Understanding the Case TR270 Parts Diagram for Efficient Maintenance

In the world of industrial equipment, comprehending the arrangement and functionality of individual elements is crucial for efficient maintenance and operation. Knowing how each part interacts within a larger system can significantly enhance performance and longevity. A detailed overview of these configurations provides valuable insights for technicians and operators alike.

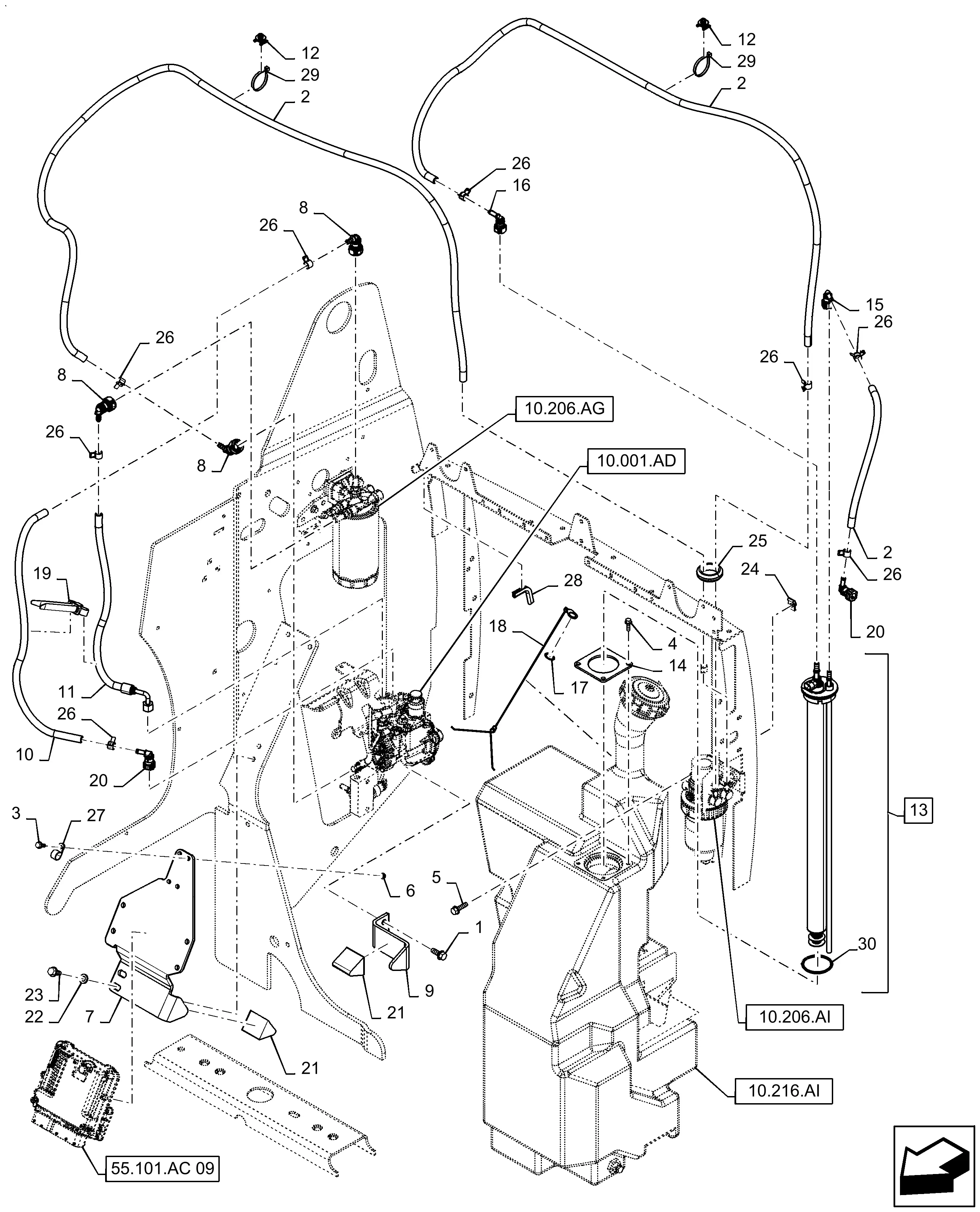

Visual representations of these assemblies serve as essential references, allowing for quick identification and troubleshooting. Such illustrations enable users to navigate complex machinery with greater ease, ensuring that each segment functions optimally. By breaking down the intricate relationships between components, one can better appreciate the engineering behind these robust machines.

Furthermore, familiarizing oneself with these schematics not only aids in repair but also fosters a deeper understanding of the overall mechanical design. This knowledge empowers users to make informed decisions regarding upgrades and modifications, ultimately leading to improved operational efficiency and reduced downtime.

Overview of Case TR270

This section provides a comprehensive look at a compact yet powerful piece of machinery designed for various applications. With its robust construction and innovative features, this equipment is an essential tool in numerous industries.

The following aspects highlight the key attributes and functionalities of this model:

- Performance: Equipped with a powerful engine, it delivers impressive output and efficiency, making it suitable for demanding tasks.

- Versatility: This machine is designed for multiple applications, from construction to landscaping, showcasing its adaptability.

- User-Friendly Design: Ergonomically crafted controls ensure ease of operation, allowing users to work efficiently.

- Durability: Built with high-quality materials, it is engineered to withstand tough conditions, ensuring longevity.

- Maintenance: Simplified service points facilitate easy upkeep, minimizing downtime and enhancing productivity.

In summary, this piece of equipment stands out for its combination of strength, efficiency, and user-centric features, making it a valuable asset in various professional settings.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide users with an organized view of various elements, facilitating better understanding and effective troubleshooting. By simplifying complex systems into clear images, these illustrations enhance the ability to identify and replace specific items, ultimately improving operational efficiency.

Benefits of Visual References

Having access to well-structured visuals allows technicians to quickly locate the necessary pieces during service. This not only saves time but also reduces the likelihood of errors in reassembly. Additionally, clear depictions contribute to better training for new personnel, ensuring that they grasp the layout and function of different elements with ease.

Enhancing Communication

These visual tools serve as a common language among technicians, engineers, and suppliers. When discussing repairs or ordering replacements, referring to a graphical representation minimizes misunderstandings, leading to faster resolutions and improved collaboration.

| Advantage | Description |

|---|---|

| Time Efficiency | Quickly identify components, reducing downtime. |

| Minimized Errors | Clear visuals help avoid mistakes during assembly. |

| Effective Training | Enhances learning for new team members. |

| Improved Communication | Facilitates clearer discussions among stakeholders. |

Key Components of Case TR270

This section explores the essential elements that contribute to the functionality and efficiency of the machinery in question. Understanding these components is vital for maintenance and performance optimization.

Main Elements

The core structure consists of various integral parts that ensure smooth operation. Each component plays a specific role, working together to achieve optimal performance.

| Component | Function |

|---|---|

| Engine | Provides power for operation |

| Hydraulic System | Facilitates movement and control |

| Transmission | Transmits power to wheels |

| Cab | Ensures operator comfort and visibility |

Additional Features

Other noteworthy aspects include safety mechanisms and technological integrations that enhance user experience. Familiarity with these features can lead to better utilization and care.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations serve as a roadmap, guiding users through the intricate assembly and disassembly of machinery. Familiarizing oneself with these visuals can significantly enhance one’s ability to identify and locate specific elements, facilitating a smoother workflow.

First, it is important to recognize the various symbols and notations used in these illustrations. Each icon typically corresponds to a particular element or assembly, and comprehending their meanings can prevent confusion. Pay close attention to any legends or keys that accompany the visuals, as they provide crucial information about the representation.

Next, break down the overall image into manageable sections. Start by identifying major assemblies before focusing on smaller components. This approach allows for a structured analysis, making it easier to pinpoint where each piece fits within the larger context.

Lastly, cross-reference the visual with accompanying documentation, such as user manuals or service guides. This practice ensures that you not only understand the representation but also grasp how it relates to the actual operation and maintenance of the equipment.

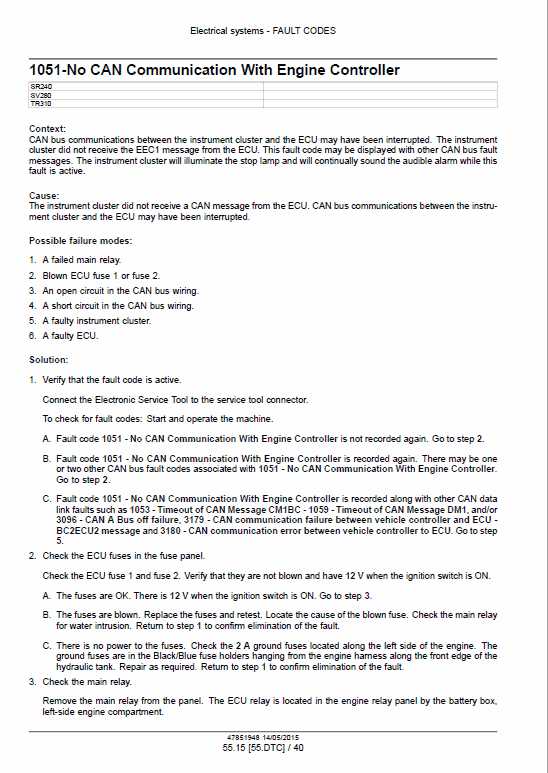

Common Issues and Solutions

This section explores frequent problems encountered in machinery and offers effective solutions. Understanding these challenges can significantly enhance operational efficiency and prolong the equipment’s lifespan.

| Issue | Description | Solution |

|---|---|---|

| Overheating | Excessive heat can lead to performance drops and damage. | Ensure proper cooling systems are functioning and clean any debris blocking airflow. |

| Noisy Operation | Unusual sounds may indicate wear or misalignment. | Inspect components for wear and realign or replace as necessary. |

| Fluid Leaks | Leaks can compromise efficiency and safety. | Check seals and hoses for damage and replace worn parts. |

| Starting Issues | Difficulty initiating operation may suggest electrical problems. | Examine wiring and connections for faults and ensure the battery is charged. |

Maintaining Your Case TR270

Proper upkeep of your machinery is essential for optimal performance and longevity. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency and safety during operation. Understanding the key aspects of care will help you keep your equipment running smoothly.

Regular Inspections: Conducting frequent checks on your machine can identify potential issues before they escalate. Focus on critical components such as the hydraulic system, engine, and electrical systems. Look for signs of wear or damage that may require attention.

Fluid Levels: Ensure that all necessary fluids, including oil and hydraulic fluid, are at appropriate levels. Low fluid levels can lead to increased wear and potential failure of essential systems. Regularly topping off and changing fluids as recommended will help maintain optimal function.

Cleaning: Keeping your equipment clean is vital. Accumulation of dirt and debris can cause overheating and affect performance. Regularly clean air filters, radiators, and other critical areas to ensure proper airflow and cooling.

Calibration and Adjustments: Periodic adjustments and calibrations of settings are necessary to maintain accuracy and efficiency. Refer to the manufacturer’s guidelines for specific procedures on how to properly adjust components for peak performance.

Professional Servicing: While many maintenance tasks can be performed independently, professional servicing is recommended for complex issues. Regular visits to a qualified technician can provide deeper insights and preventative care that may not be obvious during routine checks.

By following these maintenance guidelines, you will not only prolong the life of your machinery but also ensure that it operates at its best, providing you with reliability and performance when you need it most.

Where to Find Replacement Parts

Locating the right components for your machinery can be a daunting task, yet it is crucial for maintaining optimal performance. There are several avenues to explore, each offering unique advantages depending on your needs and preferences.

Online Marketplaces

Digital platforms have revolutionized the way we source components. Websites dedicated to machinery supplies often provide extensive catalogs, allowing users to browse and compare options easily. Additionally, customer reviews can guide your choices, ensuring you select quality items.

Local Dealers and Distributors

Establishing a relationship with local suppliers can yield significant benefits. Not only can they provide expert advice, but they may also have access to exclusive inventory. Visiting in person allows you to assess quality and ensure compatibility with your equipment.

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in various machinery, utilizing fluid power to generate force and movement. By harnessing the properties of liquids, these systems enable efficient operation across multiple applications, enhancing performance and productivity in industrial settings.

Components of Hydraulic Systems

A typical hydraulic system comprises several key elements that work in unison to achieve desired outcomes. These components include pumps, cylinders, valves, and reservoirs, each serving a specific purpose in the overall operation.

| Component | Function |

|---|---|

| Pump | Generates flow and pressure in the system. |

| Cylinder | Transforms hydraulic energy into linear motion. |

| Valve | Regulates fluid flow and direction. |

| Reservoir | Holds hydraulic fluid and allows for heat dissipation. |

Applications and Benefits

The versatility of hydraulic systems allows them to be implemented in various fields, from construction to manufacturing. Their ability to provide significant force in compact designs makes them an ultimate choice for many heavy-duty tasks.

Electrical Components Explained

Understanding the intricacies of electrical components is crucial for anyone involved in machinery and equipment. These essential elements work together to control and distribute power efficiently, ensuring optimal functionality. By delving into their roles, one can appreciate how each part contributes to the overall performance of a system.

Resistors are used to limit the flow of electric current, providing stability and protection to other components. They come in various types, each suited for specific applications.

Capacitors, on the other hand, store and release electrical energy, playing a vital role in filtering and smoothing out voltage fluctuations.

Diodes allow current to flow in one direction only, acting as a safeguard against potential damage from reverse polarity.

Transistors serve as switches or amplifiers, enabling the control of larger currents with smaller input signals, which is fundamental in modern electronics.

Understanding these components and their functions can greatly enhance one’s ability to troubleshoot and maintain various systems effectively.

Benefits of Regular Inspections

Conducting frequent evaluations of machinery and equipment is essential for maintaining optimal performance and longevity. These assessments not only help in identifying potential issues before they escalate but also enhance overall safety standards. Regular check-ups can lead to significant cost savings and improved operational efficiency.

Prevention of Major Failures: By routinely inspecting equipment, minor problems can be detected early, preventing them from developing into major malfunctions. This proactive approach minimizes downtime and reduces repair costs.

Extended Equipment Lifespan: Consistent monitoring ensures that all components are functioning correctly and are well-maintained. This not only extends the lifespan of the machinery but also maximizes return on investment.

Enhanced Safety: Regular evaluations help in identifying potential hazards that could lead to accidents. By addressing these issues promptly, a safer working environment is created for all personnel involved.

Improved Efficiency: Well-maintained equipment operates more efficiently, leading to better productivity. Inspections ensure that all systems are working as intended, allowing for smoother operations.

Compliance with Regulations: Many industries have specific guidelines that mandate regular assessments. Adhering to these regulations not only avoids fines but also ensures that operations meet safety and quality standards.

In summary, the benefits of conducting regular inspections are multifaceted, contributing to operational excellence and safeguarding both assets and personnel.

Aftermarket vs. OEM Parts

When it comes to replacing components in machinery, users often face a choice between two primary options: components manufactured by the original equipment maker and those produced by third-party suppliers. Each category presents its own set of advantages and disadvantages, making it essential for consumers to understand the implications of their decisions.

Quality and Performance

The original manufacturer’s components are designed to meet specific standards and compatibility requirements, ensuring optimal performance and longevity. In contrast, alternatives from other manufacturers can vary widely in quality. While some may offer comparable performance, others might fall short, leading to potential issues down the line.

Cost Considerations

One of the most significant factors influencing the choice between the two options is price. Third-party components often come at a lower cost, making them appealing for budget-conscious buyers. However, the initial savings may be offset by the risk of premature failure or reduced efficiency, ultimately leading to higher long-term costs.

| Aspect | OEM Components | Aftermarket Options |

|---|---|---|

| Quality | High and consistent | Varies widely |

| Compatibility | Guaranteed fit | May require adjustments |

| Price | Generally higher | Often lower |

| Warranty | Usually offered | Varies by manufacturer |

Tips for Efficient Repairs

When tackling machinery repairs, having a systematic approach can significantly enhance productivity. Streamlining the process not only saves time but also minimizes errors, leading to successful outcomes.

1. Organize Your Workspace: A clutter-free environment is crucial. Ensure all tools and components are easily accessible to maintain focus and efficiency.

2. Refer to Manuals: Always consult the manufacturer’s documentation for guidance. This ensures you are following the correct procedures and using the right specifications.

3. Gather Necessary Tools: Before starting, assemble all required tools and materials. This prevents unnecessary interruptions and maintains workflow.

4. Take Notes: Document each step of the repair process. This helps identify recurring issues and provides a reference for future maintenance.

5. Test After Repair: Always conduct a thorough test after completing repairs. This ensures that everything is functioning as intended and highlights any further adjustments needed.

Implementing these strategies can lead to smoother repair processes and ultimately enhance the longevity and performance of your equipment.