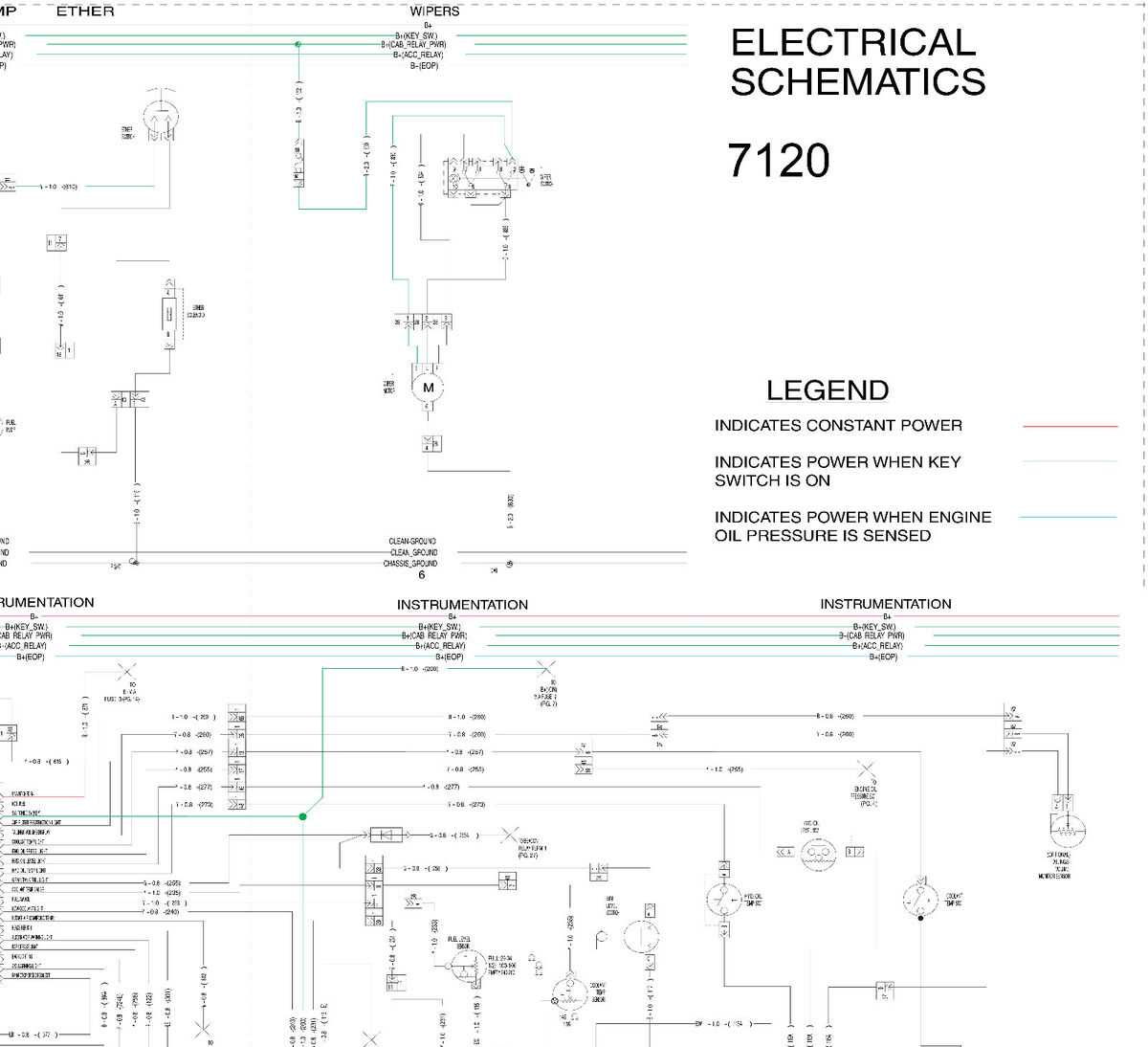

- Electrical Components

- Chassis Framework

Each of these major assemblies plays a critical role in the performance and efficiency of the equipment. Familiarizing oneself with these groupings will help in identifying issues and ensuring optimal functionality.

Assembly Breakdown

- Engine Assembly: The powerhouse that drives the entire system, responsible for converting fuel into mechanical energy.

- Transmission System: Facilitates the transfer of power from the engine to the wheels, enabling movement and speed control.

- Hydraulic Mechanism: Powers various functions such as lifting and steering through the use of pressurized fluid.

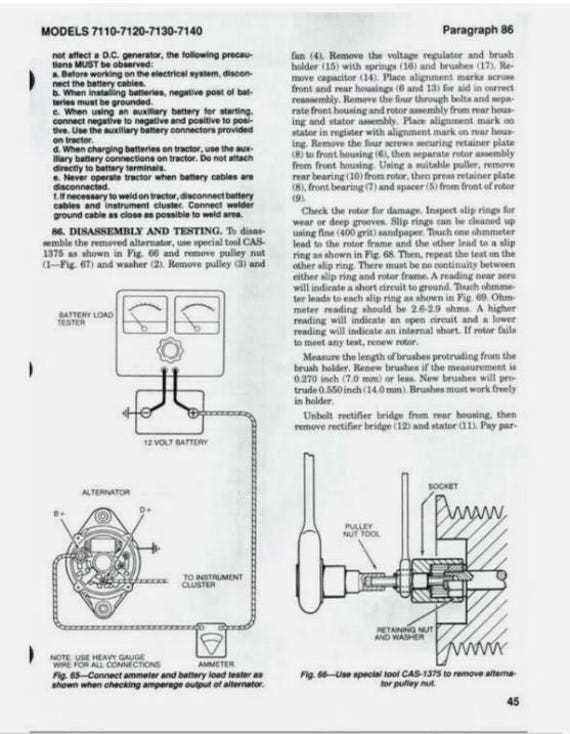

- Electrical Components: Includes the wiring, batteries, and electronic systems that manage operations and safety features.

- Chassis Framework: The structural base that supports all components and provides stability during operation.

Recognizing these major assemblies allows operators to effectively communicate issues and streamline the maintenance process, ensuring longevity and reliability in field operations.

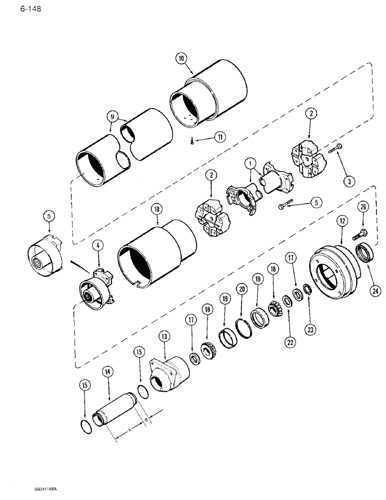

Common Replacement Parts Explained

Understanding the essential components of machinery is crucial for effective maintenance and optimal performance. Regularly replacing worn-out elements not only enhances efficiency but also extends the lifespan of the equipment. This section delves into the most frequently replaced components, highlighting their significance and function within the overall system.

Key Components

Filters are vital in maintaining fluid cleanliness, whether for oil, fuel, or air. These elements prevent contaminants from entering critical areas, ensuring smooth operation and reducing wear. Regular replacement is necessary to keep systems running efficiently and to prevent costly damage.

Belts and Hoses

Drive belts and hoses play essential roles in transferring power and fluids throughout the machinery. Over time, exposure to heat and friction can lead to wear and tear. Timely replacement of these items is important to avoid breakdowns and maintain operational integrity. Regular inspections can help identify signs of deterioration, allowing for proactive measures before failure occurs.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your agricultural machinery requires regular upkeep and attention to detail. Proper maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns and costly repairs.

- Regular Inspections: Conduct routine checks on all essential components to identify wear and tear early. This includes belts, hoses, and electrical systems.

- Fluid Levels: Maintain optimal fluid levels, including engine oil, coolant, and hydraulic fluid. Regularly replace these fluids to ensure smooth operation.

- Air Filters: Clean or replace air filters frequently to ensure proper airflow and engine efficiency.

- Tire Maintenance: Regularly check tire pressure and tread condition. Properly inflated and maintained tires improve traction and fuel efficiency.

- Cleaning: Keep the exterior and interior of the machine clean. Remove dirt and debris to prevent corrosion and mechanical issues.

By adhering to these practices, you can significantly enhance the operational efficiency and reliability of your equipment, ensuring it performs optimally for many seasons to come.

Finding OEM vs. Aftermarket Parts

When it comes to sourcing components for machinery, enthusiasts and professionals often face a choice between original manufacturer offerings and alternatives from third-party suppliers. Each option has its own set of advantages and disadvantages, making it crucial to understand what aligns best with your needs and budget.

Advantages of OEM Components

- Quality Assurance: Manufactured to the original specifications, ensuring compatibility and performance.

- Warranty Protection: Often comes with a warranty, providing peace of mind in case of defects.

- Reliability: Typically designed for long-lasting use, minimizing the risk of failure during operation.

Benefits of Aftermarket Offerings

- Cost-Effectiveness: Usually available at a lower price point, making them attractive for budget-conscious buyers.

- Variety: A wider selection may offer features or enhancements not found in original products.

- Availability: Often easier to find, especially for older or less common models.

Ultimately, the choice between these options hinges on your specific requirements, including performance expectations, budget constraints, and the importance of warranty coverage.

Cost Considerations for Replacement Parts

When it comes to maintaining agricultural machinery, understanding the financial implications of acquiring new components is crucial. Factors influencing expenses can range from the type of equipment to the specific elements that need replacement. It’s essential for operators to weigh the costs against the potential benefits of keeping their machinery in optimal working condition.

Quality vs. Price

Choosing between high-quality and budget-friendly options often presents a dilemma. While lower-priced components may seem attractive initially, they can lead to higher long-term costs due to increased wear or more frequent replacements. Investing in durable and reliable components can enhance performance and reduce downtime, ultimately proving to be more economical over time.

Availability and Sourcing

The source from which components are acquired can significantly impact pricing. Authorized dealers often offer reliable quality but at a premium, while aftermarket suppliers might provide more competitive pricing. However, it’s vital to consider the reputation of the supplier and the warranty offered, as these factors can influence the overall value of the purchase.

Understanding Warranty and Support Options

When investing in agricultural machinery, it’s essential to grasp the various warranty and support provisions available. These options not only safeguard your investment but also ensure you have access to necessary assistance throughout the machinery’s lifecycle.

Here are key components to consider regarding warranty and support:

- Types of Warranties:

- Limited Warranty: Covers specific parts for a set period.

- Comprehensive Warranty: Provides broader coverage, including labor costs.

- Extended Warranty: Options to prolong the coverage beyond the standard period.

- Support Services:

- Technical Assistance: Access to experts for troubleshooting and advice.

- Maintenance Plans: Scheduled services to keep machinery in optimal condition.

- Replacement Services: Availability of replacement parts when needed.

- Claim Process:

- Documentation: Importance of maintaining records of purchases and services.

- Procedure: Understanding the steps to initiate a claim for warranty services.

- Response Time: Awareness of expected timelines for support responses.

By familiarizing yourself with these aspects, you can ensure your equipment remains reliable and efficient, minimizing downtime and maximizing productivity.

Resources for Further Information

In today’s world, access to accurate information is essential for maintaining and repairing agricultural machinery. Whether you are a seasoned technician or a farmer looking to understand your equipment better, a variety of resources are available to enhance your knowledge and skills.

Online Resources

- Manufacturer Websites: Explore official websites for technical manuals, user guides, and troubleshooting advice specific to your machinery.

- Online Forums: Join communities of enthusiasts and professionals where you can ask questions and share experiences.

- Video Tutorials: Platforms like YouTube host numerous instructional videos that provide step-by-step guidance on various maintenance tasks.

Books and Publications

- Technical Manuals: Consider purchasing comprehensive manuals that cover detailed maintenance procedures.

- Industry Journals: Subscribe to journals that focus on agricultural technology to stay updated on the latest advancements and best practices.

- Guides and Handbooks: Look for printed or digital resources that provide insights into troubleshooting and repairs.