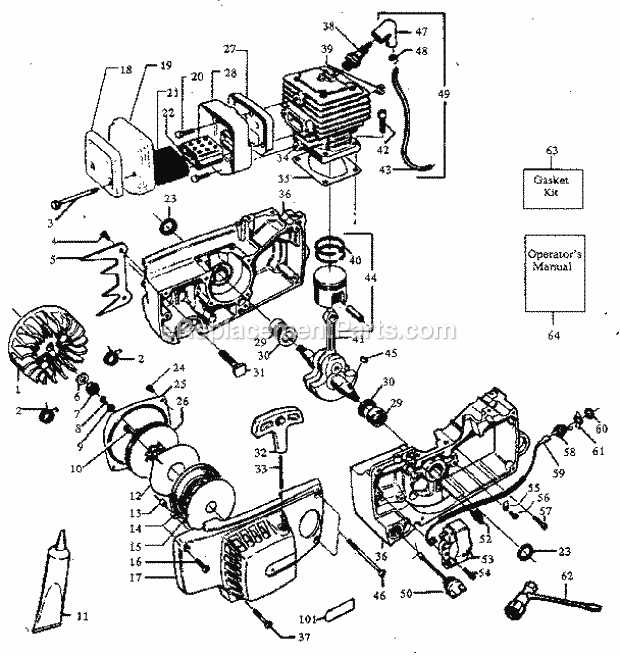

Comprehensive Parts Diagram for Craftsman 18 42cc Chainsaw

When it comes to maintaining and troubleshooting your outdoor equipment, having a clear understanding of its various elements is essential. Each component plays a critical role in the overall functionality, and knowing how they work together can make repairs and adjustments much more manageable. This guide delves into the intricacies of a specific model, offering valuable insights into its assembly and operational parts.

Every tool has its unique configuration, and familiarizing yourself with the layout of its elements is crucial for efficient usage. Whether you’re a seasoned expert or a novice user, grasping the relationship between the different sections will enhance your confidence in handling the machine. With a detailed exploration of the mechanical structure, you’ll be better equipped to identify potential issues and ensure optimal performance.

In this discussion, we will explore the key segments, highlighting their functions and interconnections. By the end, you will have a comprehensive view that not only aids in effective maintenance but also enhances your overall understanding of how to operate your equipment safely and effectively.

Understanding Chainsaw Components

Exploring the various elements of a cutting tool reveals a complex system designed for efficiency and power. Each segment plays a crucial role in the overall functionality, contributing to the seamless operation of this mechanical marvel. By familiarizing oneself with these components, one can enhance both maintenance practices and performance expectations.

Main Parts and Their Functions

The primary sections include the engine, which provides the necessary power, and the guide bar that directs the cutting action. The cutting chain, often crafted from durable materials, is responsible for slicing through wood, while the tensioning mechanism ensures optimal chain performance. Understanding these key elements is essential for effective use and care.

Overview of Craftsman 18 Chainsaw

This section provides an in-depth look at a specific model of a powerful cutting tool, renowned for its efficiency and reliability. Designed for both novice users and seasoned professionals, this equipment is ideal for a variety of outdoor tasks.

Key Features

- Lightweight design for easy maneuverability.

- High-performance engine ensuring effective cutting.

- Ergonomic handle for enhanced comfort during use.

- Safety features to prevent accidents.

Applications

- Tree trimming and pruning.

- Firewood cutting.

- Yard maintenance and landscaping.

- General outdoor tasks requiring precise cutting.

Key Parts of a 42cc Chainsaw

Understanding the essential components of a power saw enhances both safety and efficiency during use. Each element plays a crucial role in the tool’s performance and reliability.

- Engine: The heart of the device, responsible for generating power.

- Guide Bar: The long, flat metal piece that supports the cutting chain.

- Cutting Chain: The looped component with sharp teeth that does the actual cutting.

- Throttle Trigger: Controls the speed of the engine for varying cutting needs.

- Chain Brake: A safety feature that stops the chain in case of kickback.

- Fuel Tank: Stores the mixture of gasoline and oil for the engine.

- Air Filter: Keeps dirt and debris out of the engine for optimal performance.

- Clutch: Engages and disengages the chain from the engine power.

Recognizing these elements can significantly enhance your understanding and usage of the tool.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the prolonged functionality and reliability of any tool. By dedicating time and effort to maintain equipment, users can prevent premature wear and costly repairs, ultimately enhancing performance and extending the lifespan of their machinery.

Preventative Care

Preventative maintenance plays a critical role in identifying potential issues before they escalate. Regular inspections and cleaning can help detect wear on vital components, allowing for timely replacements. This proactive approach not only saves money in the long run but also ensures that the equipment operates at peak efficiency.

Safety Considerations

Another key aspect of maintenance is safety. Well-maintained machinery is less likely to malfunction, reducing the risk of accidents. Ensuring that all parts are functioning properly and that safety features are intact can protect the user and those nearby, making proper care an essential practice for anyone who relies on these tools.

Identifying Common Replacement Parts

Understanding the essential components of a power cutting tool is crucial for maintenance and repair. Regular usage can lead to wear and tear, necessitating the replacement of certain elements to ensure optimal performance. Familiarity with these critical items can help users quickly identify when a replacement is needed and streamline the repair process.

1. Bar and Chain: The cutting edge of any power tool, the bar and chain are vital for efficient operation. Over time, these components may become dull or damaged, requiring replacement to maintain cutting effectiveness.

2. Air Filter: This element plays a key role in keeping the engine clean by filtering out debris and contaminants. A clogged air filter can lead to reduced performance, making it essential to inspect and replace it regularly.

3. Spark Plug: Responsible for igniting the fuel-air mixture, the spark plug is crucial for engine starting and performance. A worn or faulty spark plug can result in difficult starts or misfires, signaling the need for a new one.

4. Fuel Lines: These components transport fuel from the tank to the engine. Cracks or leaks can impede fuel flow, leading to performance issues. Checking and replacing damaged fuel lines is important for proper function.

5. Oiler: Ensuring that the chain remains lubricated is essential for reducing friction and wear. A malfunctioning oiler can cause the chain to overheat and wear prematurely, necessitating a replacement to avoid further damage.

By recognizing these common components, users can maintain their tools effectively, ensuring longevity and reliability in performance.

Using a Parts Diagram Effectively

Understanding how to utilize a visual representation of components can greatly enhance your ability to repair and maintain your equipment. This resource serves as a guide to identifying various elements, making it easier to troubleshoot issues and streamline the replacement process.

Identifying Components

Begin by familiarizing yourself with each labeled section. Take time to analyze the layout and note how parts interact with one another. This clarity can save you time and prevent errors during assembly or disassembly.

Streamlining Maintenance

Utilizing this resource allows you to efficiently plan your maintenance tasks. By pinpointing which elements require attention, you can prioritize repairs and ensure your equipment remains in optimal condition.

Safety Precautions When Disassembling

Disassembling equipment requires careful attention to ensure safety and prevent accidents. Proper preparation and awareness of potential hazards can greatly reduce risks associated with this task.

Preparation Steps

- Always wear appropriate personal protective equipment, including gloves and safety goggles.

- Work in a well-lit, clutter-free area to minimize distractions.

- Ensure the device is powered off and disconnected from any power source.

During Disassembly

- Keep hands and tools clear of moving parts to avoid injury.

- Organize and label components as they are removed to simplify reassembly.

- Be mindful of sharp edges and hot surfaces; use caution when handling.

Steps for Chainsaw Assembly

Assembling a power cutting tool requires careful attention to detail and understanding of each component’s role. This guide outlines the essential stages to ensure a smooth and effective construction process.

1. Gather Your Tools: Before beginning, collect all necessary tools and components. This will help streamline the assembly and prevent unnecessary interruptions.

2. Prepare the Base Unit: Start with the main housing. Ensure it is clean and free from debris. Align any pre-drilled holes for future attachments.

3. Install the Drive Mechanism: Carefully fit the drive system into the designated area, ensuring all connections are secure. This is critical for optimal performance.

4. Attach the Cutting Head: Position the cutting attachment and fasten it according to the manufacturer’s specifications. Ensure it is firmly secured to avoid any operational issues.

5. Connect the Fuel System: Attach the fuel lines and tank, ensuring there are no leaks. Proper fuel delivery is vital for functionality.

6. Final Assembly Checks: Go through each component and connection, confirming everything is tight and correctly positioned. This step is crucial for safety and efficiency.

7. Test the Tool: Once assembled, conduct a test run in a safe environment. Monitor for any unusual sounds or vibrations that may indicate issues.

Following these steps will help ensure that your tool is assembled correctly and ready for effective operation.

Troubleshooting Common Issues

Addressing frequent problems with power tools can significantly enhance their performance and longevity. Identifying and resolving these issues often involves a systematic approach to ensure that every component is functioning optimally.

- Engine Won’t Start:

- Check the fuel level and ensure it’s fresh.

- Inspect the spark plug for damage or wear.

- Verify that the on/off switch is set to the correct position.

- Excessive Vibration:

- Examine the cutting chain for proper tension.

- Ensure the guide bar is aligned correctly.

- Check for debris buildup around the motor.

- Poor Cutting Performance:

- Inspect the sharpness of the cutting blade.

- Evaluate the chain lubrication system.

- Make sure the tool is not being overworked.

By carefully reviewing these areas, users can effectively tackle common challenges and maintain optimal functionality.

Where to Buy Replacement Parts

Finding quality components for your equipment is crucial to maintain its efficiency and longevity. There are various avenues to explore when searching for replacements, ensuring you can keep your tools in top condition.

Online Retailers

One of the most convenient options is to shop through online marketplaces. Websites dedicated to tool supplies often provide a wide selection of components. You can compare prices, read reviews, and even find detailed descriptions to ensure compatibility with your model. Look for reputable sellers that offer reliable shipping options.

Local Hardware Stores

Visiting nearby hardware shops can also be beneficial. Many of these establishments carry a range of components and can offer personalized assistance. The advantage of shopping locally includes immediate availability and the opportunity to consult with knowledgeable staff who can guide you to the right choices.

Remember, whether you choose to shop online or in-store, always verify that the components meet the required specifications for your equipment. Investing time in sourcing the right items will ultimately lead to better performance and durability.

Expert Tips for DIY Repairs

Embarking on repair projects can be both rewarding and challenging. Understanding key strategies can enhance your efficiency and ensure successful outcomes. Here are some essential insights for tackling maintenance tasks effectively.

Preparation is Key

Before diving into repairs, gather all necessary tools and materials. A well-organized workspace can streamline the process and reduce frustration. Always consult manuals or online resources for guidance.

Safety First

Prioritize safety by wearing appropriate gear and working in a well-ventilated area. Familiarize yourself with the equipment and follow proper procedures to minimize risks during your repairs.

| Tip | Description |

|---|---|

| Research | Look for instructional videos and articles related to your specific task. |

| Label Parts | Keep track of small components by labeling them during disassembly. |

| Test Functionality | After repairs, thoroughly test the equipment to ensure it operates correctly. |